Patents

Literature

45results about How to "Preparation parameters are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-loaded titanium-based catalyst and preparation method thereof

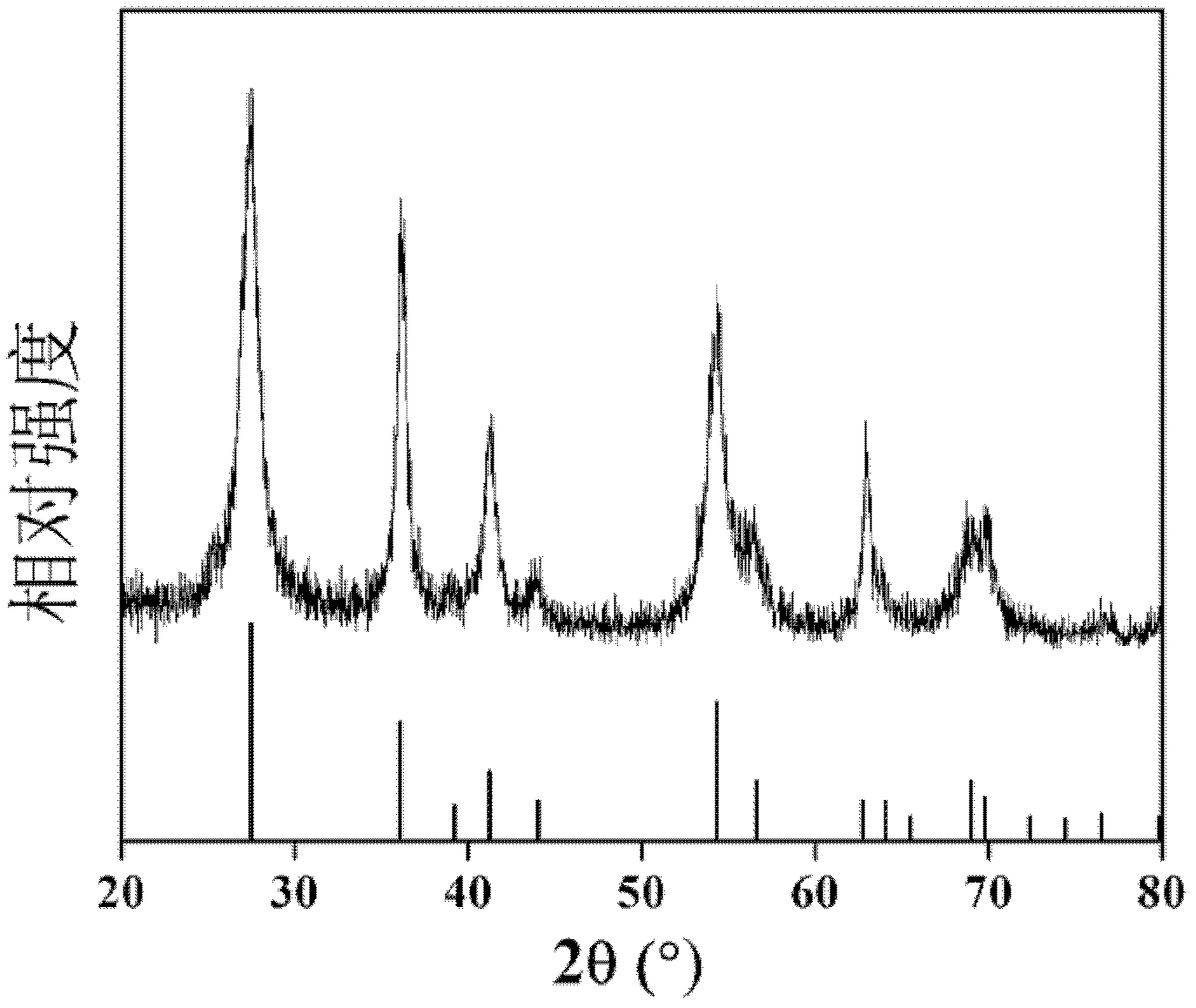

InactiveCN102489295AEvenly distributedSmall particle sizeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPlatinumRuthenium

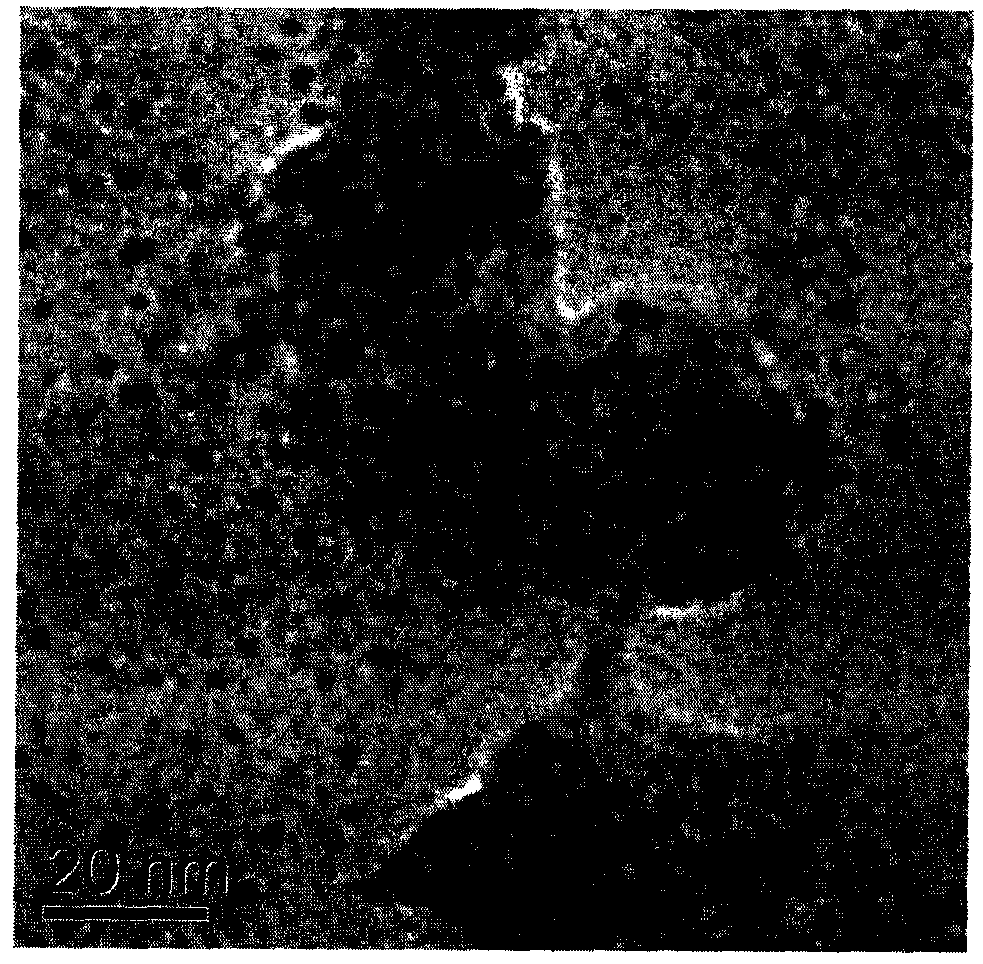

The invention discloses a metal-loaded titanium-based catalyst and a preparation method thereof. The chemical general formula of the metal-loaded titanium-based catalyst is M / TiO2, (M=Pt, Au, Ag, Cu, Pd, Ru and Rh), a titanium dioxide carrier is of rod-like morphology and is assembled by rutile-phase titanium dioxide nano-particles in the grain size of 4-8nm, a loaded metal, such as platinum, gold, silver, copper, palladium, ruthenium and rhodium, is of elemental state, and the particle size is 2-10nm. The metal-loaded catalyst can be used as an effective carbon monoxide catalytic material for being applied to control of an atmospheric environment.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

