Hetero atom-doped hollow spherical grapheme composite material, and preparation method and applications thereof

A composite material and graphene technology, applied in the field of graphene composite materials, heteroatom-doped hollow sphere graphene composite materials and their preparation, can solve the problems of difficult control, low actual utilization of specific surface, and influence of heteroatom-doped graphite To reduce the thickness and good solvent dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

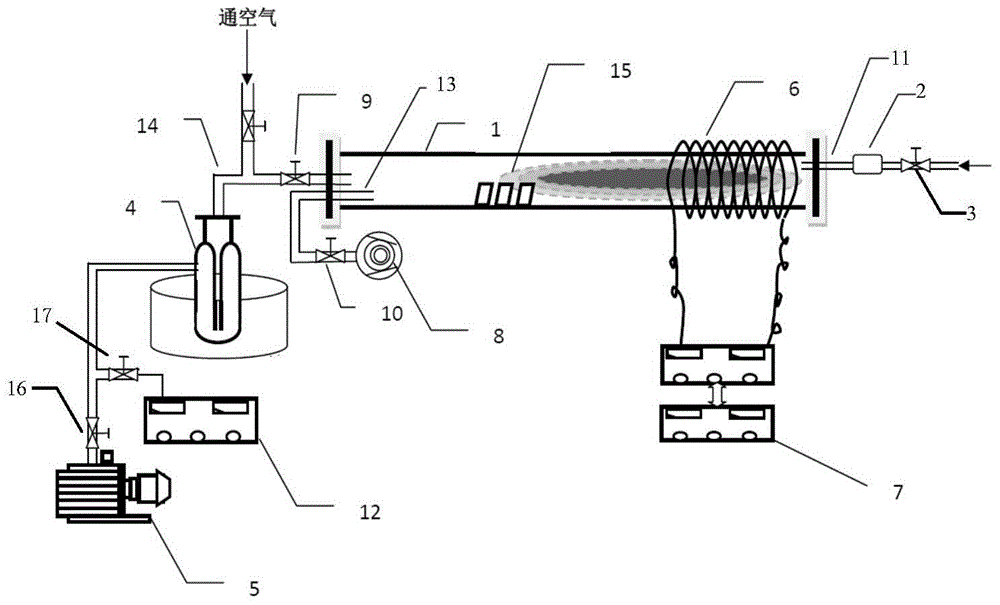

Method used

Image

Examples

Embodiment 1

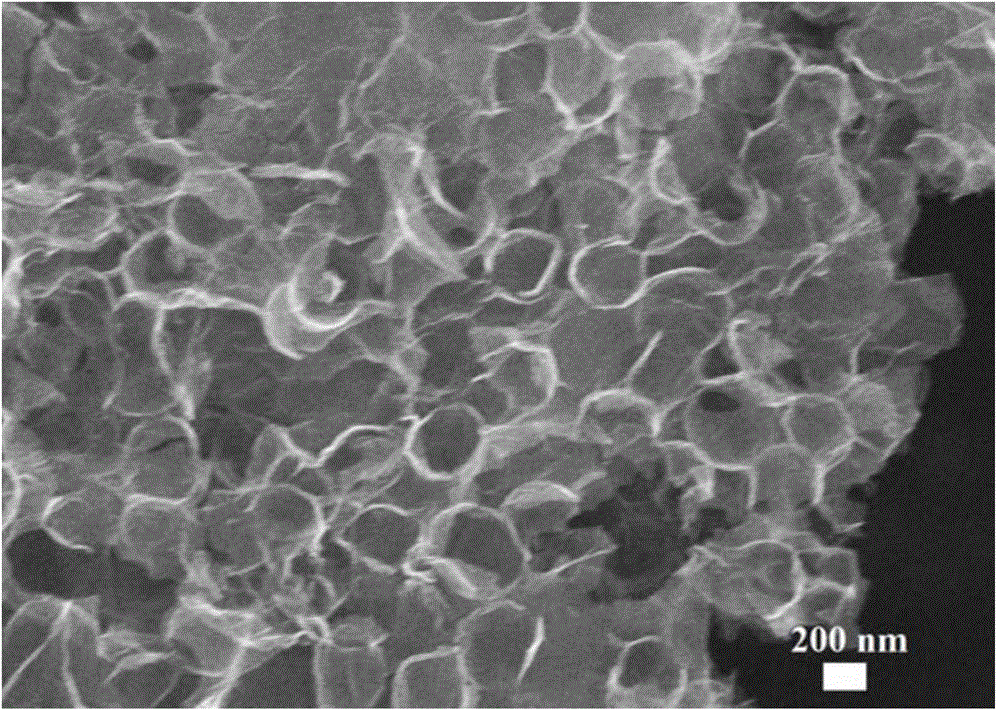

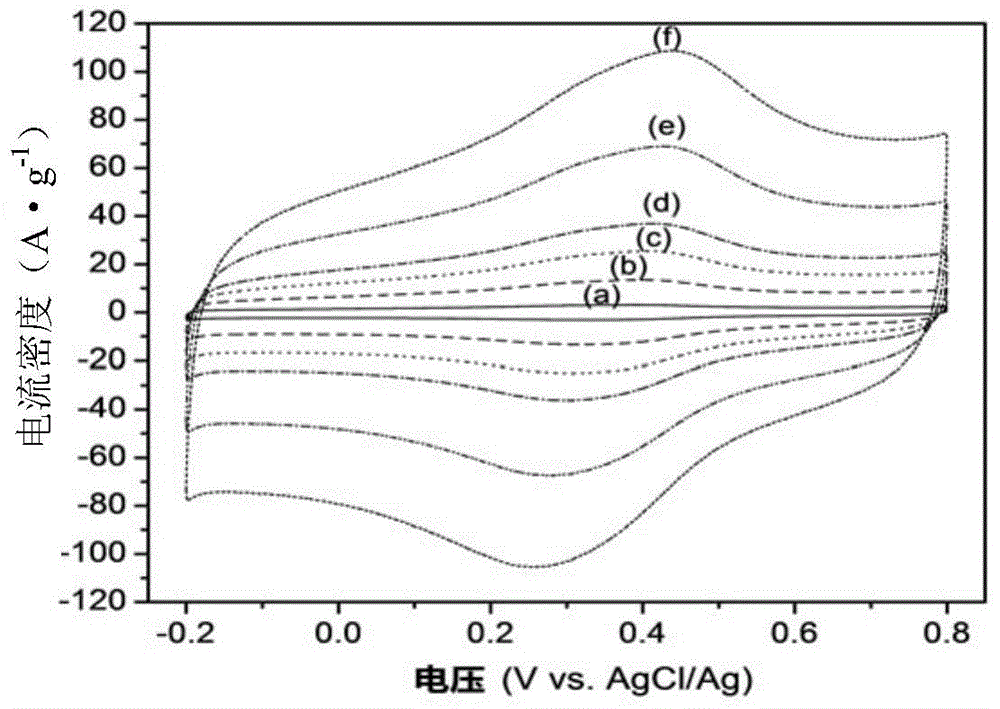

[0054] A heteroatom-doped hollow sphere graphene composite material is prepared by the following method:

[0055] (1) Synthesis of graphene oxide

[0056] Adopt improved Hummers method to prepare graphene oxide, its technological process is as follows:

[0057] (1-1) Assemble the reaction flask in an ice-water bath, add a solid mixture of 1g of expanded graphite powder and 2.5g of sodium nitrate to the reaction flask under stirring (the stirring speed is 500r / min), and then add 150mL of mass percentage 95% concentrated sulfuric acid, reacted in an ice-water bath for 30 minutes; then, added 15 g of potassium permanganate 60 times (1 min each time), controlled the reaction temperature not to exceed 20 ° C, and continued to react for 12 h; then added 150 mL of deionized water After diluting, stirring and reacting for 30 minutes (stirring speed is 500r / min), the temperature was raised to 98° C. at a heating rate of 10° C. / min, and the temperature was kept for 48 hours. The color ...

Embodiment 2

[0078] A heteroatom-doped hollow sphere graphene composite material is prepared by the following method:

[0079] (1) synthesis of graphene oxide: same as embodiment 1 synthetic method;

