Conductive nozzle punching machine feeding system

A technology of feeding system and punching machine, applied in metal processing and other directions, can solve the problem of low degree of automation, and achieve the effects of liberating labor, improving cleanliness, and improving movement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

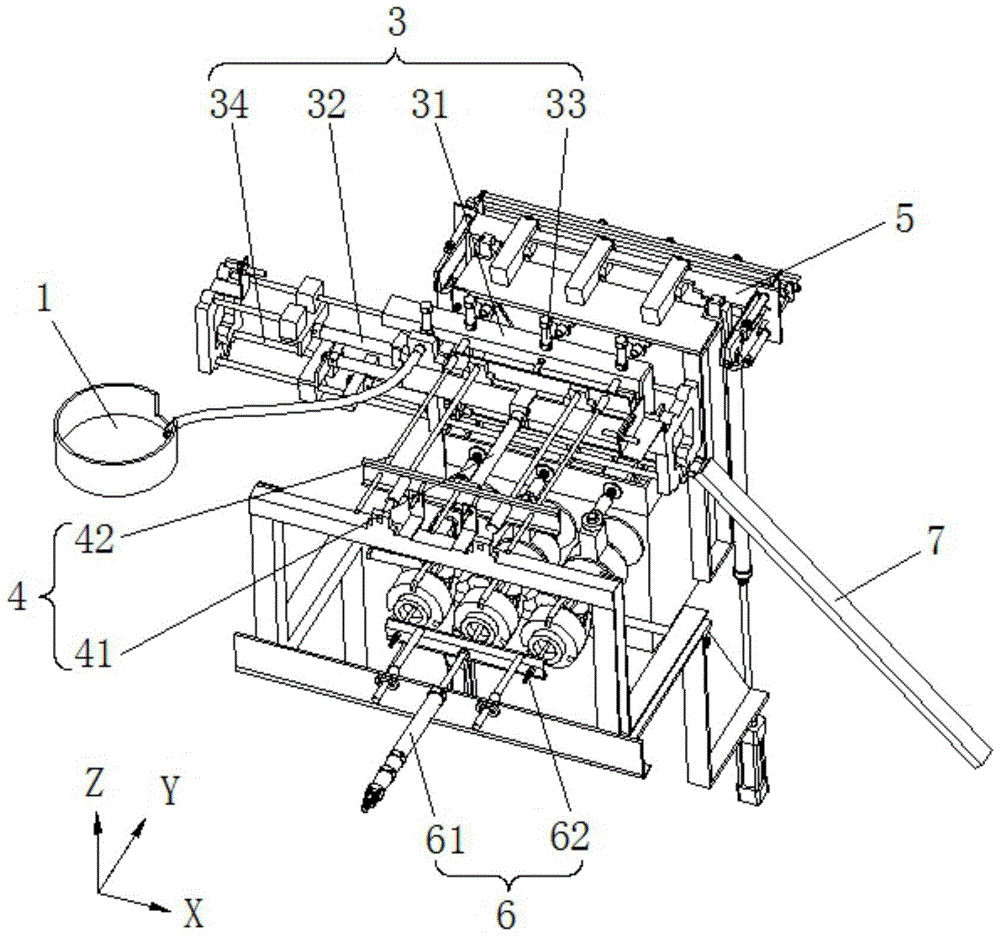

[0026] See Figure 1 to Figure 8 , the present invention includes a frame and a processing spindle, the processing spindle is provided with a processing hole for clamping workpieces; it also includes a feeding port fixed on the frame, an induction head 2, a charging unit 3, and a first ejection assembly 4. The transfer unit 5, the second ejector assembly 6 and the aggregate assembly 7; the feeding port is set opposite to the induction head 2, and the feeding port is provided with a first locking device 11 that can limit the discharge; The feeding port is connected with the discharge end of the vibrating plate.