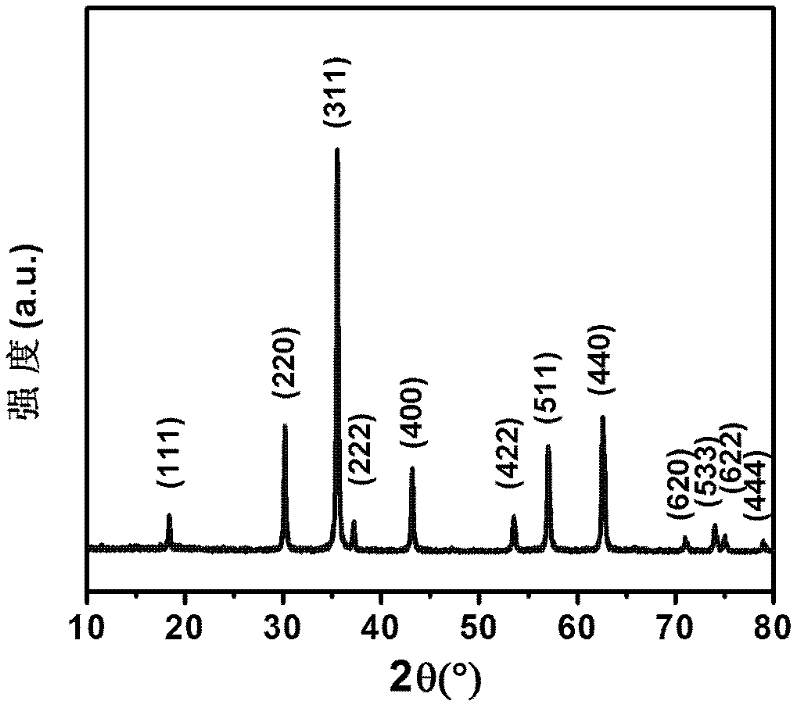

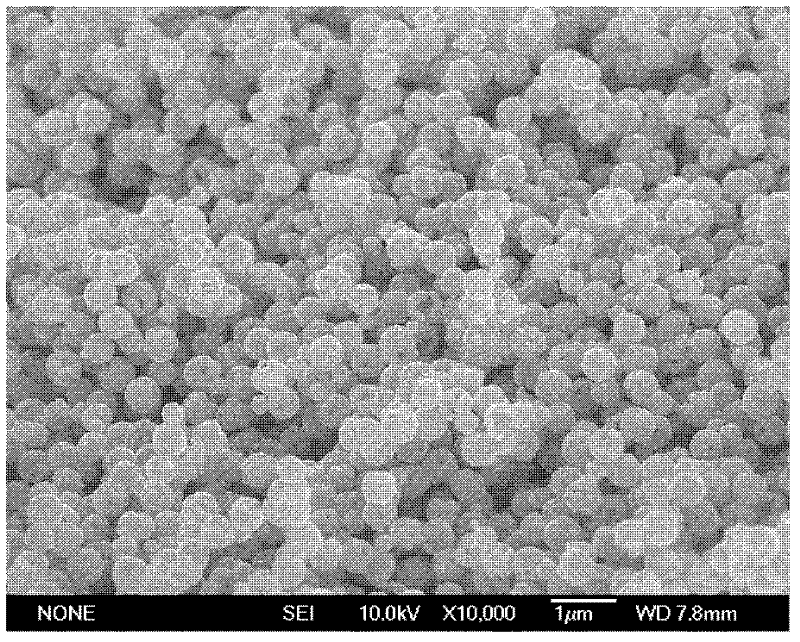

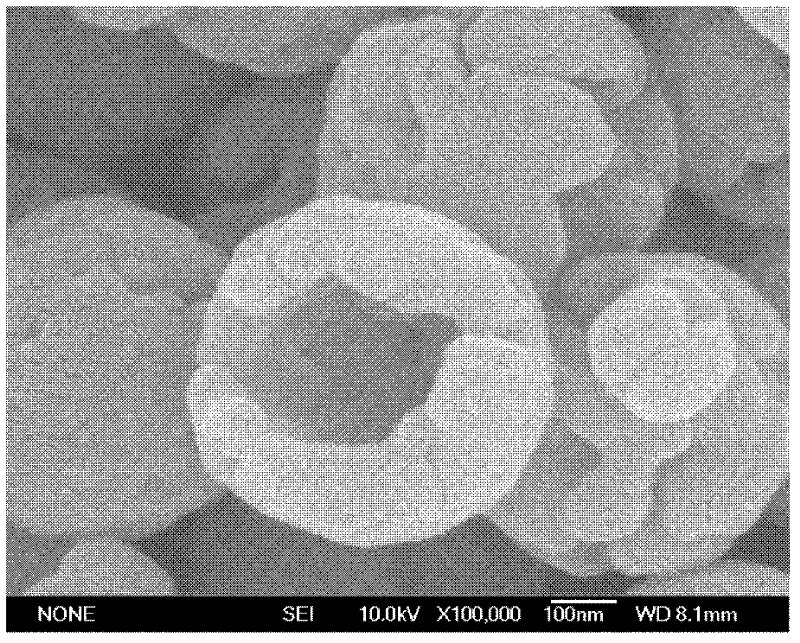

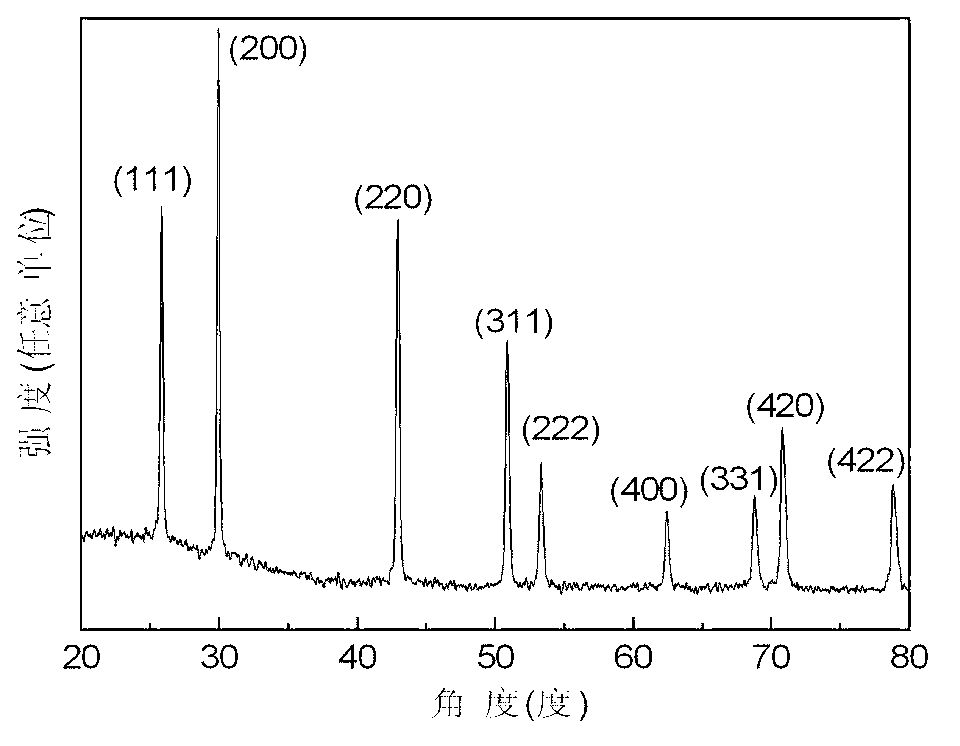

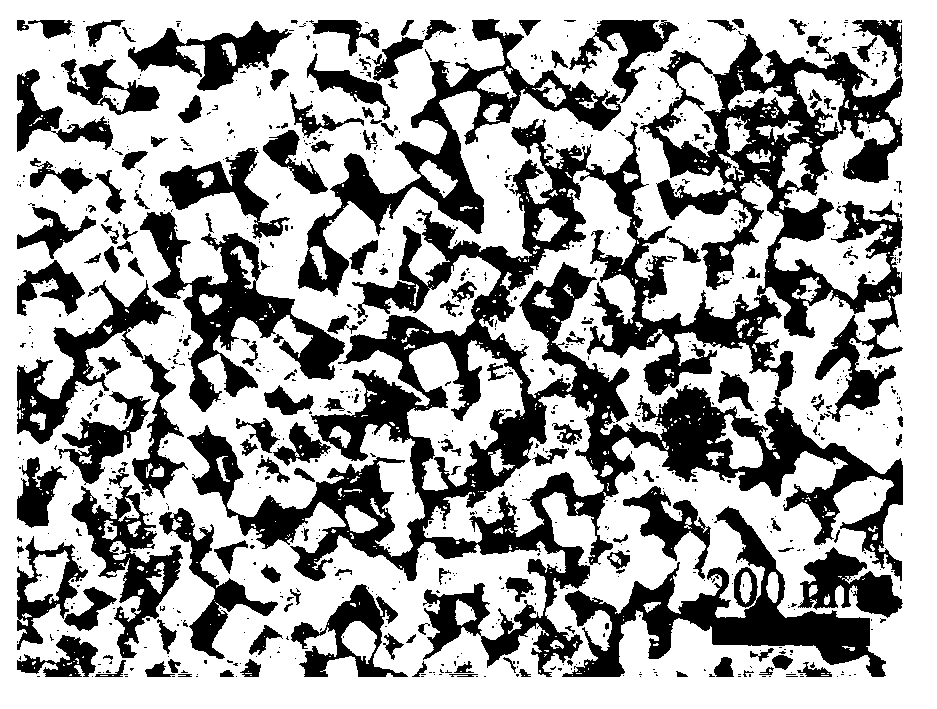

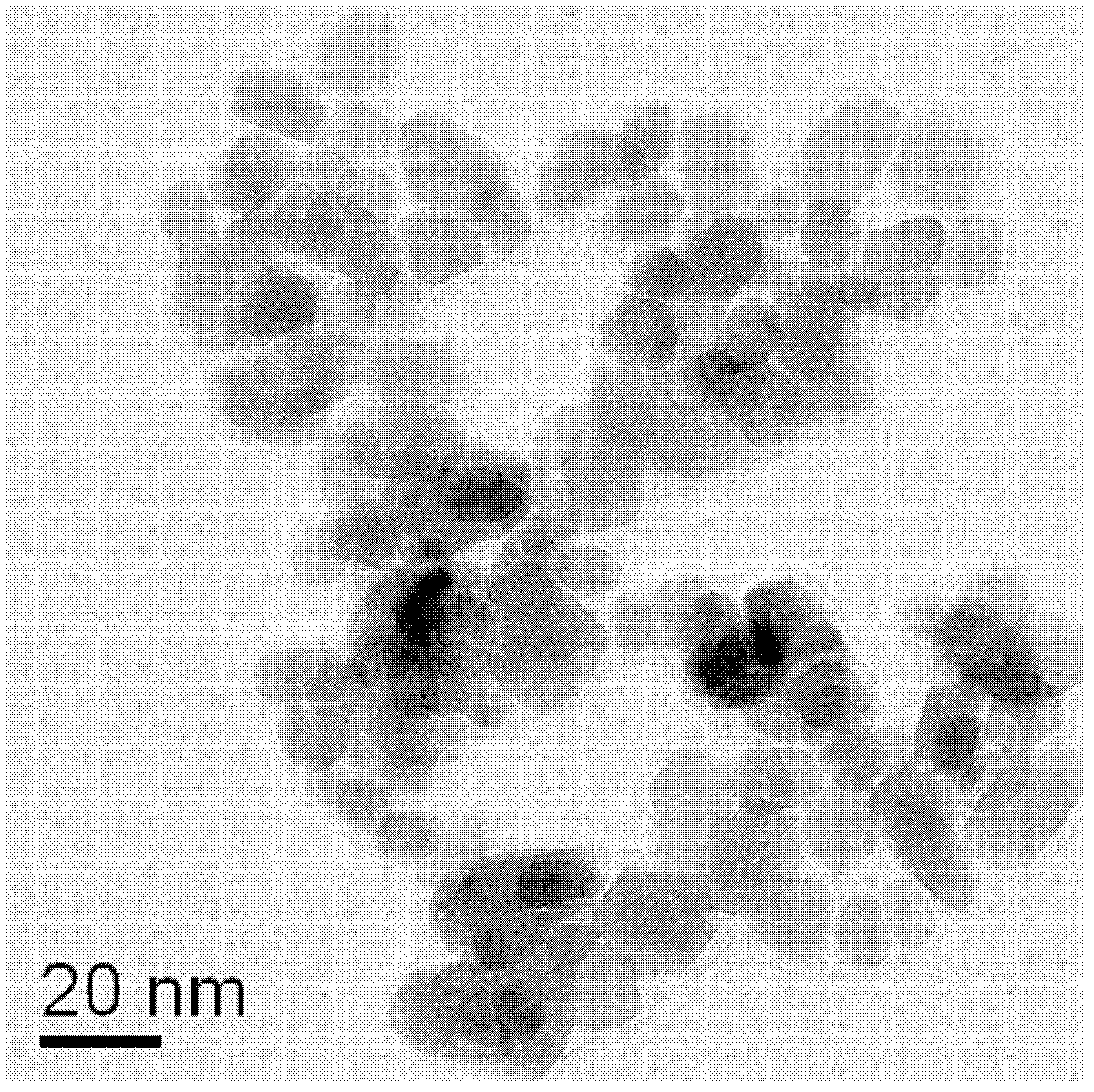

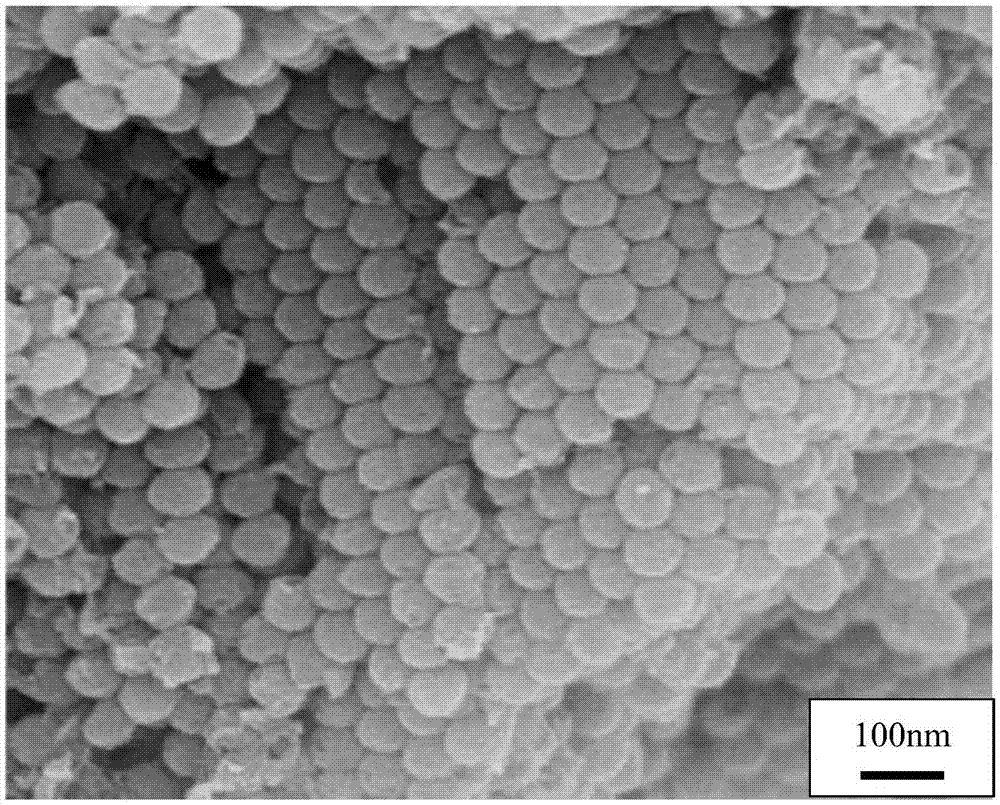

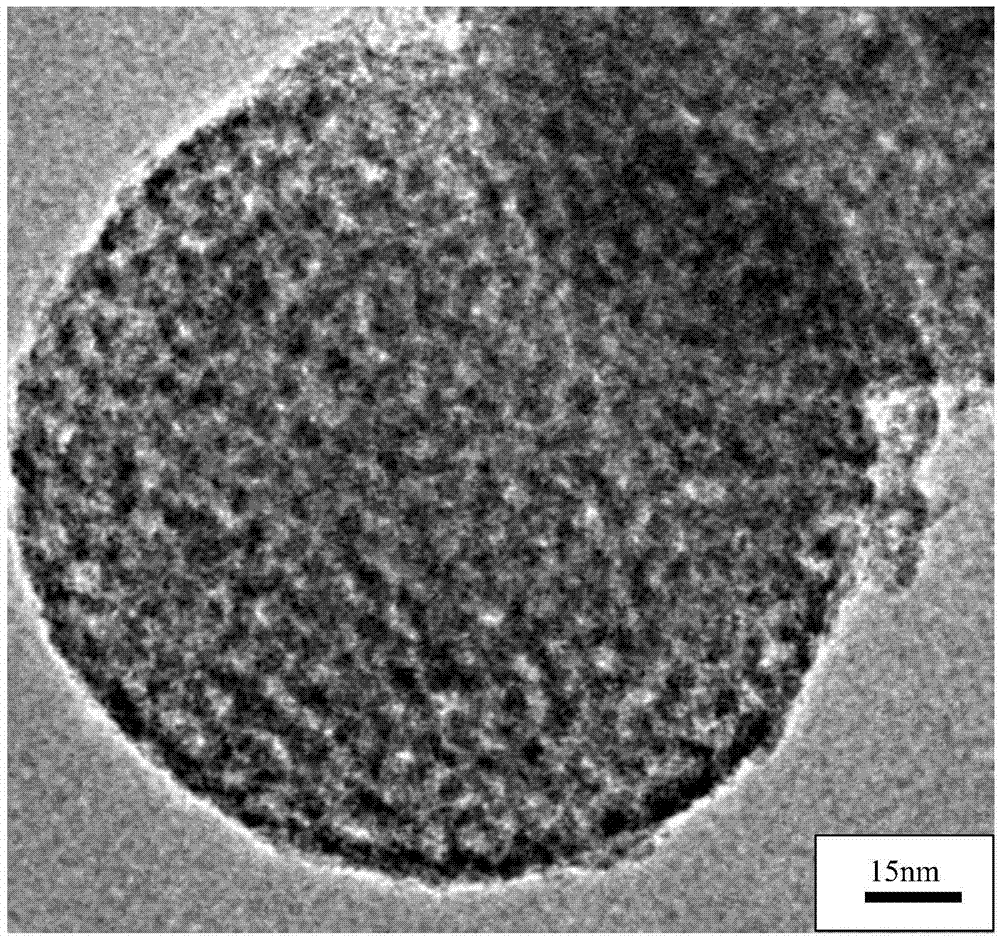

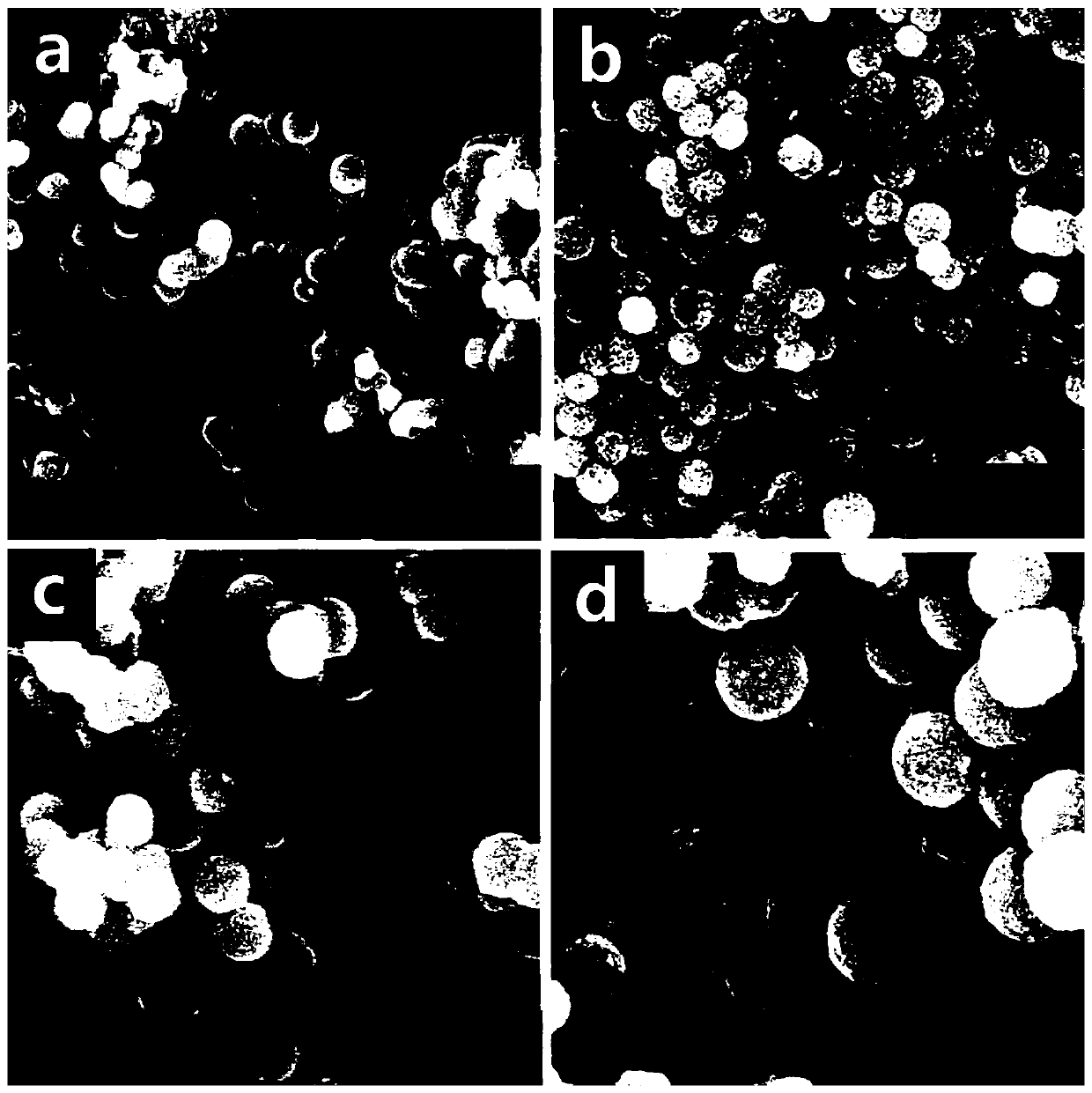

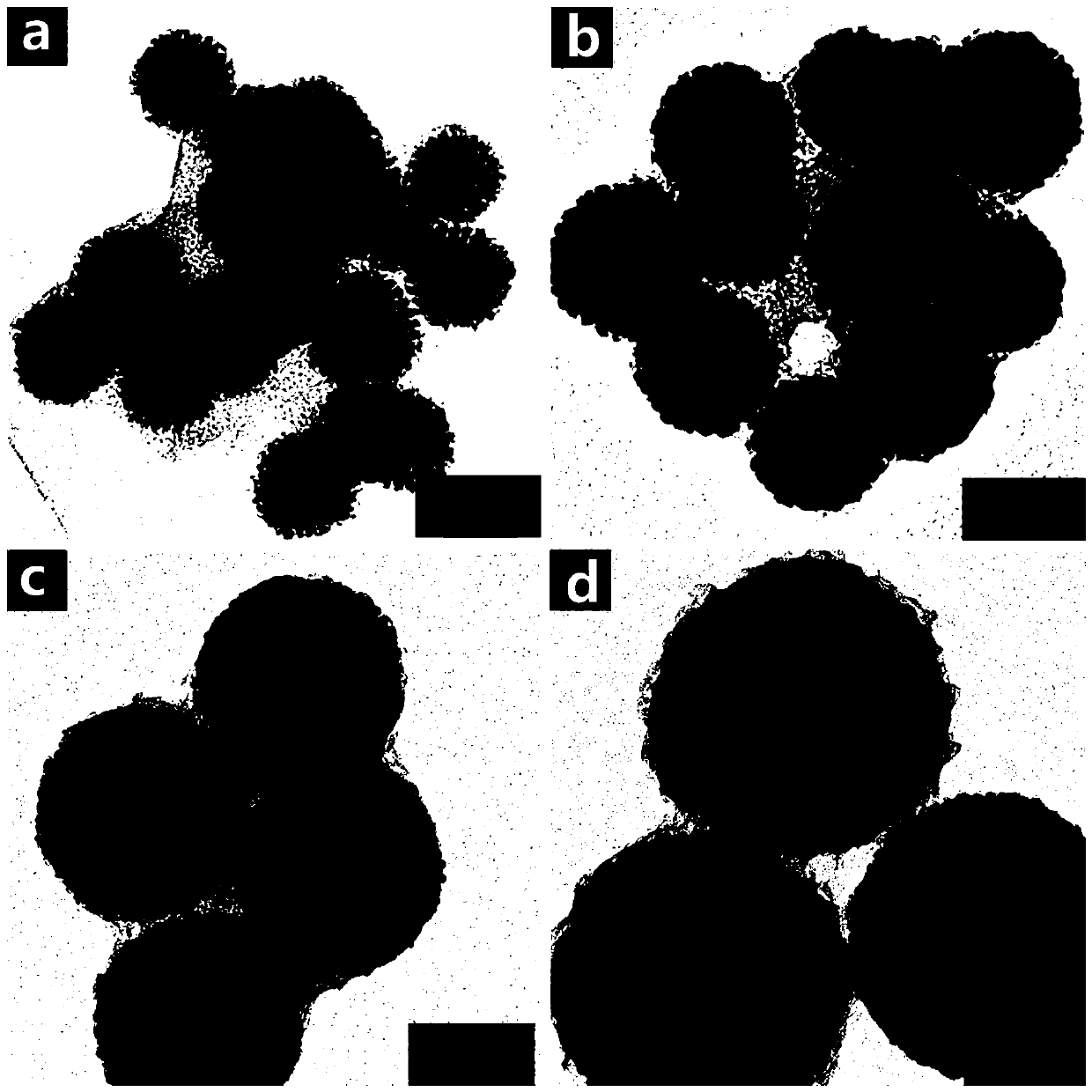

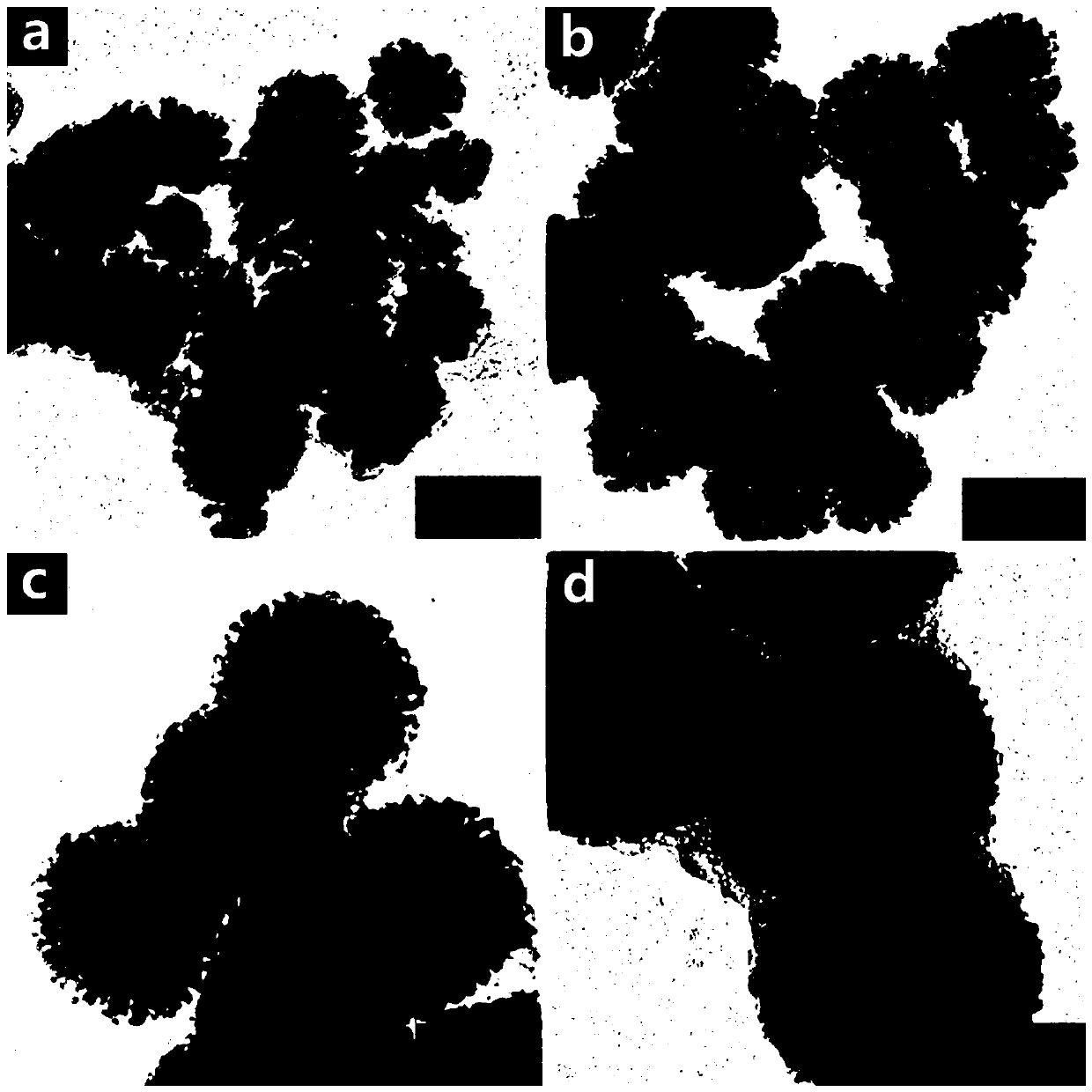

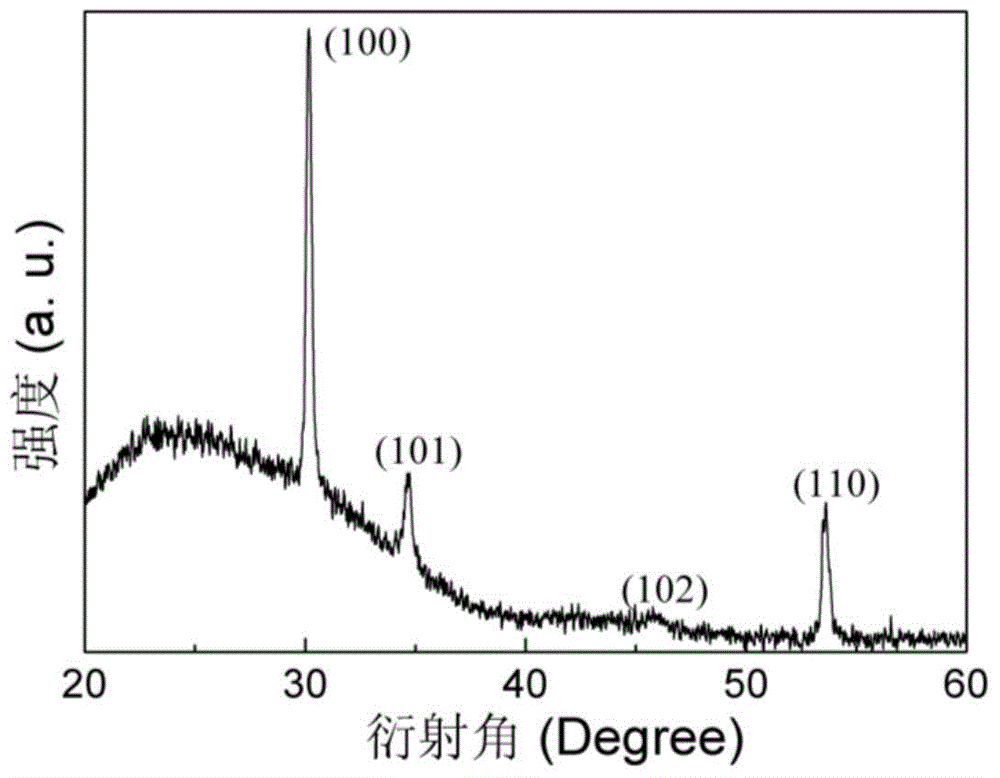

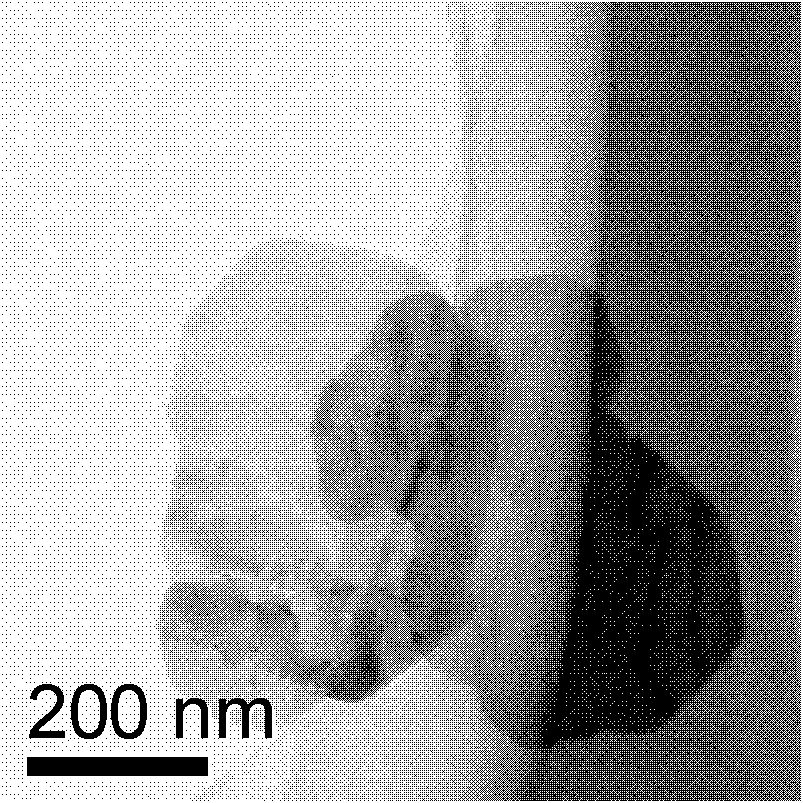

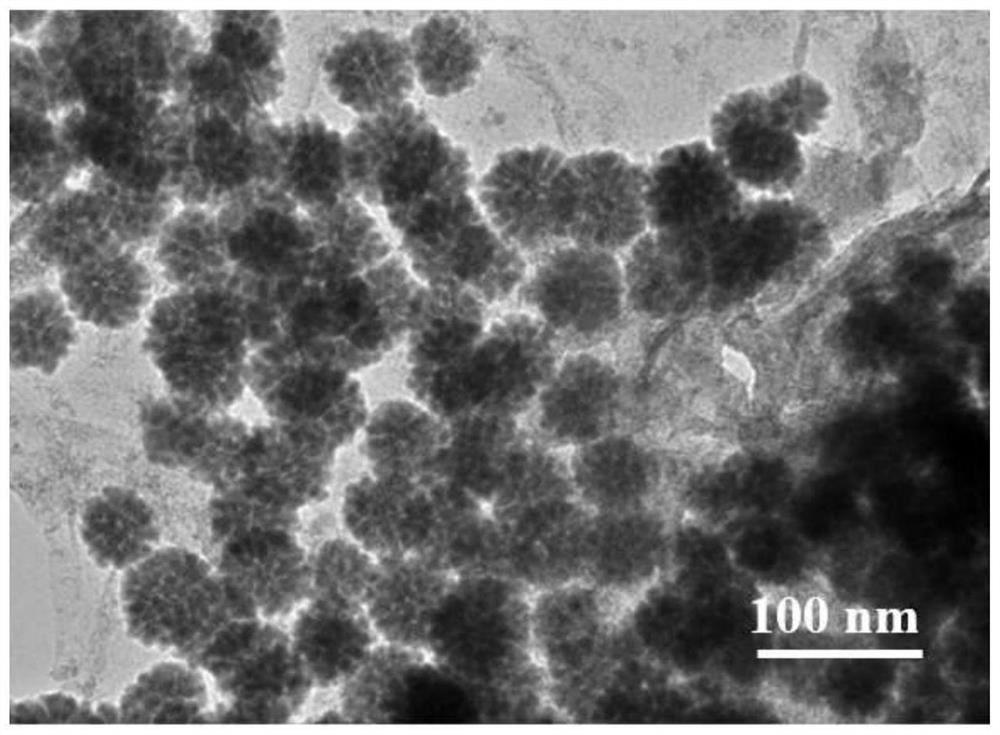

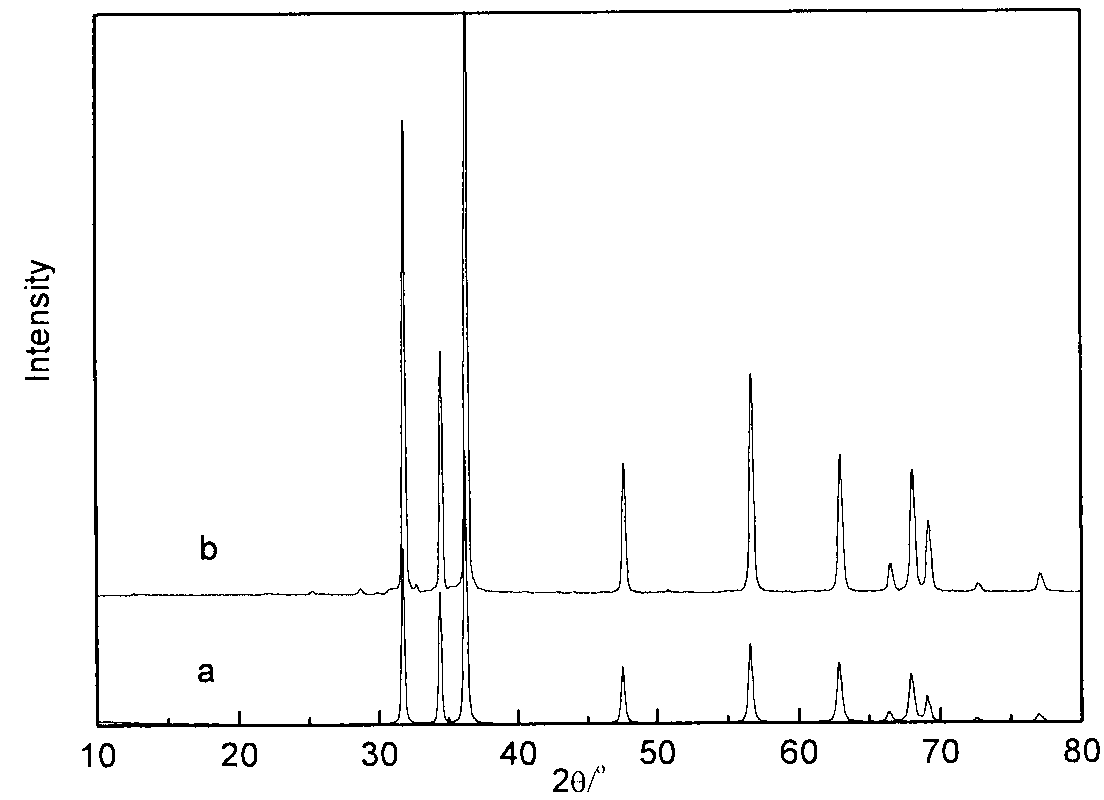

Spherical ferrate having hollow structure and preparation method thereof

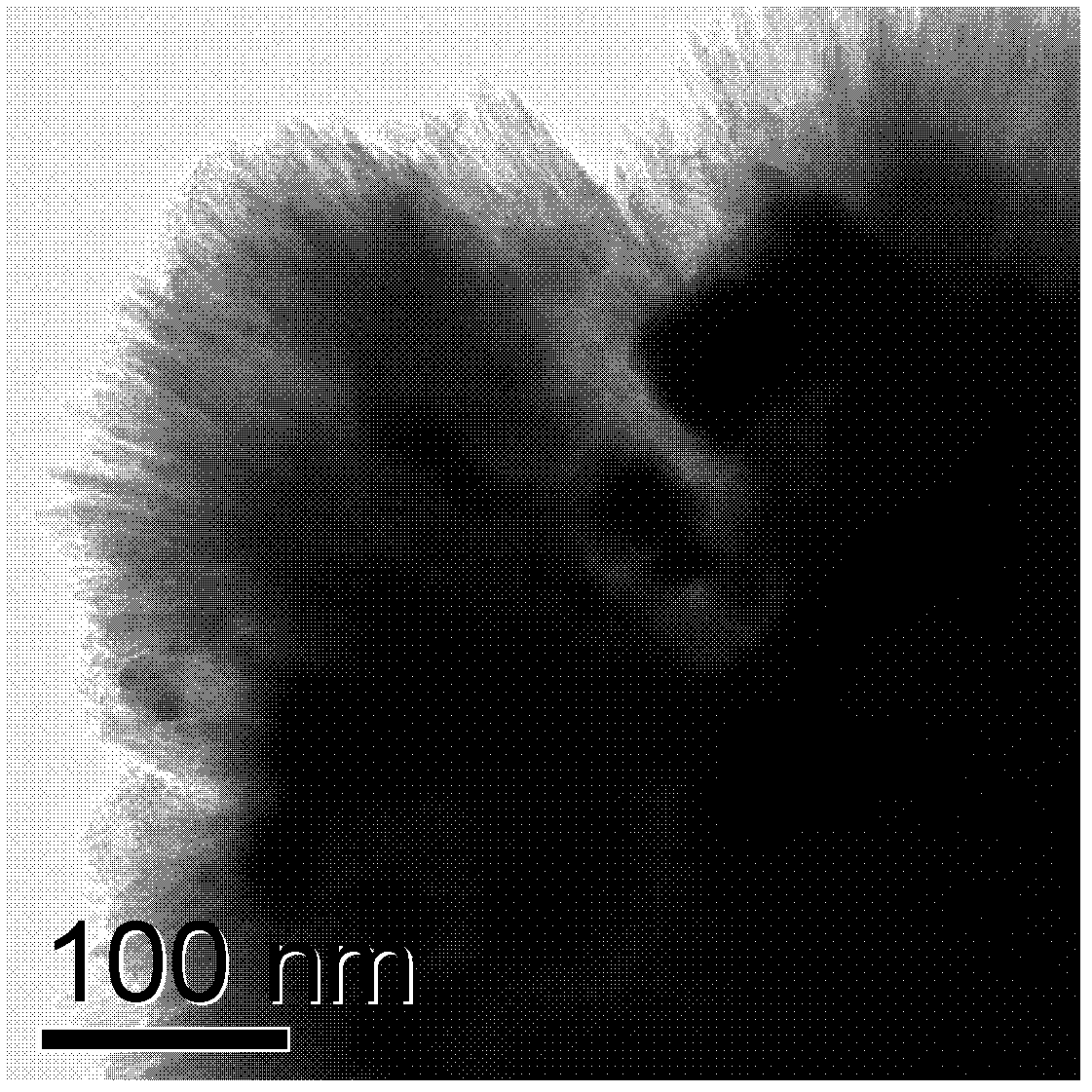

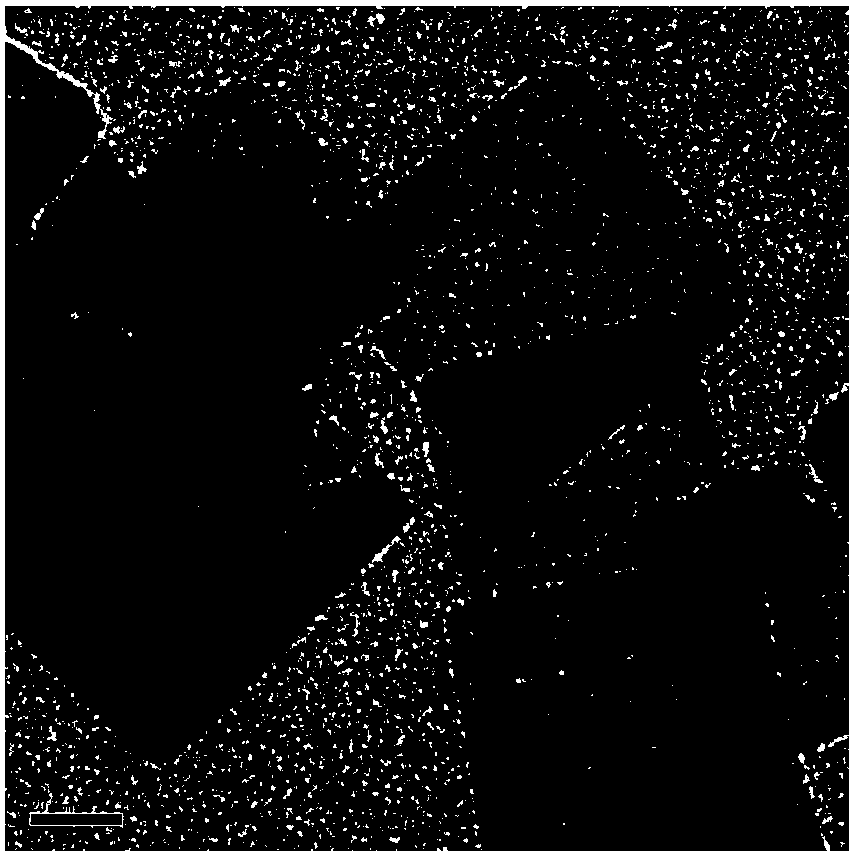

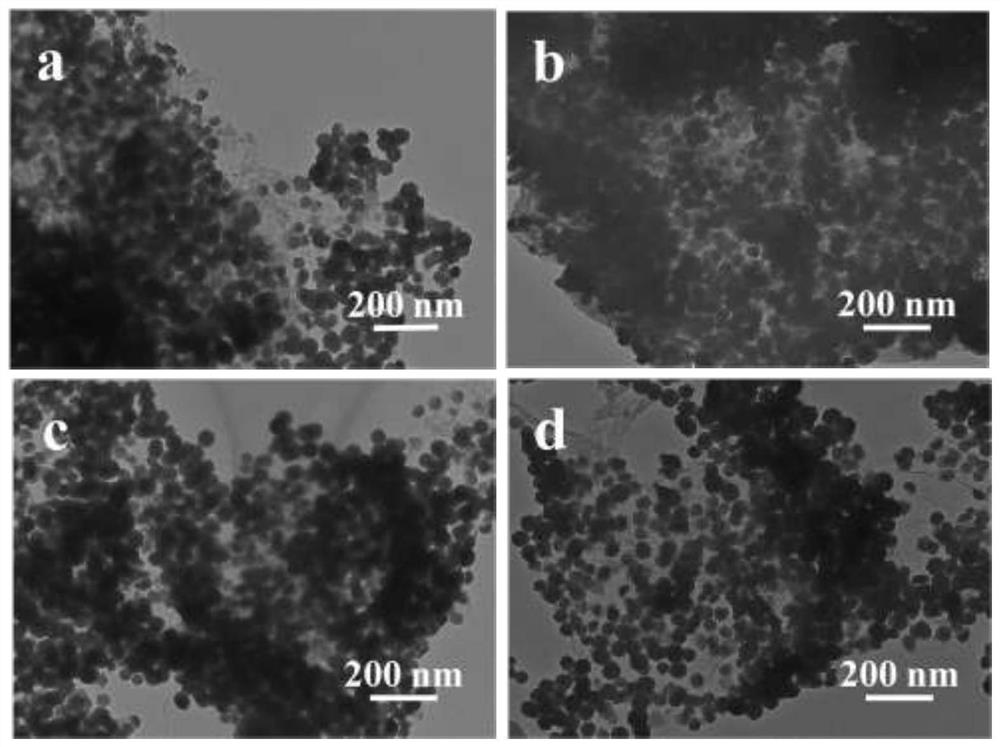

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

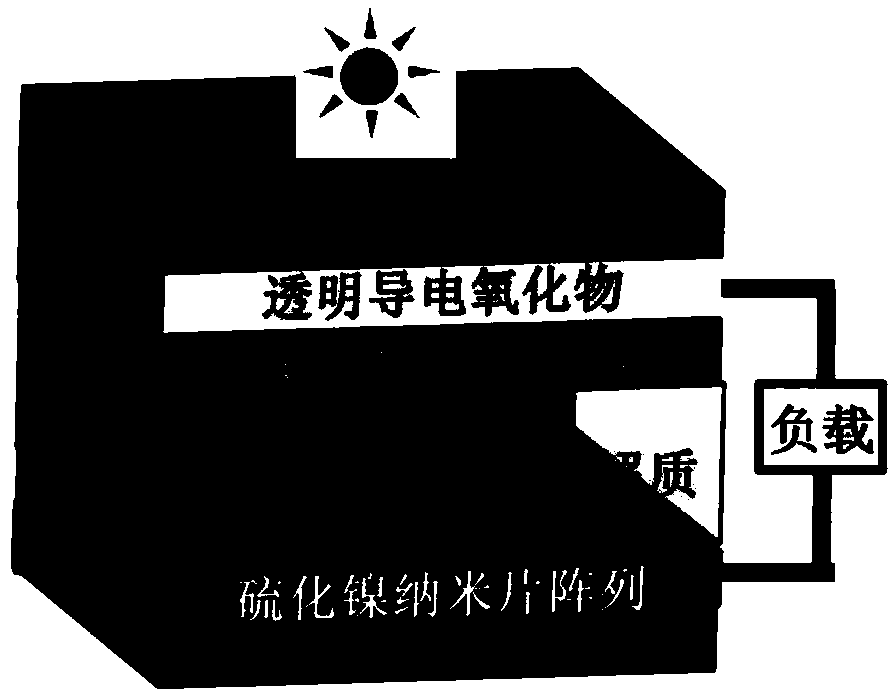

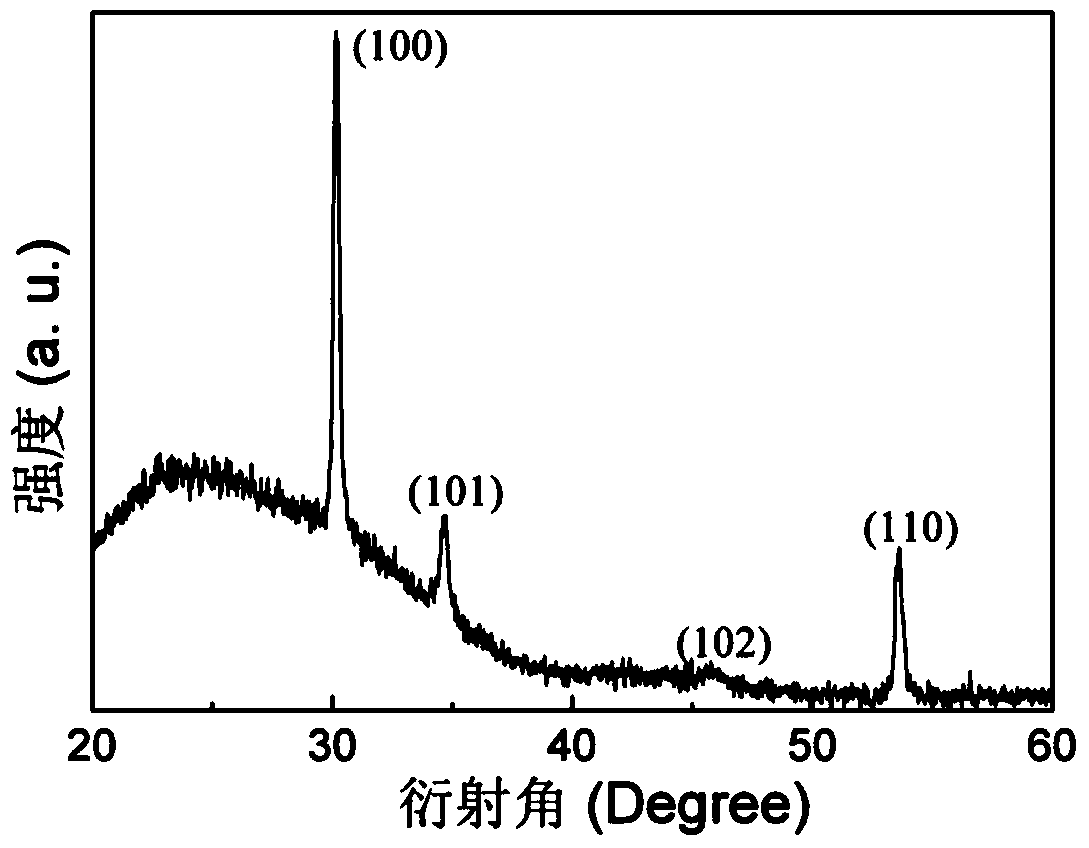

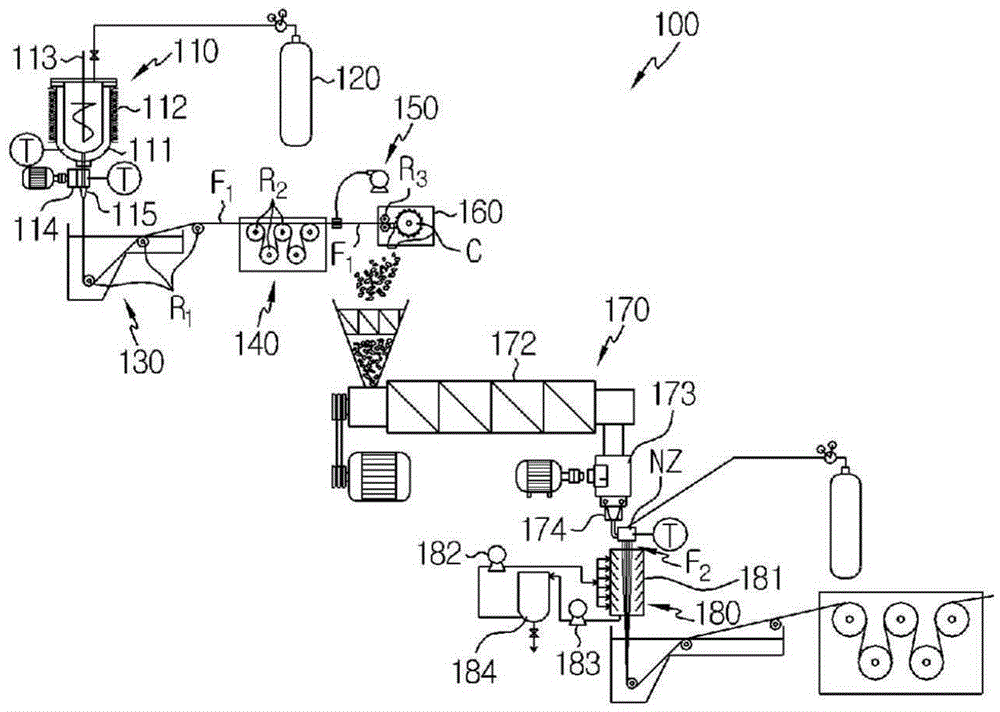

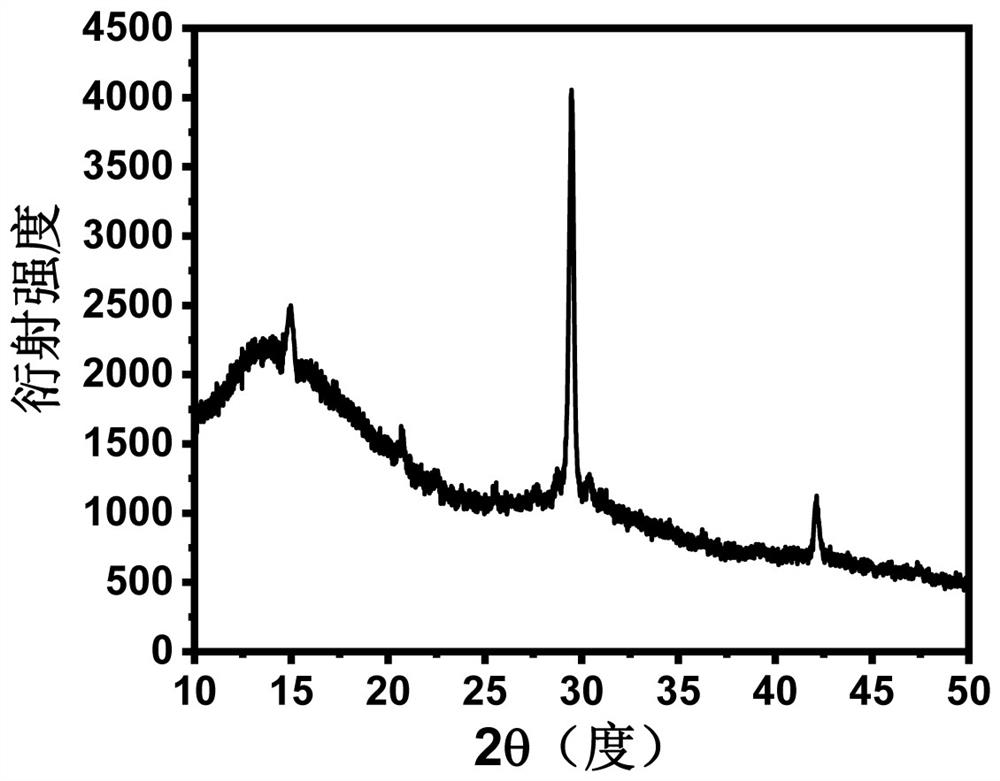

Preparation method for dye-sensitized solar cell counter electrode based on nickel sulfide nanosheets

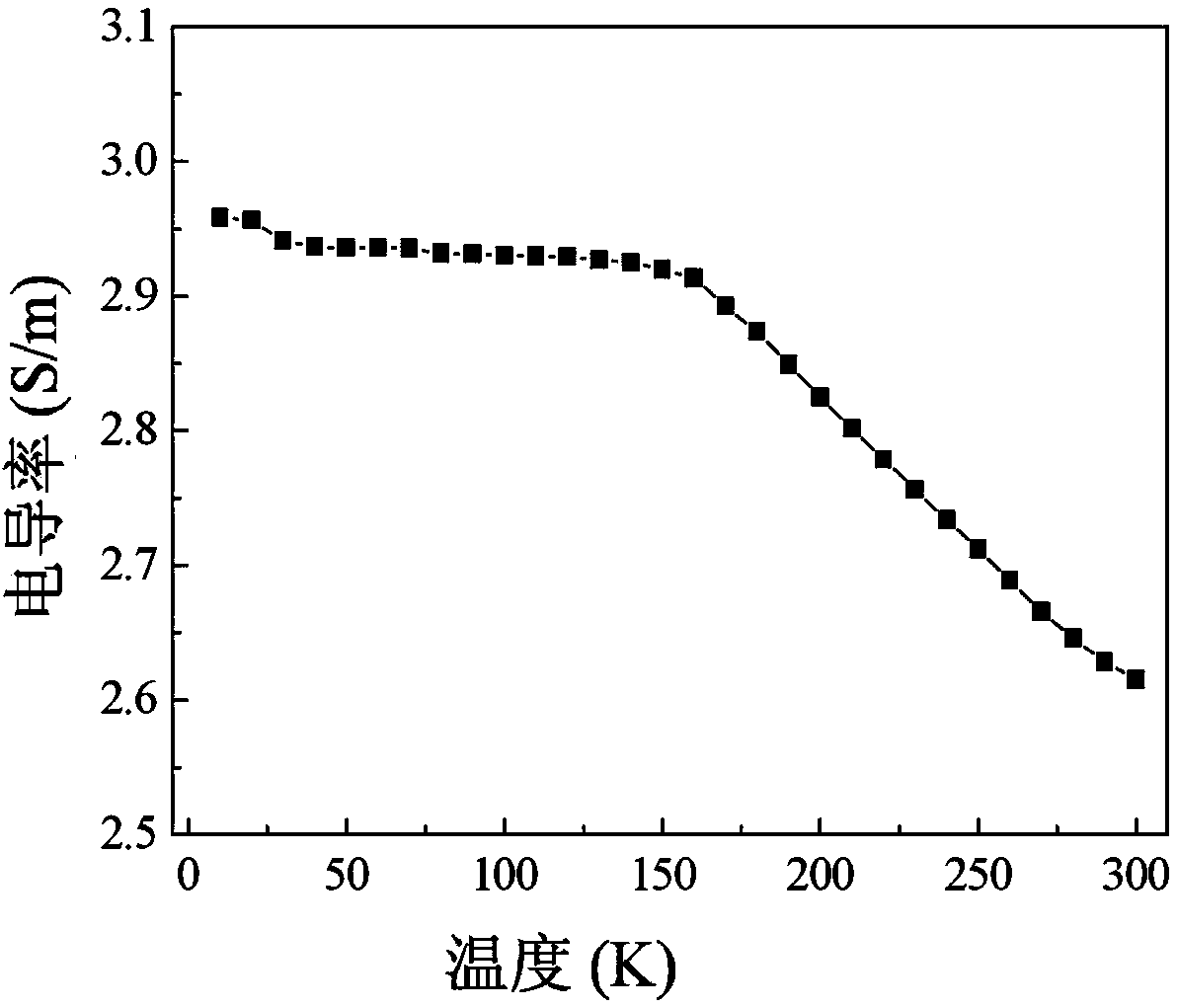

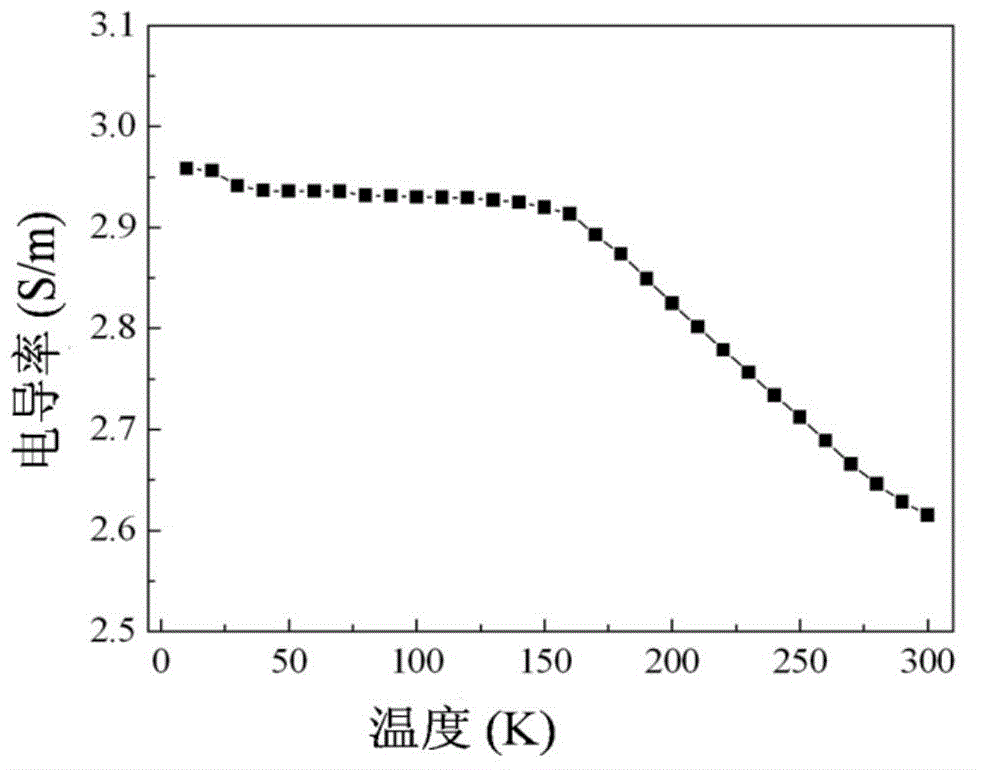

ActiveCN103474243AHigh conductivity at room temperatureEfficient collectionLight-sensitive devicesCapacitor electrodesAlcoholNickel sulfide

The invention discloses a preparation method for a dye-sensitized solar cell counter electrode based on nickel sulfide nanosheets. The method includes the steps that (1) nickel xanthate precursor is synthesized; (2) the nickel sulfide nanosheet counter