Gold-base catalyst for room-temperature carbon monoxide removal and preparation method thereof

A gold catalyst, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the loss of active centers, complex carrier surface, gold particle agglomeration problem, to achieve the effect of convenient operation, simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

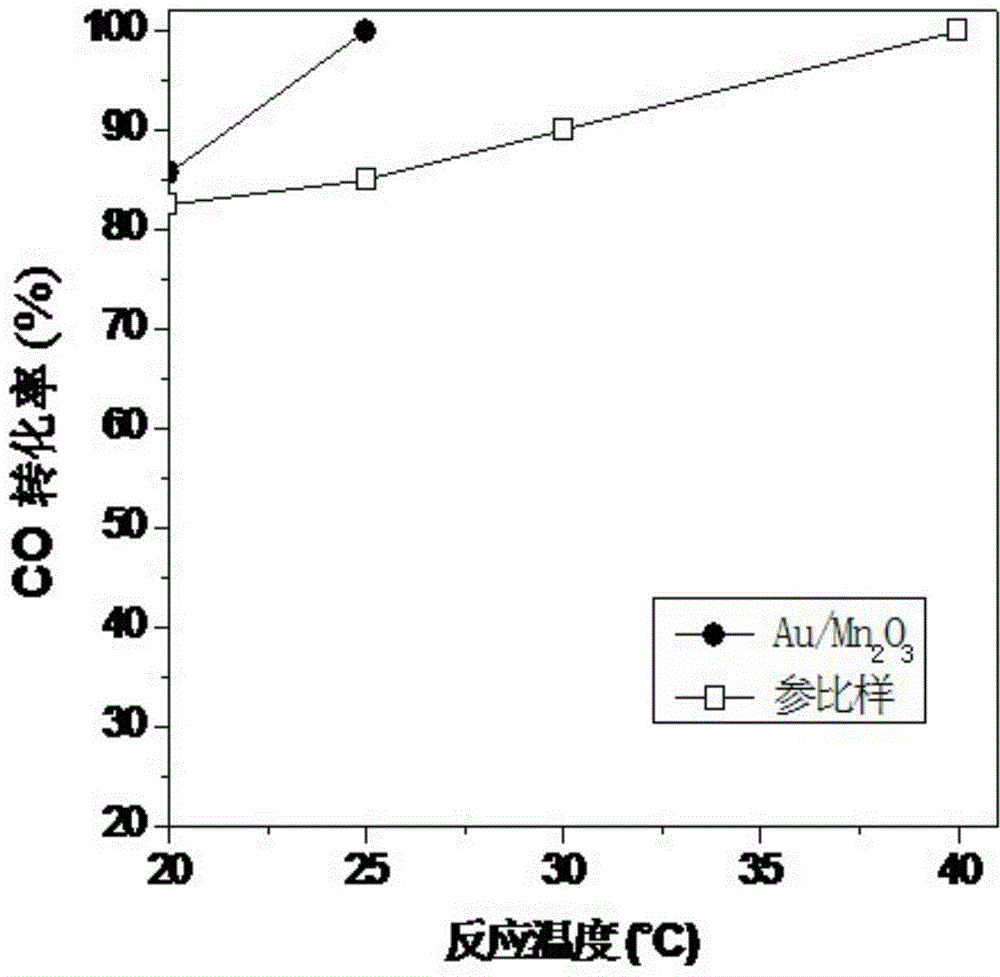

[0016] At room temperature, take 100mL of distilled water and place it in a 200mL beaker, disperse 0.1mL of chloroauric acid solution with a gold equivalent concentration of 9.6g / L in it, add 2.5g of urea under magnetic stirring, wait for the urea to dissolve, then add 2g of mn 2 o 3 The carrier was then placed in a water bath at 80°C, and after magnetic stirring for 1 hour, it was taken out and cooled to room temperature. The suspension was filtered and washed several times with deionized water, and the obtained solid was redispersed in 100 mL of distilled water. Stir magnetically at room temperature, and irradiate with a UV lamp for 1 hour, filter, wash several times, and dry in an oven at 80°C for 12 hours. Finally, the obtained solid powder was calcined in a muffle furnace at 300°C for 2 hours to obtain the catalyst Au / Mn 2 o 3 .

