Brake shoe workshop curing furnace waste gas treating system and method

A waste gas treatment and treatment system technology, applied in waste heat treatment, incinerators, combustion methods, etc., can solve the problems of failing to meet environmental protection standards, inconvenient maintenance, and high operating costs, and achieve stable operating performance, easy management, and simple maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

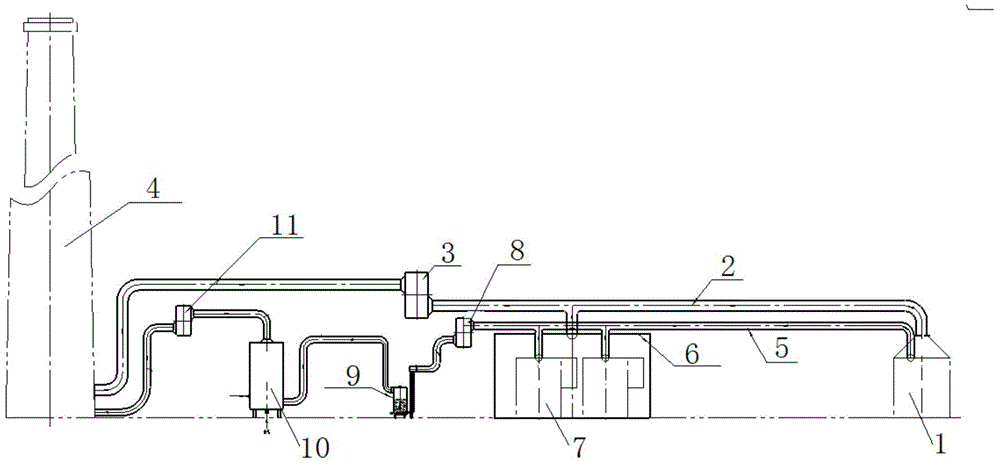

[0011] A brake shoe workshop curing furnace exhaust gas treatment system, such as figure 1 As shown, it includes: the first curing furnace 1, the first flue 2, the first centrifugal fan 3, the outer chimney 4, the second flue 5, the airtight chamber 6, the second curing furnace 7, the second centrifugal fan 8, the gas Water seal tank device 9, combustion chamber 10, third centrifugal fan 11, etc., wherein:

[0012] The first centrifugal fan 3 and the third centrifugal fan 11 are explosion-proof centrifugal fans; the second centrifugal fan 8 is an explosion-proof and anti-corrosion centrifugal fan. The first curing furnace 1 is an old curing furnace, and the second curing furnace 7 is a new curing furnace.

[0013] The smoke outlets of the first curing furnace 1 and the second curing furnace airtight chamber 6 are connected with the first centrifugal fan 3 and the outer chimney 4 successively through the first flue 2; the waste gas of the first curing furnace 1 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com