Automatic feeding cutter for metal bar stock

A technology of automatic feeding and metal rods, which is applied in metal sawing equipment, metal processing machinery parts, metal processing, etc., can solve the problems of high labor cost, cost saving for enterprises that do not meet the requirements of enterprises, and difficulty of rework, etc., so as to reduce labor intensity , Facilitate the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

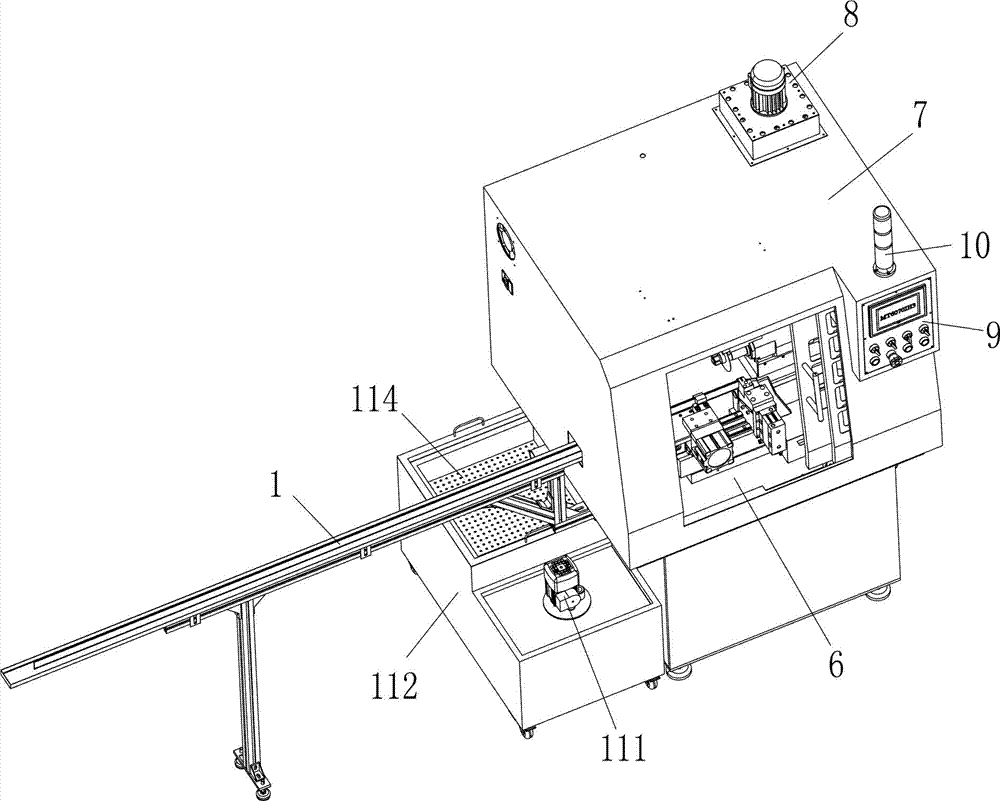

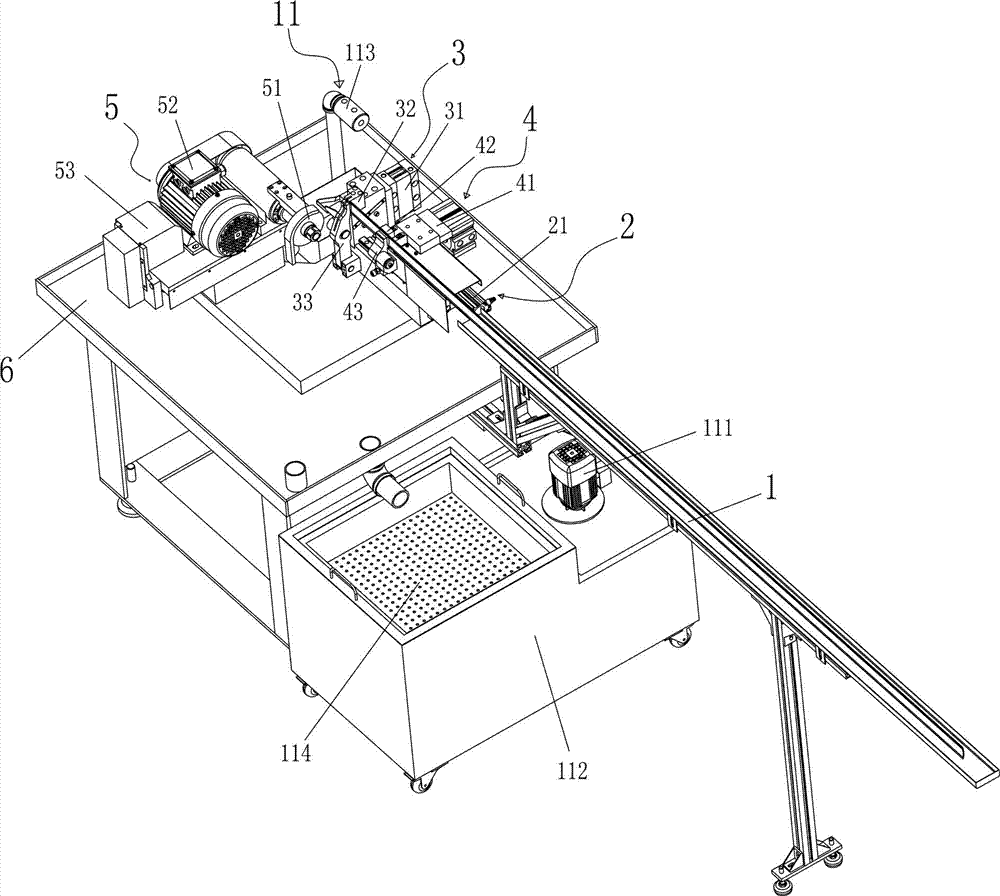

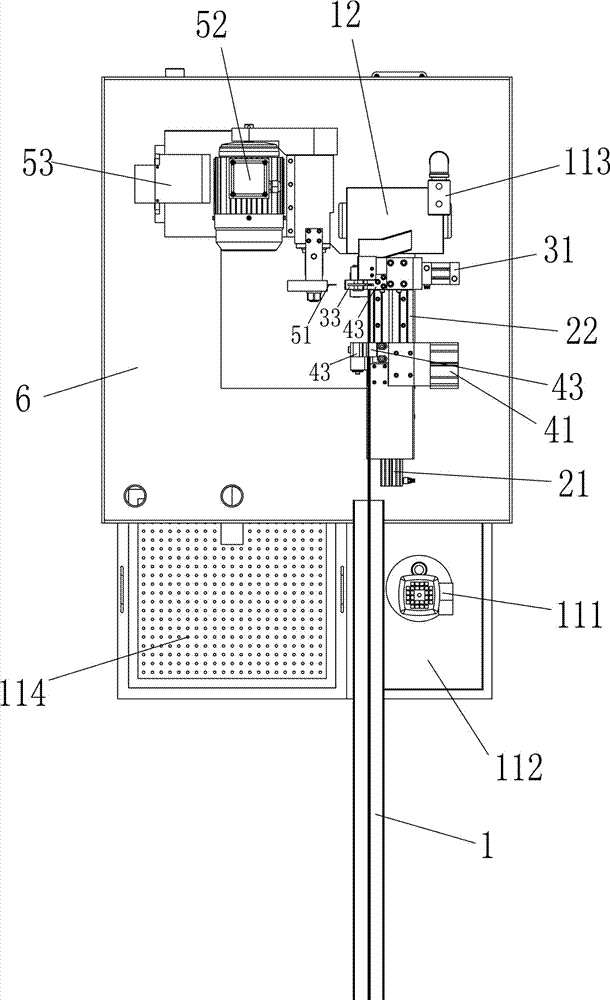

[0028] Such as figure 1 , 2 , 3, 4, and 5 show an automatic feeding and cutting machine for a metal bar, including an automatic feeding mechanism and an automatic cutting mechanism 5, the metal bar is placed on the rack 1, and one end of the metal bar is inserted into the automatic In the feeding mechanism, the first cutting position is manually set in the automatic feeding mechanism. After the first cutting, the cut is the material head, which needs to be removed; after the material head is removed, start the automatic positioning mode, and pass the automatic feeding mechanism. Adjust the position of the metal bar, and finally position the subsequent cutting position of the metal bar, and so on; the automatic cutting mechanism 5 starts after the metal bar is positioned successfully and cuts the metal bar in the automatic feeding mechanism.

[0029] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com