electrode is prepared, firstly, a substrate is cleaned by the adoption of ethyl alcohol and acetone and dried for use, then, the substrate is placed to the position, nearby the nickel xanthate precursor, in a heating device and heated to 160-360 DEG C, the temperature is kept for 10-300mins, and the substrate is cooled to normal temperature and taken out to obtain the nickel sulfide nanosheet counter electrode; (3) a dye-sensitized titanium dioxide photo anode and the prepared counter electrode are assembled together, an electrolytic solution is injected to obtain a dye-sensitized solar cell, and the dye-sensitized solar cell counter electrode is compared with a traditional platinized conducting glass counter electrode to test photovoltaic conversion performance of the dye-sensitized solar cell counter electrode. The preparation method is simple in technical process, good in repeatability and excellent in material and device performance and can be produced on a large scale in an industrialized mode, and the preparation parameters are easy to control. Through the processes, common multi-step complex processes, long process periods and expensive high-vacuum devices can be avoided.

Owner:山东百帝气动科技股份有限公司

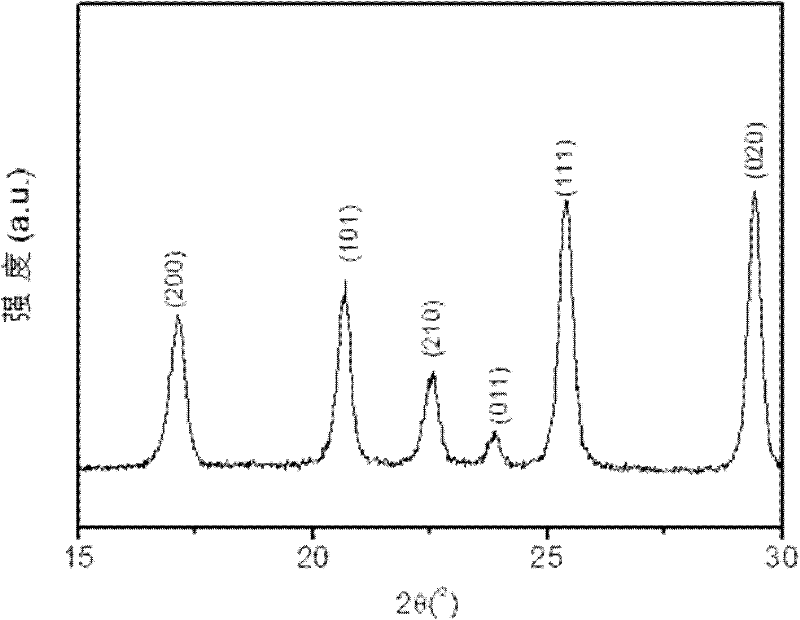

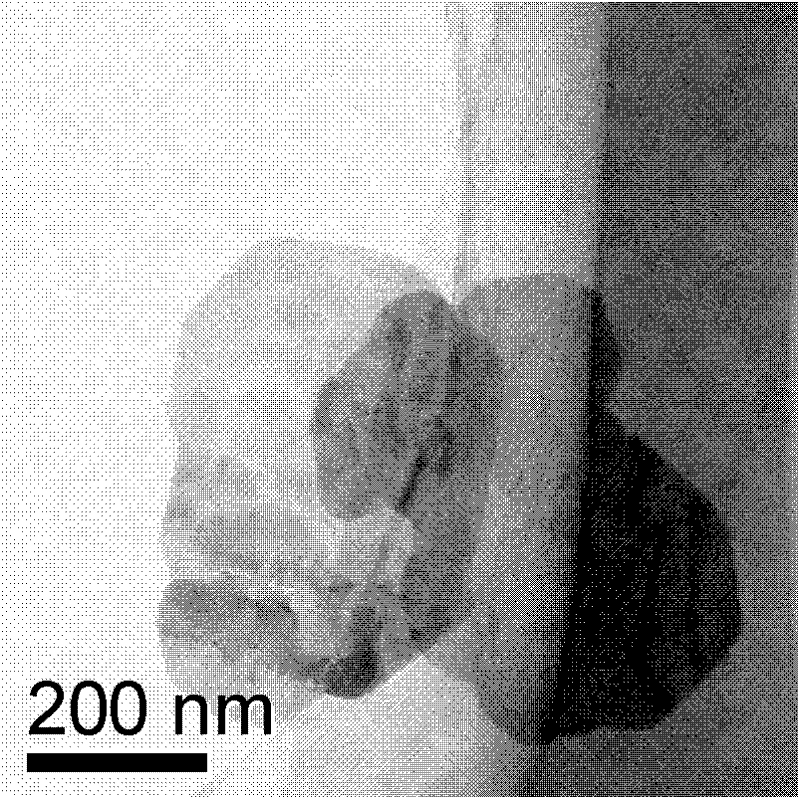

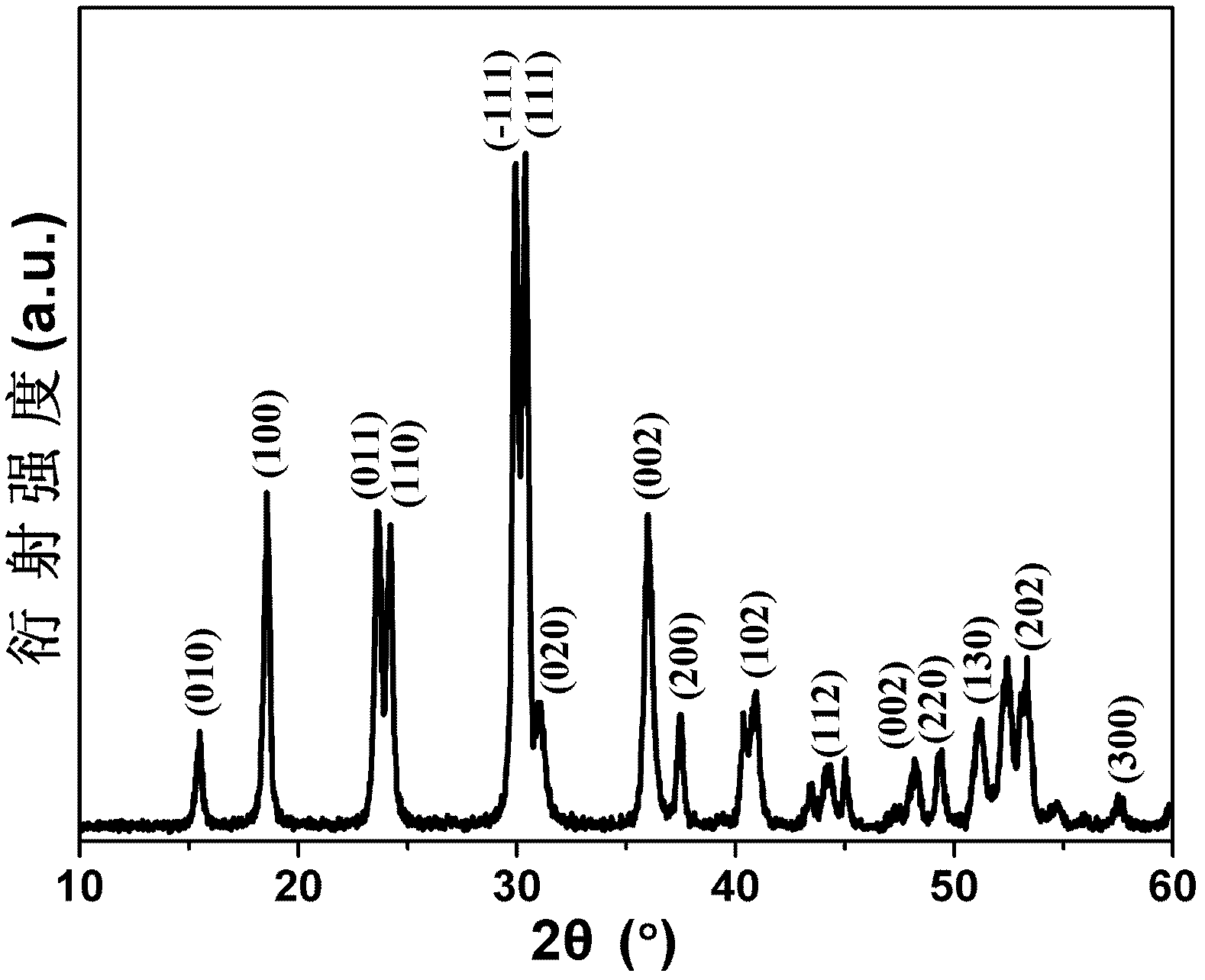

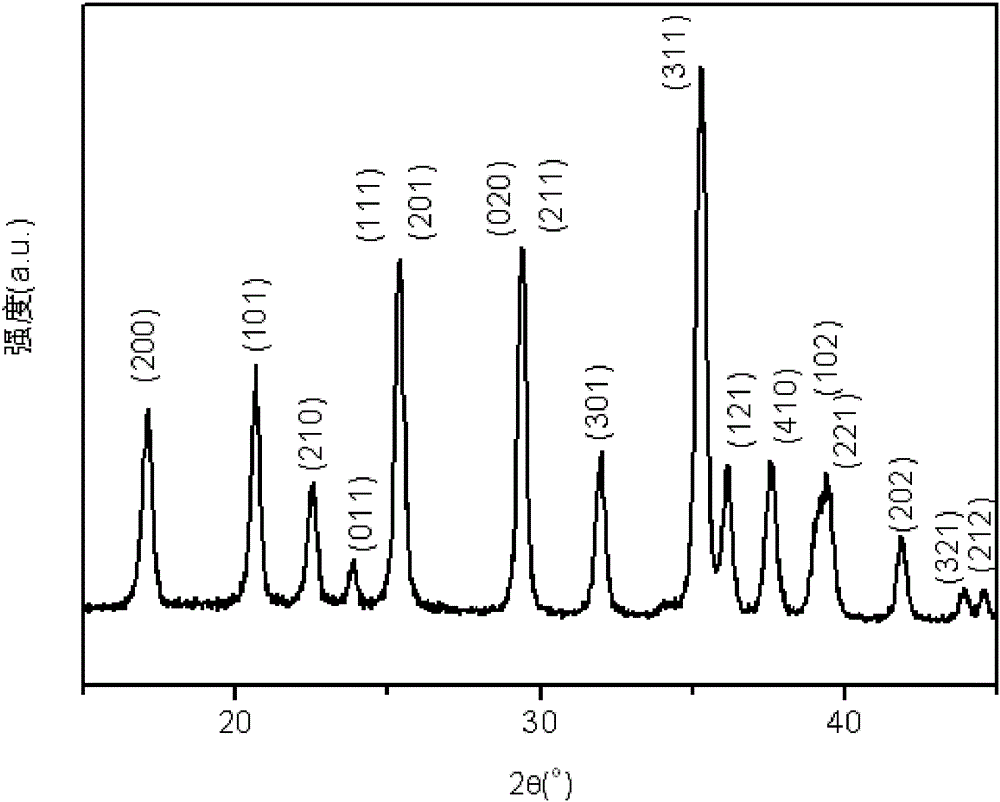

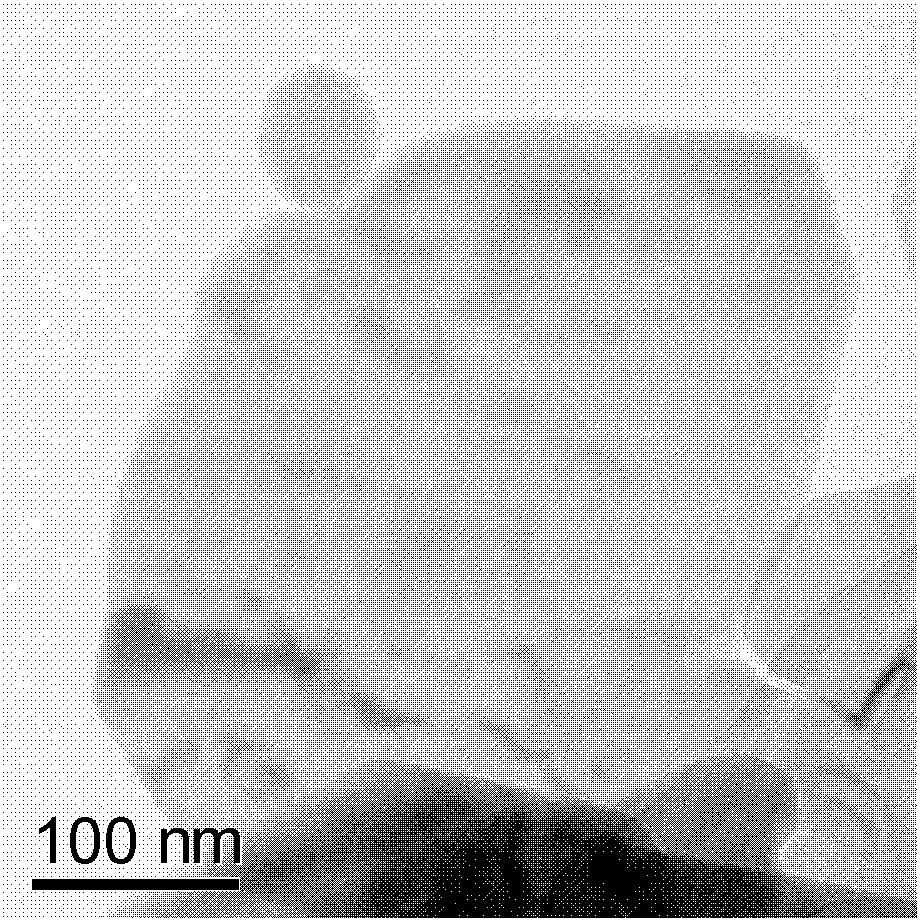

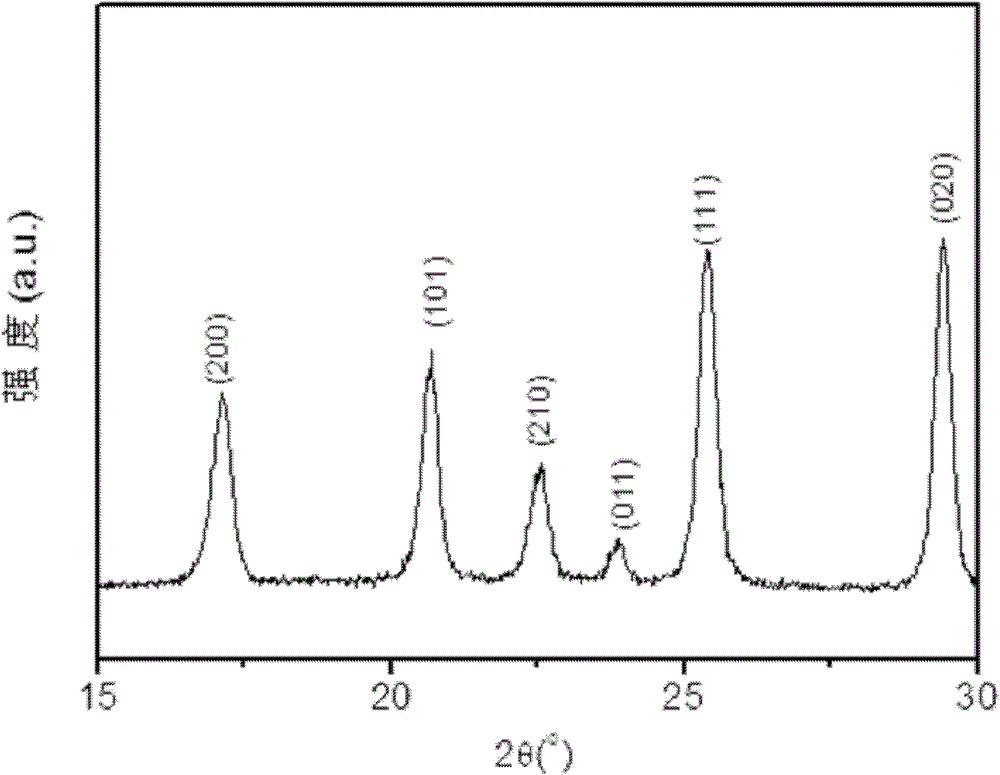

Lamellar manganese lithium phosphate (LiMnPO4) nano-crystal with high-proportion 020 crystal face and method for preparing lamellar LiMnPO4 nano-crystal

