Split type photovoltaic junction box feeding device

A technology of feeding device and junction box, applied in transportation and packaging, conveyors, vibrating conveyors, etc., can solve the problems of labor, time, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

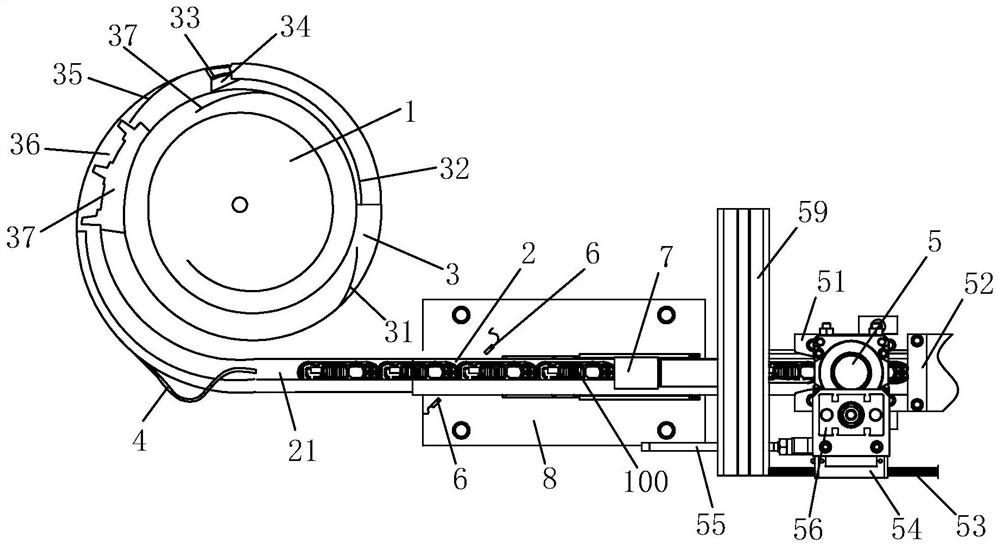

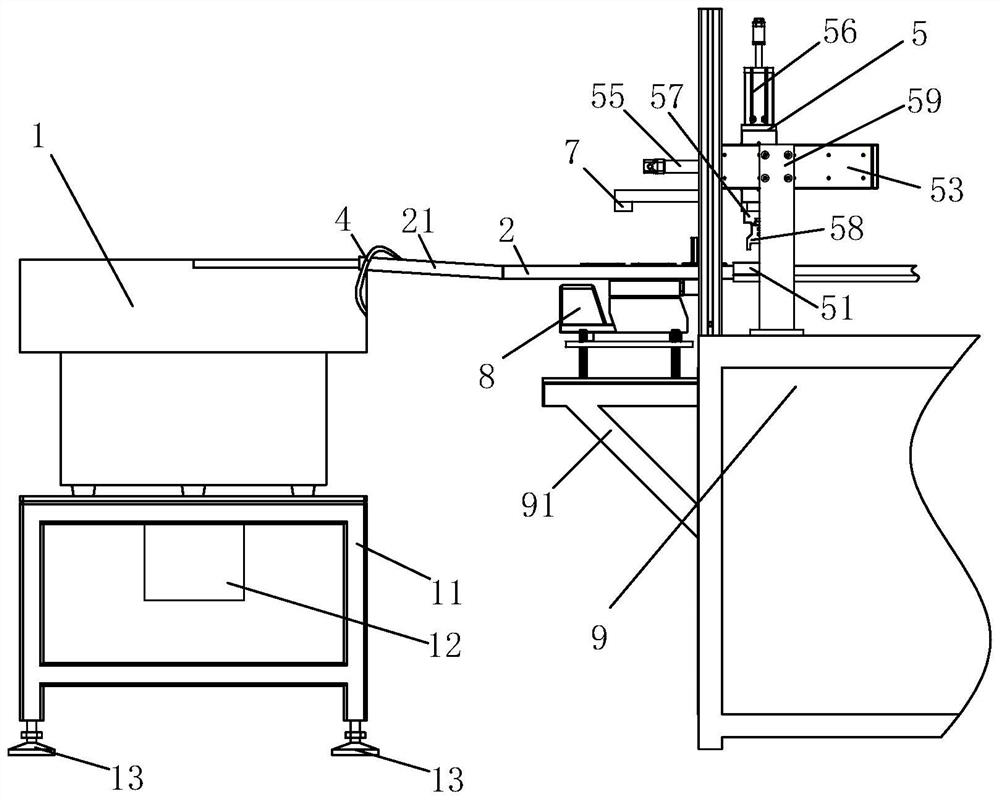

[0031] See figure 1 and figure 2 , the split-type photovoltaic junction box feeding device of this embodiment includes a vibration plate 1, a discharge track 2, an air blowing pipe 4, a translation clamping mechanism 5, an infrared limit switch 6, a camera unit 7, a control unit, and a vibration platform 8 and workbench 9.

[0032]The inner wall of the vibrating plate 1 is provided with a spiral feeding track 3, the top of the discharging track 2 is open, and the camera unit 7 is a camera, the camera unit 7 is located above the discharging track 2 and aligned in the discharging track 2, and is clamped in translation. Mechanism 5 comprises positioning seat 51, limit seat 52, mechanical claw 58 and the driving unit for driving mechanical claw, and positioning seat 51 and limit seat 52 are arranged side by side, and positioning seat 51 and limit seat 52 are all provided with photovoltaic The groove matching the shape of the junction box 100, one end of the discharge track 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com