A nanoflower spinel COMN for catalytic oxidation of VOCs 2 o 4 Catalyst, preparation method and application

A catalytic oxidation and nanoflower technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. control, increase the cost of catalyst preparation, etc., to achieve good industrial application prospects, good low-temperature activity and stability, and good low-temperature reduction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

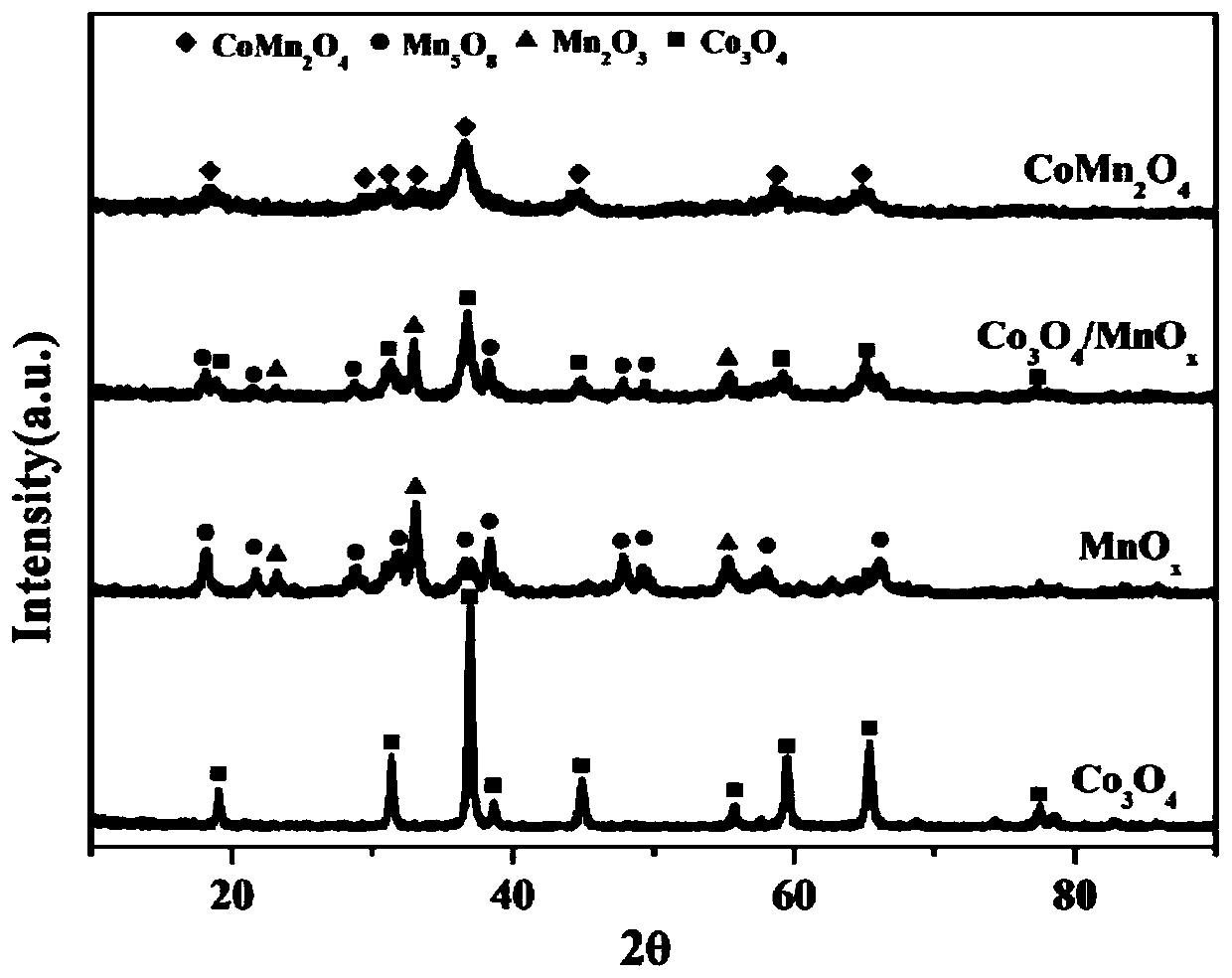

[0020] Spinel CoMn 2 O 4 Preparation:

[0021] 0.04 mol manganese acetate and 0.02 mol cobalt nitrate were dissolved and dispersed in 10 mL of ethanol solution, and placed in a heat-collecting thermostatic magnetic stirrer at 80°C for vigorous stirring. Then quickly add 0.24 mol / L oxalic acid solution, control the ratio of metal to oxalic acid to 1:1.2, and continue to stir for 30 minutes in a heat-collecting thermostatic magnetic stirrer at 80°C. The obtained material was washed by centrifugation, placed in an oven at 60-100℃, dried for 12-24h, and finally calcined in a muffle furnace at 400℃ for 3h at a heating rate of 1℃ / min to obtain spinel CoMn 2 O 4 catalyst.