[0017] 50 mg of catalyst was placed in a fixed bed reactor, and a mixed gas of 1% CO and 99% air was introduced, the flow rate was 20 mL / m...

Embodiment 2

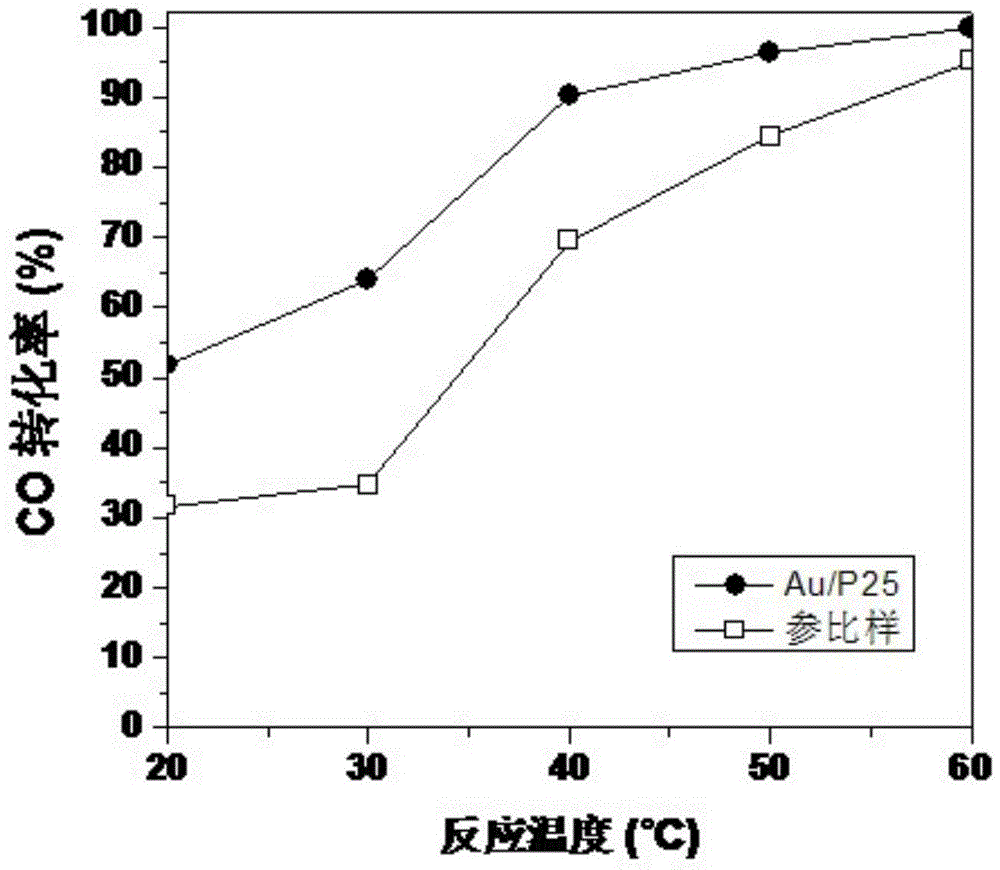

[0019] At room temperature, take 50mL of distilled water and place it in a 100mL beaker, disperse 0.05mL of chloroauric acid solution with a gold equivalent concentration of 9.6g / L in it, add 2g of urea under magnetic stirring, wait for the urea to dissolve, then add 1g of titanium oxide (P25, Degussa Company), then placed in a water bath at 80°C, stirred by magnetic force for 1 hour, took out and cooled to room temperature, filtered the suspension and washed it several times with deionized water, and then dispersed the obtained solid in 100mL of distilled water, Stir magnetically at room temperature, and irradiate with a UV lamp for 1 hour, filter, wash several times, and dry in an oven at 80°C for 12 hours. Finally, the obtained solid powder was calcined in a muffle furnace at 300° C. for 2 h to obtain the catalyst Au / P25.

[0020] The test was carried out according to the catalyst activity evaluation method described in Example 1. figure 1 Activity curves for carbon monoxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com