Feeding and discharging device for plastic pipe fitting cutting

A technology for plastic pipe fittings and feeding, which is applied in the field of feeding and unloading devices for cutting plastic pipe fittings, can solve the problems of low feeding efficiency, insufficient feeding and poor effect, and achieves good feeding effect, good effect and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

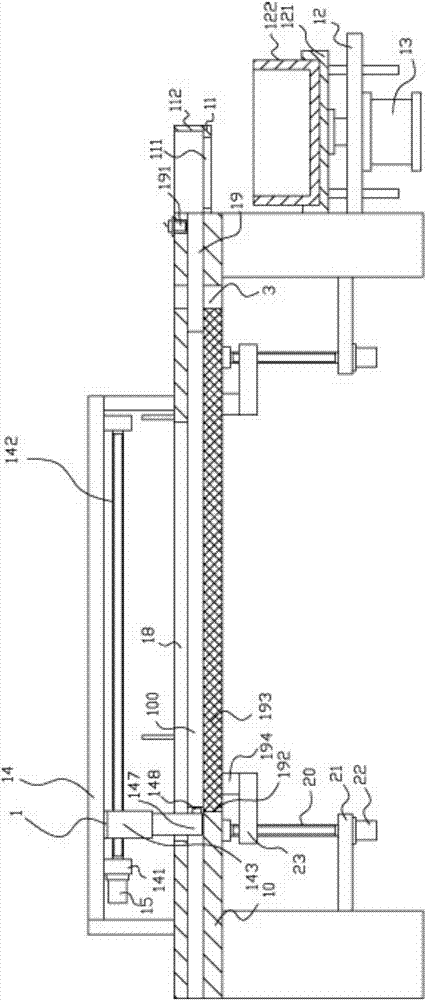

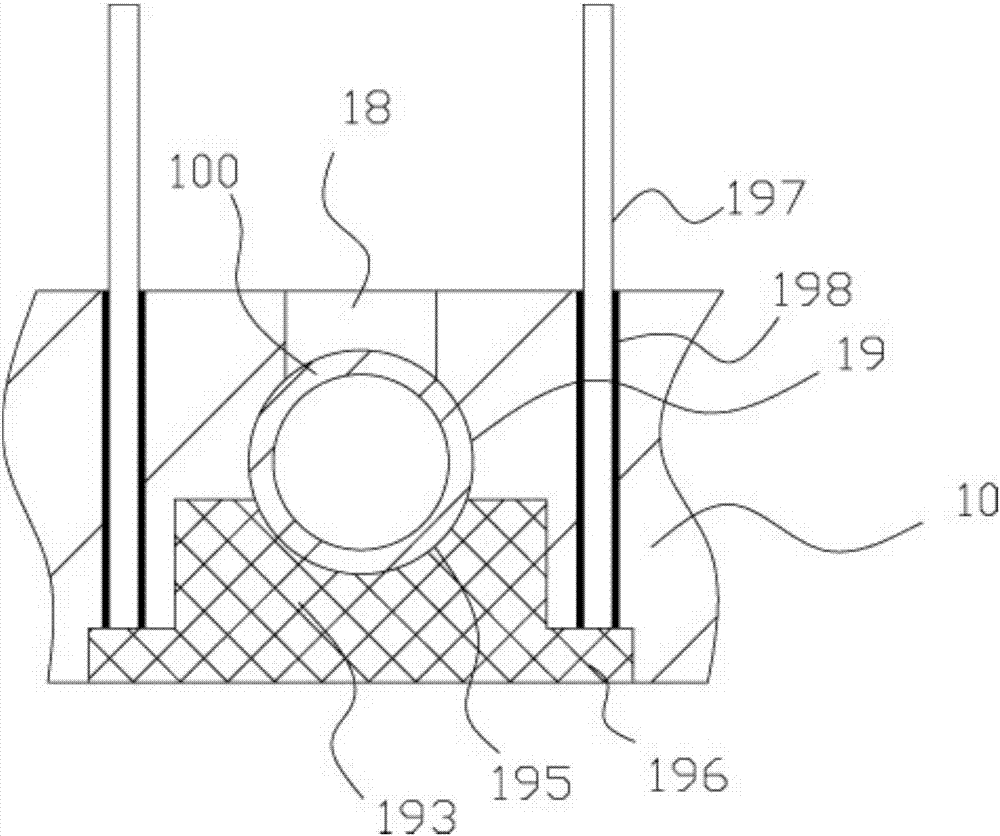

[0023] Example: see Figure 1 to Figure 2 Shown, a kind of plastic pipe fittings cutting is used material loading and unloading device, comprises frame 10, and the top plate of described frame 10 is provided with push horizontal plate 14, and the bottom surface of both sides of push horizontal plate 14 is fixed with pillar, and pillar is fixed on On the top plate of the frame 10, push the bottom two ends of the horizontal plate 14 to fix the limiting plate 141. Motor 15, the output shaft of driving motor 15 is a spline shaft, and the spline shaft is inserted in the spline hole that one end of the transverse screw rod 142 has, and the pushing block 143 is screwed in the transverse screw rod 142, and the bottom of the pushing block 143 is fixed with Guide block 147, the bottom right end of guide block 147 is fixed with pushing part 148, and guide block 147 inserts in the pusher guide channel 18 that the top surface of the top plate of frame 10 forms, and there are left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com