Treatment system and treatment method for controlling pipeline corrosion stink

A treatment system and pipeline technology, applied in the direction of special treatment goals, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of long-term actual control, high cost of FNA reagents, large consumption, etc., and achieve a stable and simple preparation process Energy saving, convenience and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

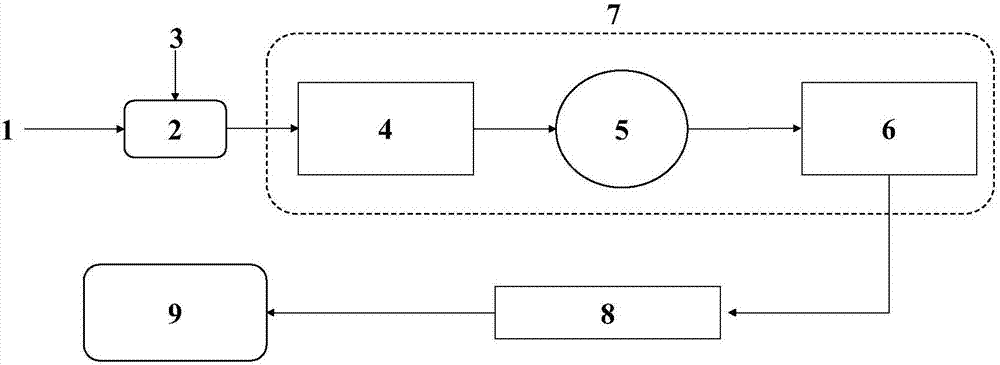

[0060] Such as figure 1 As shown, the treatment system for controlling pipeline corrosion and stench includes: source separation toilet 2, flushing device 3, urine storage tank 4, SBR reaction tank 5, FNA storage tank 6, FNA preparation device 7, sewage pipeline 8 and Sewage treatment plant 9 , wherein the FNA preparation device includes a urine storage tank 4 , an SBR reaction tank 5 and an FNA storage tank 6 .