ActiveCN102544484AReduce the formation temperatureControl facet growthCell electrodesManganeseLITHIUM PHOSPHATE

The invention discloses a lamellar manganese lithium phosphate (LiMnPO4) nano-crystal with a high-proportion 020 crystal face and a method for preparing the lamellar LiMnPO4 nano-crystal. The LiMnPO4 nano-crystal has a lamellar shape, 80 to 95 percent of 020 crystal face of the LiMnPO4 nano-crystal is exposed, a lamella along the [020] direction has a thickness of 10 to 30 nm and a size of 100 to 300 nm, and the tap density of powder is 1.2 to 1.6 g / cm<3>. Lamellar LiMnPO4 nano-crystal powder can serve as a cathode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

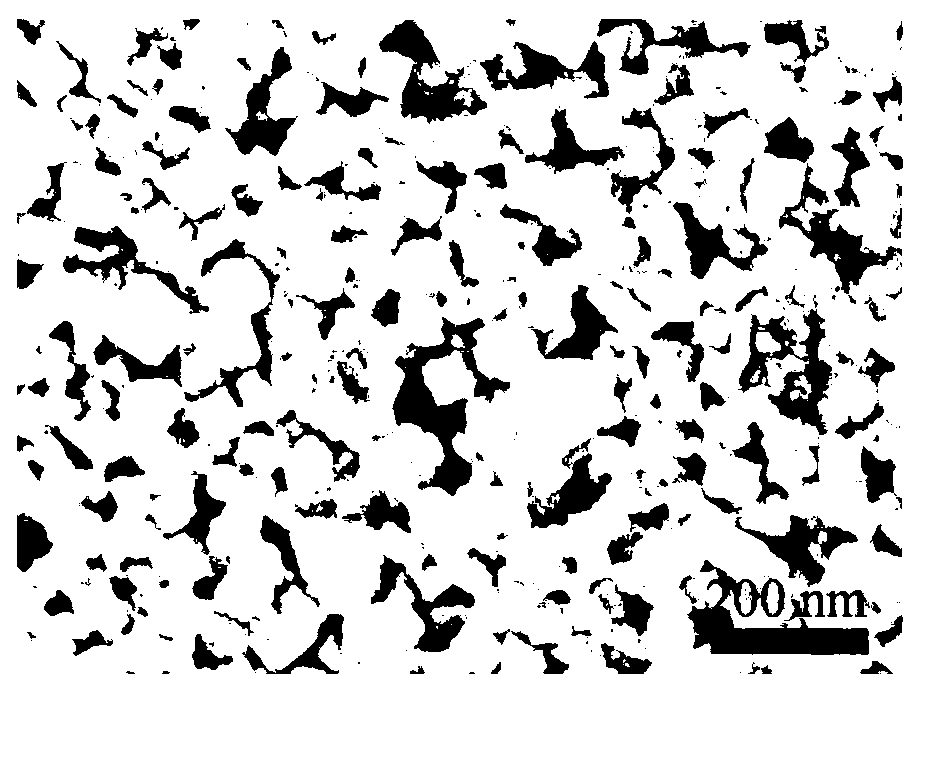

Method for directly synthesizing lead sulfide cube nano particle film

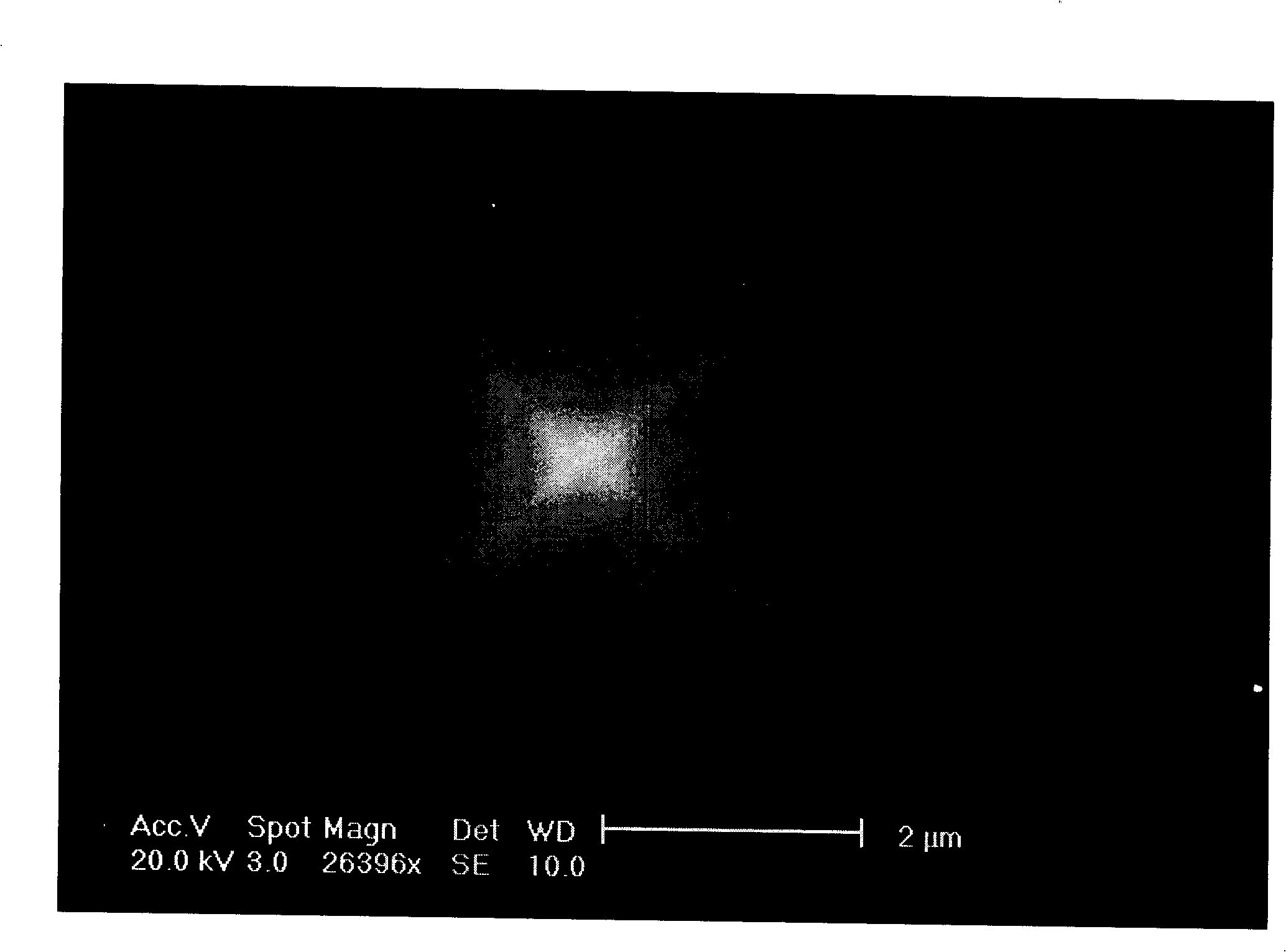

InactiveCN103073053AAvoid high temperature pyrolysisSimple processMaterial nanotechnologyLead sulfidesLead nitratePotassium

The invention discloses a method for directly synthesizing a lead sulfide cube nano particle film. The method comprises the following specific steps of: 1, mixing deionized water transparent solution of sodium or potassium ethylxanthate with deionized water solution of lead nitrate or lead acetate, wherein the mol ratio of the sodium or potassium ethylxanthate to lead is 0.5-2, fully stirring uniformly to form a sediment, filtering, washing and drying to obtain lead ethylxanthate powder; 2, dissolving and dispersing the lead ethylxanthate powder in pyridine to form a uniform solution with a concentration of 10-500mg / ml; and 3, coating a lead ethylxanthate precursor solution on a substrate by adopting a rotary coating, drop-coating or dip-coating process, and annealing at a temperature of 120-300 DEG C for 10-100min. The method is simple in process, the preparation parameter is easily controlled, the repeatability is good, and the large-scale synthesis can be carried out, a large-area uniform lead sulfide cube nano particle film can be directly assembled on the substrate, and thus a multi-step complex process in a conventional synthesizing and assembling process is avoided.

Owner:SHANDONG UNIV

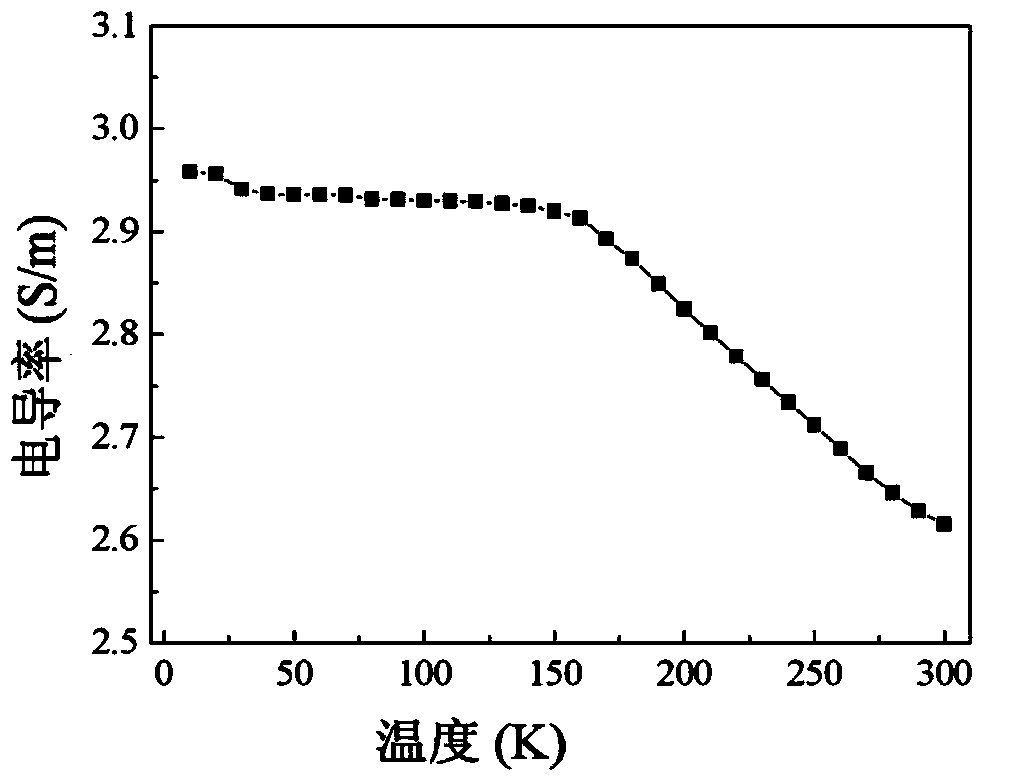

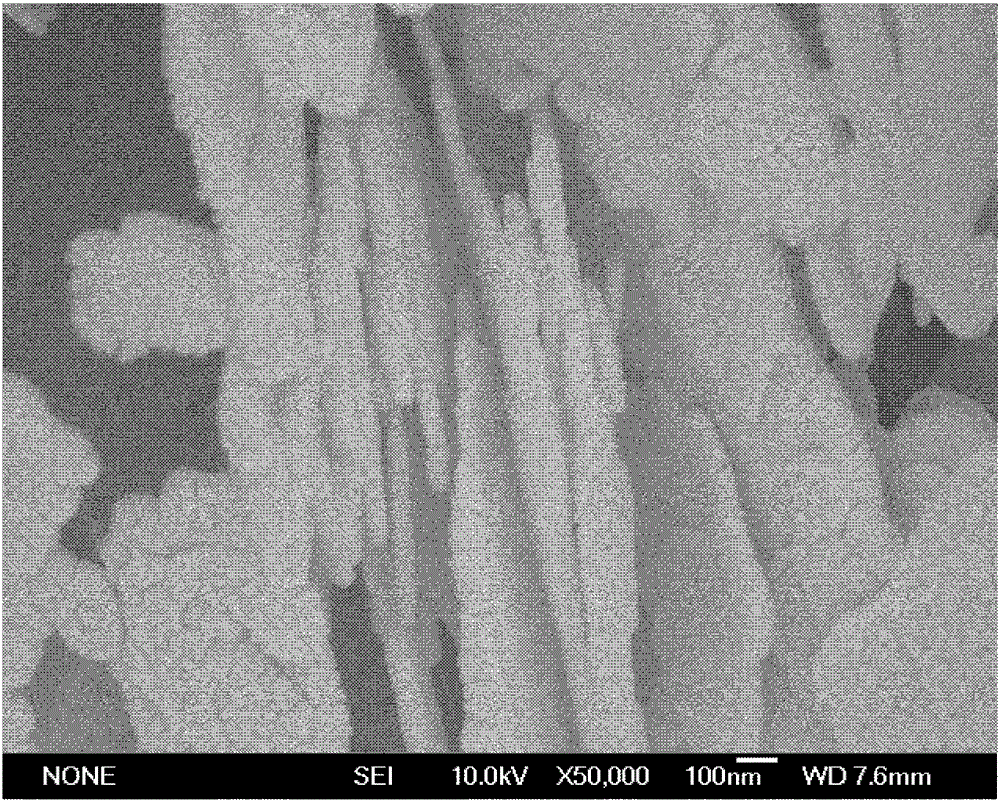

Method for directly synthesizing high conductivity nickel sulfide two-dimension nanosheet array in large scale

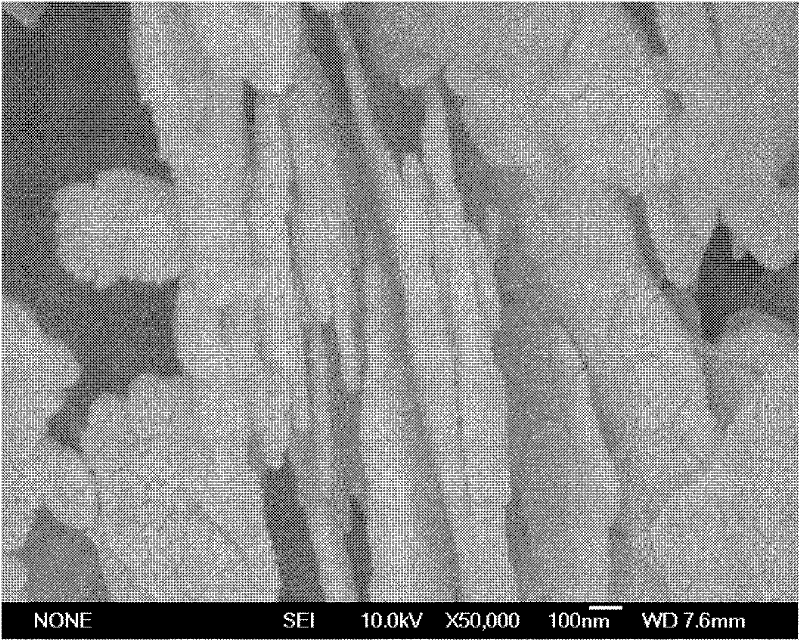

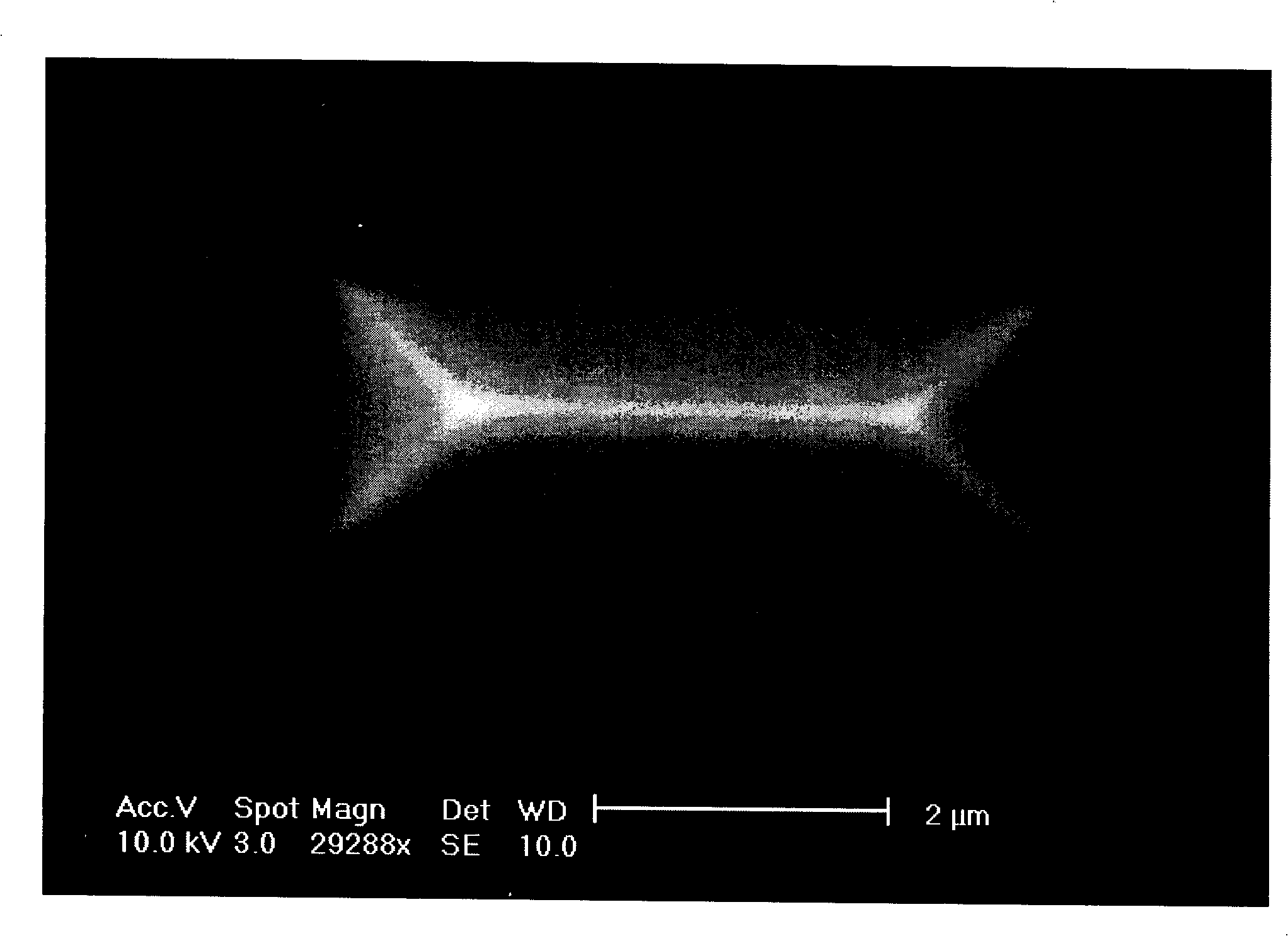

ActiveCN103466726AHomogeneous nanostructureHigh conductivity at room temperatureMaterial nanotechnologyNickel sulfidesNickel sulfideRepeatability

The invention discloses a method for directly synthesizing a high conductivity nickel sulfide two-dimension nanosheet array in large scale. The method comprises the first step of synthesizing a xanthogenic acid nickel precursor, and the second step of preparing the nickel sulfide two-dimension nanosheet array, wherein the xanthogenic acid nickel precursor powder is placed into a heating device to be heated to reach the temperature ranging from 160 DEG C to 360 DEG C, the heat preservation is carried out on the xanthogenic acid nickel precursor powder for 10-300 mintues, and then the nickel sulfide two-dimension nanosheet array can be generated on a substrate near the xanthogenic acid nickel precursor. The technological process is simple, parameters are obtained easily and controllably, the repeatability is good, and large-scale industrial production can be achieved. The data result is detailed and accurate, so that the feasibility of the method is fully proven. By means of the technology, the problem that the multi-step processing procedures are commonly complex or the technology period is long or high vacuum equipment is high in cost can be avoided, and an extremely potential candidate scheme is provided for the low-cost and large-scale application of the high conductivity nickel sulfide two-dimension nanosheet array.

Owner:山东百帝气动科技股份有限公司

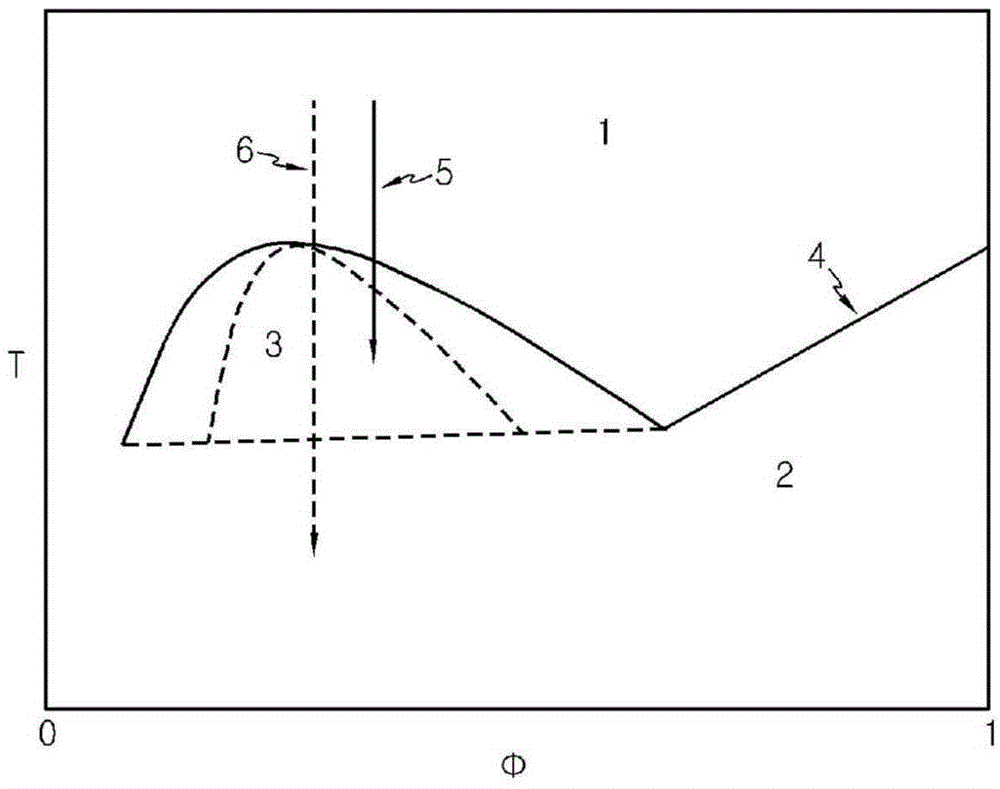

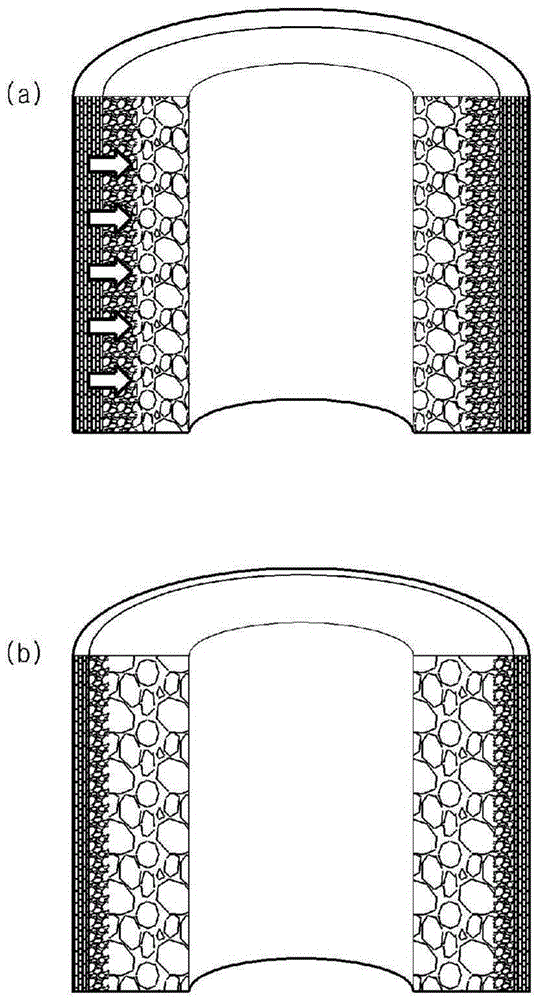

Method for manufacturing asymmetric polyvinlylidenefluoride hollow fiber membrane and hollow fiber membrane manufactured therefrom

ActiveCN105555393AHigh porosityGood water permeabilityMembranesSemi-permeable membranesHollow fibrePolymer science

The present invention relates to a method for manufacturing an asymmetric polyvinlylidenefluoride (PVDF) hollow fiber membrane, which enables effective mixing of PVDF and a diluent without using separate inorganic fine powder, such as silica; in which a PVDF hollow fiber membrane is manufactured using a thermally induced phase separation method having an advantage of allowing easy obtaining of a separation membrane of consistent quality due to a key factor in controlling the phase separation in the two-substance mixture system of the polymer and the diluent being temperature, which is a manufacturing variable that is relatively simple and easy to control; in which a technique is applied for producing a temperature difference between the outer and the inner surfaces of a PVDF hollow fiber, and therefore, finally an asymmetric structure is expressed in which the inner surface side and the outer surface side of the PVDF hollow fiber have mutually different pore sizes and distributions; and which, even when an extraction process and a drawing process are applied, achieves a higher tensile strength and a larger average pore size, and thus higher porosity and water permeability than conventional hollow fiber membranes, since inorganic fine powder is not included. The asymmetric PVDF hollow fiber membrane has a pore symmetry index, defined as the ratio between the pore area on the outer surface and the pore area on the inner surface, of 0.1-0.8 and has superior water permeability and tensile strength unlike a PVDF separation membrane manufactured by the existing method.

