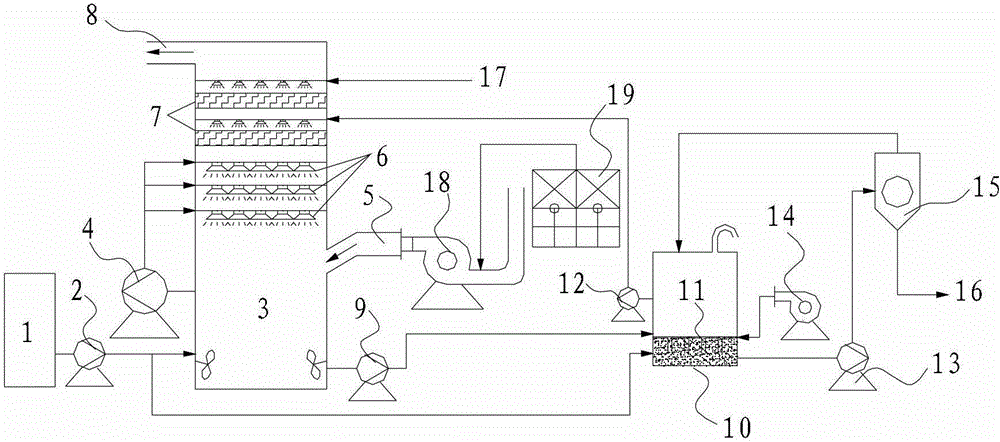

Amino wet combined desulfurization and denitration device and process

A technology of desulfurization, denitrification, and wet method, which is applied in the direction of separation method, ammonium sulfate, chemical equipment and methods, etc., can solve the problems of large fluctuation range of pH value, inability to take into account desulfurization efficiency, and a large amount of aerosol generation, etc., to improve the purity , Improve desulfurization efficiency and ammonium sulfate crystal quality, save operating costs and investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In a thermal power plant, three 130t / h boilers adopt this desulfurization and denitrification process, and the liquid-gas ratio of the desulfurization tower is 8L / m 3 , the pH value of the desulfurization tower is controlled at 5.9-6.0, the pH value of the oxidation tank is controlled at 5.6-6.0, the ozone supply is 1:1, the perforated plate is located 0.6m above the oxidation duct; the inlet SO 2 The concentration is 6324mg / m 3 , NO concentration is 273mg / m 3 , the flue gas temperature is 142°C, the outlet SO 2 The concentration is 38mg / m 3 , NO concentration is 13mg / m 3 , the purity of ammonium sulfate is 96.9%, and the crystal particle size range of ammonium sulfate is 1mm-3mm.

Embodiment 2

[0055] A self-provided power plant, one 335WM unit adopts this desulfurization and denitrification process, the liquid-gas ratio of the desulfurization tower is 8, the pH value of the desulfurization tower is controlled at 5.9-6.2, the pH value of the oxidation tank is controlled at 5.8-6.0, and the ozone supply is 1: 1. The porous plate is located 0.5m above the oxidation air duct; the inlet SO 2 The concentration is 5428mg / m 3 , NO concentration is 413mg / m 3 , the flue gas temperature is 139°C, the outlet SO 2 Concentration is 27mg / m3, NO concentration is 17mg / m 3 , the purity of ammonium sulfate is 97.3%, and the crystal particle size range of ammonium sulfate is 1mm-3mm.

Embodiment 3

[0057] In a power plant, five 75t / h boilers adopt this desulfurization and denitrification process. The liquid-gas ratio of the desulfurization tower is 7, the pH value of the desulfurization tower is controlled at 5.9-6.1, the pH value of the oxidation tank is controlled at 5.6-5.8, and the ozone supply is 1: 1. The perforated plate is located 0.7m above the oxidation air duct; the inlet SO 2 The concentration is 3861mg / m 3 , NO concentration is 477mg / m 3 , the flue gas temperature is 137°C, the outlet SO 2 The concentration is 18mg / m3, the NO concentration is 21mg / m 3 , the purity of ammonium sulfate is 96.1%, and the crystal particle size range of ammonium sulfate is 1mm-3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com