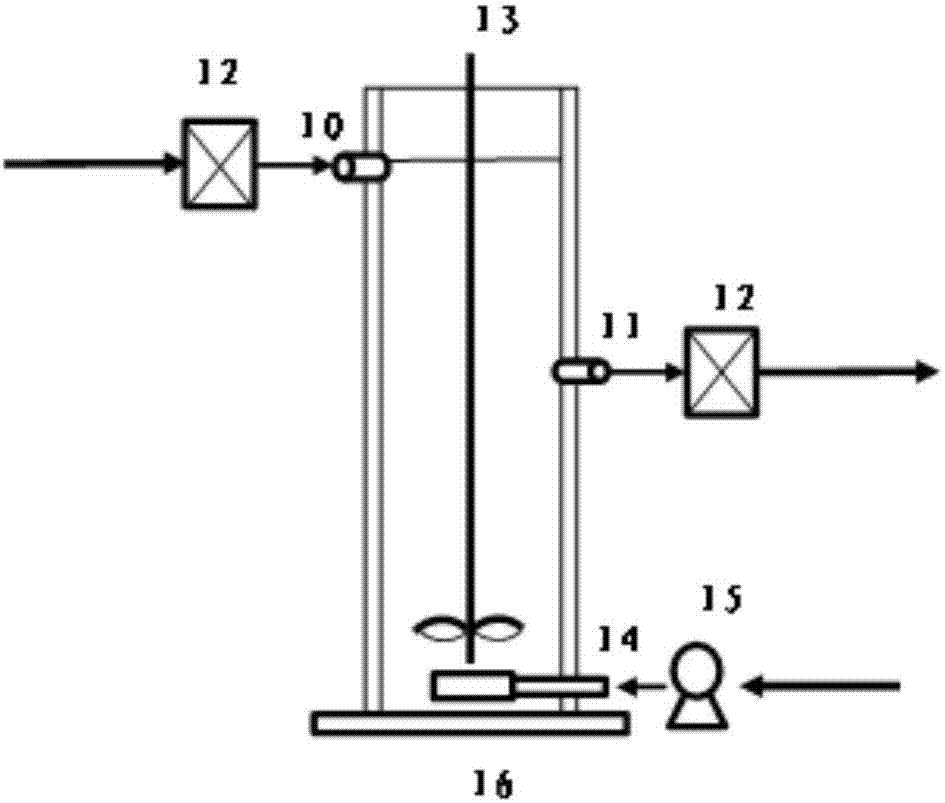

[0061] In this embodiment, in combination with the number and location of the population, the treatment system is set up upstream of the sewage pipeline, and the diluted urine is pumped into the SRB reaction tank after staying in the urine storage tank for 2 days. The urine ammonia nitrogen concentration is 400-900mgN / L, the residence time is 1 day, and the dissolved oxygen concentration is 0.2-0.3mgDO / L.

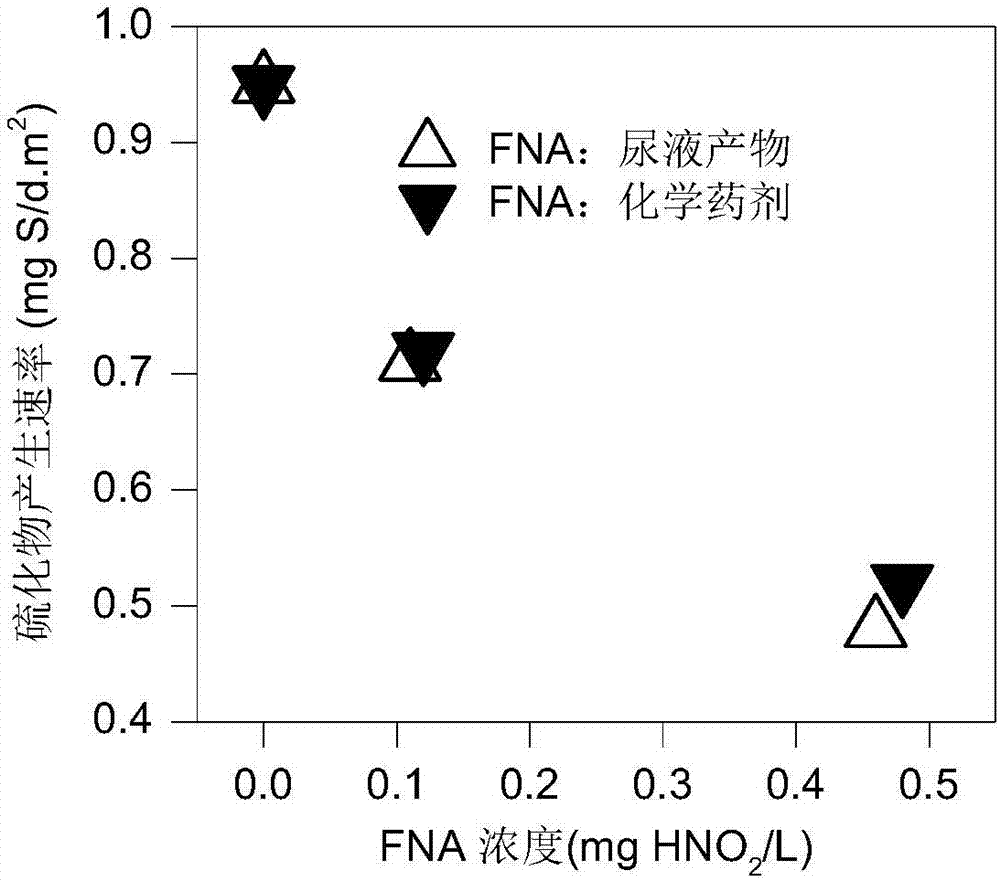

[0062] Such as image 3 As shown, use the urine product of the system of the present invention and the existing chemical agents that can produce FNA to treat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com