Owner:爱科利态株式会社

Manganese tungstate electrode material and preparation method thereof

InactiveCN102664105AParticle size controllableUniform particle distributionElectrolytic capacitorsCapacitanceNanoparticle

The invention relates to a manganese tungstate electrode material and a preparation method thereof. A primary particle of the electrode material has a nanometer particle structure and a controllable particle size of 5 to 500 nm. A manganese tungstate super-capacitor electrode material which is prepared by the method has specific capacitance of more than 153 F.g<-1>. Compared with the conventional preparation method, the preparation method has the advantages of operability, practical process, high reproducibility, low cost, high material purity, high electrochemical performance and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

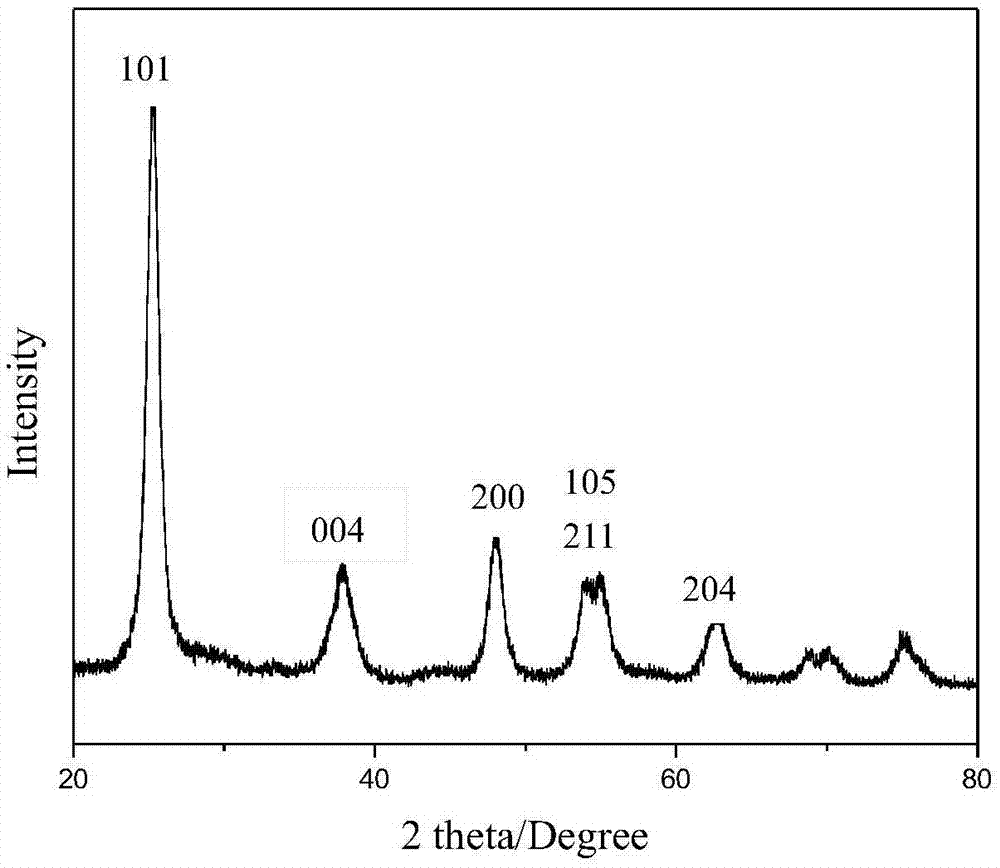

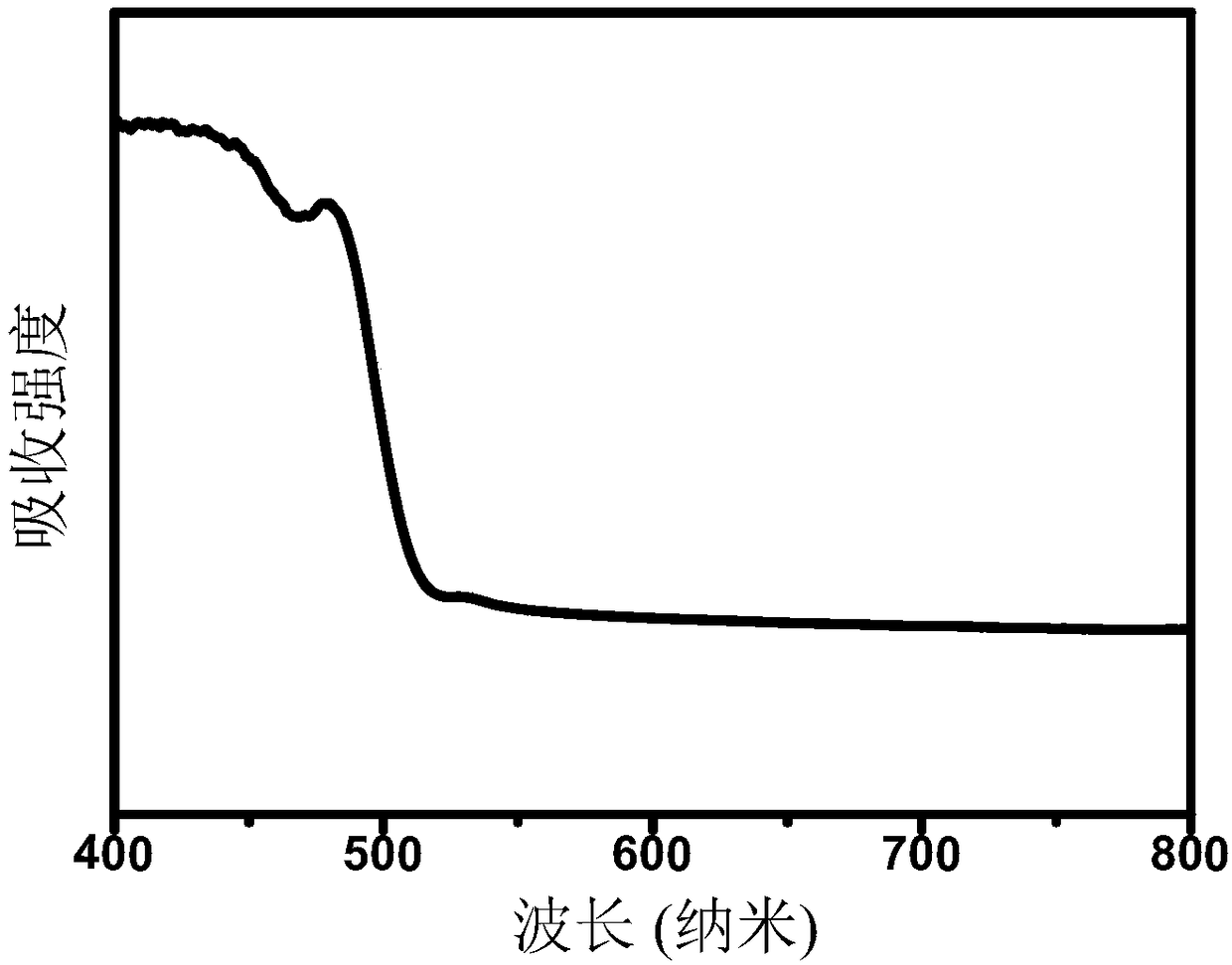

Fe and N co-doped mesoporous TiO2 microsphere array visible light photocatalyst and preparation method

InactiveCN105435828AReduced band gapReduce recombination ratePhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereMesoporous material

The invention discloses a Fe and N co-doped mesoporous TiO2 microsphere array visible light photocatalyst and a preparation method and belongs to the technical field of TiO2 photocatalysis. The photocatalyst is a three-dimensional ordered Fe and N co-doped mesoporous TiO2 microsphere array prepared with a two-step template method, and microspheres are arranged orderly in a three-dimensional manner, have uniform size and obvious mespores and are all anatase. TiO2 is modified through Fe and N co-doping, and the Fe and N co-doped TiO2 microsphere array is obtained; due to a slow photon effect and a multiple scattering effect of the microsphere array and the excellent mass transfer performance and high specific surface area of a hierarchical porous (macroporous or mesoporous) material, light absorption of TiO2 can be improved. The smallest band gap of Fe and N co-doped TiO2 is realized at the optimal doping content, and absorbed light is extended to visible light. The solar energy utilization rate can be increased by the aid of Fe and N co-doped TiO2. The method is easy to operate and control, and the visible light photocatalytic performance is good.

Owner:BEIJING UNIV OF CHEM TECH

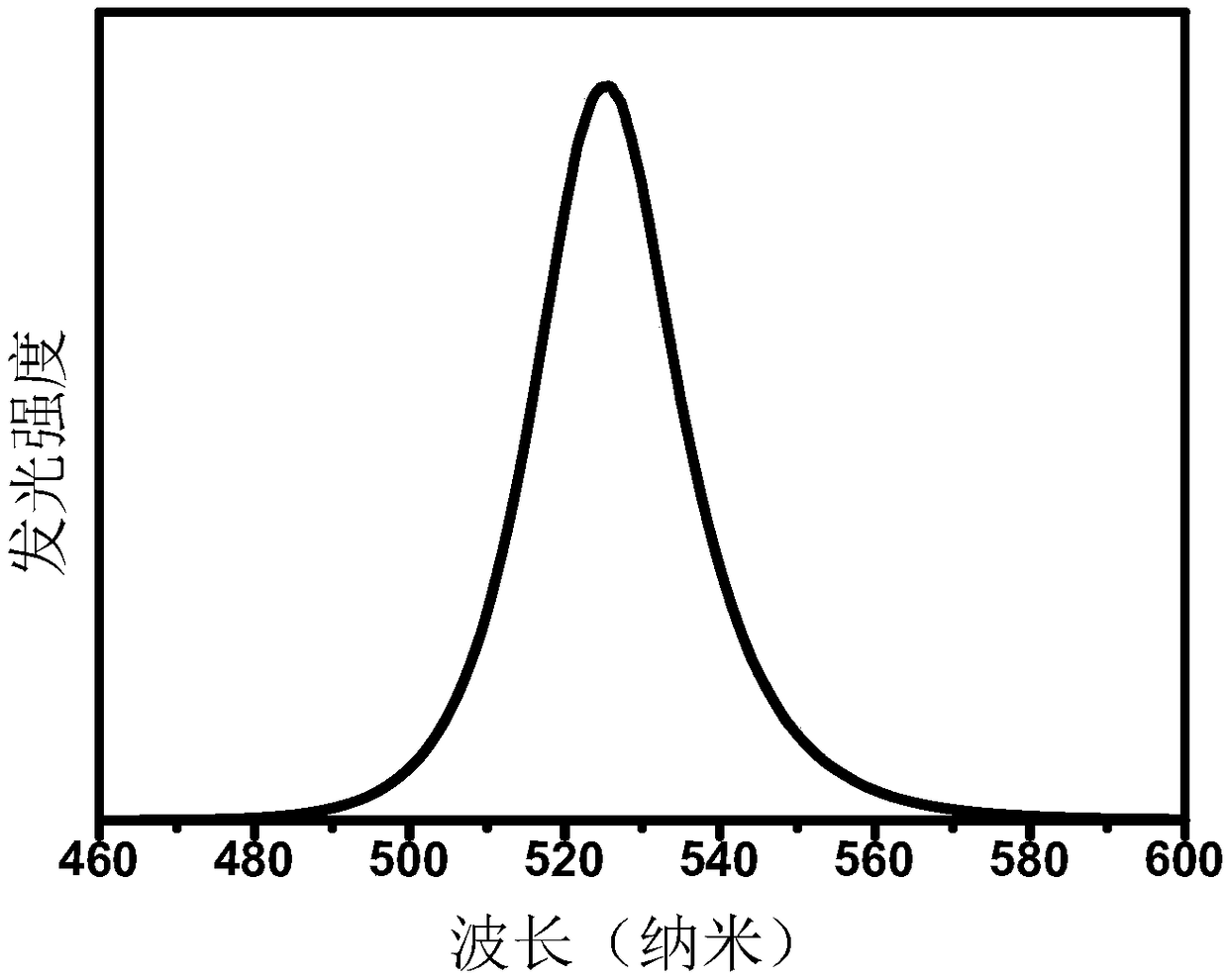

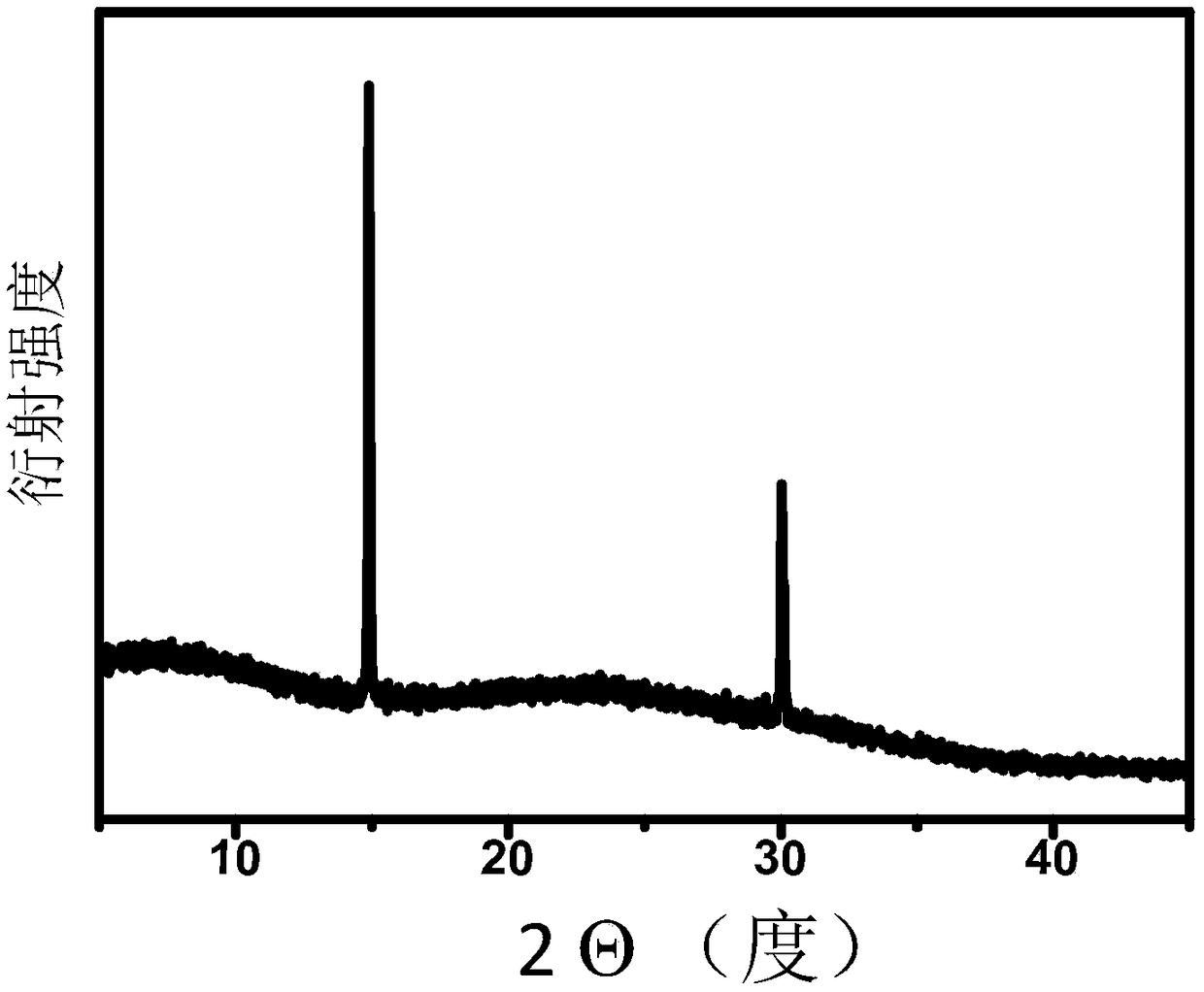

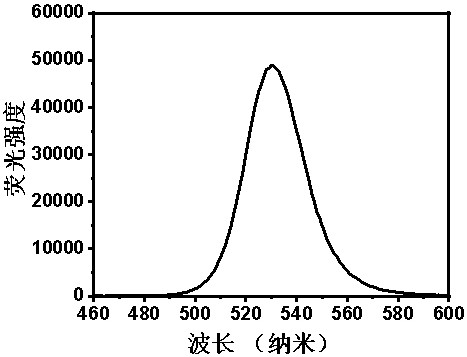

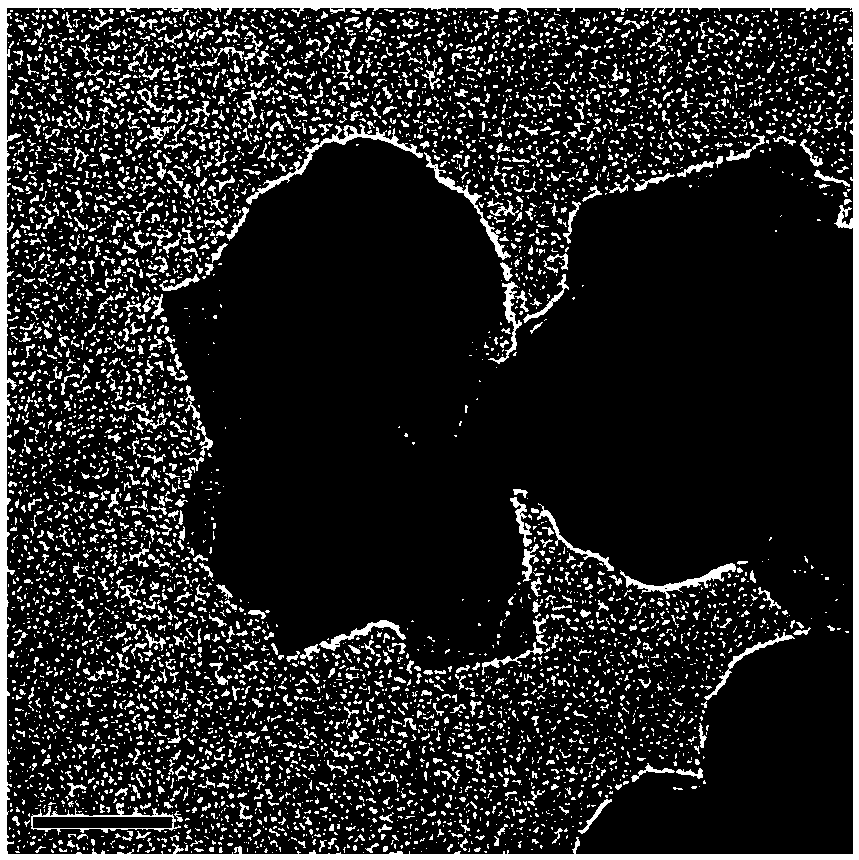

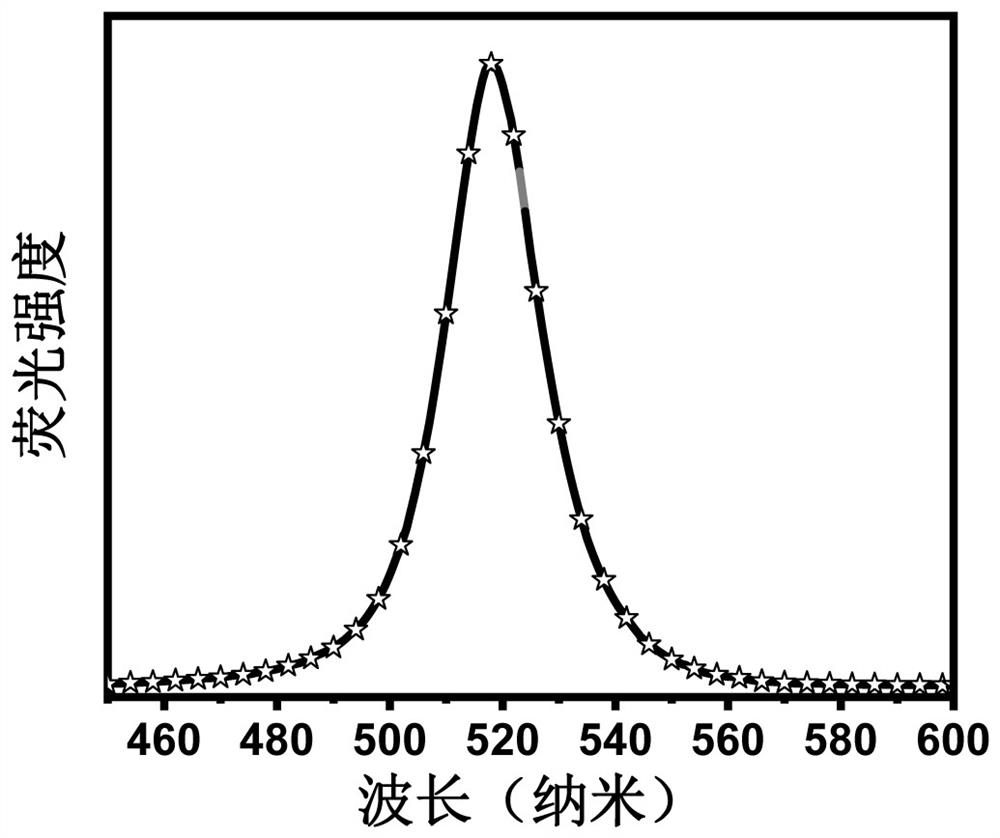

Method for preparing organic-inorganic hybrid perovskite CH3NH3PbBr3 quantum dot with high brightness stability

ActiveCN108658780AHigh fluorescence quantum yieldImprove stabilityOrganic compound preparationNanoopticsQuantum yieldQuantum dot

The invention provides a method for preparing a CH3NH3PbBr3 quantum dot with high fluorescence quantum yield rate and stability by introducing thiocyanate groups in situ. The method is characterized in that in the process of preparing the CH3NH3PbBr3 quantum dot by a ligand-assisted precipitation method, the lead thiocyanate with thiocyanate groups is used as a lead source and is introduced into aprecursor solution, so as to prepare the CH3NH3PbBr3 quantum dot. The prepared CH3NH3PbBr3 quantum dot has the advantages of coordinated light emitting, high fluorescent quantum yield rate, better stability in air, and the like.

Owner:NANCHANG UNIV

Method for preparing high-stability perovskite quantum dot film by in-situ crosslinking method

ActiveCN114196401AEfficient FluorescenceSimple processLuminescent compositionsQuantum dotMethylamines

The invention discloses a method for preparing a high-stability perovskite quantum dot film by an in-situ crosslinking method. The method comprises the following steps: S1, preparing a lead-containing precursor solution; S2, preparing an isopropanol solution of halogenated methylamine, halogenated formamidine and halogenated cesium; S3, preparing a lead-containing polymer film; according to the method provided by the invention, the perovskite quantum dot / polymer hybrid film with high brightness and high stability can be prepared in an atmospheric environment.

Owner:NANCHANG UNIV

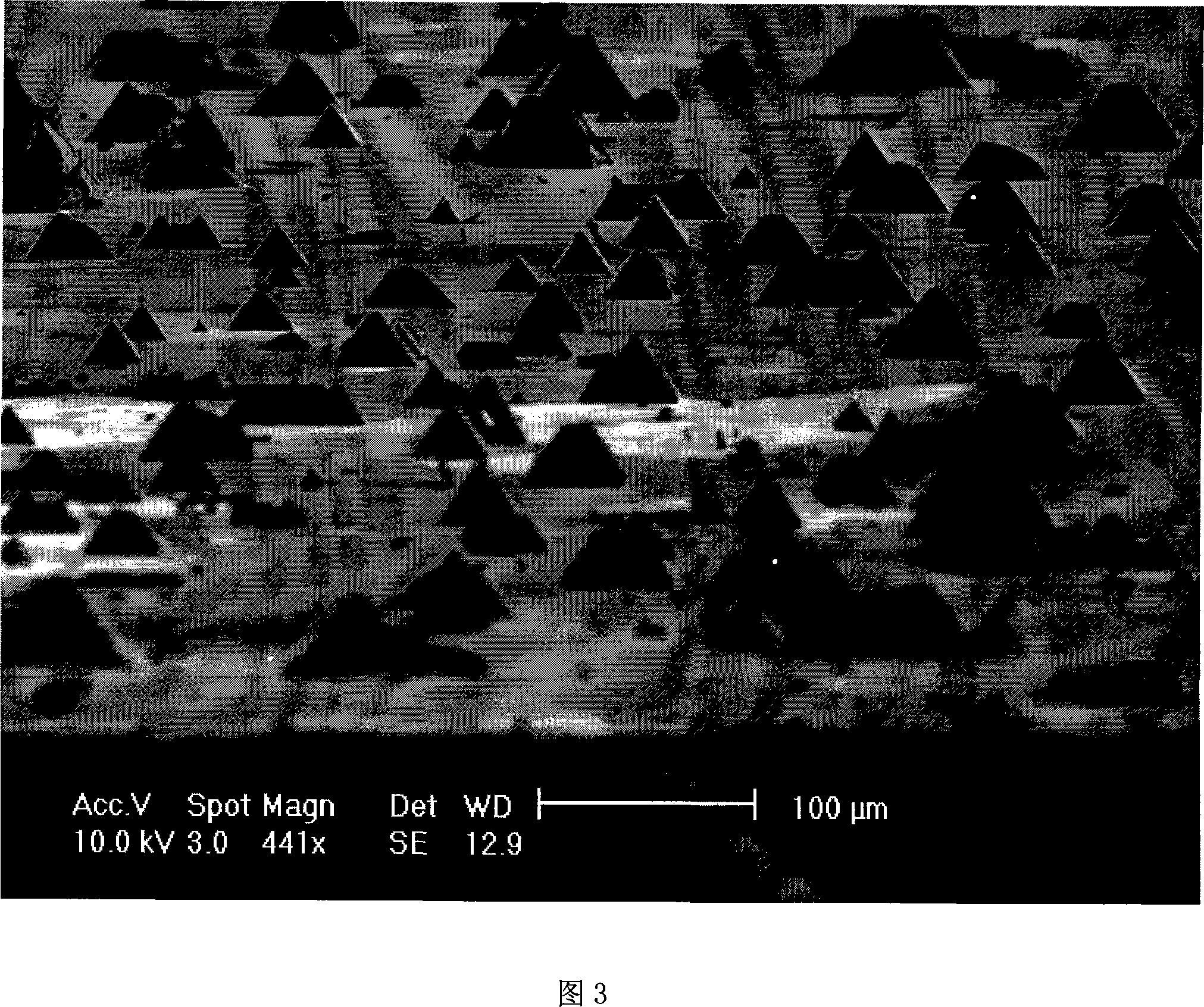

Silicon with three-dimensional depression structure and method for preparing same

