Manganese tungstate electrode material and preparation method thereof

An electrode material, the technology of manganese tungstate, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of difficult to meet industrial applications, cumbersome preparation process, narrow particle size distribution, etc., to achieve easy control of preparation parameters, simple process, The effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

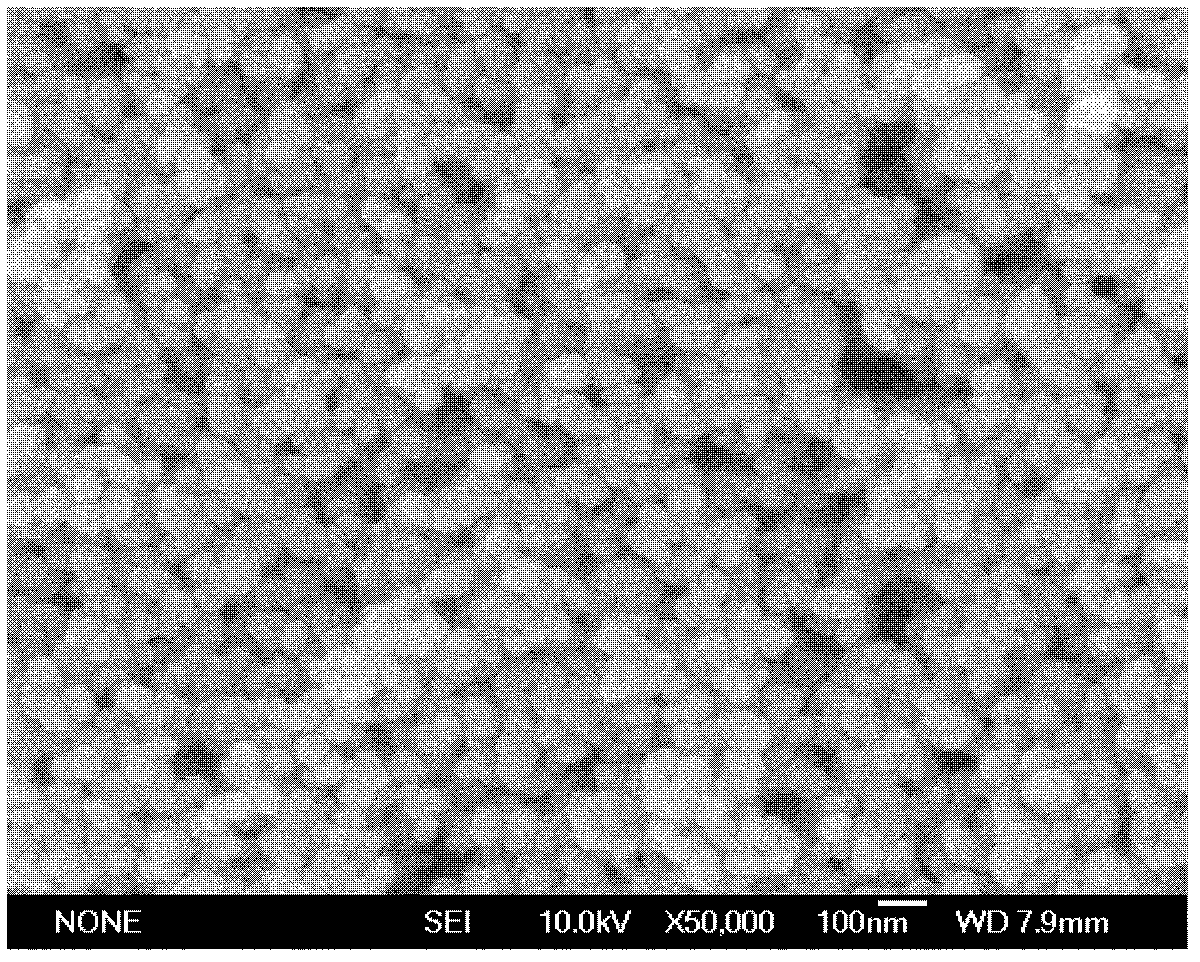

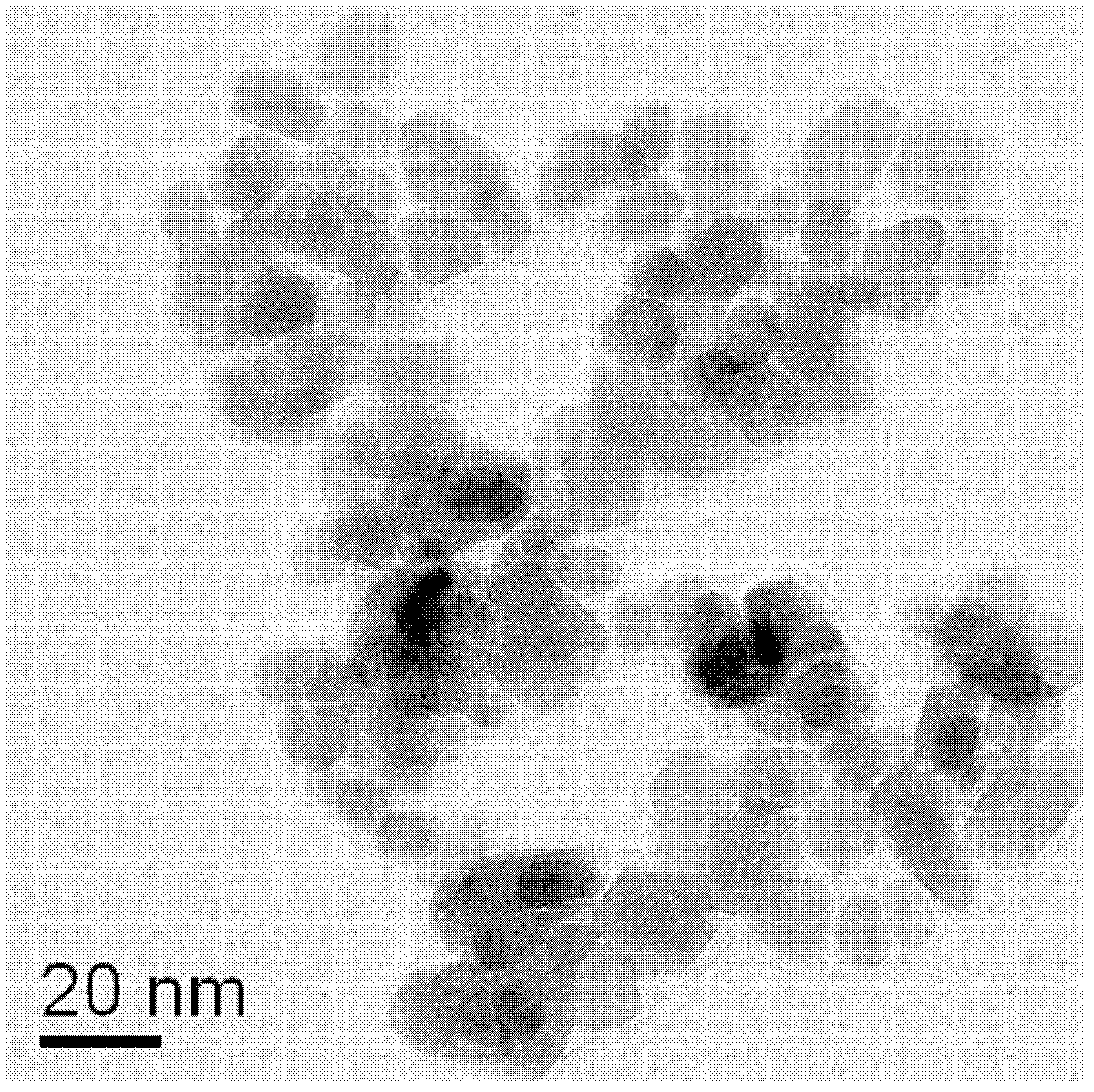

[0035] Using manganese sulfate and sodium tungstate as starting materials and citric acid as additive, dissolve them in deionized water to prepare a solution with manganese salt concentration and tungstate concentration of 0.21M, and the additive concentration is 0.75M; Stoichiometric ratio Measure a certain amount of manganese salt and tungstate solution and mix and stir for 1 hour to obtain an emulsion; under magnetic stirring, add the additive dropwise to the above emulsion to adjust its pH to 2; Put the emulsion into a hydrothermal kettle for heat treatment, control the temperature at 100°C, and react continuously for 16 hours, and then separate the reacted solution to obtain a precipitate; wash the obtained precipitate with deionized water several times, and heat it at 50°C After drying for 4 hours, the target product can be obtained, which can be used as a supercapacitor electrode material. The plasma emission spectrum of the synthesized material shows that the actual co...

