Waste rubber tire horizontal composite dicer

A technology of waste rubber and dicing machine, which is applied in recycling technology, metal processing, plastic recycling, etc. It can solve the problems of inconvenient feeding of waste tires, high production cost, and large power consumption, so as to reduce labor and labor The effect of strength, small footprint and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

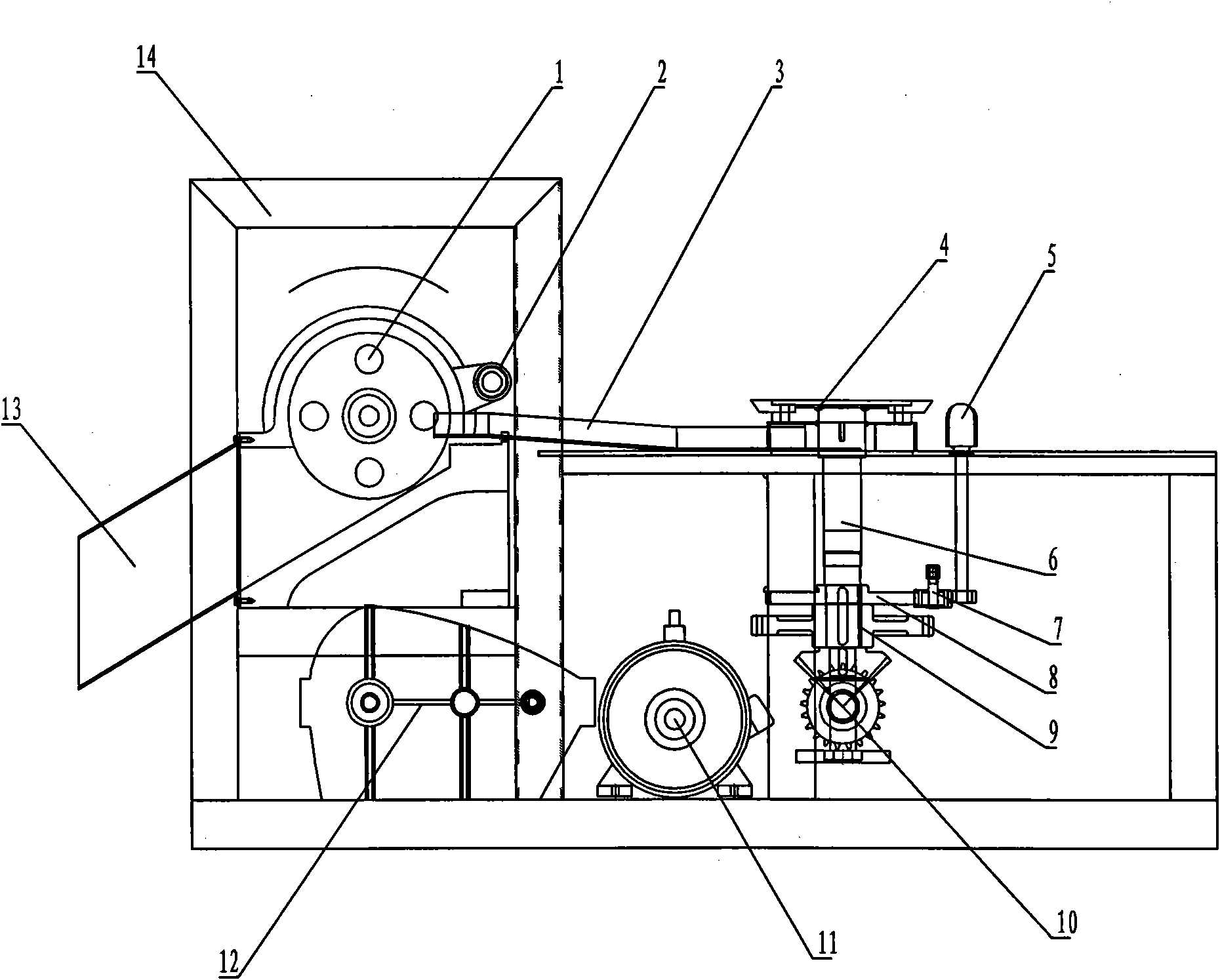

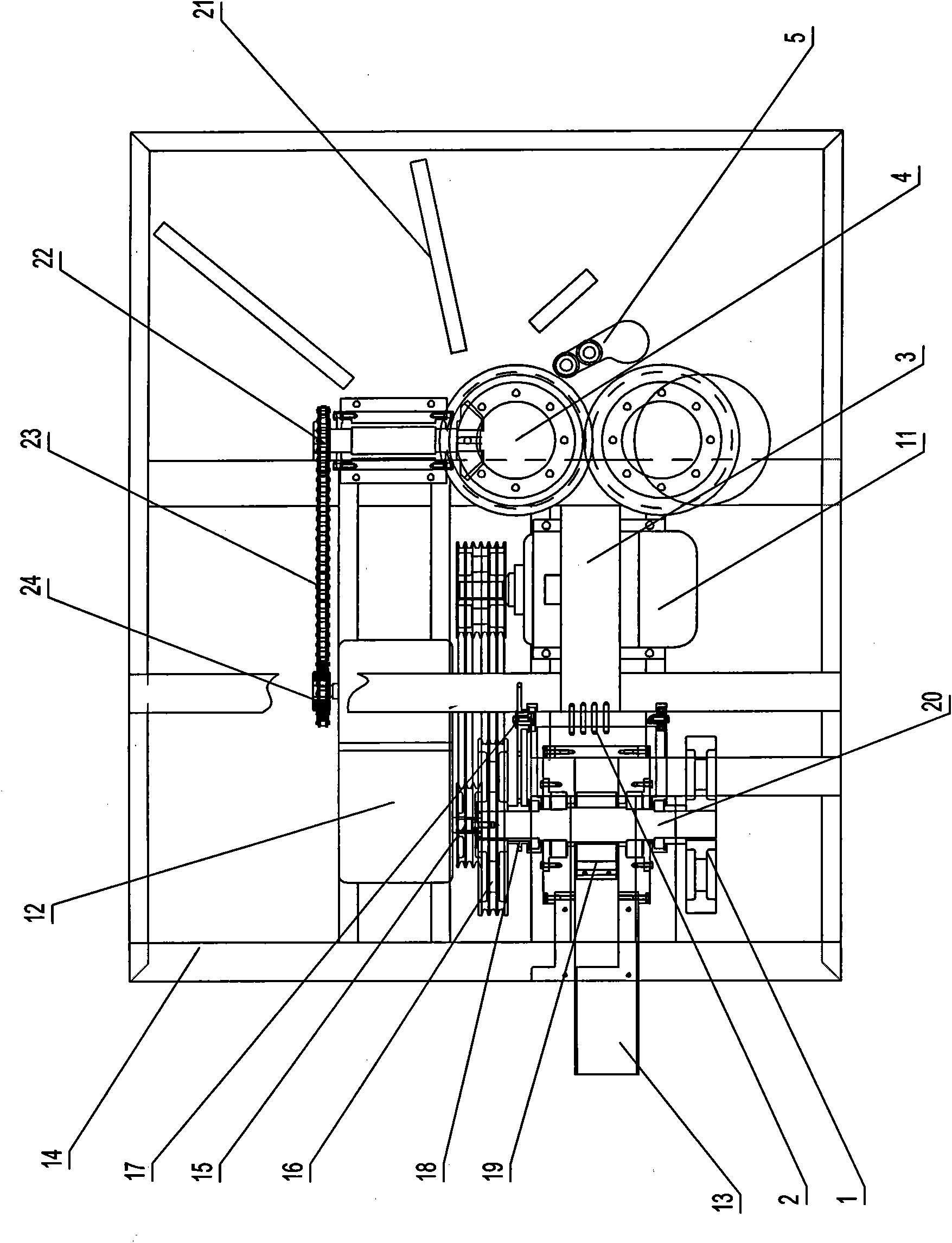

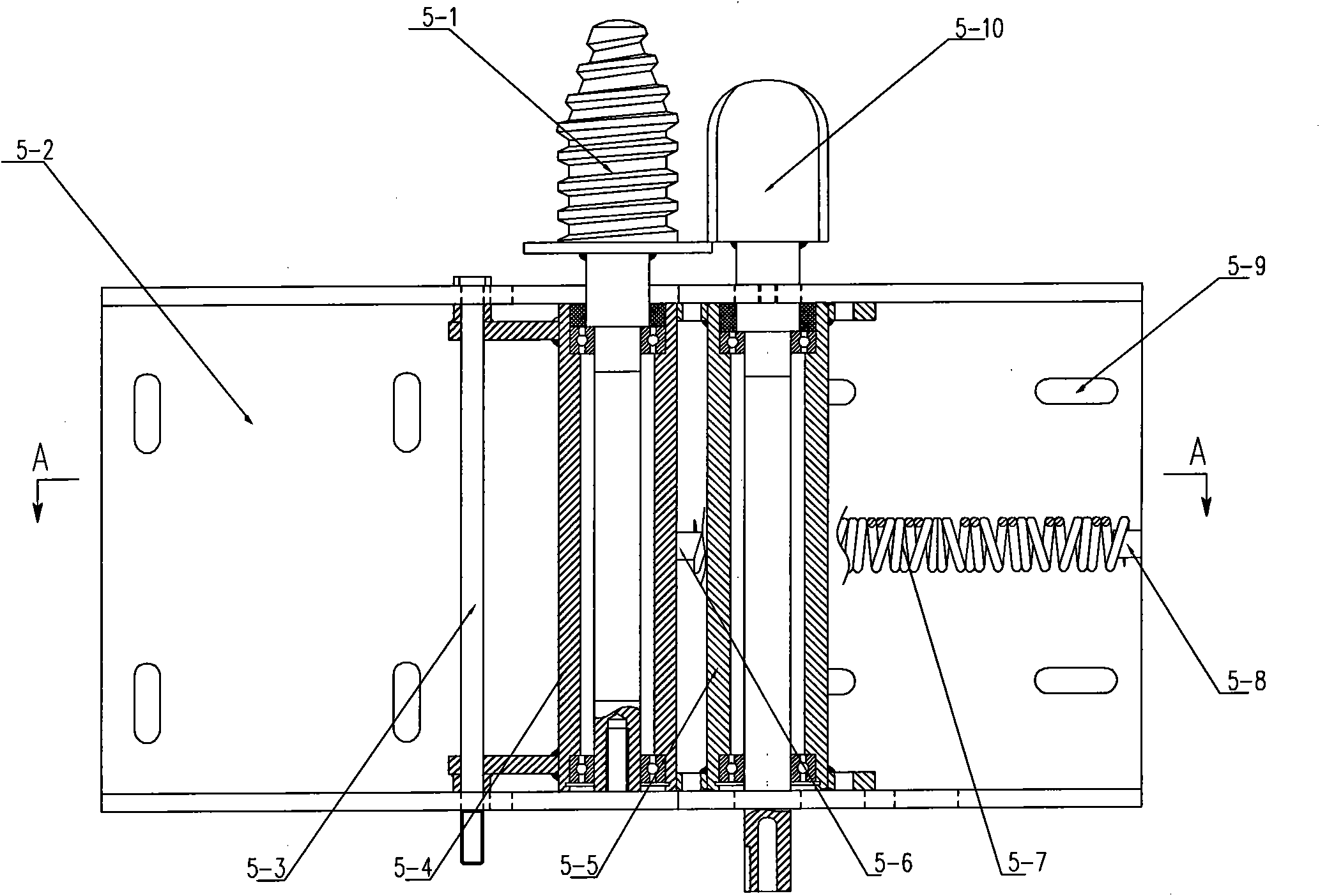

[0022] Embodiment one: see Figure 1-Figure 4 In the figure, a horizontal comprehensive cutting machine for waste rubber tires contains a frame, a power source, a transmission device, a strip cutting device, a cutting device, and a tire feeding device. The strip cutting device and the cutting device are installed on On the upper part of the frame, the power source and the transmission device are installed on the bottom of the frame; the tire conveying device is installed near the strip cutting device, and the strip cutting device contains a horizontal knife in contact with the upper and lower working surfaces disc, the shafts of the two cutter discs are driven through various matching gears, such as figure 1 middle gear 9; the lower end of the shaft of one of the cutterheads is equipped with a transmission device and is connected to the power source; Wheel, the cutting main shaft is connected with the power source through the transmission device; a material guide groove is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com