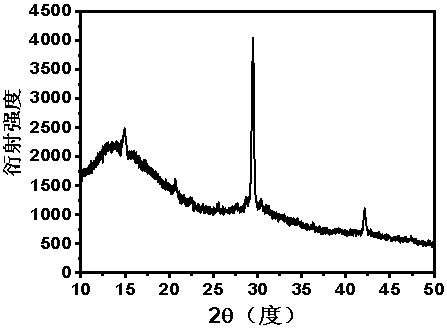

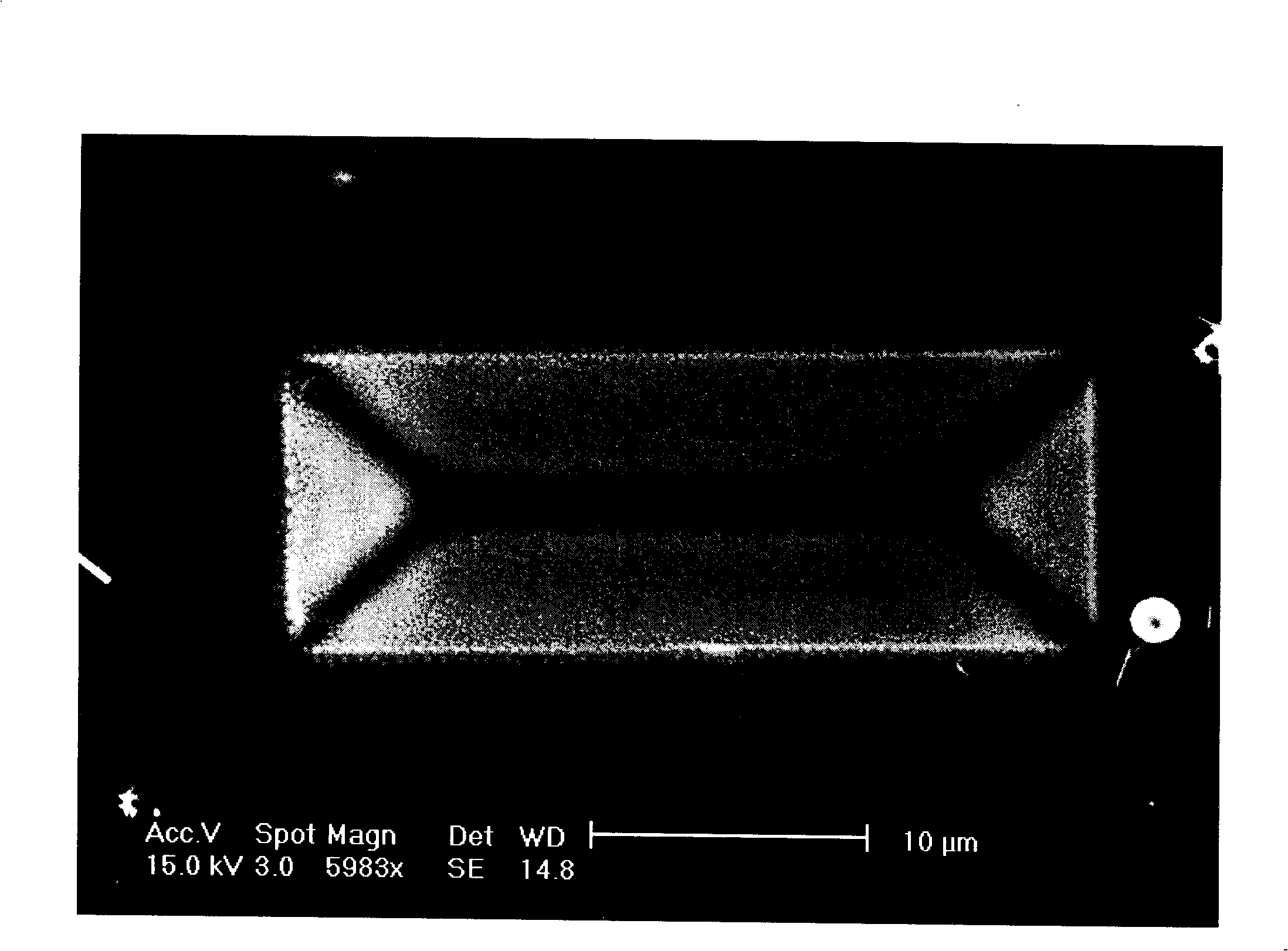

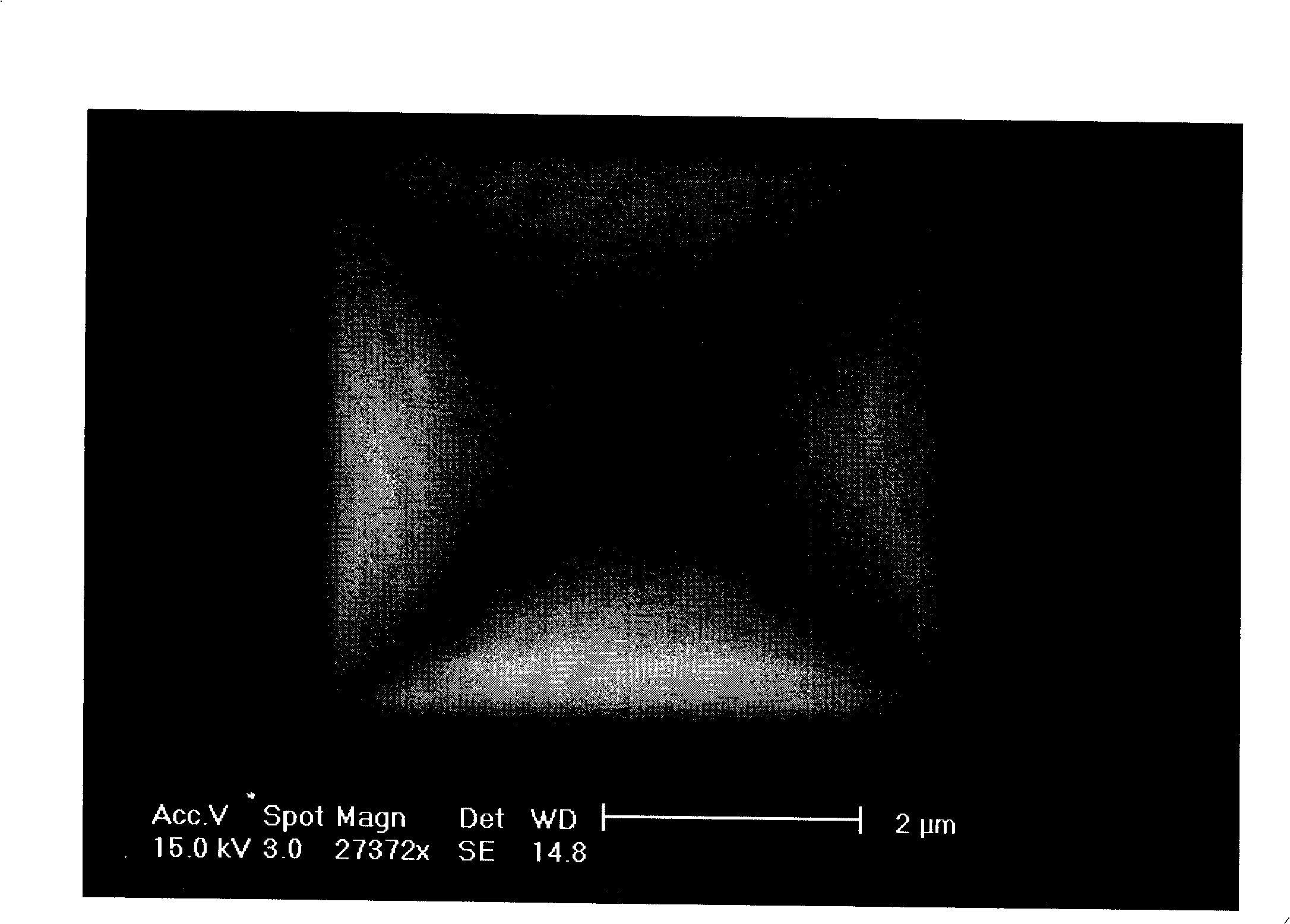

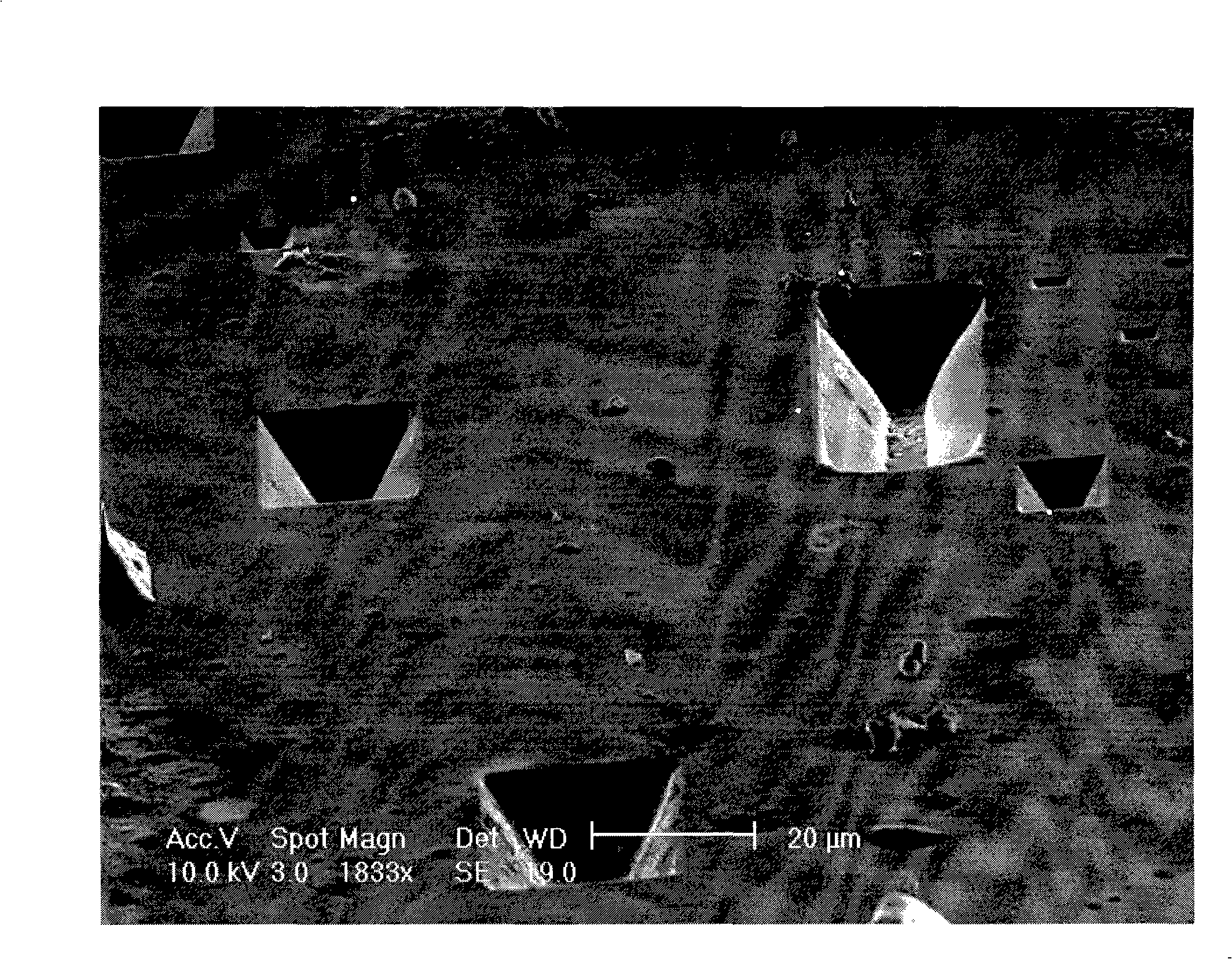

InactiveCN101311349ASmooth appearancePromote crystallizationPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsSolid structure

The invention discloses silicon with a three-dimensional sunken structure and a preparation method thereof, which belongs to the field of semiconductor material and preparation thereof. A three-dimensional structure of the silicon with a three-dimensional sunken structure of the invention has an outline that is similar to a reversed roof, namely, a rectangular superface, two pairs of same sized triangles and trapezoids shaped sides, wherein, the length of the rectangular superface is equal to the sum of the length of a reversed roof-shaped ridge and the width of the rectangular superface; particularly, when the length of the reversed roof-shaped ridge is zero, the reversed roof is degraded to the shape of a reversed pyramid. Meanwhile, the invention provides a method for preparing the silicon with the three-dimensional sunken structure by a vapor deposition method. Compared with the prior art, the invention has the advantages that raw material of the preparation is very cheap; the preparing procedures are simple and easy to be repeated; the preparation parameter is easy to control; the pattern of a generated product is neat; the crystallization is good; a regular three-dimensional solid structure is provided.

Owner:PEKING UNIV

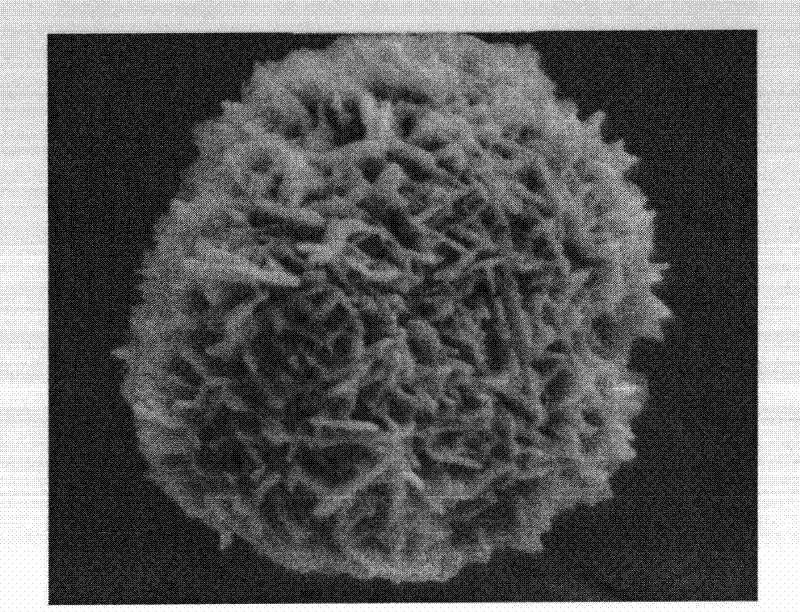

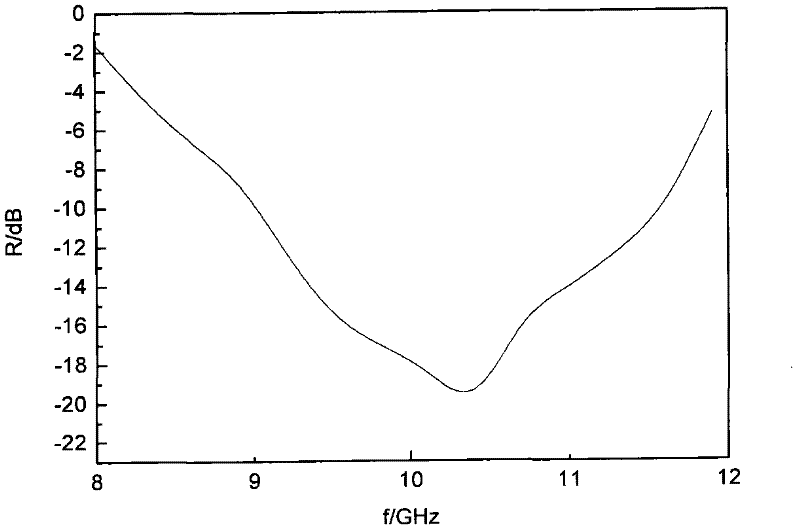

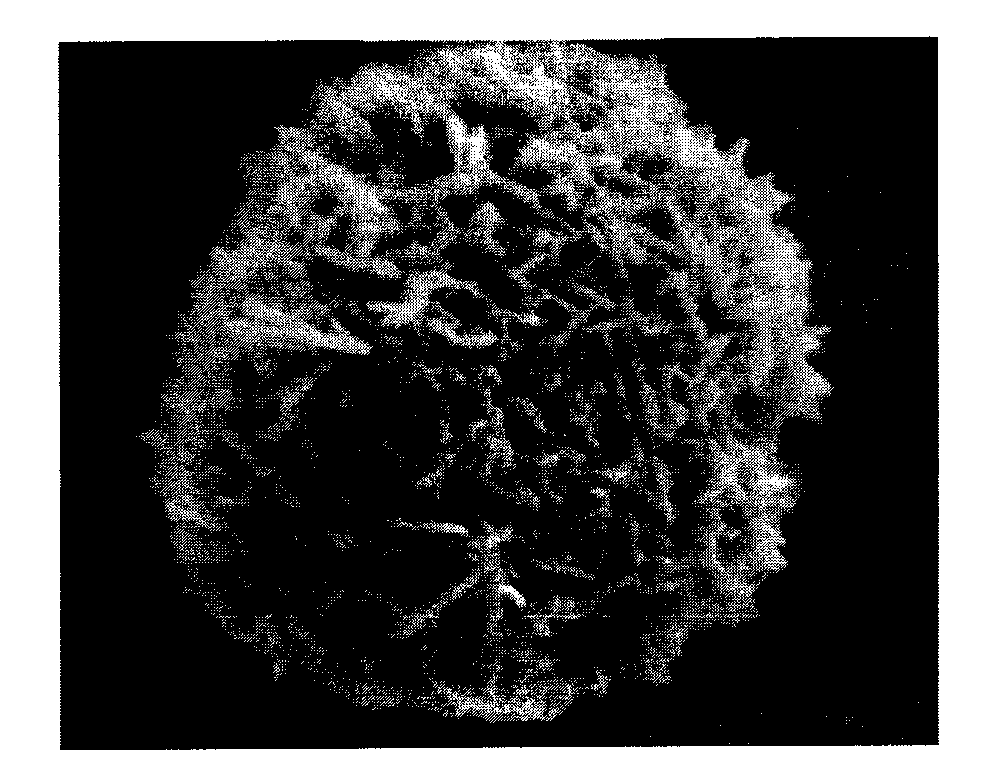

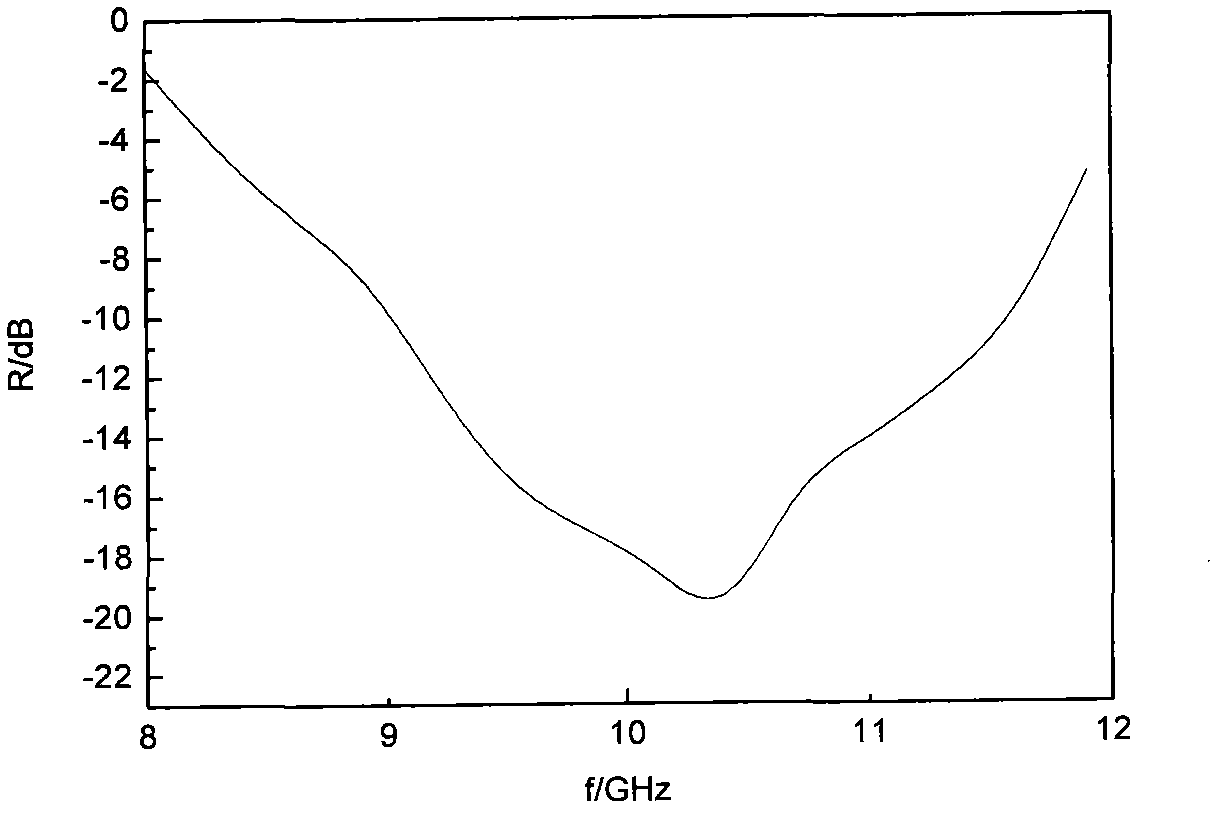

Preparation method of lanthanum-doped zinc oxide microsphere with wave absorbing performance

InactiveCN102502780AImprove performanceImprove absorbing performanceOther chemical processesZinc oxides/hydroxidesAlkalinityMicrosphere

The invention relates to a preparation method of lanthanum-doped zinc oxide microsphere with wave absorbing performance. The invention has the advantages that: firstly, the lanthanum-doped zinc oxide microsphere with perfect sphere shape and appearance is prepared innovatively by controlling the doping concentration, the reaction time, the reaction temperature, the solution alkalinity and the like; secondly, the lanthanum-doped zinc oxide microsphere has excellent performance and particularly has good wave absorbing performance as well as wide application prospect and important strategic significance as novel wave absorbing material; and thirdly, the raw materials for preparing the lanthanum-doped zinc oxide microsphere are conventional raw materials and readily available, the preparationmethod is simple and practical, and the preparation parameters are convenient to control.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Traditional Chinese medicine composition for treating non-hodgkin lymphoma and preparation method thereof

PendingCN110151947AEasy to preparePreparation parameters are easy to controlDispersion deliveryAnthropod material medical ingredientsNH lymphomaEndothelium

The invention discloses a traditional Chinese medicine composition for treating non-hodgkin lymphoma and a preparation method thereof. The composition is prepared from, by weight, American ginseng, radix ophiopogonis, flos farfarae, oldenlandia diffusa, deer-horn glue, radix curcumae, amber, bulbus fritillariae cirrhosae, cortex moutan radicis, vervain, radix trichosanthis, radix paeoniae alba, pilos deer horn, bletilla, the seed of Chinese dodder, endothelium corneum gigeriae galli, radix glehniae, ternate buttercup root, edible tulip, dendrobe, seaweed, honeycombs, silkworm larvae, dried bodies of ground beetle, rhizoma arisaematis, lumbricus, Immature Bitter Orange obtained after stir-baking with bran, selfheal, corydalis tuber, the root of three-nerved spicebush, vinegar rhizoma cyperi, pseudo-ginseng, denon, pomegranate peel, unprocessed tortoise plastron, unprocessed turtle shells and licorice roots. The composition obtained through the certain technology can effectively treat the non-hodgkin lymphoma.

Owner:陈海林

Preparation method of grain size controllable ordered mesoporous Ni nanoparticles

ActiveCN110102773AParticle size controllableControllable two-dimensional hexagonal mesoporous structureMaterial nanotechnologyTransportation and packagingHigh concentrationStandard electrode potential

The invention relates to a preparation method of grain size controllable ordered mesoporous Ni nanoparticles and belongs to the technical field of Ni nanoparticles. The preparation method comprises the following steps: uniformly mixing a template mixture containing a Ni source, a Pd source and a high concentration nonionic surfactant cetanol polyoxyethylene ether (Brij 58) to self-assemble a metalsource-containing solute liquid crystal; carrying out a reaction on Pd ions, the standard electrode potentials of which are relatively high, and a reducer dimethylammonoborane (DMAB) preferably to generate a reaction cores and carrying out a reaction continuously on Ni ions and DMAB; after the reaction, removing a solute liquid crystal soft template to obtain the ordered mesoporous Ni nanoparticles; and controlling the amount of palladium chloride in a precursor liquid, and controlling the average grain size of the ordered mesoporous Ni nanoparticles at 70-200 nm. The preparation method provided by the invention is easy to operate and control. The obtained Ni nanoparticles are ordered in mesopore, controllable in grain size and narrow in distribution and have a very good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Method for directly synthesizing high conductivity nickel sulfide two-dimension nanosheet array in large scale

ActiveCN103466726BHomogeneous nanostructureHigh conductivity at room temperatureMaterial nanotechnologyNickel sulfidesNickel sulfideRepeatability

The invention discloses a method for directly synthesizing a high conductivity nickel sulfide two-dimension nanosheet array in large scale. The method comprises the first step of synthesizing a xanthogenic acid nickel precursor, and the second step of preparing the nickel sulfide two-dimension nanosheet array, wherein the xanthogenic acid nickel precursor powder is placed into a heating device to be heated to reach the temperature ranging from 160 DEG C to 360 DEG C, the heat preservation is carried out on the xanthogenic acid nickel precursor powder for 10-300 mintues, and then the nickel sulfide two-dimension nanosheet array can be generated on a substrate near the xanthogenic acid nickel precursor. The technological process is simple, parameters are obtained easily and controllably, the repeatability is good, and large-scale industrial production can be achieved. The data result is detailed and accurate, so that the feasibility of the method is fully proven. By means of the technology, the problem that the multi-step processing procedures are commonly complex or the technology period is long or high vacuum equipment is high in cost can be avoided, and an extremely potential candidate scheme is provided for the low-cost and large-scale application of the high conductivity nickel sulfide two-dimension nanosheet array.

Owner:山东百帝气动科技股份有限公司

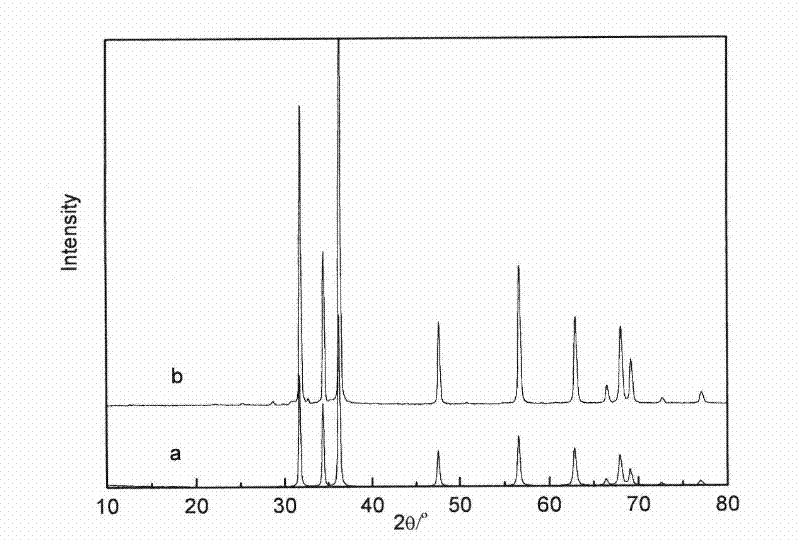

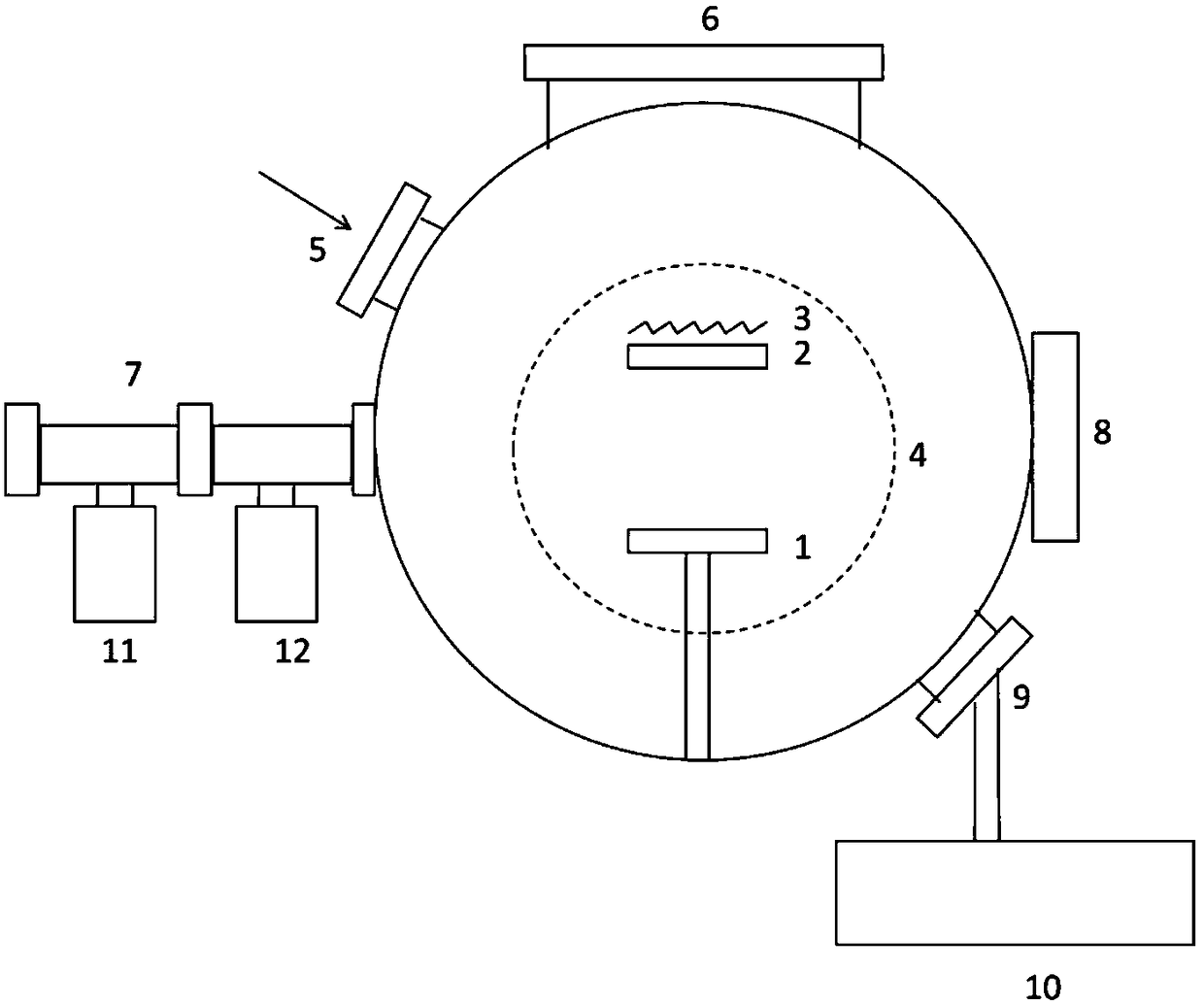

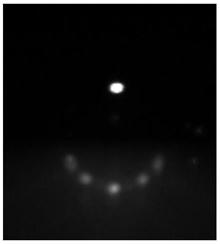

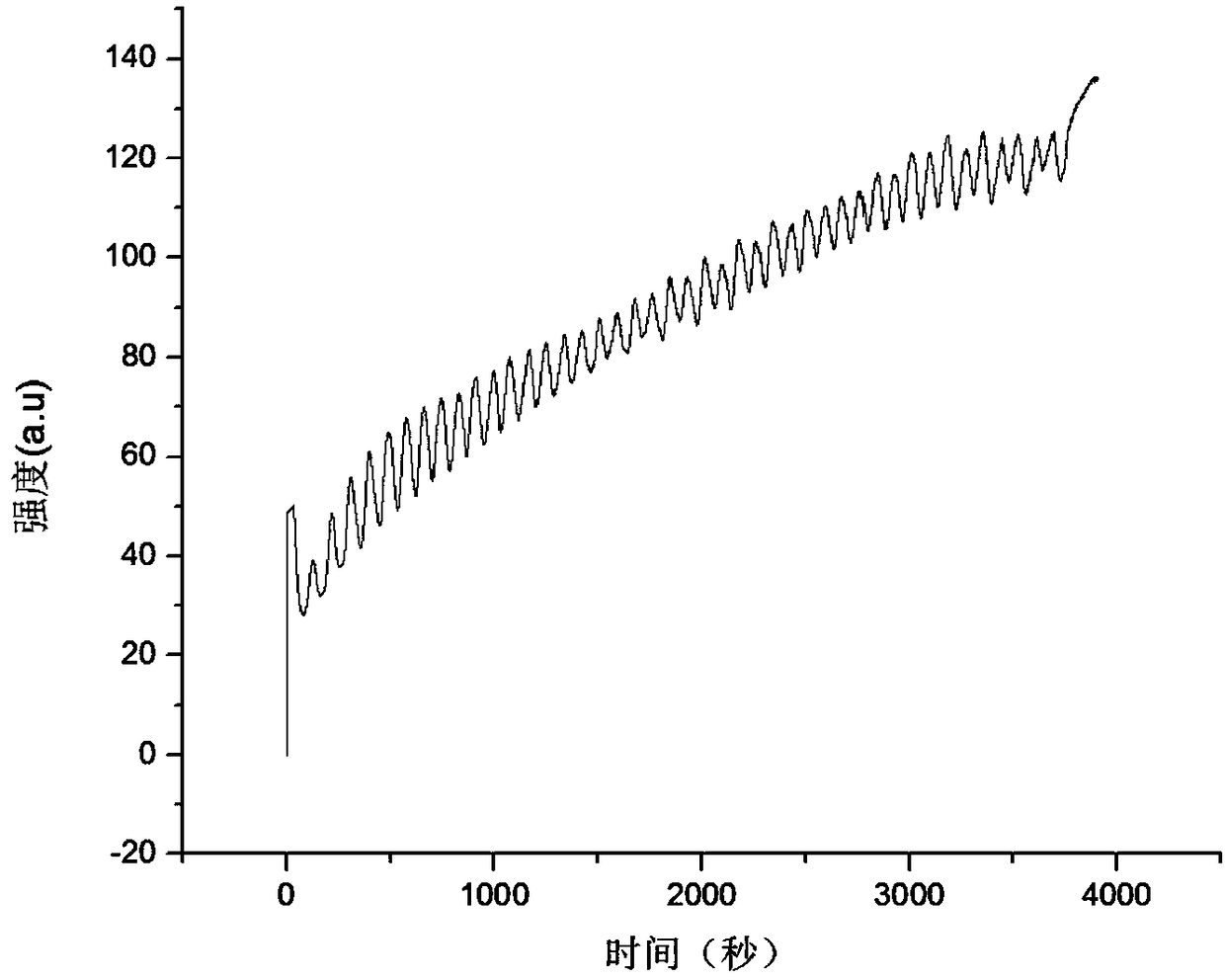

A kind of epitaxial growth method of yttrium iron garnet film

ActiveCN106048726BQuality improvementPreparation parameters are easy to adjustPolycrystalline material growthFrom chemically reactive gasesHigh energyRoom temperature

