Exfoliating foam aerosol product for personal care

A foam aerosol, personal care technology, used in skin care preparations, cosmetic preparations, cosmetics, etc., can solve the problems of secondary pollution, trouble, time-consuming, etc., and achieve low VOC, convenient use, and low GWP. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

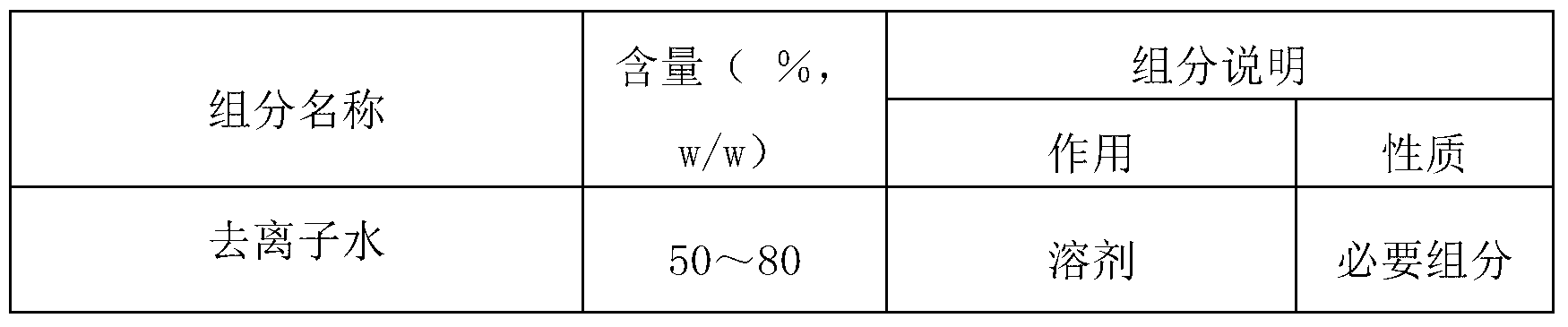

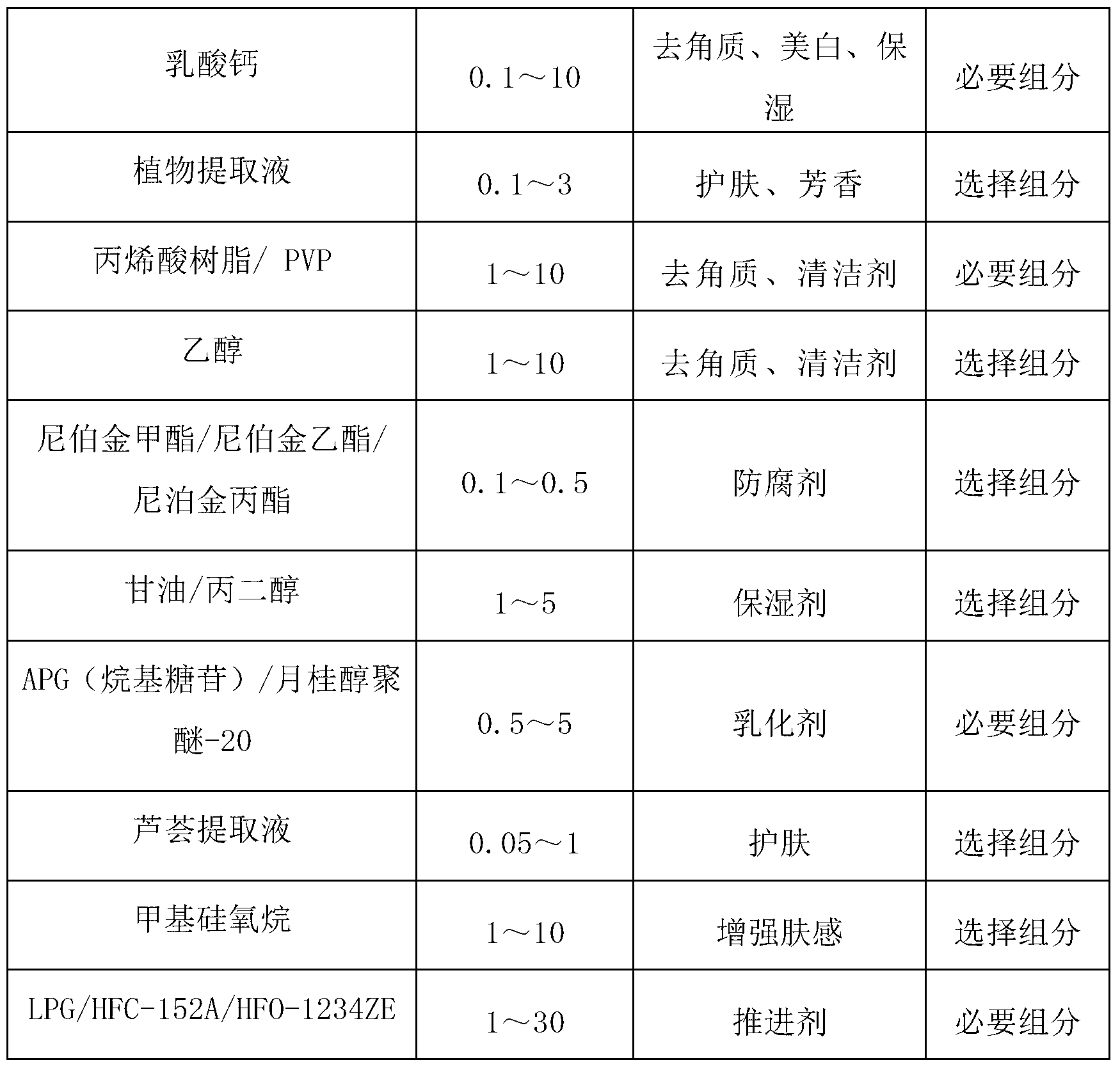

Method used

Image

Examples

Embodiment 1

[0032] Preparation

[0033] Preparation of the solution:

[0034] Phase A: Dissolve methyl paraben, ethyl paraben, propyl paraben, and plant extracts in ethanol, glycerin, and propylene glycol.

[0035] Phase B: Emulsify and dissolve APG (alkyl glucoside), laureth-20, acrylic resin, PVP, methyl silicone, calcium lactate, and aloe extract in deionized water.

[0036] In the state of stirring, slowly add the phase A agent liquid into the B phase agent liquid, and stir until the milky white liquid.

[0037] Pour the solution into the aerosol can, install the valve, seal it, fill it with LPG, take a water bath, install the nozzle, install the outer cover, and pack it into a box.

Embodiment 2

8

[0041] Preparation

[0042] Preparation of the solution:

[0043] Phase A: Dissolve methylparaben, ethylparaben, propylparaben, and plant extracts in ethanol and propylene glycol.

[0044] Phase B: Emulsify and dissolve APG (alkyl glucoside), laureth-20, PVP, methyl siloxane, calcium lactate, and aloe extract in deionized water.

[0045] In the state of stirring, slowly add the phase A agent liquid into the B phase agent liquid, and stir until the milky white liquid.

[0046] Pour the solution into the aerosol can, install the valve, seal it, fill it with HFC-152A, bathe it in water, install the nozzle, install the outer cover, and pack it into a box.

Embodiment 3

[0049] Preparation

[0050] Preparation of the solution:

[0051] Phase A: Dissolve paraben methyl ester and plant extract in ethanol and glycerin.

[0052] Phase B: Laureth-20, acrylic resin, calcium lactate emulsified and dissolved in deionized water.

[0053] In the state of stirring, slowly add the phase A agent solution into the B phase agent solution, and stir until the milky white liquid.

[0054] Pour the solution into the aerosol can, install the valve, seal it, fill it with HFO-1234ZE, bathe it in water, install the nozzle, install the outer cover, and pack it into a box.

[0055] The formulations in the above examples are divided into phase A and phase B to prepare respectively, and then the oil phase and the water phase are mixed and stirred homogeneously to form an emulsion. It is also possible to fill phase A and phase B into the tank separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com