Feeding device for soybean grinding machine

A technology of feeding device and refining machine, which is applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of affecting product quality, low efficiency, high labor intensity, etc., and achieves improved quality, convenient operation, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

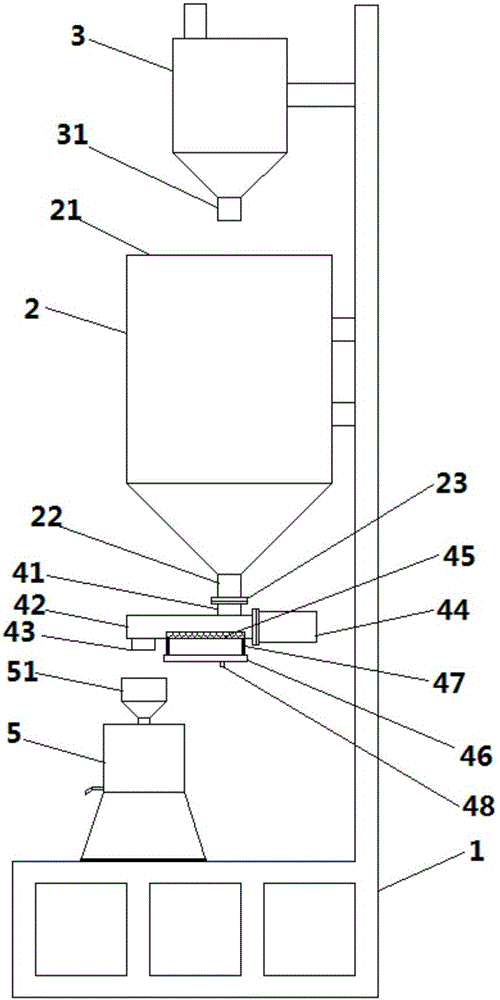

[0013] A feeding device for a soybean refiner, such as figure 1 As shown, it includes a frame 1 and a storage hopper 2. The storage hopper 2 is fixed on the frame 1. The upper part of the storage hopper 2 is a cylinder, and the bottom of the storage hopper 2 is conical. The frame above the storage hopper 2 1 is provided with a material suction machine 3, and the discharge port 31 of the material suction machine 3 is located directly above the bucket opening 21 at the upper end of the storage hopper 2. The bottom of the storage hopper 2 is provided with a vertically downward discharge pipe 22. The feed pipe 22 is connected and fixed with the feed port 41 of the screw conveyor 4 through the flange 23, and the feed port 41 is located on the side wall of the barrel 42 of the screw conveyor 4, and the screw conveyor 4 is suspended horizontally. Fixed on the bottom of the storage hopper 2, the outlet 43 of the screw conveyor 4 is located directly above the feed hopper 51 of the soyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com