Novel stirring device for producing dry-mixed mortar and stirring method thereof

A dry powder mortar and mixing device technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of single mixing direction, reduced mixing efficiency, material handling, etc., to improve mixing effect, increase Effect of blending direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

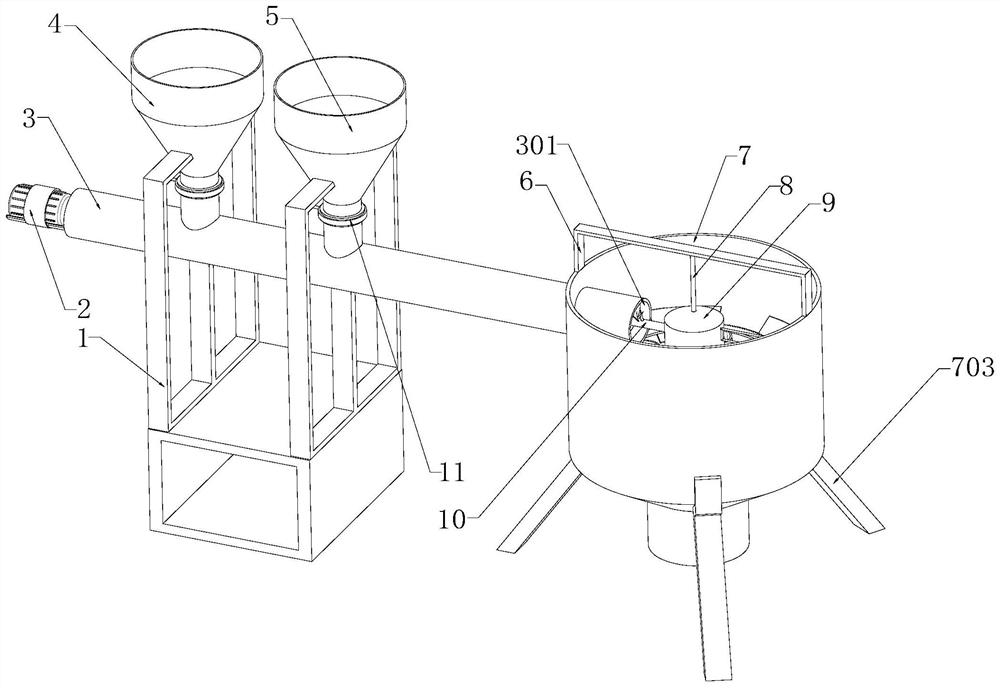

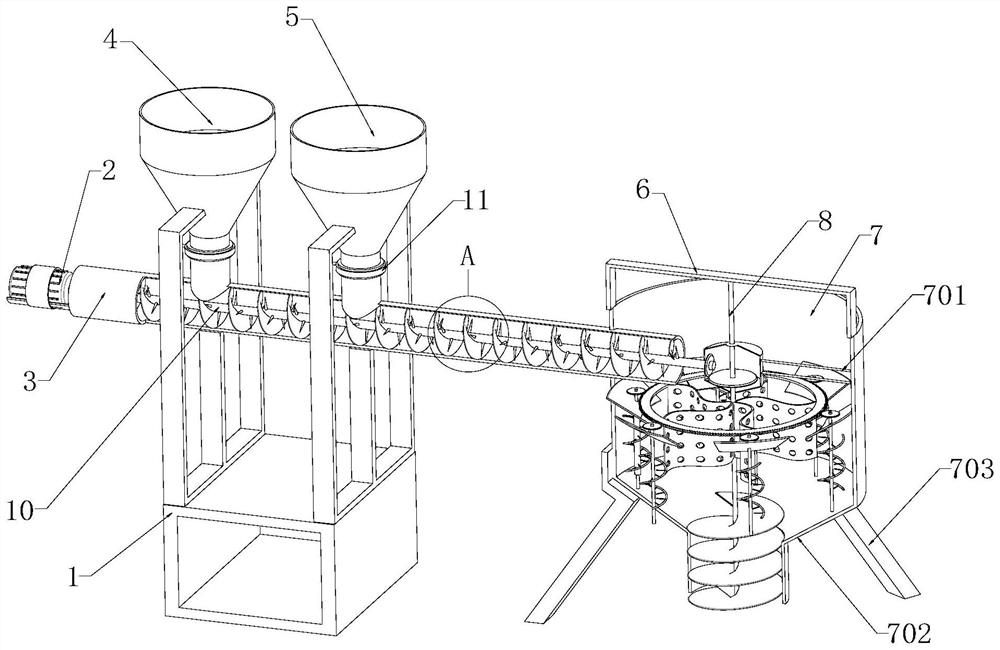

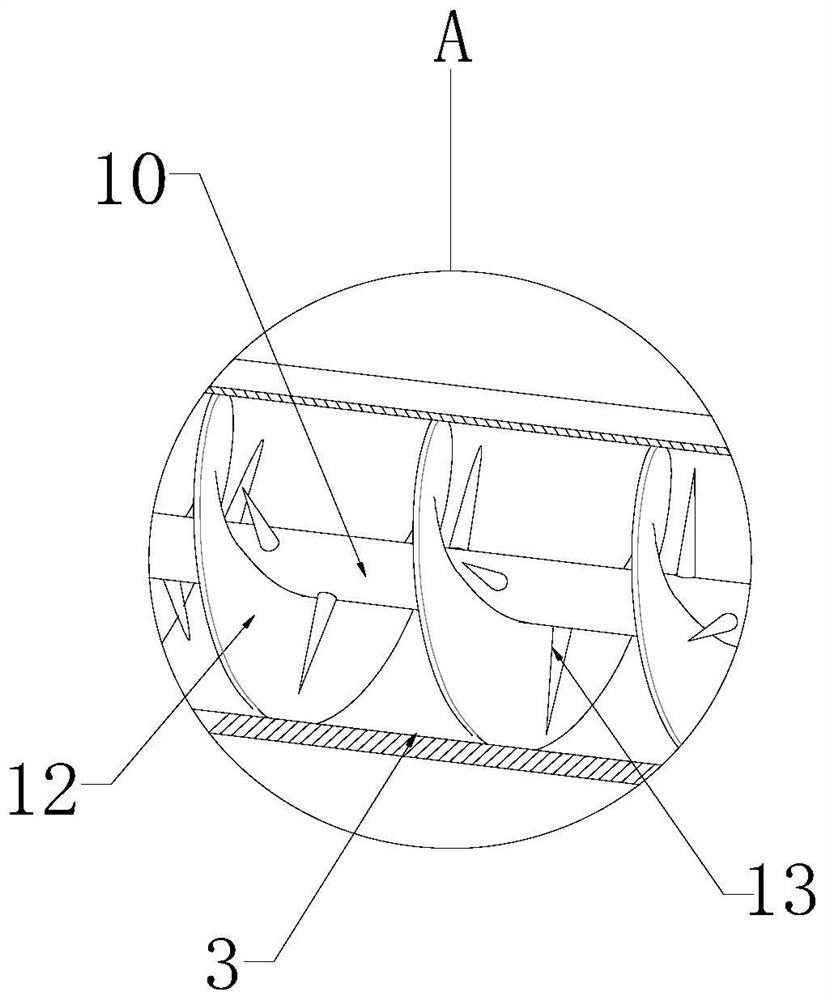

[0040] Such as Figure 1-Figure 7 Shown, a new type of mixing device for dry powder mortar production, including a feeding mechanism and a mixing mechanism, the feeding mechanism includes a support frame 1, and the two sides of the top of the support frame 1 are fixedly installed with a raw material cylinder 1 4 and a raw material cylinder 2 5 with the same specifications, respectively. The bottom ends of raw material cylinder 1 4 and raw material cylinder 2 5 are jointly connected with feeding cylinder 3, and feeding cylinder 3 is arranged horizontally, and the stirring mechanism includes stirring tank 7, and one end of adding material cylinder 3 runs through one end of stirring tank 7. side, the bottom side of the feeding tube 3 is fixedly connected with the support frame 1, and the inside of the mixing tank 7 is provided with a mixing assembly, and the mixing assembly includes a top frame 6 fixedly installed on the outer wall of the top of the feeding tube 3, and the top fra...

Embodiment 2

[0058] This embodiment discloses a new type of mixing method for producing a dry powder mortar mixing device, which specifically includes the following steps:

[0059] Step 1: Put the basic materials into the first raw material barrel 4 and the second raw material barrel 5 respectively, at the same time, open the shut-off valve 11 and control the start-up drive motor 2 to drive the shaft 10 to rotate, and the materials flow from the first raw material barrel 4 and the second raw material barrel 5 Falling at a constant speed, the material is sent out through the discharge port 301 through the shaft 10 and the feeding auger piece 12, and the agglomerated material can be crushed and refined during the feeding process by using the protruding thorns 13 provided;

[0060] Step 2: When the shaft 10 is driven by the driving motor 2 to rotate, it drives the main end column 8 to rotate through the transmission effect of the transmission conical tooth 23 and the conical toothed plate 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com