Ammonia process desulfurization device capable of saving energy by more than 50%

A technology of ammonia desulfurization and desulfurization tower, which is applied in the field of ammonia desulfurization energy saving more than doubled, energy-saving transformation, can solve the problems of large investment in the oxidation system, poor effect, large gas cap resistance, damage to the anti-corrosion layer, etc., to save money , reduce investment and save heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

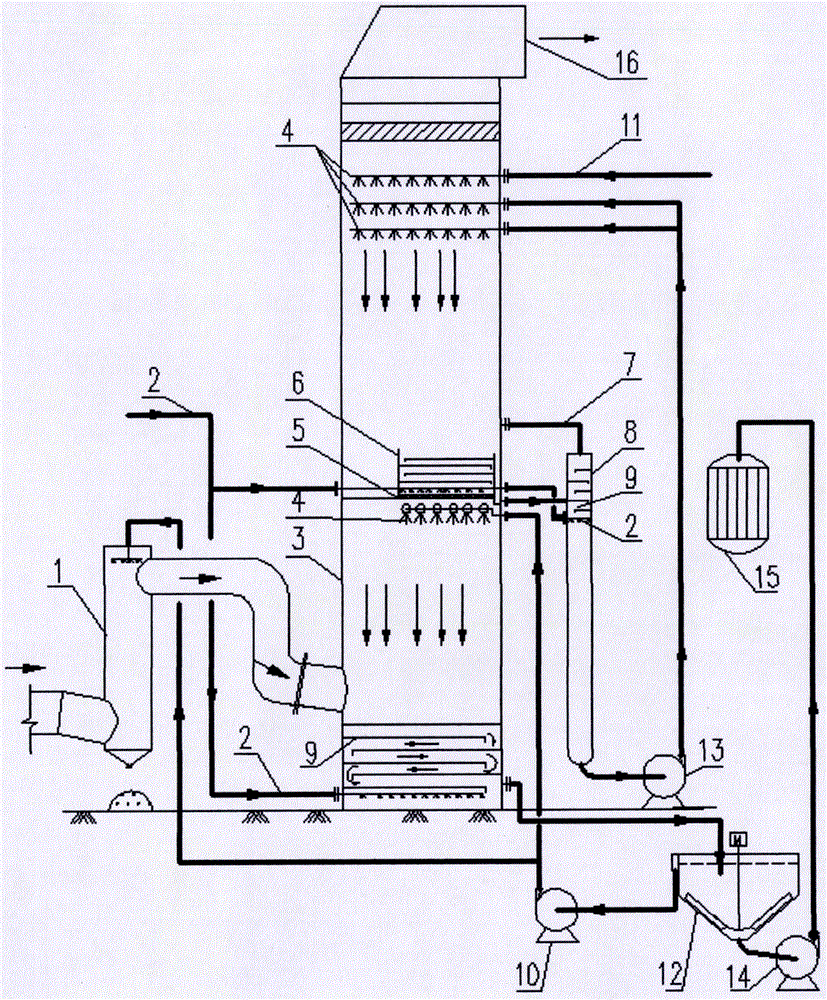

[0022] Below in conjunction with accompanying drawing, device of the present invention is described in further detail:

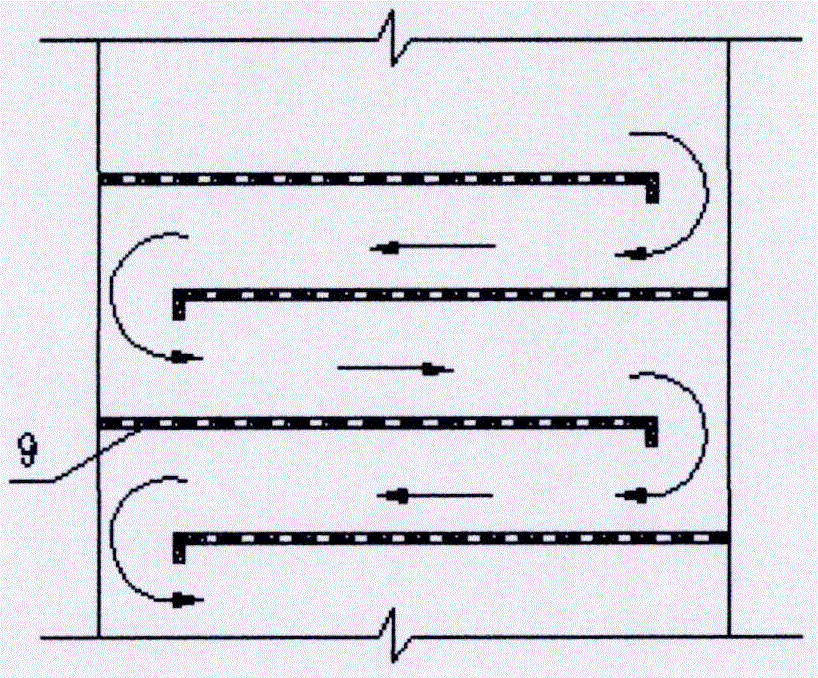

[0023] Such as figure 1 As shown, it includes a desulfurization tower (3), and a cooling and dry powder integrated pipe (1) located in front of the tower. One side of the desulfurization tower (3) has a multifunctional low-speed rotating solid-liquid separator (12), energy recovery pipe (8), low-level circulation pump (10), high-level circulation pump (13), thick slurry pump (14) and dryer system (15); the desulfurization tower (3) is divided into an upper section and a lower section, and the upper section and the lower section There is no separation plate between the sections, and because there are only two layers of design, the height of the desulfurization tower (3) is greatly shortened, thereby reducing the cost; the upper section of the desulfurization tower (3) is provided with a purified flue gas outlet (16) and a nozzle (4), the lower section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com