Embodiment 2

[0027] The toluene oxidation performance test of the four catalysts prepared in Example 1 and Comparative Example 1 was carried out continuously on a self-built micro response device, with argon as the balance gas, and gas chromatography GC2014 equipped with TCD and FID detectors for online detection After the reaction, the gaseous substance toluene molecule and the product CO 2 molecular.

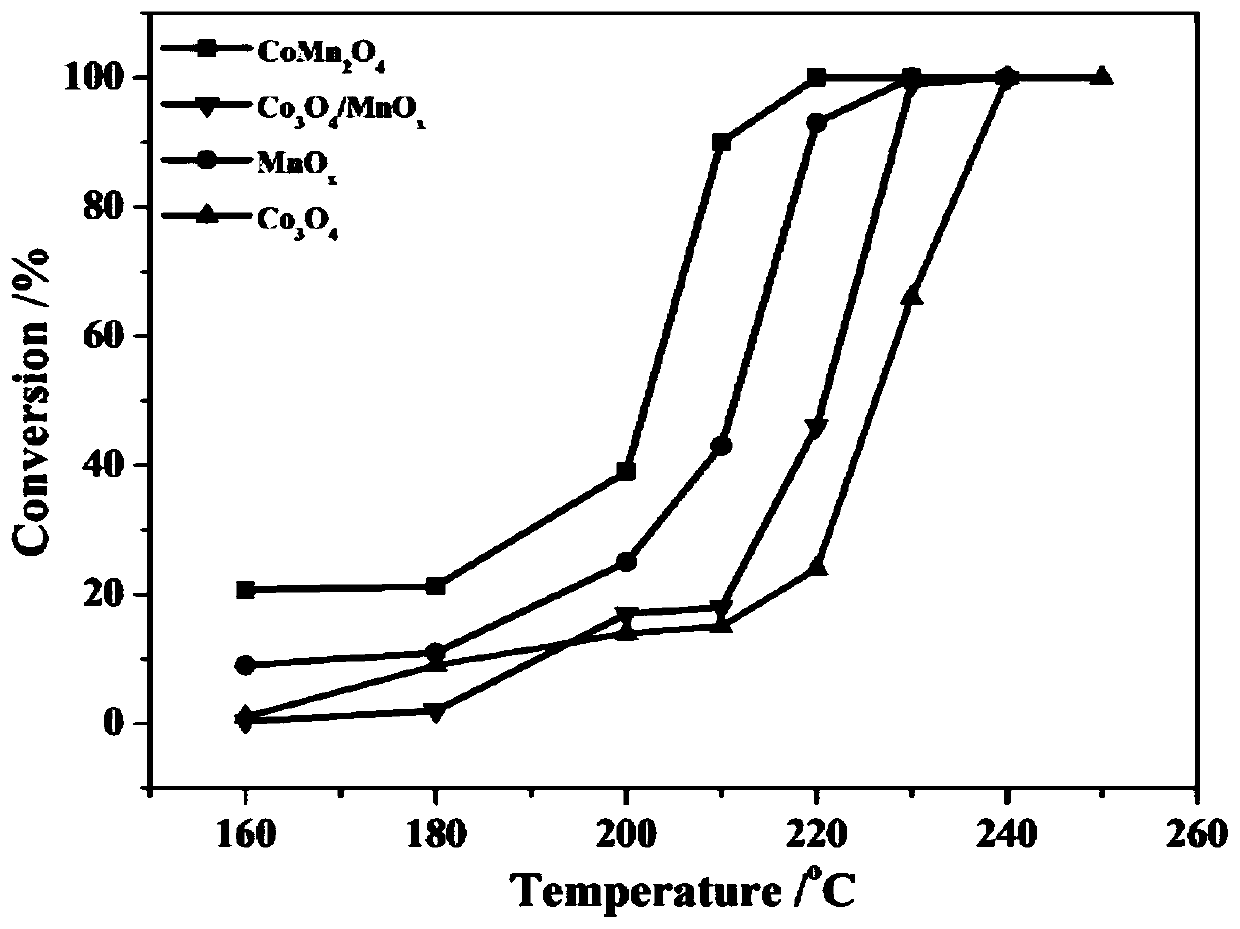

[0028] The specific reaction conditions are: the concentration of toluene is 500 ppm, the flow rate of the mixed gas is 75 mL / min, and the reaction space velocity is 22500 mL / g h. Toluene oxidation conversion rate calculation formula: toluene conversion rate %=[(initial concentration of toluene-concentration after toluene reaction) / initial concentration of toluene]*100. Reactivity as figure 1 As shown, the spinel CoMn 2 O 4 The catalyst has the best activity, reaching 90% toluene conversion at 210°C.