[0080] (2) Preparation of positively charged polystyrene ball template: same as the preparation method of Example 1;

[0081] (3) Preparation of graphene oxide polystyrene spheres with core-shell structure and solid film of dibenzyl disulfide:

[0082] Disperse step (2) positively charged polystyrene balls in water and prepare the polystyrene ball dispersion of 25mg / mL; disperse graphene oxide in water and prepare the graphene oxide dispersion of 15mg / mL; Positively charged polystyrene sphere dispersion and 15 mL of graphene oxide dispersion were sequentially added to the reactor, magnetically stirred at room temperature for 24 h (stirring speed was 500 r / min), and filtered to obtain graphene oxide polymer with core-shell structure. Styrene sphere compound; Add 3g dibenzyl disulfide and sol...

Embodiment 3

[0087] A heteroatom-doped hollow sphere graphene composite material is prepared by the following method:

[0088] (1) synthesis of graphene oxide: same as embodiment 1 synthetic method;

[0089] (2) Preparation of positively charged polystyrene ball template: same as the preparation method of Example 1;

[0090] (3) Preparation of solid film of graphene oxide polystyrene spheres with core-shell structure and triphenylphosphine:

[0091] Disperse step (2) positively charged polystyrene balls in water and prepare the polystyrene ball dispersion of 25mg / mL; disperse graphene oxide in water and prepare the graphene oxide dispersion of 15mg / mL; Positively charged polystyrene sphere dispersion and 15 mL of graphene oxide dispersion were sequentially added to the reactor, magnetically stirred at room temperature for 24 h (stirring speed was 500 r / min), and filtered to obtain graphene oxide polymer with core-shell structure. Styrene sphere compound; Add 3g triphenylphosphine and sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com