Process for treating electrolytic aluminum carbon residues through supercritical water oxidation

A supercritical water oxidation and electrolytic aluminum technology, applied in the field of electrolytic aluminum, can solve the problems of F-containing flue gas volatilization, increased electrolyte volatilization, electrolyte denaturation, etc., and achieve the effect of shortening the process flow, shortening the processing time, and complete oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The electrolyte contained in the carbon slag is mainly cryolite, subcryolite and fluoride salt, and the reaction is carried out under high temperature and high pressure conditions. Therefore, the material of the inner wall of the reactor must be a nickel-chromium alloy or a nickel-chromium-molybdenum alloy that is resistant to fluoride ion corrosion. , In this embodiment, the Hastelloy of the grade G35 is selected, and the inner wall of the reactor is welded by surfacing, and the corrosion-resistant layer after 3mm is formed by surfacing. During the supercritical oxidation process, the fluoride ions in the electrolyte It has strong corrosiveness. By surfacing a corrosion-resistant layer on the surface of the reactor, the service life of the reactor can be extended, and the reaction can be carried out smoothly in the reactor.

[0038] Carbon slag pretreatment: put the electrolytic aluminum carbon slag into a ball mill, use corundum balls as the ball mill medium, and grind...

Embodiment 2

[0044] The electrolyte contained in the carbon slag is mainly cryolite, subcryolite and fluoride salt, and the reaction is carried out under high temperature and high pressure conditions. Therefore, the material of the inner wall of the reactor must be a nickel-chromium alloy or a nickel-chromium-molybdenum alloy that is resistant to fluoride ion corrosion. , In this embodiment, the Hastelloy of the grade G276 is selected, and the inner wall of the reactor is welded by surfacing welding, and the corrosion-resistant layer after 4 mm is formed by surfacing welding.

[0045] Carbon slag pretreatment: put the electrolytic aluminum carbon slag into a ball mill, use corundum balls as the ball mill medium, and grind it in the ball mill for 30 minutes, then take out the pulverized carbon slag, pass it through an 80-mesh sieve, and select the part under the sieve for use. , the average particle size is 0.6mm; the upper part of the sieve is mixed with other coarse carbon residues for the...

Embodiment 3

[0050] The electrolyte contained in the carbon slag is mainly cryolite, subcryolite and fluoride salt, and the reaction is carried out under high temperature and high pressure conditions. Therefore, the material of the inner wall of the reactor must be a nickel-chromium alloy or a nickel-chromium-molybdenum alloy that is resistant to fluoride ion corrosion. , In this embodiment, the Hastelloy grade G35 is selected, and the inner wall of the reactor is welded by surfacing welding, and a corrosion-resistant layer of 5 mm is formed by surfacing welding.

[0051] Carbon slag pretreatment: put the electrolytic aluminum carbon slag into a ball mill, use corundum balls as the ball mill medium, and grind it in the ball mill for 60 minutes. The upper part of the screen is mixed with other coarse carbon residues for the second ball milling.

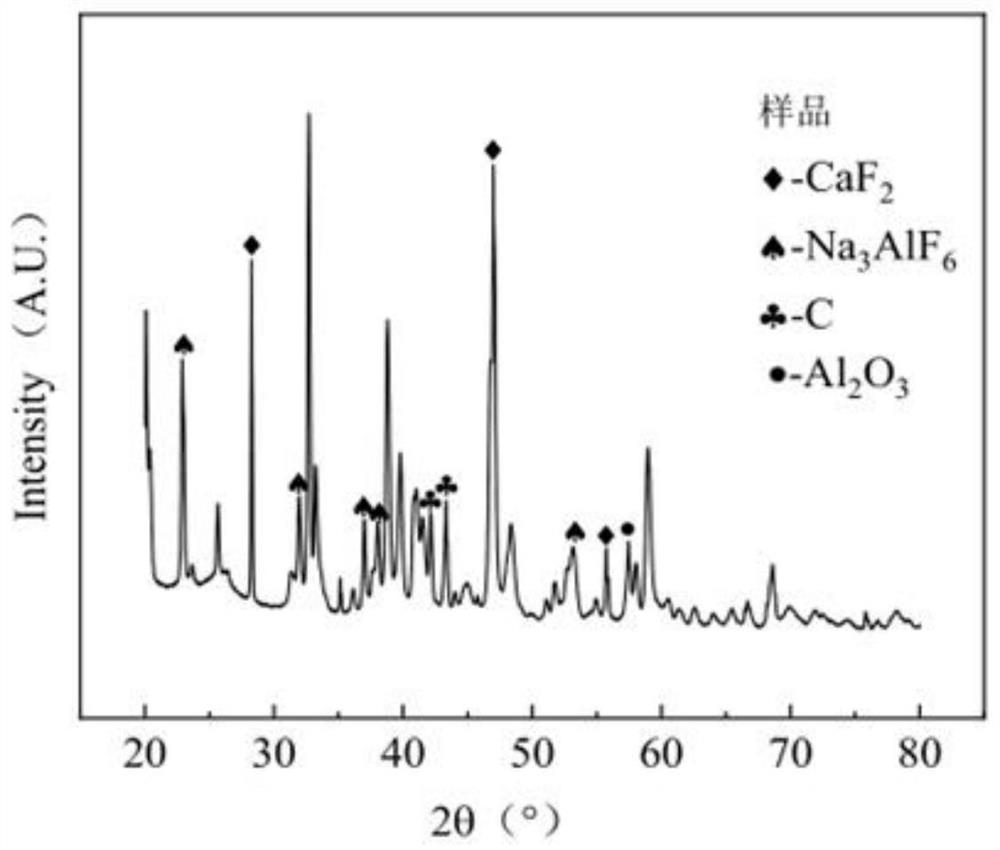

[0052] Preparation of oxidant: In this embodiment, the oxidant is an aqueous hydrogen peroxide solution with a concentration of 10%. X-ray fluore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com