Embodiment 2

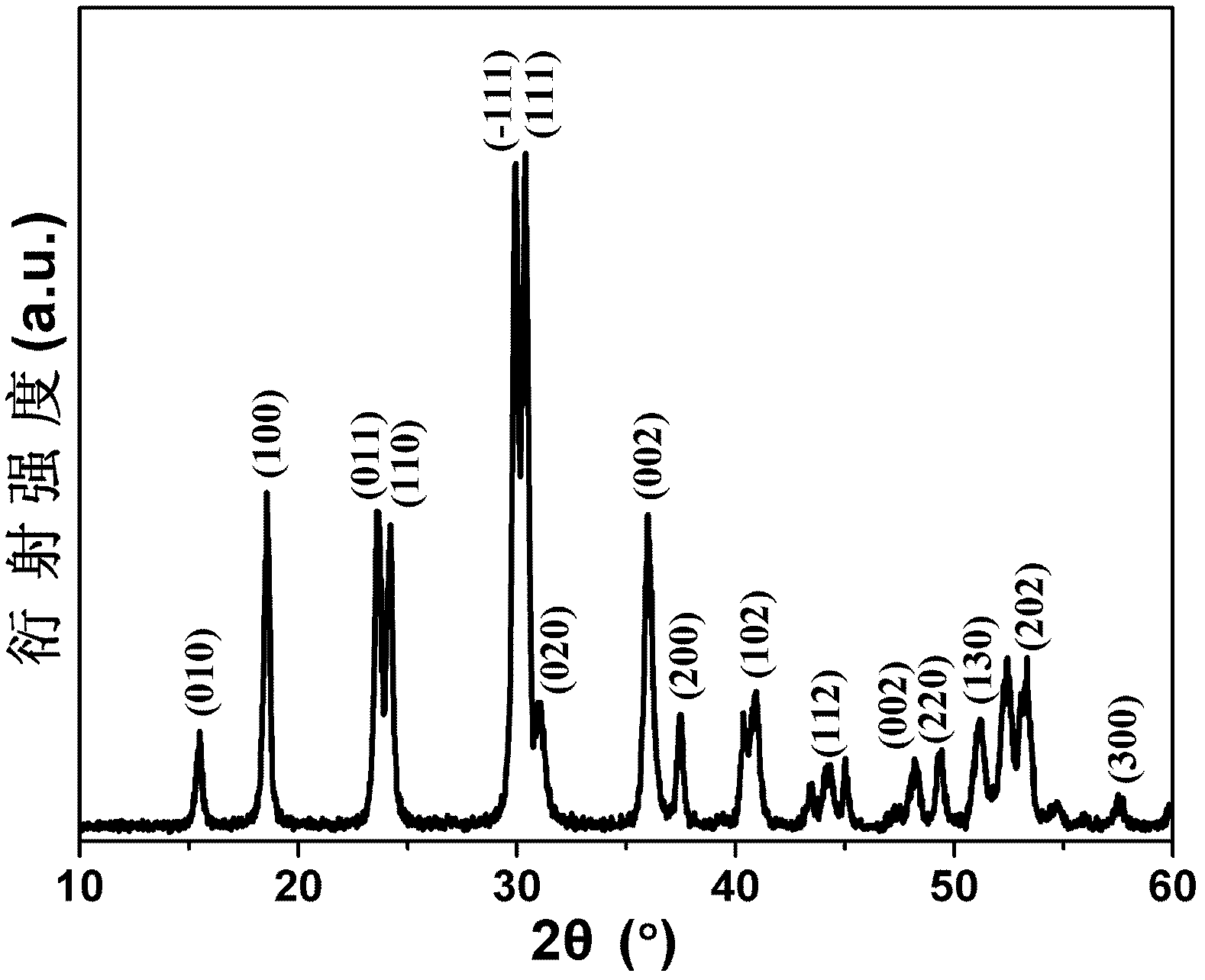

[0037] Using manganese chloride and sodium tungstate as starting materials and sodium hydroxide as additive, dissolve them in deionized water to make a solution with manganese salt concentration and tungstate concentration of 1M, and the additive concentration is 2.5M; massage According to the stoichiometric ratio, measure a certain amount of manganese salt and tungstate solution and mix and stir for 3 hours to obtain an emulsion; under magnetic stirring, add the additive dropwise to the above emulsion to adjust its pH to 12; The emulsion is put into a hydrothermal kettle for heat treatment, the temperature is controlled at 160°C, and the reaction is continued for 48 hours, and then the reacted solution is separated to obtain a precipitate; the obtained precipitate is washed several times with deionized water, and the After drying at ℃ for 4 hours, the target product can be obtained, which can be used as a supercapacitor electrode material. Image 6 For the X-ray diffraction s...

Embodiment 3

[0039] Using manganese nitrate and ammonium tungstate as starting materials and ammonia water as additive, dissolve them in deionized water to prepare a solution with manganese salt concentration and tungstate concentration of 0.46M, and the additive concentration is 0.5M; Metering ratio Measure a certain amount of manganese salt and tungstate solution and mix and stir for 12 hours to obtain an emulsion; under magnetic stirring, add the additive dropwise to the above emulsion to adjust its pH to 8; Put the turbid liquid into a hydrothermal kettle for heat treatment, control the temperature at 140°C, and react continuously for 24 hours, then separate the reacted solution to obtain a precipitate; wash the obtained precipitate with deionized water several times, and dry at 100°C After 2 hours, the target product can be obtained, which can be used as a supercapacitor electrode material. The X-ray diffraction analysis results show that its phase is manganese tungstate (P2 / c) with m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com