An epitaxial growth method of a yttrium iron garnet film comprises the following steps: vacuumizing a vacuum cavity with a treated yttrium iron garnet substrate to be 8.6+ / -1*10-6 Pa, and heating the yttrium iron garnet substrate to the constant temperature which is 736 DEG C; in a heating process, feeding ozone when heating to the temperature of 250 DEG C; after heating to the temperature of 736 DEG C, maintaining air pressure of the vacuum cavity, adjusting the mass fraction of the ozone to be 40%, meanwhile insulating for half a hour, and starting a reflective high-energy electron diffraction instrument (RHEED) to adjust so as to obtain diffraction spots of a substrate; maintaining real-time and in-situ monitoring of the RHEED in the whole process, and focusing laser onto a YIG target through a lens by using a KrF excimer laser of which the wavelength is 248 nm; after growth of the film is finished, maintaining the temperature of the substrate unchanged, annealing in situ for 15 minutes, then naturally cooling the film to the temperature about 250 DEG C, stopping protective gas and cooling to the room temperature. The obtained YIG film has uniform components, is controllable in thickness and good in process repeatability, and has high preparation efficiency.

Owner:NANJING UNIV

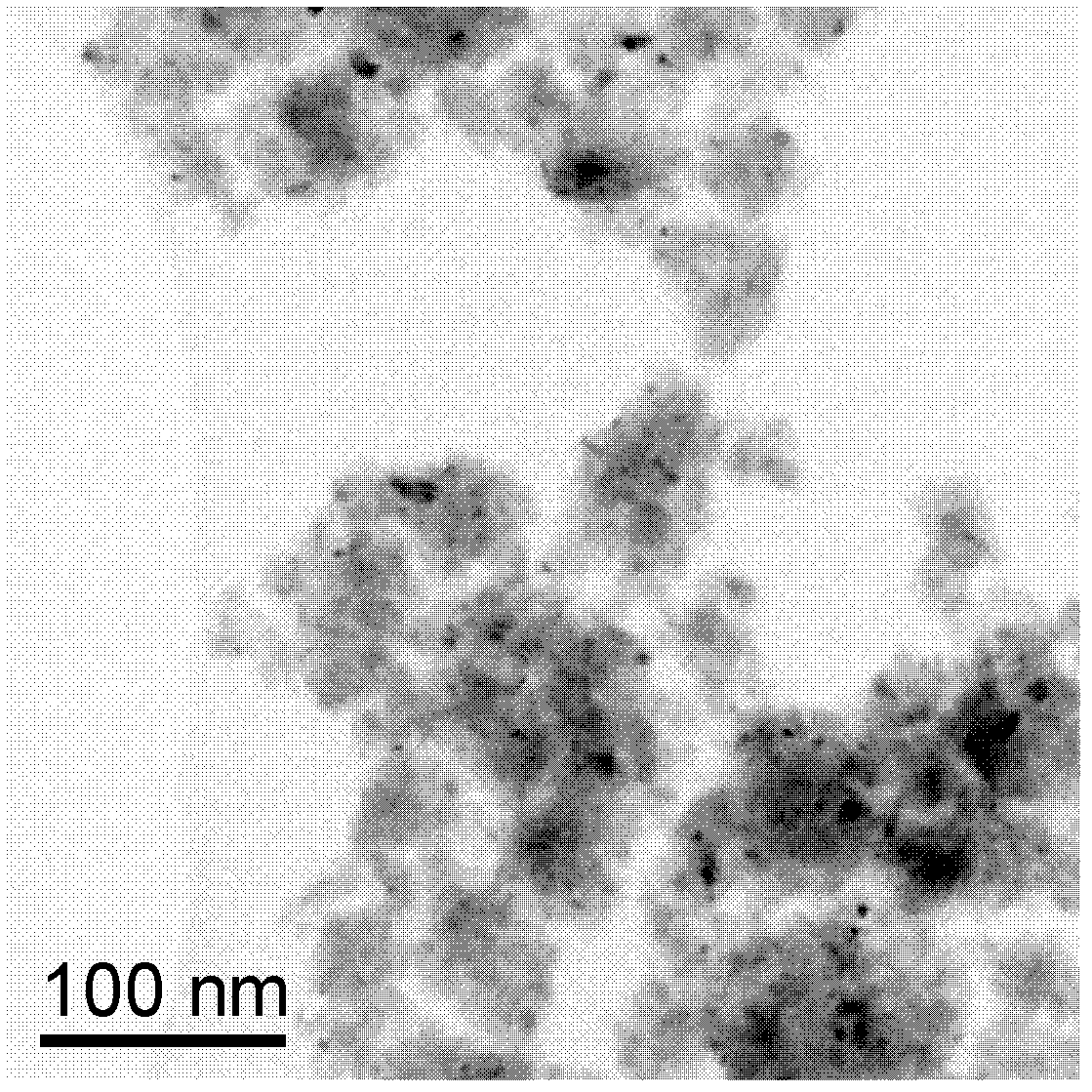

A kind of positive electrode composite material of lithium ion battery and preparation method thereof

ActiveCN102544483BHigh purityGranularity controllableCell electrodesCarbon compositesComposite cathode

The invention discloses a lithium-ion battery composite cathode material and a preparation method thereof. The lithium-ion battery composite cathode material is composed of LMMP and a carbon material; the LMMP is phosphate in an olivine structure, and the phosphate is in stoichiometric proportion as shown in LiMn1-xMgxPO4, wherein x is not less than 0 and not more than 0.1; the LMMP is in a laminated structure, the sheet thickness is 10-30 nm, the size is 200-300 nm, and the powder tap density is 1.2-1.6g / cm<3>; and the carbon material is one or any combination of conductive carbon black and a carbon nano-tube. The preparation method comprises the following steps: solvothermal preparation of nano LMMP particles; ball-milling and mixed cladding of carbon; and annealing. Compared with the prior art, the adopted solvothermal method has the advantages of rapid reaction, low synthesis temperature and effectively controllable product appearance; and the product has uniform chemical components and uniformly distributed particles. By the subsequent ball-milling-annealing method, the nano LMMP / carbon composite material with high uniform dispersion can be obtained. The preparation method disclosed by the invention has the advantages that the technical process is simple, preparation parameters are easy to control, the repeatability is good, and the large-scale synthesis can be realized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

A kind of sheet-like limnpo4 nanocrystal with high proportion of 020 crystal face and preparation method thereof

ActiveCN102544484BReduce the formation temperatureControl facet growthCell electrodesLITHIUM PHOSPHATENanocrystal

The invention discloses a lamellar manganese lithium phosphate (LiMnPO4) nano-crystal with a high-proportion 020 crystal face and a method for preparing the lamellar LiMnPO4 nano-crystal. The LiMnPO4 nano-crystal has a lamellar shape, 80 to 95 percent of 020 crystal face of the LiMnPO4 nano-crystal is exposed, a lamella along the [020] direction has a thickness of 10 to 30 nm and a size of 100 to 300 nm, and the tap density of powder is 1.2 to 1.6 g / cm<3>. Lamellar LiMnPO4 nano-crystal powder can serve as a cathode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

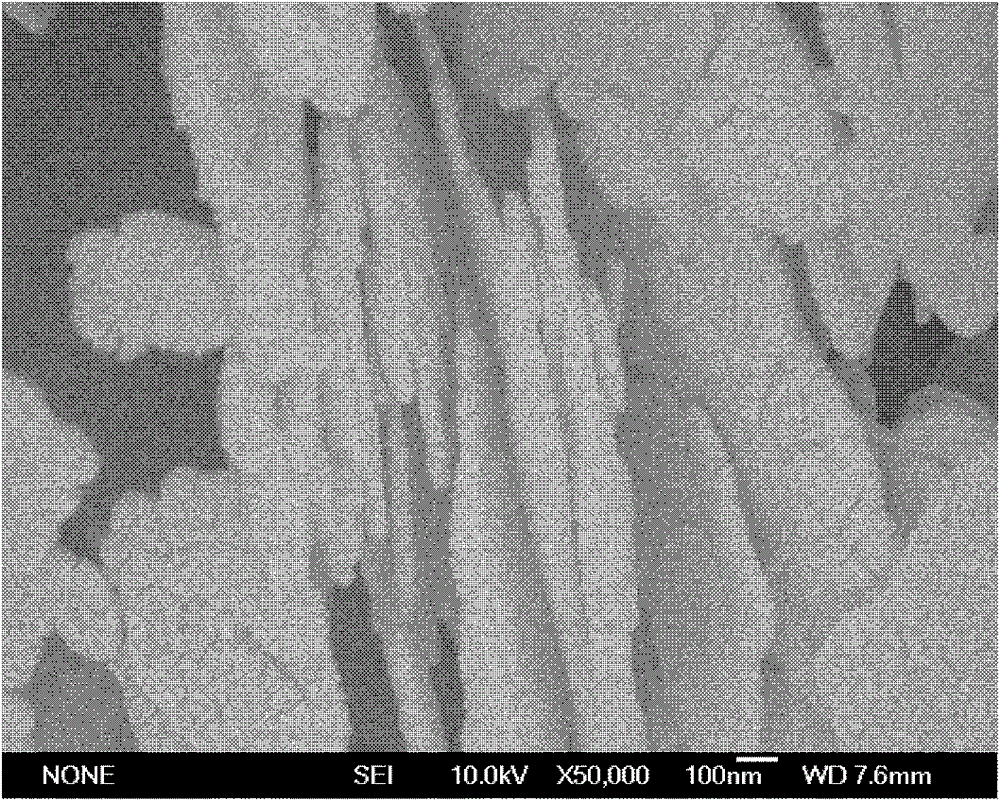

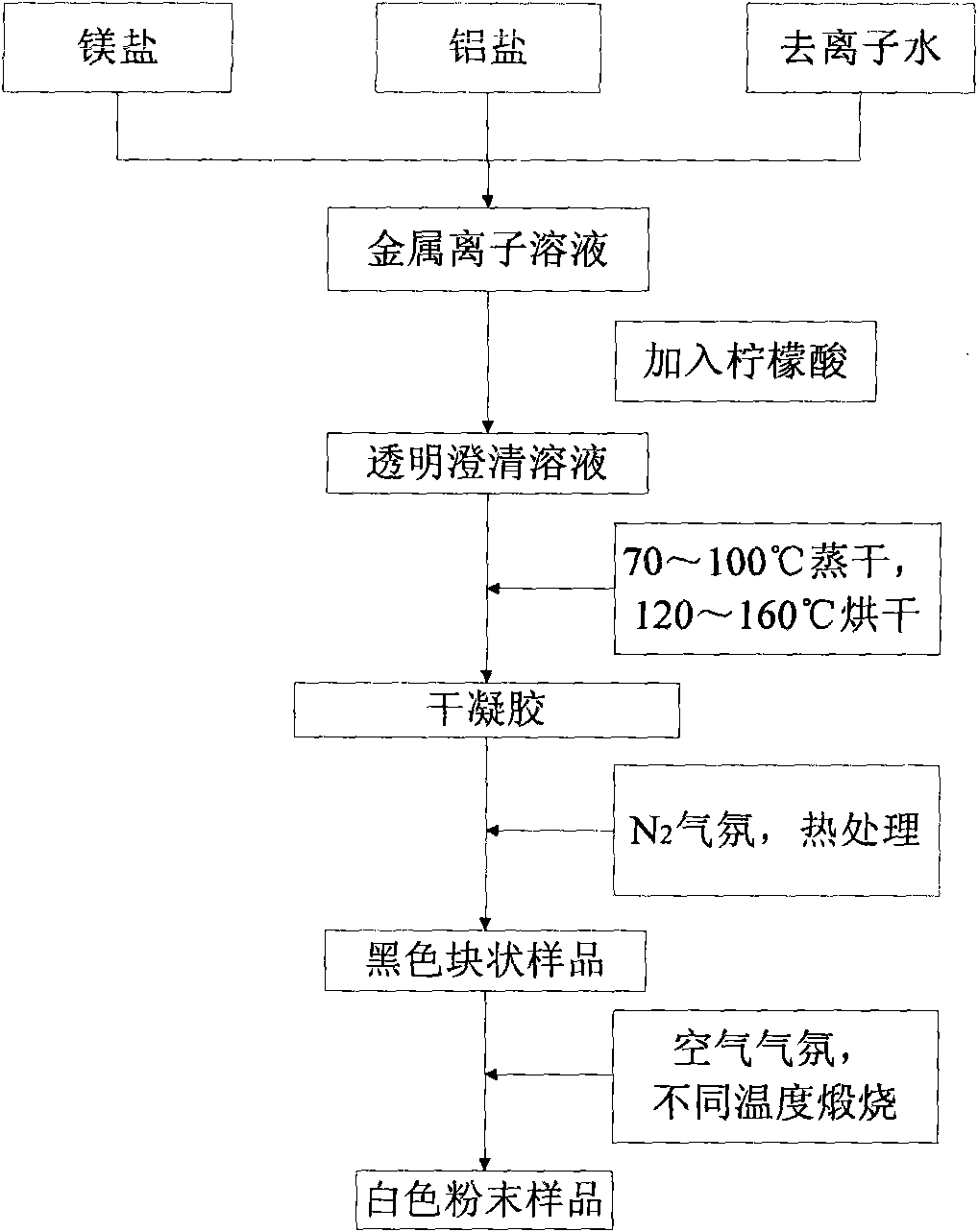

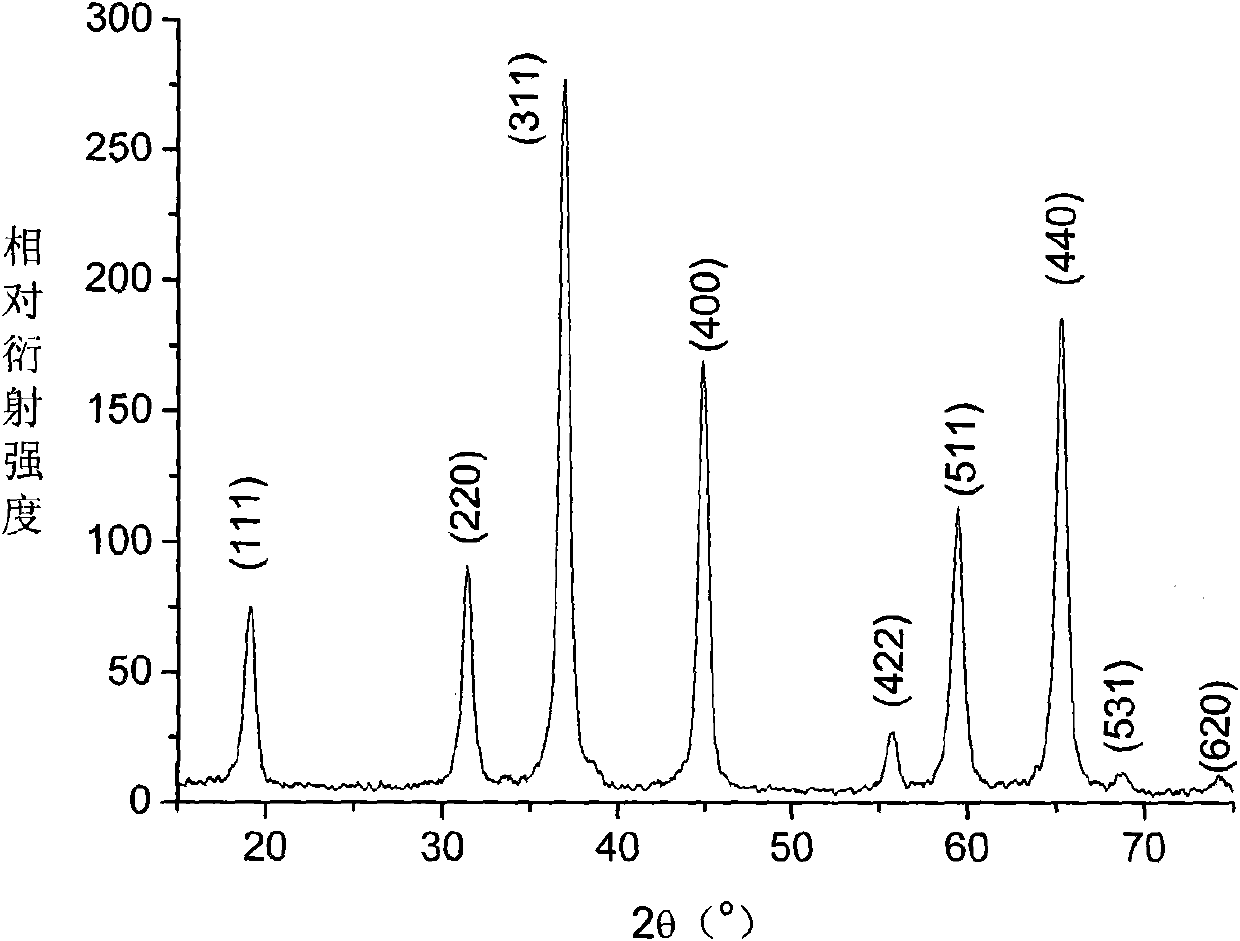

Nano mesoporous magnesium aluminate material and preparation method thereof

ActiveCN102190321BUniform particle size distributionFine grainPhysical/chemical process catalystsAluminium oxides/hydroxidesAluminum IonMagnesium salt

The invention discloses a nano mesoporous magnesium aluminate material and a preparation method thereof. The nano mesoporous magnesium aluminate material has the grain size of 3-20nm, the specific surface area of 90-300m<2> / g, and the most probable pore diameter of 2-10nm. The preparation method comprises the following steps of: (1) dissolving initiative materials, namely magnesium salt and aluminum nitrate in water to obtain metal ion mixed solution in which the molar ratio of magnesium ions to aluminum ions is 1:2, fully mixing uniformly, adding citric acid, ensuring that the molar ratio of the citric acid to the metal ions is (1.5-2.5):1, and obtaining a complex by using the citric acid as a complexing agent; (2) regulating the PH value of the solution to be 2-5, heating, and evaporating to remove water at the temperature of between 70 and 100 DEG C so as to form gel; (3) evaporating all water in the gel obtained in the step (2), heating and drying at the temperature of between 120 and 160DEG C for 2 to 6 hours in a constant temperature oven to obtain dried gel; (4) grinding the dried gel obtained in the step (3), and calcining at the temperature of between 700 and 900DEG C for 0.5 to 3 hours in the atmosphere of N2 to obtain black powder; and (5) calcining the black powder obtained in the step (4) at the temperature of between 500 and 900DEG C for 1 to 2 hours in the atmosphere of air to obtain the nano mesoporous magnesium aluminate material. The nano mesoporous magnesium aluminate material can be used as a catalyst for improving performance of a solid propellant.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Silicon with three-dimensional hollow structure and method for preparing same

InactiveCN101311348BPromote crystallizationSave raw materialsPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsGas phase

Owner:PEKING UNIV

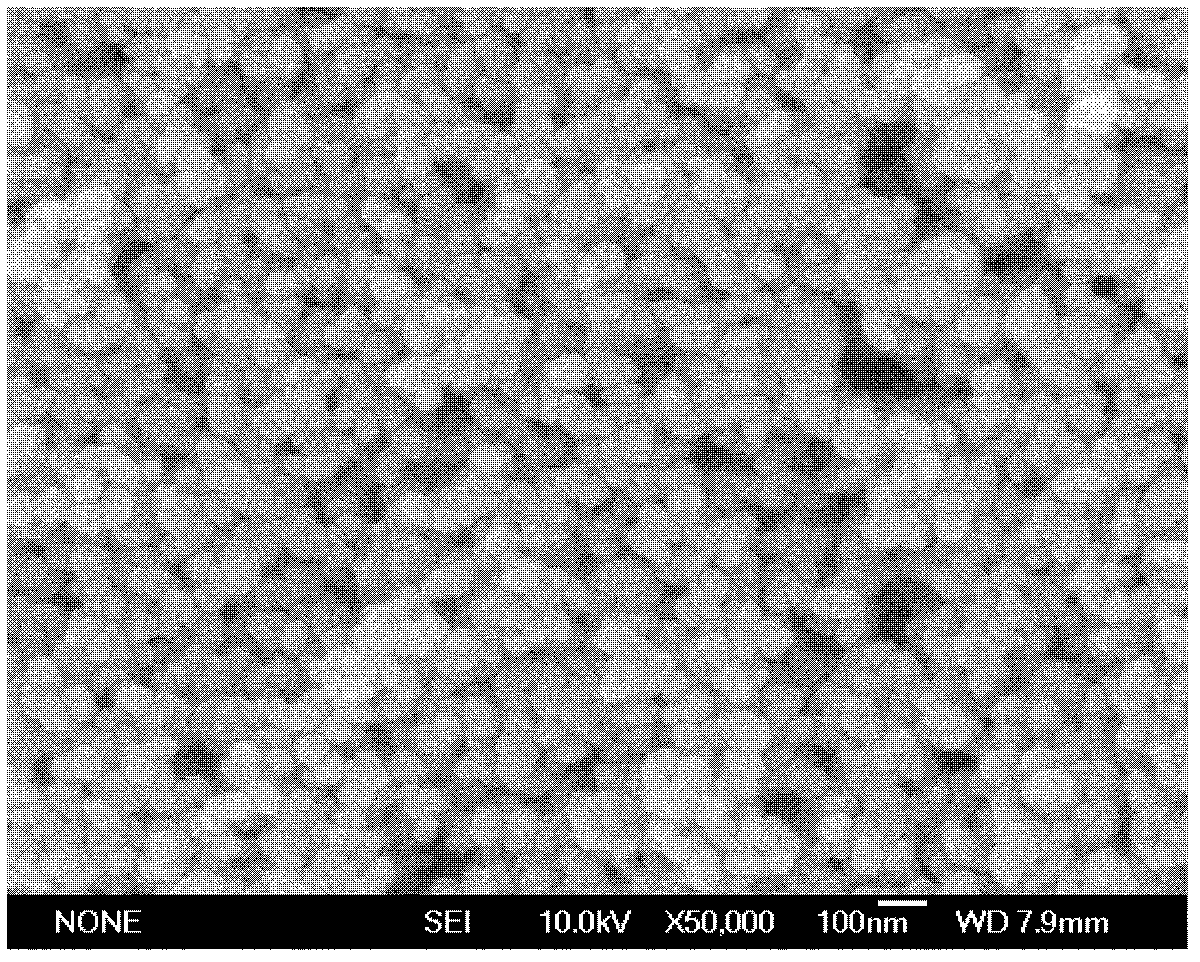

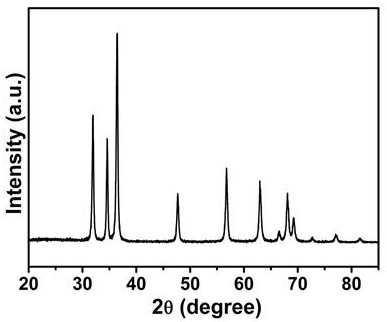

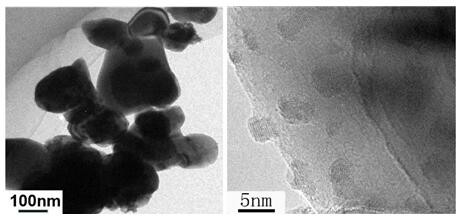

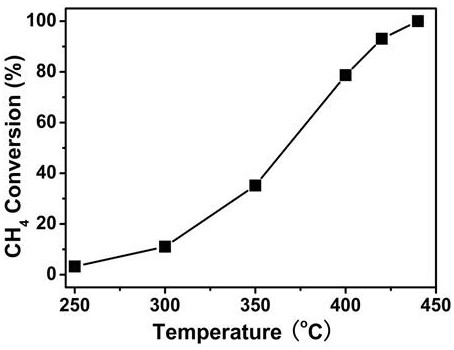

Palladium oxide supported zinc-based catalyst and preparation method and application thereof

ActiveCN113546620AUniform particle sizeGood dispersionCatalyst carriersGaseous fuelsPtru catalystPalladium oxide

The invention discloses a palladium oxide supported zinc-based catalyst and a preparation method thereof, which belong to the field of catalytic combustion of organic gas pollutants. The catalyst carrier is zinc oxide with the particle size of 150-300 nm, the loaded precious metal palladium exists in the form of oxide, the particle size is mainly distributed in the range of 1.5-2.5 nm, the loading amount of the palladium oxide accounts for 0.2-0.6% by mass of the catalyst, and the palladium oxide is uniformly dispersed on the surface of the zinc oxide carrier. According to the catalyst, loading of palladium oxide on a zinc oxide carrier is achieved through an ultrasonic-roasting two-step method, compared with an existing palladium-based methane catalytic combustion catalyst, the catalyst has the advantages of being low in palladium loading capacity, high in activity and stability, simple in preparation process and easy to apply and popularize.

