Agricultural fermentation device

A fermentation device and agricultural technology, applied in the agricultural field, can solve the problems of affecting the fermentation effect and bio-organic fertilizer agglomeration, and achieve the effect of ensuring uniform mixing and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

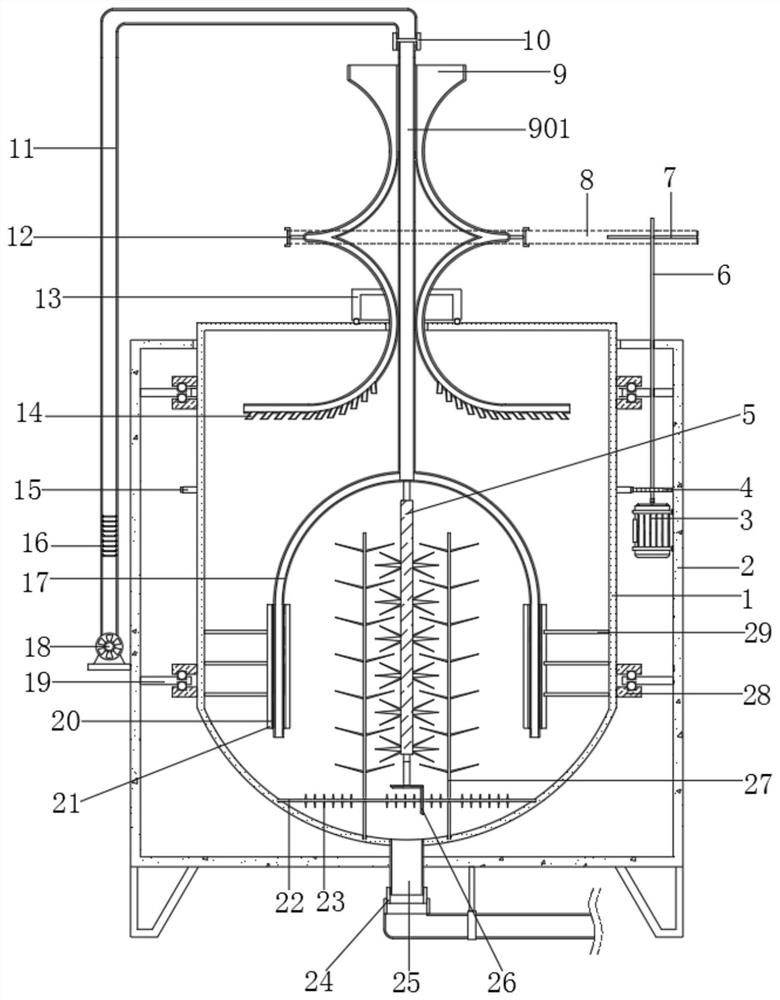

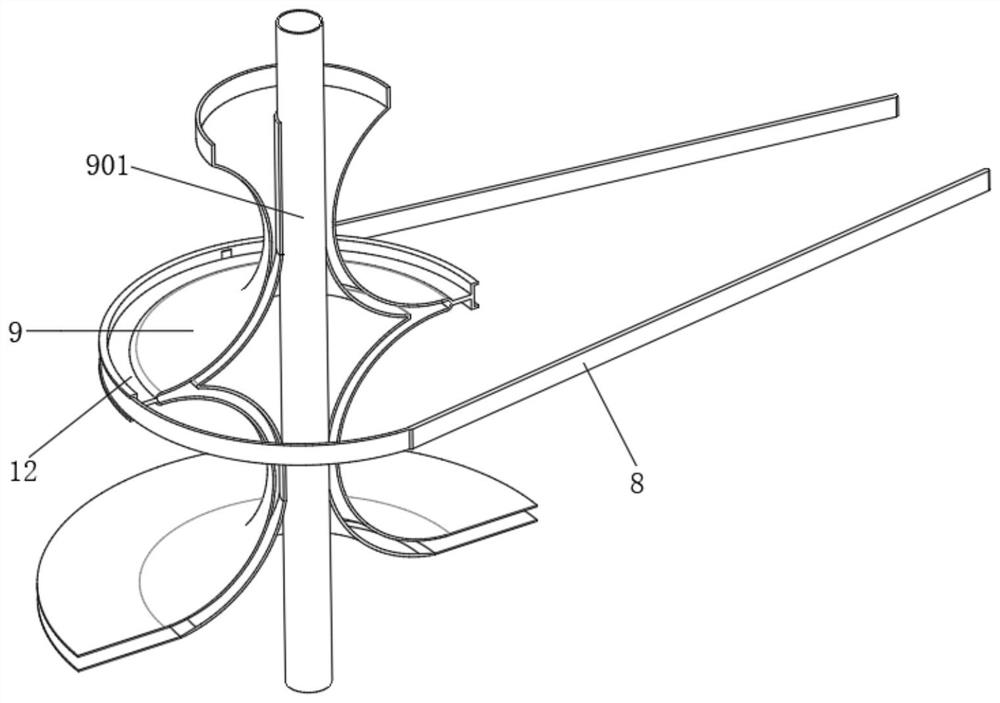

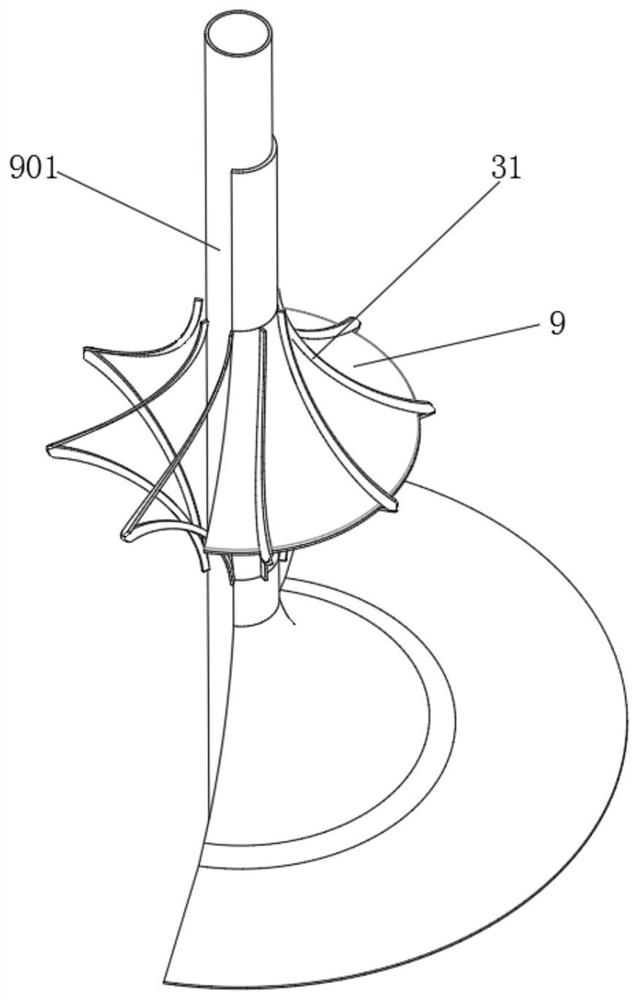

[0031] refer to Figure 1-6 , an agricultural fermentation device, comprising a fixed outer tank 2 and a fermentation inner tank 1 rotatably connected to the top of the fixed outer tank 2, a drive mechanism is installed on the opposite side of the fixed outer tank 2 and the fermentation inner tank 1, and the drive mechanism includes Bolts are fixed to the rotating motor 3 on the inner wall of one side of the fixed outer tank 2, and the output shaft of the rotating motor 3 is connected to the transmission rod 6 that is rotationally connected with the fixed outer tank 2 through a coupling. One side is respectively key-connected with the driven gear ring 15 and the driving gear 4 which are engaged with each other, and an oxygen supply mechanism is installed on one side of the fixed outer tank 2, and the supply mechanism includes an air inlet pipe 901, and the outer wall of the air inlet pipe 901 is welded There is a special-shaped feeding hopper 9, and the section of the special-...

Embodiment 2

[0042] refer to Figure 7 , a fermenting device for agriculture. Compared with Embodiment 1, this embodiment also includes that the top of the outlet arc tube 17 is welded with the same conical helical angle leaf 34, and the top of the conical helical angle leaf 34 is welded with a spiral top sheet 35; the conical helical angle vane 34 and the helical top piece 35 arranged on the top of the outlet arc tube 17 can drive the material downward during the rotation of the outlet arc tube 17, so that the material can continue to drum toward refinement mechanism to improve the refinement effect.

[0043] When the present invention is used: the conical helical angle blade 34 and the helical top piece 35 arranged at the top of the outlet arc tube 17 can drive the material downward during the rotation process of the outlet arc tube 17, which is beneficial to the material Convection is generated, so that the material continues to drum toward the refining mechanism, so as to achieve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com