Energy-saving corn threshing machine

A peeling machine and corn technology, applied in the agricultural field, can solve the problems of inconvenient promotion and implementation, low production efficiency, complex structure, etc., and achieve the effects of easy promotion and implementation, high production efficiency and high peeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

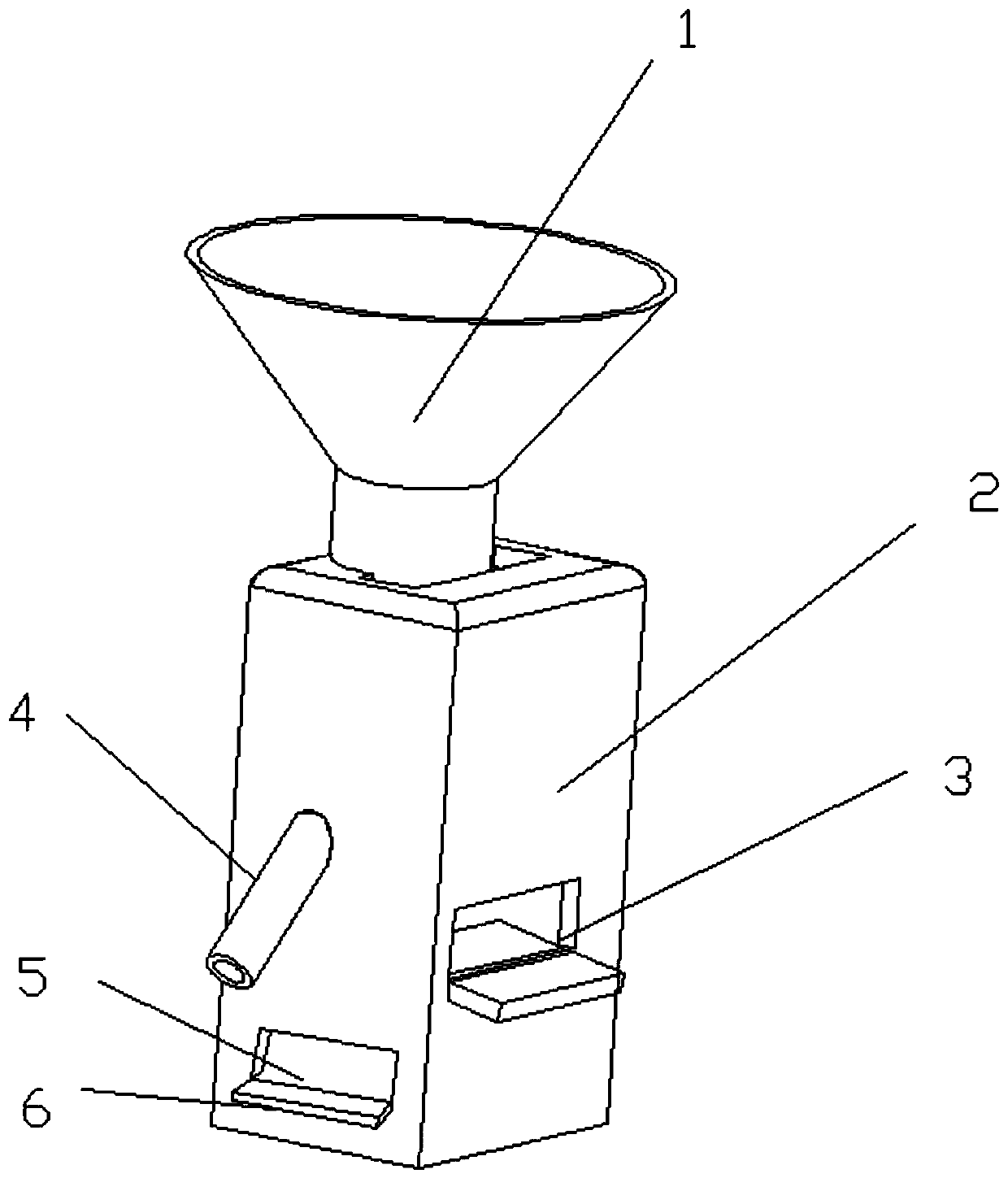

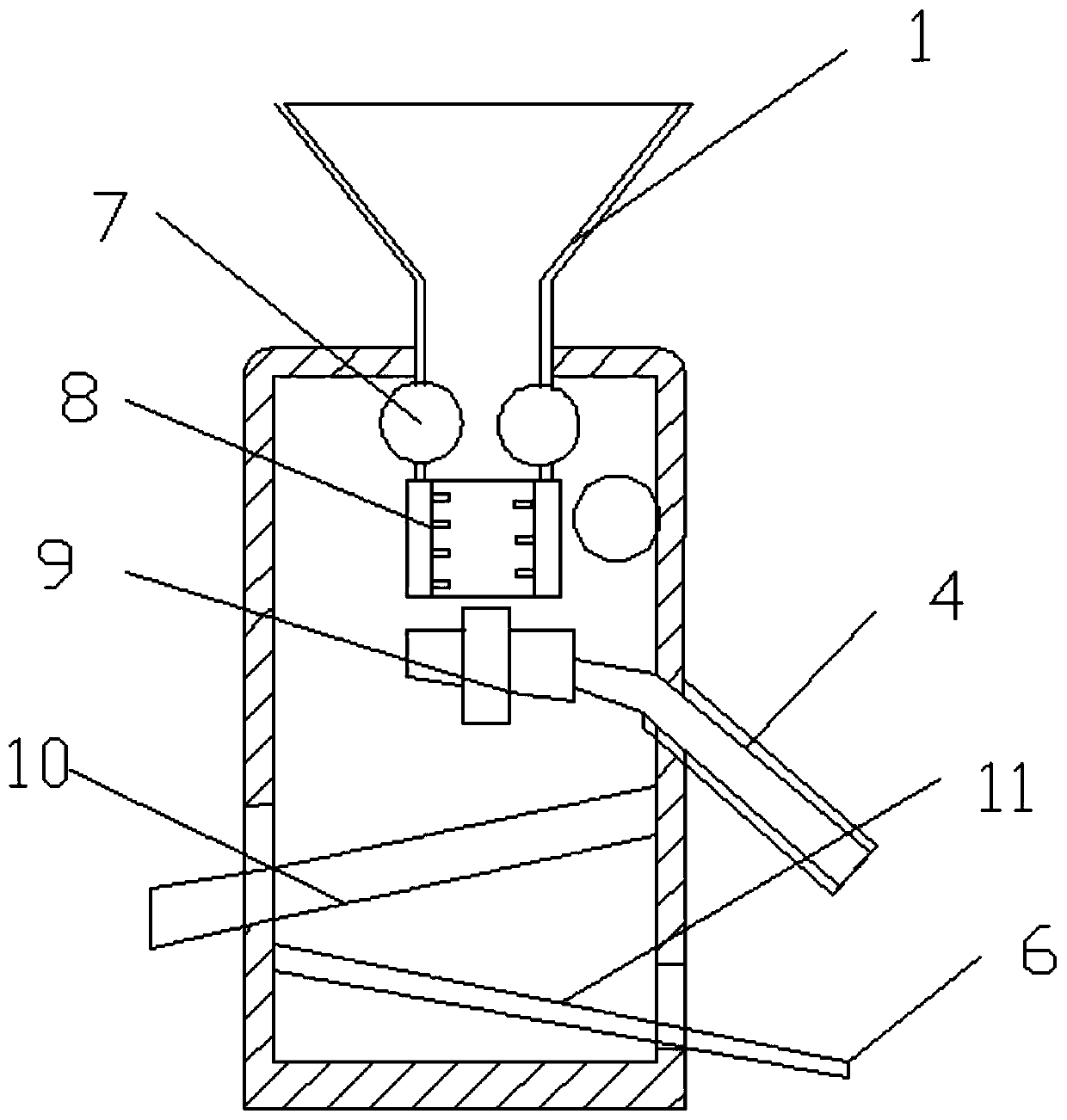

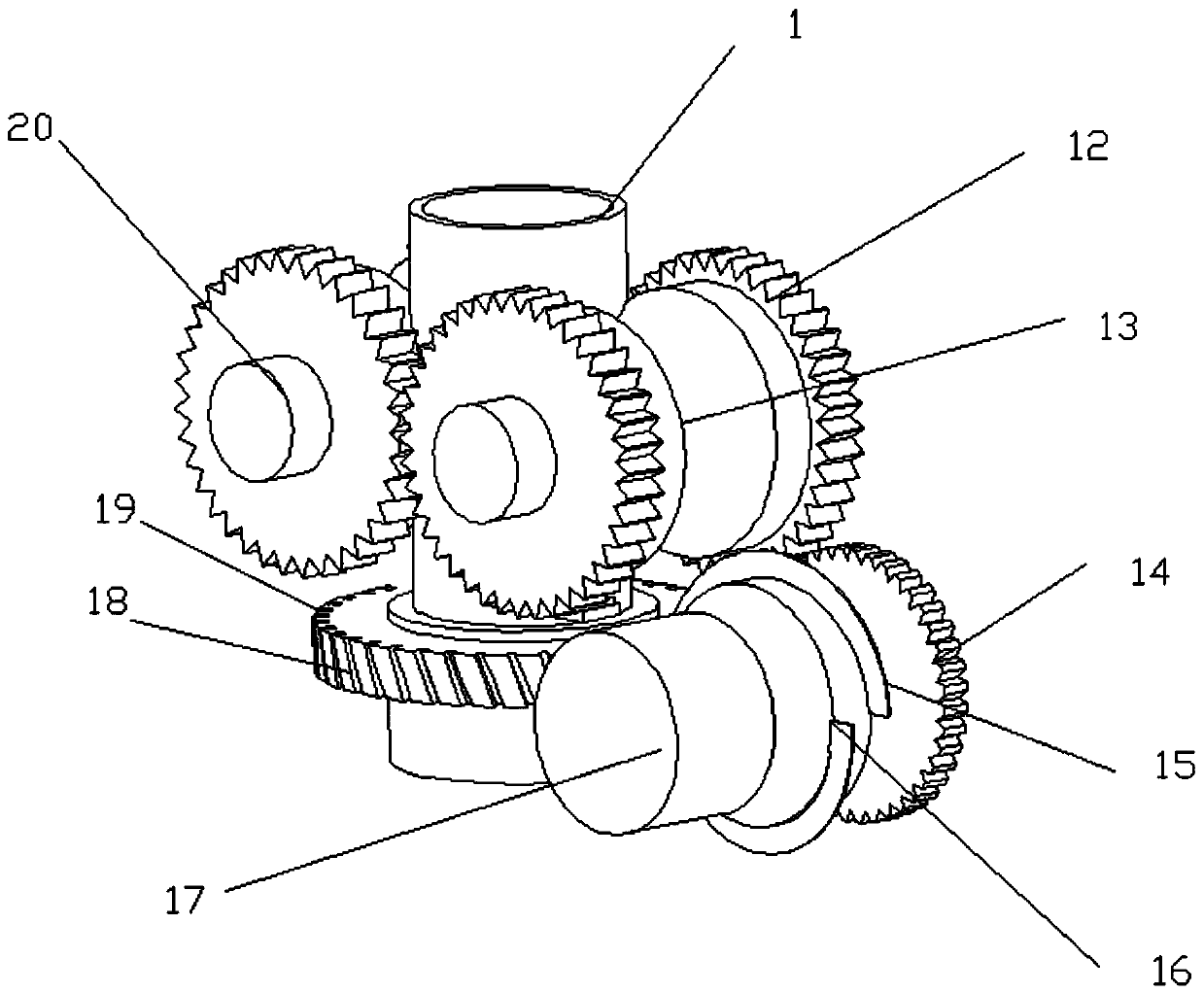

[0026] see Figure 1-5 , an energy-saving corn peeling machine, including a housing 2, a transmission part 7, a peeling cylinder 8 and a separation part 9. The top of the housing 2 is connected with a feed hopper 1, and the corn that needs to be peeled is placed inside the feed hopper 1. The feed hopper 1 is a