Owner:SHANXI UNIV

Preparation and Application of Titanium Dioxide Nanosheets Loaded Mil-100(fe) Composite Photocatalytic Material

ActiveCN106238100BShape is easy to controlImprove adsorption capacityWater/sewage treatment by irradiationWater treatment compoundsWater bathsHigh concentration

A preparation and application method of titanium dioxide nanosheet-loaded MIL-100 (Fe) composite photocatalytic material, which belongs to the field of titanium dioxide photocatalysis, and particularly relates to the field of titanium dioxide nanosheet-loaded porous metal-organic framework (MOFs) composite materials. In the present invention, tetrabutyl titanate and hydrofluoric acid are stirred evenly at room temperature, put into a hydrothermal reactor for reaction, and titanium dioxide nanosheets are obtained after separation, washing and drying; the titanium dioxide nanosheets are then evenly dispersed in three Ferric chloride absolute ethanol solution, stir magnetically at room temperature for 15 minutes, separate by suction filtration, disperse the obtained product in trimesic acid absolute ethanol solution, react in a water bath at 50-80°C for 20-50 minutes, and then suction filtration The product obtained after separation is repeated 2 to 50 times to obtain titanium dioxide nanosheet-loaded MIL-100 (Fe) composite photocatalytic material; the catalyst prepared by this method is particularly suitable for catalytic degradation of high-concentration organic dyes (such as methylene blue) under visible light irradiation. ), achieving a very high degradation rate.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing perovskite quantum dot-polymer porous composite material

ActiveCN114058067AImprove luminous brightnessImprove stabilityMaterial nanotechnologyNanoopticsMethylaminesPolymer composites

The invention discloses a method for preparing a perovskite quantum dot-polymer porous composite material with high brightness and high stability. The method comprises the following steps: S1, preparing a lead-containing precursor solution; s2, preparing a solution of halogenated methylamine, halogenated formamidine and halogenated cesium; s3, preparing a lead-containing porous polymer material; s4, preparing a porous perovskite quantum dot-polymer composite material. According to the method provided by the invention, the porous perovskite quantum dot-polymer composite material with high luminance and good stability can be obtained.

Owner:NANCHANG UNIV

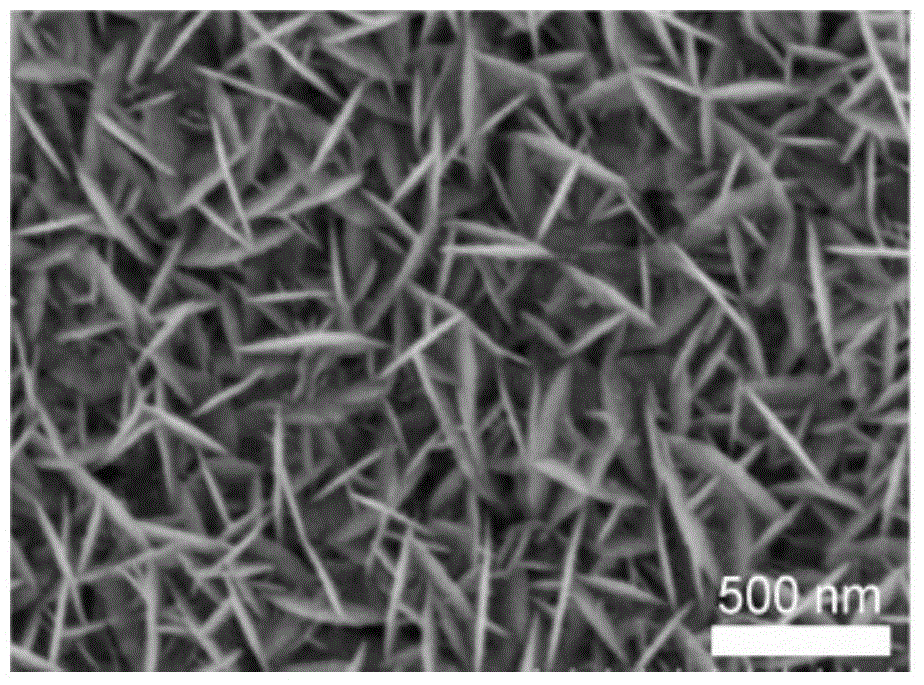

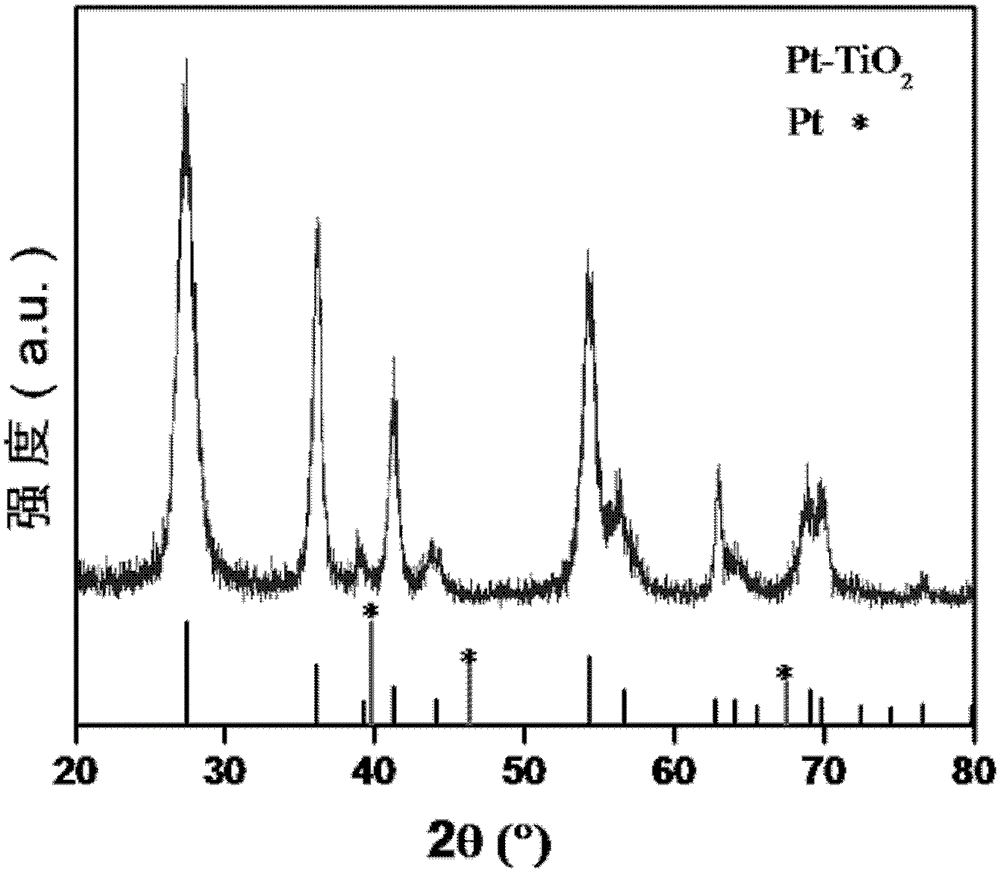

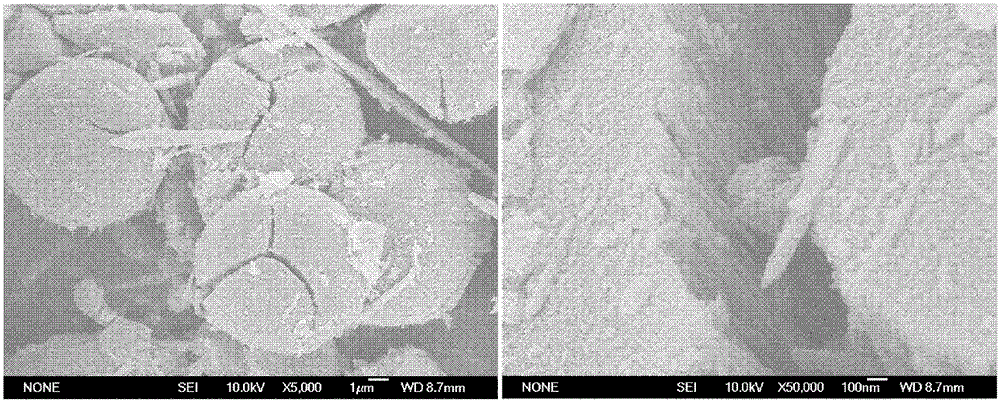

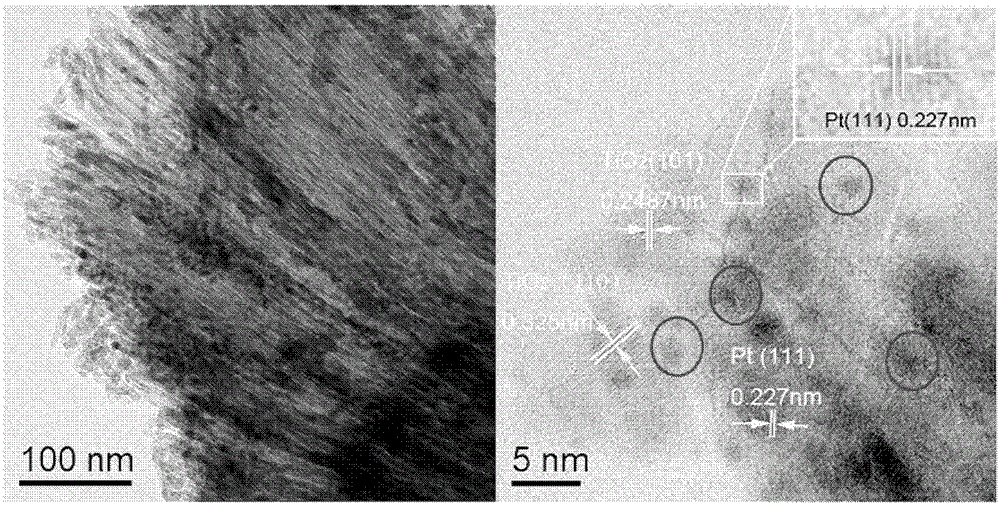

Noble metal directional loaded titanium dioxide photocatalyst and preparation method thereof

ActiveCN102500363BHas visible light catalytic activityEasy transferCatalyst carriersWater/sewage treatment by irradiationNanowireMicrosphere

The invention discloses a noble metal orientation load titanium dioxide photocatalyst and a preparation method thereof. A titanium dioxide carrier has a rutile phase structure and a uniform spherical appearance, wherein the microsphere diameter is about 10 to 16 mu m; the surface is cracked; the titanium dioxide carrier is formed by self-assembling nanowires with the length of 5 to 8 mu m and diameter of 3 to 6 mu m; and the exposed surface of each nanowire is a crystal face (110). The noble metal is one or more of platinum, gold, ruthenium, rhodium, silver and palladium; the load quantity of the noble metal is 0 to 3 percent of the mass of the titanium dioxide carrier; the noble metal exists in the form of a zero-valence simple substance; the grain size of the noble metal is 2 to 10 nm; and the noble metal is orientationally deposited on the crystal face (110) of the titanium dioxide nanowires. The noble metal load titanium dioxide material serving as an effective photocatalyst is applied to light degradation of organic pollutants in a waste water solution.

Owner:厦门下元环保科技有限公司

A kind of magnesium oxide nanopowder doped with zinc and copper and preparation method thereof

ActiveCN105293537BInhibit growthLarge specific surface areaZinc oxides/hydroxidesNanotechnologyMagnesium acetateCopper oxide

The invention discloses a zinc-copper-doped magnesium oxide nanopowder and a preparation method thereof. The zinc-copper is prepared by using magnesium acetate, zinc acetate and copper acetate as raw materials through mixing, evaporation, drying and two heat treatments. Doped magnesium oxide nanopowder, containing magnesium oxide, zinc oxide and copper oxide in the zinc copper doped magnesium oxide nanopowder, its general formula is Mg1‑xZnx‑yCuyO, wherein, 0.05≤x≤0.1,0

Owner:FUJIAN JIANGXIA UNIV

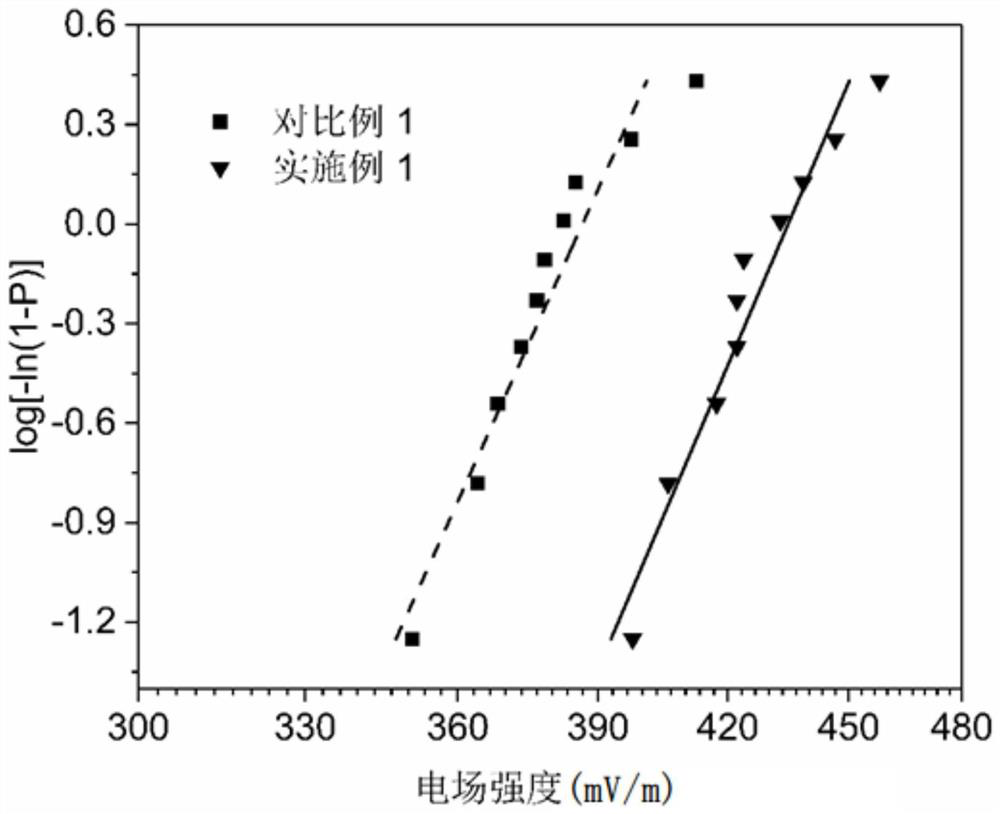

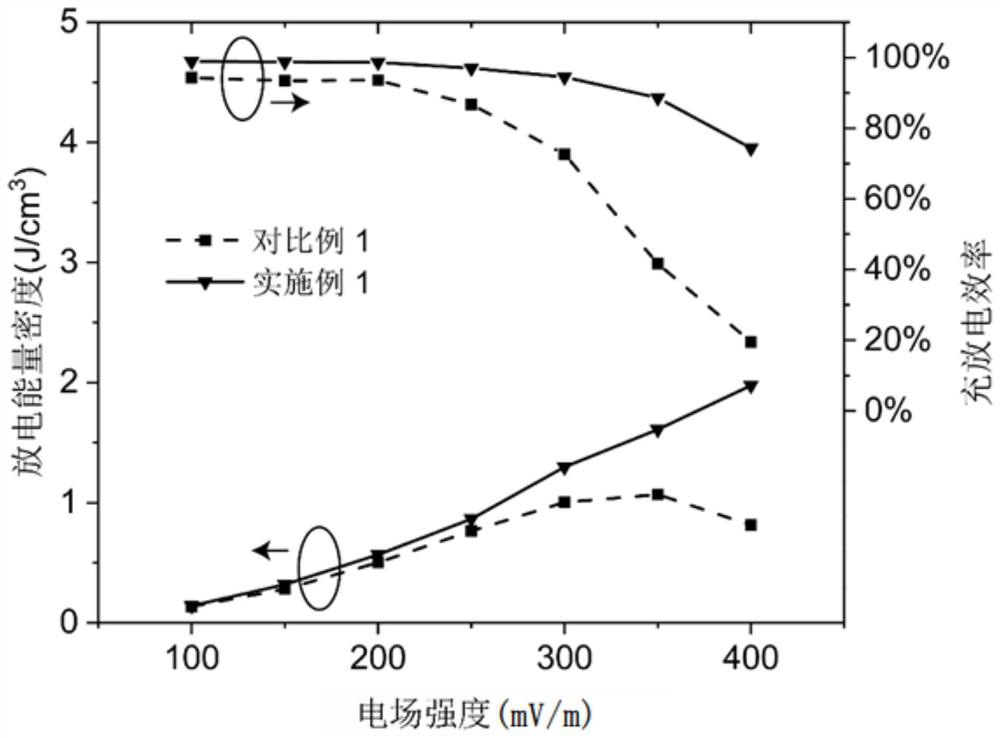

Energy storage polymer dielectric and preparation method and application thereof

InactiveCN113496820AHigh purityPromote densificationFixed capacitor dielectricSputteringPolymer dielectrics

The invention discloses an energy storage polymer dielectric as well as a preparation method and application thereof. The energy storage polymer dielectric comprises a polymer dielectric base film and a metal oxide thin film. The preparation method comprises the following steps of cleaning the dielectric medium film in advance, and depositing the metal oxide film on the clean polymer dielectric base film in a mixed atmosphere of Ar and O2 by taking a metal oxide as a target material and adopting magnetron sputtering. The method for preparing the energy storage polymer dielectric and improving the charging and discharging efficiency has the following advantages that the deposition rate is high, the temperature rise is small, and damage to the polymer dielectric base film is small; the bonding property of the sputtered film and the polymer dielectric medium is good; the sputtered metal oxide is high in purity, compact in film formation and good in uniformity; and compared with an original base film, the composite energy storage dielectric prepared after sputtering has the advantages that the charging and discharging efficiency is greatly improved, and the breakdown strength is also improved. The technology has good repeatability, film preparation parameters are easy to adjust, and the technology has the potential of achieving industrialization.

Owner:TSINGHUA UNIV +1

A high-performance graphene-supported mesoporous nickel-iron alloy electrocatalyst and its preparation method

ActiveCN111450831BHigh activityImprove stabilityMaterial nanotechnologyTransportation and packagingPtru catalystActive agent

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of lanthanum-doped zinc oxide microsphere with wave absorbing performance

InactiveCN102502780BImprove performanceImprove absorbing performanceOther chemical processesZinc oxides/hydroxidesAlkalinityMicrosphere

The invention relates to a preparation method of lanthanum-doped zinc oxide microsphere with wave absorbing performance. The invention has the advantages that: firstly, the lanthanum-doped zinc oxide microsphere with perfect sphere shape and appearance is prepared innovatively by controlling the doping concentration, the reaction time, the reaction temperature, the solution alkalinity and the like; secondly, the lanthanum-doped zinc oxide microsphere has excellent performance and particularly has good wave absorbing performance as well as wide application prospect and important strategic significance as novel wave absorbing material; and thirdly, the raw materials for preparing the lanthanum-doped zinc oxide microsphere are conventional raw materials and readily available, the preparationmethod is simple and practical, and the preparation parameters are convenient to control.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

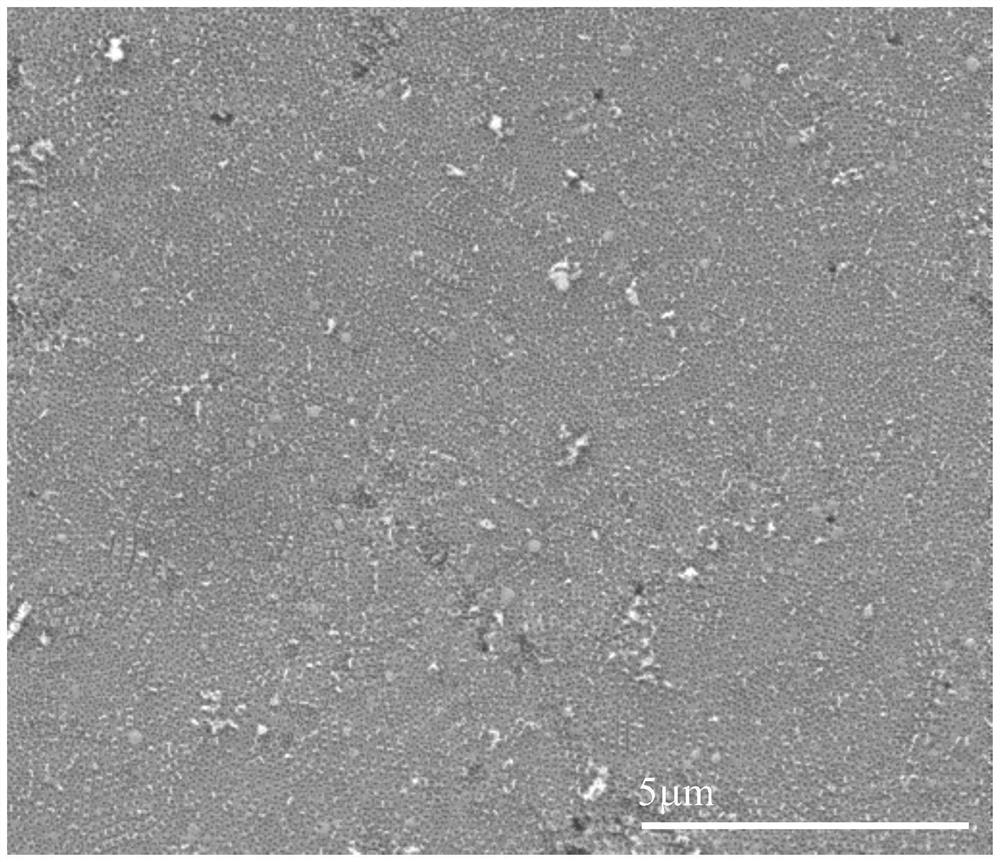

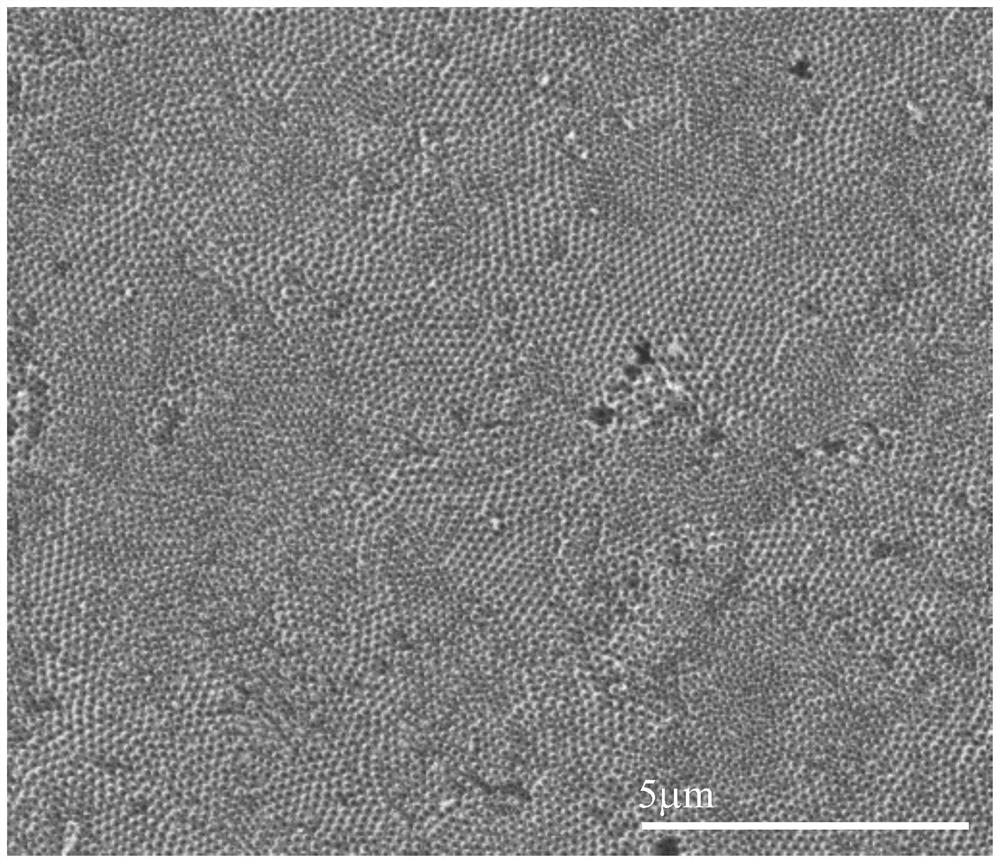

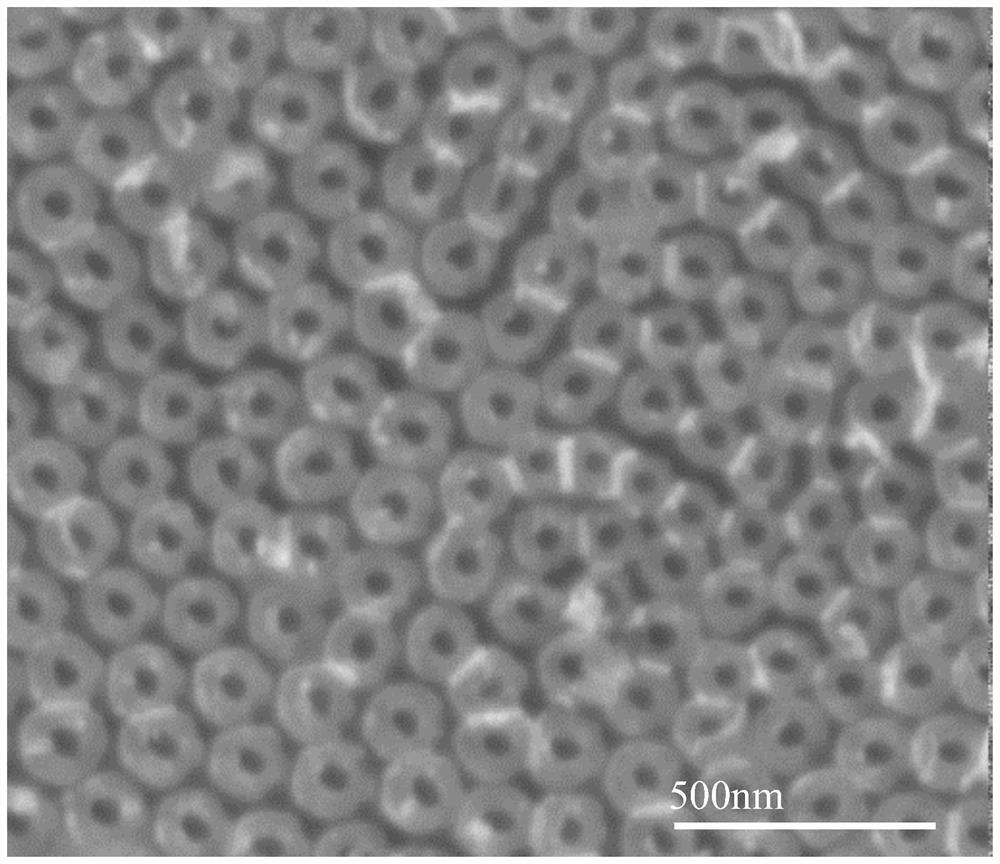

Bipass large-area aluminum oxide, titanium dioxide or zirconium dioxide nanotube array film and preparation method thereof

PendingCN114395784AImprove the opening effectEasy to makeSurface reaction electrolytic coatingTitanium zirconiumTitanium oxide

The invention discloses a bi-pass large-area aluminum oxide, titanium dioxide or zirconium dioxide nanotube array film and a preparation method thereof. The method comprises the following steps: carrying out anodic oxidation on a pretreated pure aluminum sheet, a pretreated titanium sheet and a pretreated zirconium sheet to prepare a first-grade primary product; dissolving by using a mixed solution of liquid bromine and methanol to remove aluminum, titanium and zirconium metal matrixes, so as to obtain aluminum oxide, titanium dioxide and zirconium dioxide nanotube array films and obtain a secondary preliminary product; after cleaning with absolute ethyl alcohol, putting into a critical CO2 atmosphere drying box for drying, so as to obtain a third-stage preliminary product with a barrier layer at the bottom; and putting into a plasma cleaning instrument containing fluoride gas, and removing the barrier layer at the bottom to obtain the bi-pass nanotube array film. The preparation process is reasonable in design and simple and convenient to operate, and the prepared bi-pass nanotube array film has high regularity and flatness and can be effectively applied to the fields of gas separation, drug delivery, nano templates and the like.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com