Automatic lentinus edodes pileus slicing machine and using method thereof

A technology of shiitake mushrooms and slicers, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of slow efficiency, low degree of automation, waste of manpower, etc., to facilitate the replacement of blades, avoid The effect of manual feeding and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

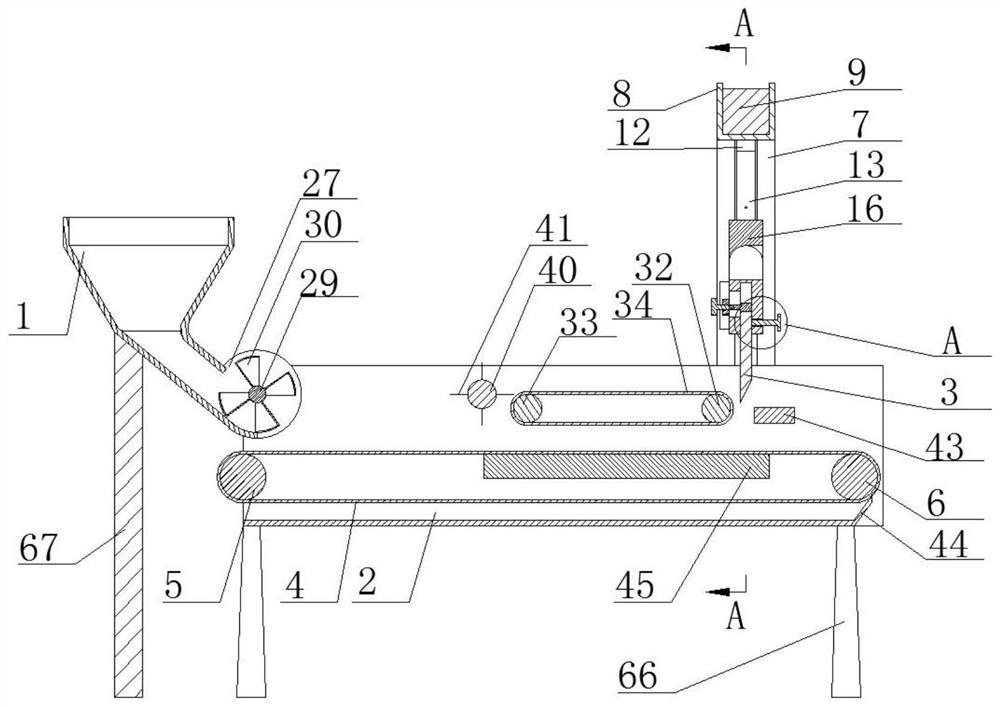

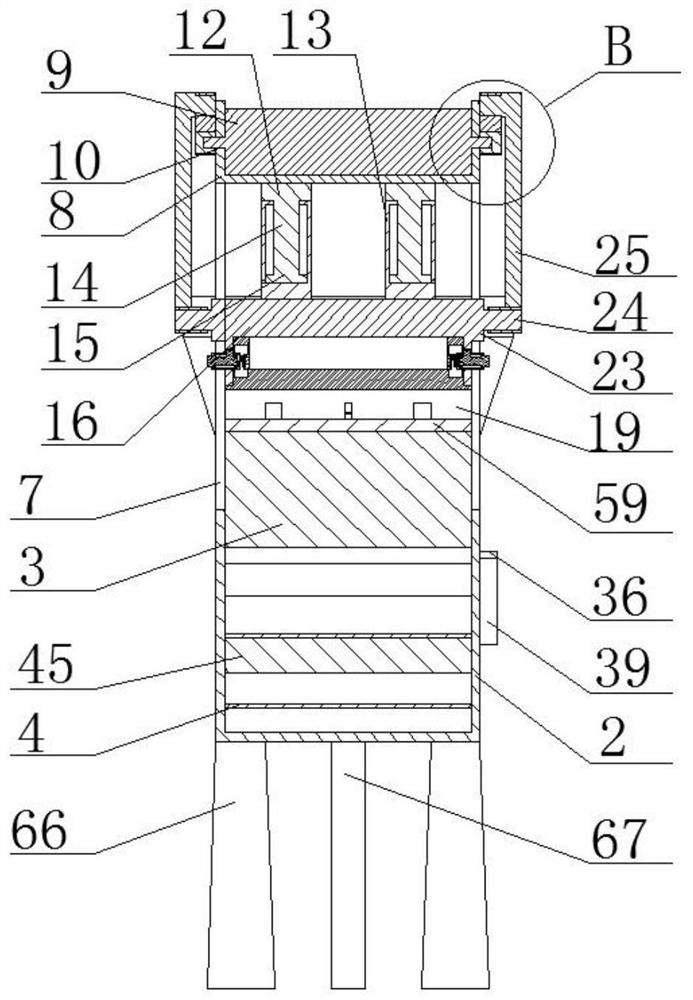

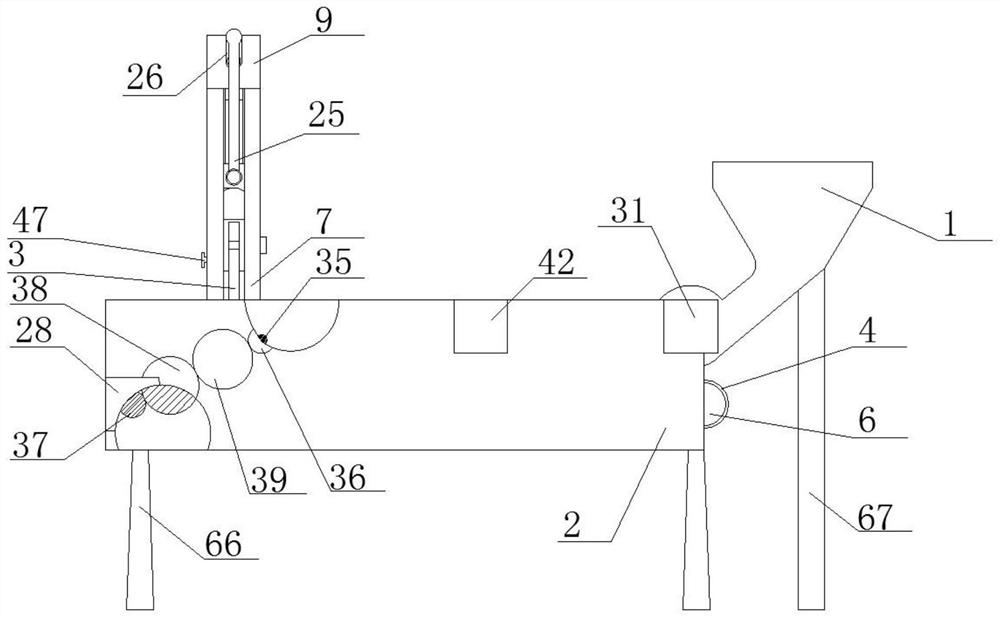

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] Refer to attached Figure 1-12 Shown: an automatic slicing machine for mushroom caps, comprising a feed hopper 1, a casing 2, a slicing knife 3, a conveyor belt 4, a driving pulley 5 and a driven pulley 6, the upper ends of the front and rear walls of the casing 2 are arranged There are guide rails 7, and the top of the guide rails 7 on the front and rear sides is provided with a motor box 8, and a biaxial motor 9 is installed in the motor box 8, and a first circular opening 10 is arranged on the front and rear walls of the motor box 8, and the biaxial motor 9 The output shaft passes through the first circular opening 10 in the motor box 8, and the first circular boss 11 is installed on the outside of the front and rear walls. The limit sleeve 13 is installed at the lower end, the piston fixed block 12 lower end is provided with a short rod 14 positioned in the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com