Mobile phone cover plate, manufacturing method thereof, and adopted device

A manufacturing method and a technology of a mobile phone cover, which are applied to branch office equipment, telephone structure, telephone communication, etc., can solve the problems of wasting raw materials, increasing costs, and high costs, and achieve the effects of improved construction safety, convenient production, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

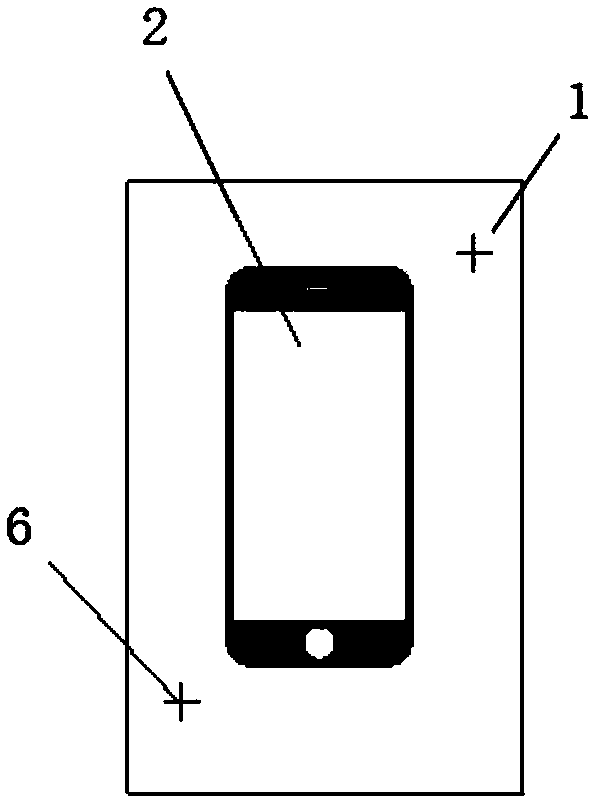

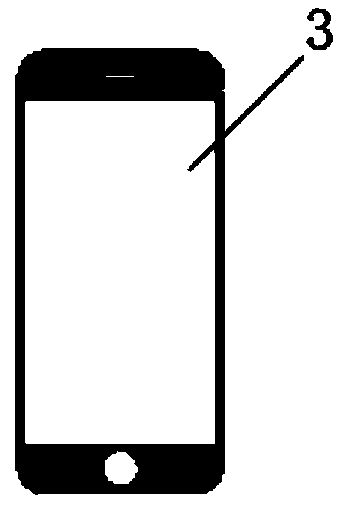

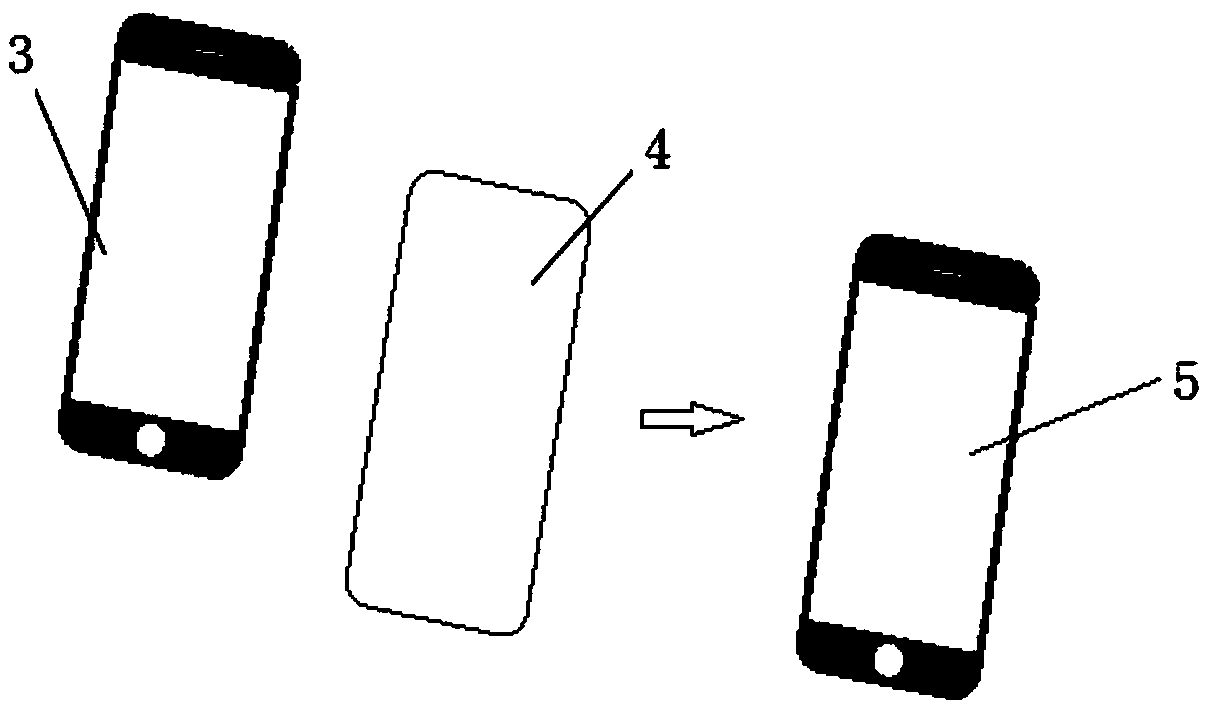

[0033] see Figure 1-Figure 3 , a mobile phone cover plate, including a mobile phone panel 4, a film sheet 1 attached to the mobile phone panel, and a window frame pattern 2 printed on the film sheet, and the film sheet and the window frame pattern form a film sheet window 3 . The specifications of the mobile phone panel 4, the film sheet 1 and the window frame graphic 2 are the same. Here the mobile phone panel 4 can be 0.03-0.2mm larger than the single side of the film window 3, and this parameter depends on the accuracy of the laminating machine.

[0034] The manufacturing method of the mobile phone cover includes the following steps:

[0035] The equipment used in this method includes a screen frame for printing window frame graphics, a graphics controller for positioning the window frame graphics on large film sheets, a carbon dioxide laser machine for cutting window frame graphics, and a A laminating machine for bonding with glass and a defoaming machine for laminatin...

Embodiment 2- Embodiment 20

[0044] Embodiment 2-embodiment 20 differs from the embodiment only in the parameters in Table 1, see Table 1 for details, specifically:

[0045] Embodiment 1-Example 4 investigated the influence of laser wavelength on the performance of the processed mobile phone cover plate; Implementation 1 investigated the impact of laser energy on the performance of the processed mobile phone cover plate in conjunction with Examples 5-8; Embodiment 1 In conjunction with Examples 9-12, the influence of laser frequency on the performance of the processed mobile phone cover is investigated; embodiment 1 is combined with Examples 13-16 to investigate the impact of laser cutting speed on the performance of the processed mobile phone cover; embodiment 1 In combination with Examples 17-20, the influence of the pulse width of the laser on the performance of the processed mobile phone cover was investigated.

[0046] The parameter statistical table of table 1 embodiment 1-20

[0047]

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com