Embodiment 3

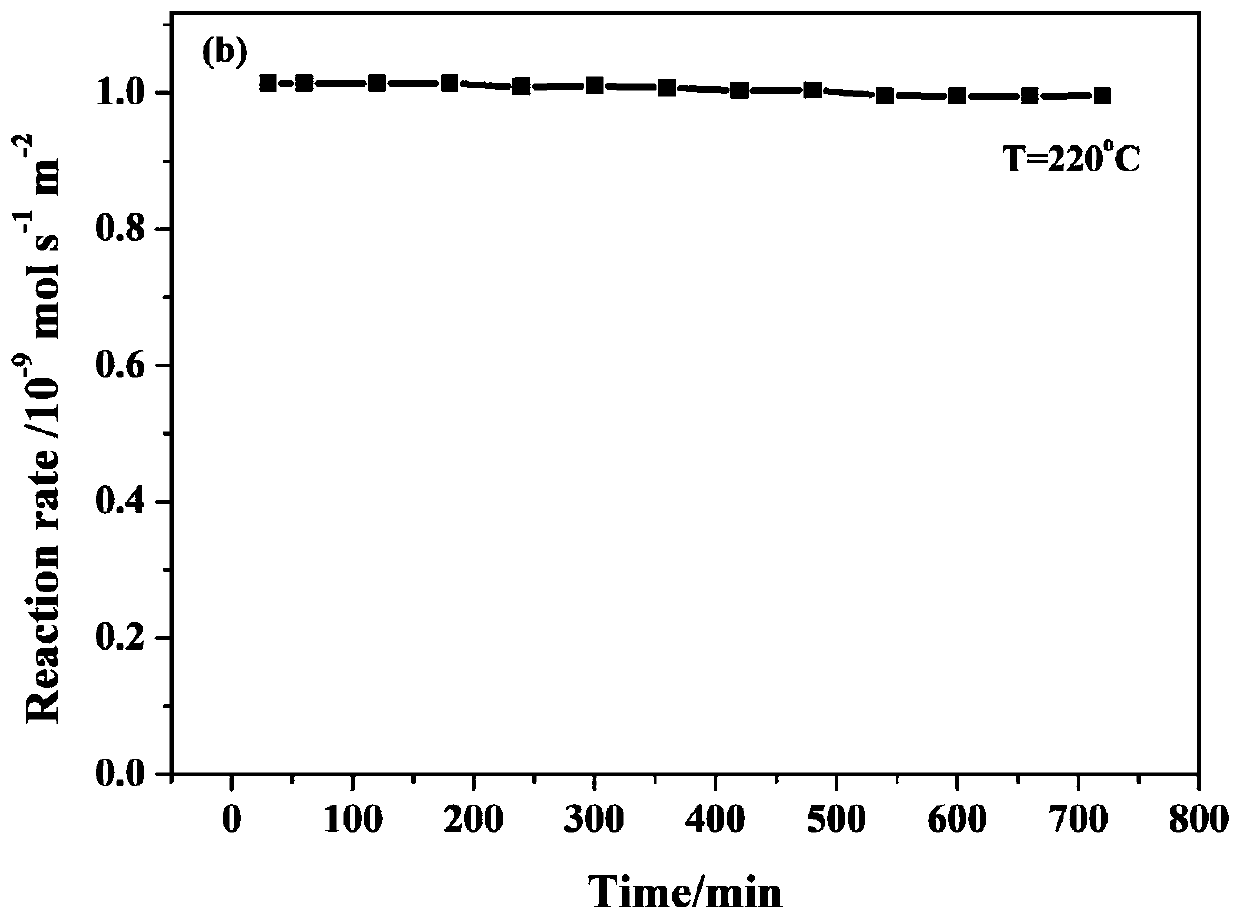

[0030] For the spinel CoMn prepared in Example 1 2 O 4 The catalyst was continuously operated at 220°C under the reaction conditions of Example 2 to test the stability performance of the catalyst. The stability performance was as follows: figure 2 As shown, the conversion rate remained above 98% within 700 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com