BOPP matting transfer film for coating transfer and preparation method thereof

A transfer film and matting technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problem of reducing the gloss of patterns, achieve excellent performance indicators, large elastic modulus, and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

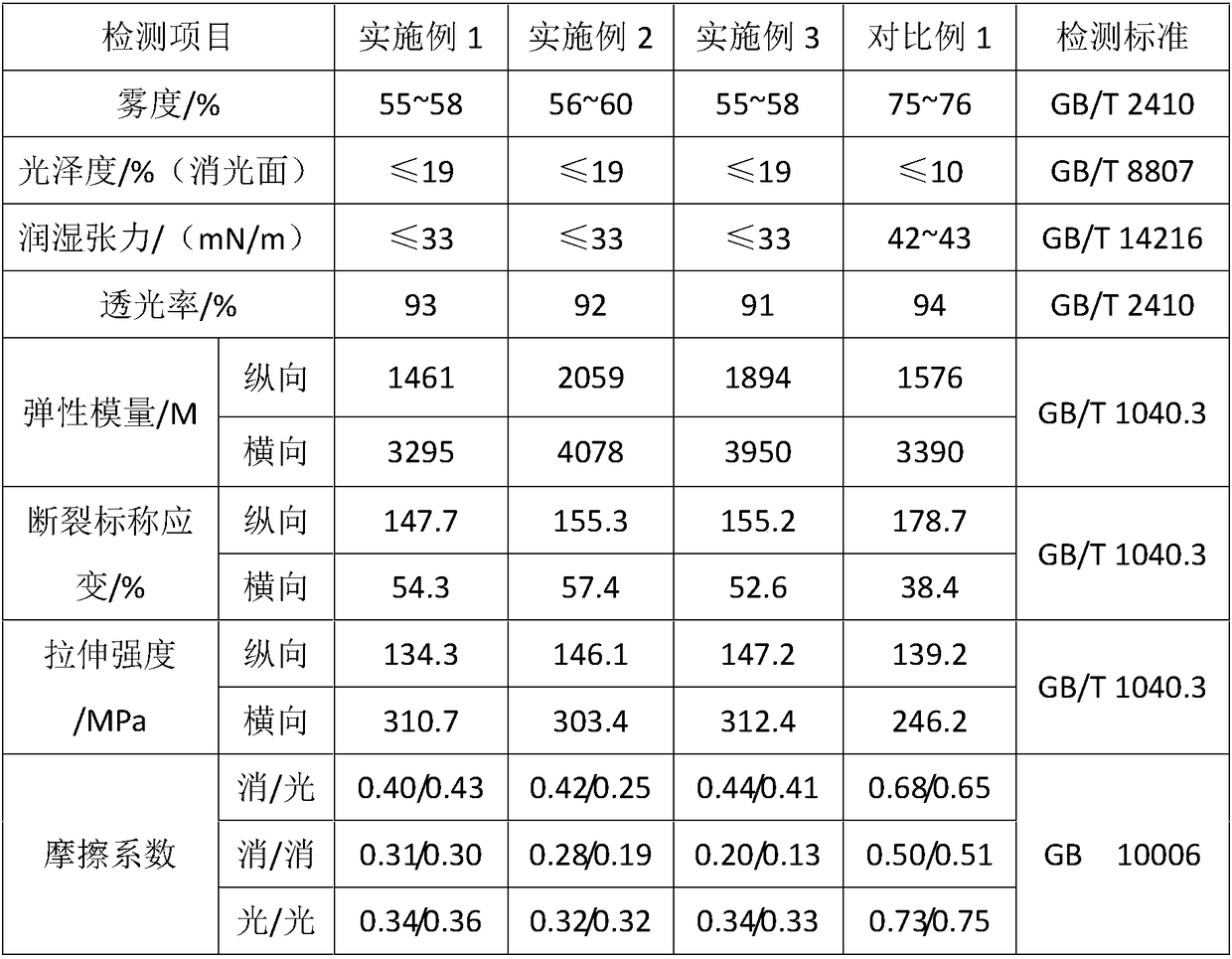

Examples

Embodiment 1

[0028] A BOPP matting transfer film for coating transfer, which is sequentially composed of an upper surface layer, an upper core layer, a lower core layer and a lower surface layer;

[0029] The upper surface layer is an anti-adhesive layer, which is composed of the following components by weight percentage: 95% of copolymerized polypropylene and 5% of anti-adhesive masterbatch; the melt index of the copolymerized polypropylene is 230°C / 2.16kg Greater than 2.8g / 10min; anti-adhesive masterbatch is composed of 96% carrier and 4% silica particles, where the carrier refers to homopolypropylene with a melt index greater than 2.8g / 10min at 230°C / 2.16kg;

[0030] The upper core layer is a polypropylene layer, which is composed of the following components by weight percentage: 0.5% of antistatic agent glyceryl stearate, 0.5% of smooth agent ethylene bisstearamide, and 99% of film grade homopolypropylene.

[0031] The lower core layer and the lower surface layer are all transfer layer...

Embodiment 2

[0040] A BOPP matting transfer film for coating transfer, which is sequentially composed of an upper surface layer, an upper core layer, a lower core layer and a lower surface layer;

[0041] The upper surface layer is an anti-adhesive layer, which is composed of the following components by weight percentage: 97% of copolymerized polypropylene and 3% of anti-adhesive masterbatch; the melt index of the copolymerized polypropylene is at 230°C / 2.16kg Greater than 2.8g / 10min; anti-adhesive masterbatch is composed of 94% carrier and 6% silica particles, where the carrier refers to terpolymer with a melt index greater than 2.8g / 10min at 230°C / 2.16kg;

[0042] The upper core layer is a polypropylene layer, which is composed of the following components by weight percentage: antistatic agent glyceryl stearate 1.0%, smooth agent ethylene bisstearamide 2.0%, and film grade homopolypropylene 97%.

[0043] The lower core layer and the lower surface layer are all transfer layers, and their ...

Embodiment 3

[0052] A BOPP matting transfer film for coating transfer, which is sequentially composed of an upper surface layer, an upper core layer, a lower core layer and a lower surface layer;

[0053] The upper surface layer is an anti-adhesive layer, which is composed of the following components by weight percentage: 96% of copolymerized polypropylene and 4% of anti-adhesive masterbatch; the melt index of the copolymerized polypropylene is 230°C / 2.16kg Greater than 2.8g / 10min; anti-adhesive masterbatch is composed of 95% carrier and 5% silica particles, where the carrier refers to homopolypropylene with a melt index greater than 2.8g / 10min at 230°C / 2.16kg;

[0054] The upper core layer is a polypropylene layer, which is composed of the following components by weight percentage: 0.8% of glyceryl stearate as an antistatic agent, 1% of ethylene bisstearamide as a slippery agent, and 98.2% of film grade homopolypropylene.

[0055] The lower core layer and the lower surface layer are all t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com