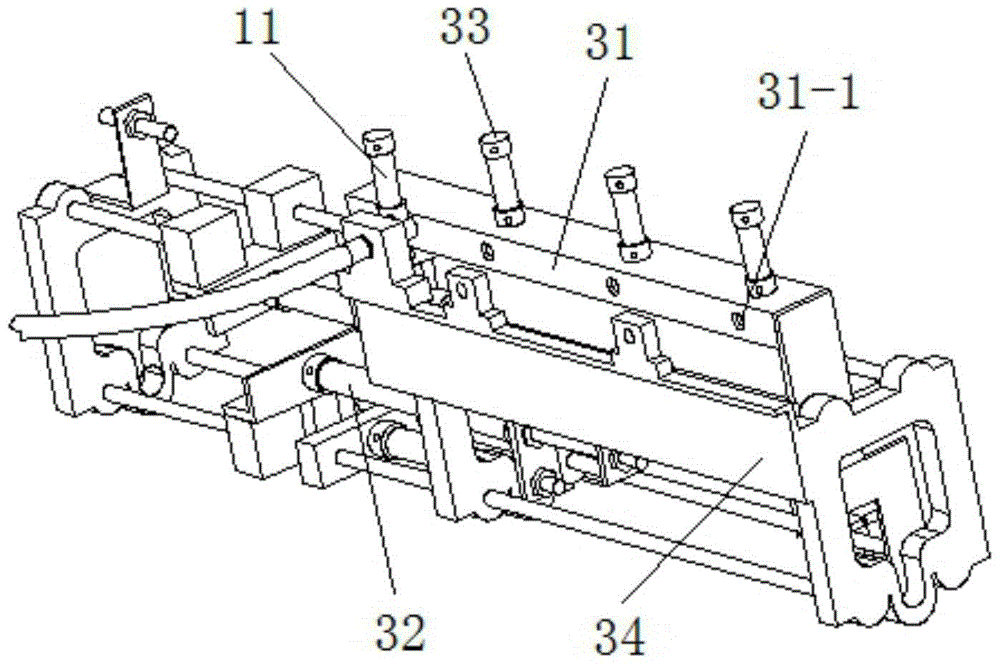

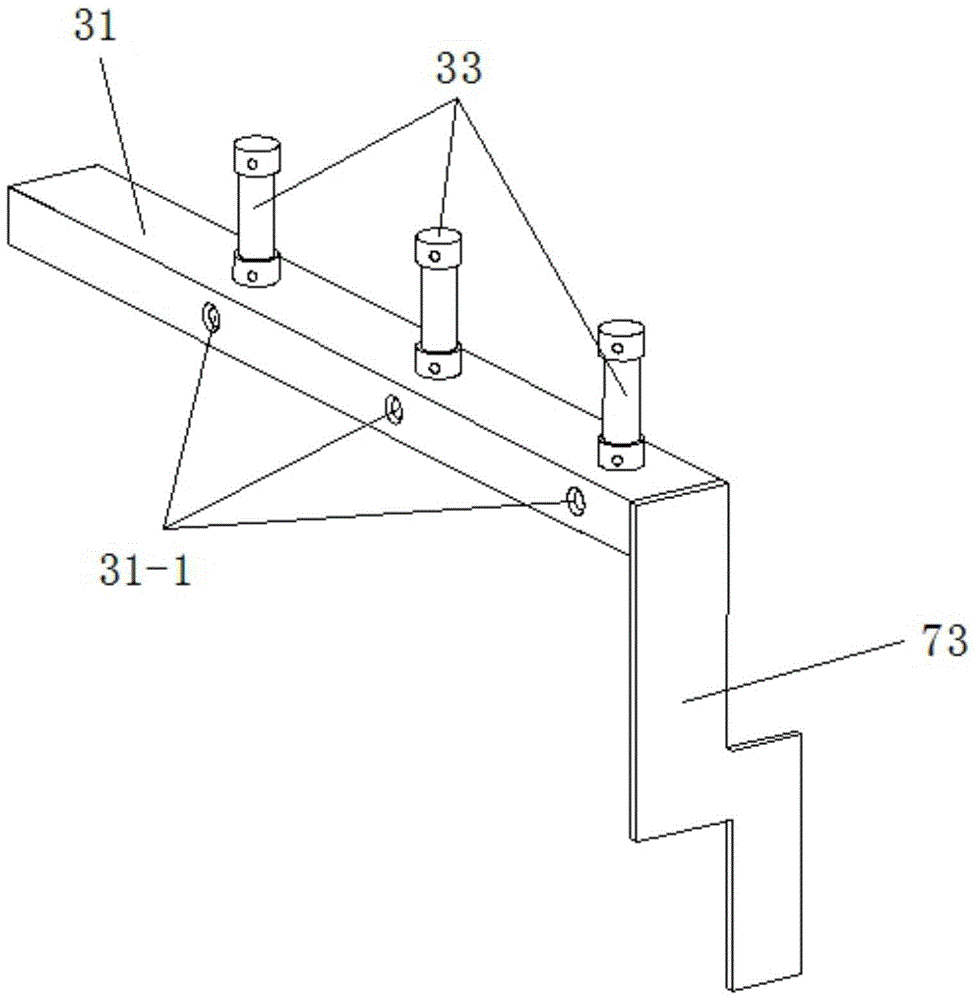

[0027]The charging unit 3 includes a charging rack 31, a charging cylinder 32, a charging skid 34 and a slider; above; the charging rack 31 is fixedly arranged on the slider, the charging cylinder 32 is fixedly arranged on the charging slide frame 34, and the output shaft of the charging cylinder 32 is fixedly connected with the slider; the charging rack 31 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com