funnel-shaped structure, and the setting of the feed hopper 1 is convenient for the corn to enter the inside of the housing 2 for separation. The bottom of the feed hopper 1 extends into the inside of the housing 2 , and the inner top of the housing 2 is rotatably provided with a transmission member 7 , and the transmission member 7 extends into the feed hopper 1 . The bottom of feed hopper 1 is connected to the top of shelling cylinder 8 in rotation. The transmission member 7 includes a transmission roller 20 and a driven gear 12, two transmission rollers 20 are arranged horizontally, the two ends of the transmission roller 20 are coaxially fixedly connected with a dri...

Embodiment 2

[0032] On the basis of Embodiment 1, a first sieve plate 10 is provided in the inside of the housing 2 below the separator 9, and a material guide plate 11 is provided at the inner bottom of the housing 2 below the first sieve plate 10, and the material guide The end of the plate 11 is provided with a leaking grain outlet 5 on the side wall of the housing 2, and corn cobs, debris and dropped corn kernels fall on the first sieve plate 10, and the corn kernels and debris pass through the first sieve plate 10 , falls on the material guide plate 11 and is discharged from the leaking grain outlet 5, which avoids the waste of corn grains and improves the recovery rate of stripping. The outer material guide plate 11 of the leakage grain outlet 5 is connected with a second sieve plate 6, and the second sieve plate 6 sieves the corn kernels, removes debris, and improves the cleanliness of the corn kernels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com