Feeding device for automatic shaping machine

A feeding device and shaping machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low efficiency and unsafe manual feeding, achieve the effect of automatic feeding, ensure safety, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

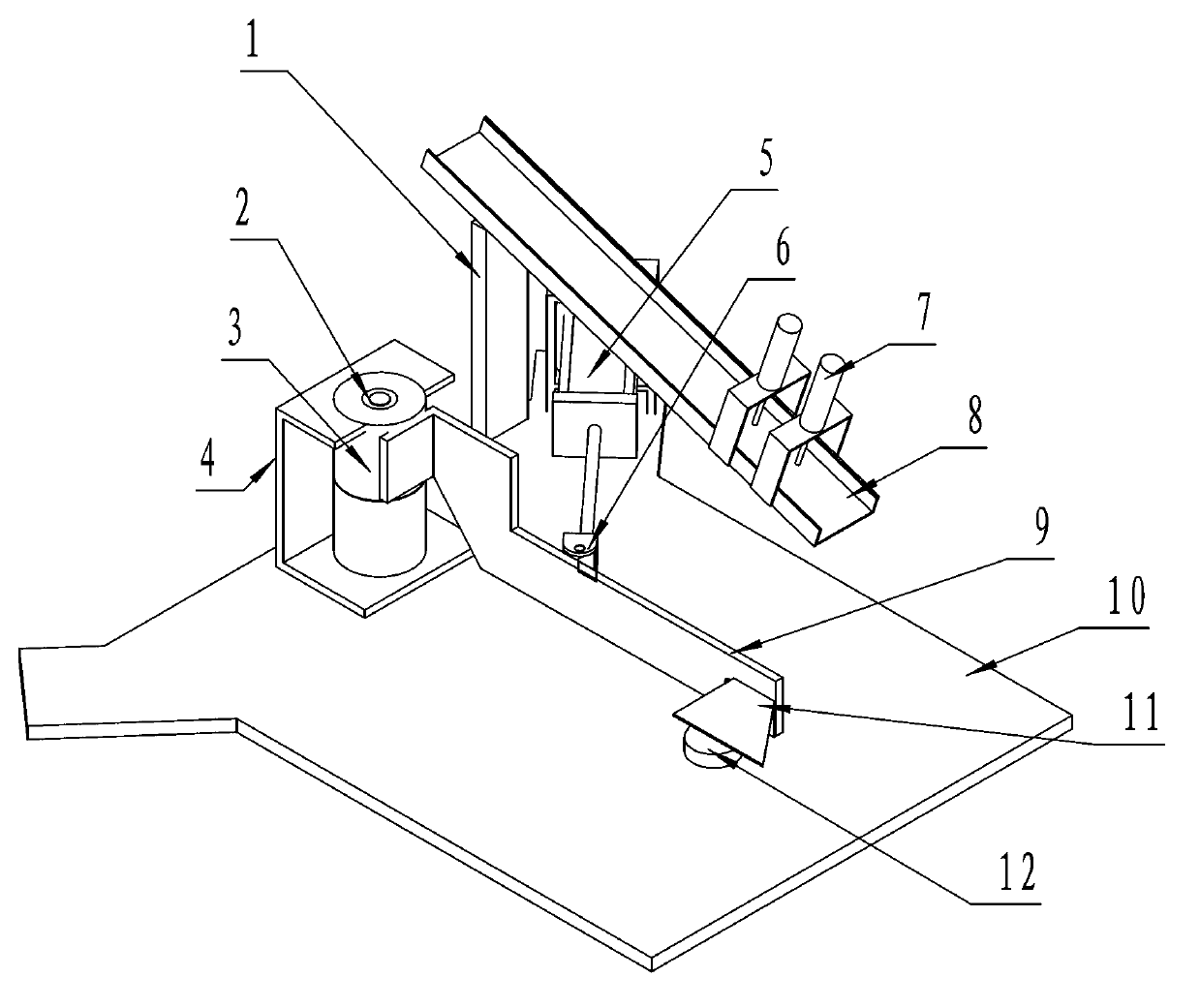

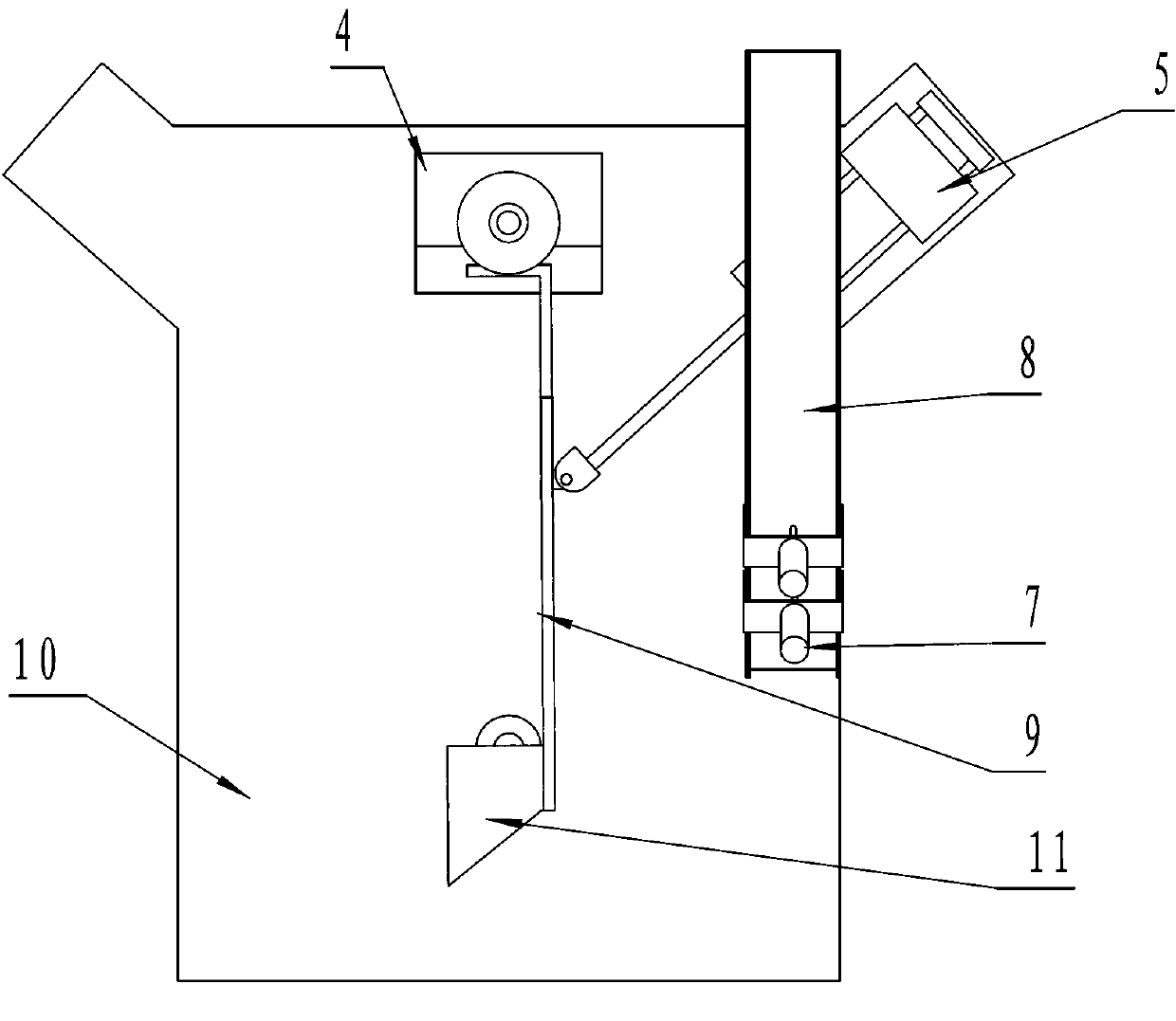

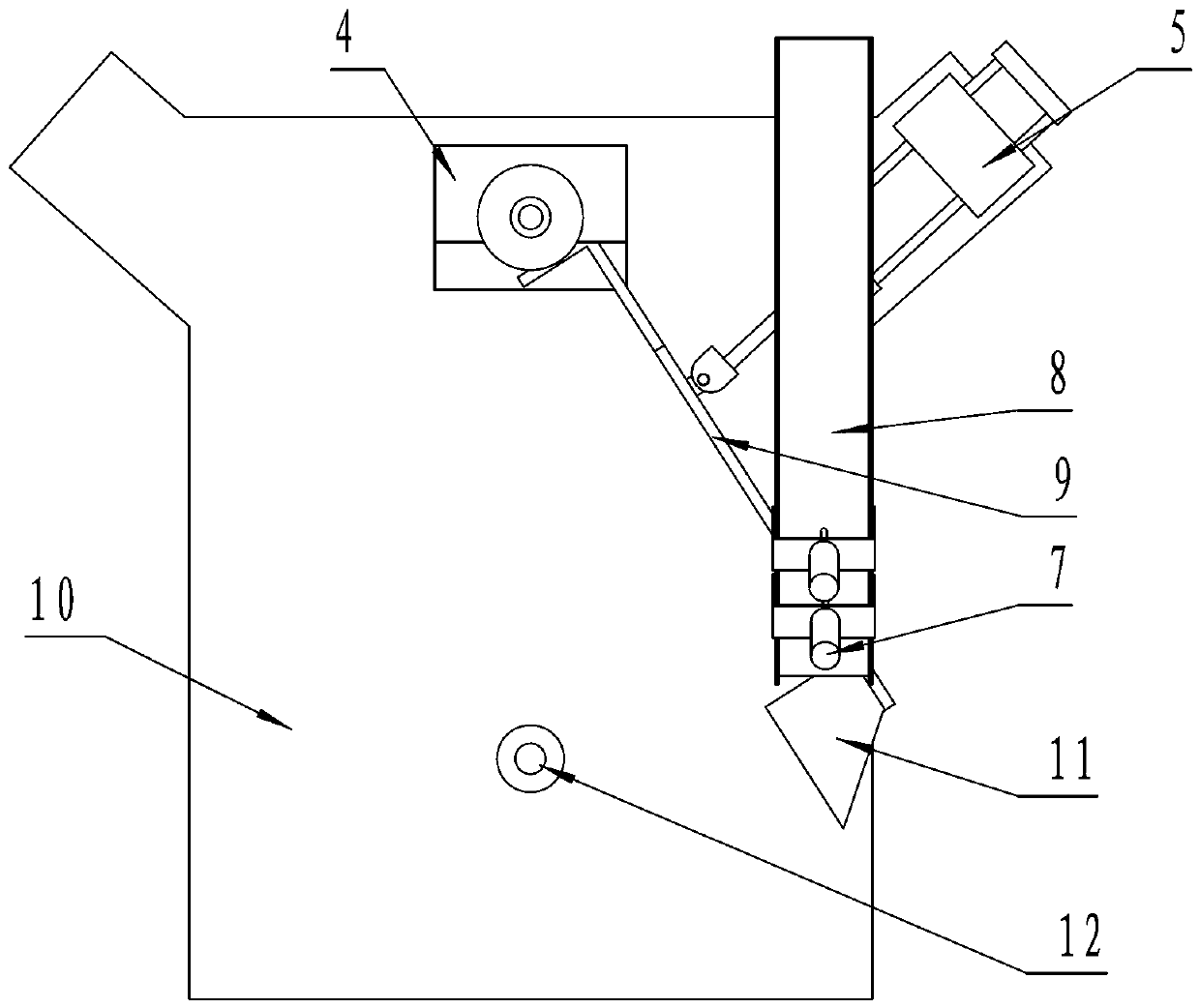

[0016] Embodiment 1, a feeding device of an automatic shaping machine, comprising a worktable 10, a shaping punch 12 fixed on the worktable, and is characterized in that: a trough 8 installed on the worktable, a rotary shaft 2 and a drive feeding The arm 9 is composed of a feeding cylinder 5 that rotates around a rotary axis,

[0017] The rotating shaft is fixed on the worktable by the rotating shaft bracket 4, the feeding arm bearing 3 equipped with the feeding arm is sleeved on the rotating shaft, and the front end of the feeding arm is equipped with a supporting plate 11.

[0018] The front end of the push rod of the feeding cylinder is equipped with a cylinder connecting lug 6 connected to the feeding arm.

Embodiment 2

[0019] Embodiment 2, a feeding device for an automatic shaping machine, comprising a worktable 10, a shaping punch 12 fixed on the worktable, and is characterized in that: a trough 8 installed on the worktable, a rotary shaft 2 and a drive feeding The arm 9 is composed of a feeding cylinder 5 that rotates around a rotary axis,

[0020] The rotating shaft is fixed on the worktable by the rotating shaft bracket 4, the feeding arm bearing 3 equipped with the feeding arm is sleeved on the rotating shaft, the front end of the feeding arm is equipped with a supporting plate 11, and the supporting plate is equipped with a suction magnet .

[0021] The front end of the push rod of the feeding cylinder is equipped with a cylinder connecting lug 6 connected to the feeding arm.

[0022] The trough is fixed on the workbench by the trough bracket 1, and two single-piece cylinders 7 are installed at the outlet end of the trough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com