Patents

Literature

83results about How to "Process parameters are easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanorod-like lithium manganese phosphate anode material and preparation method thereof

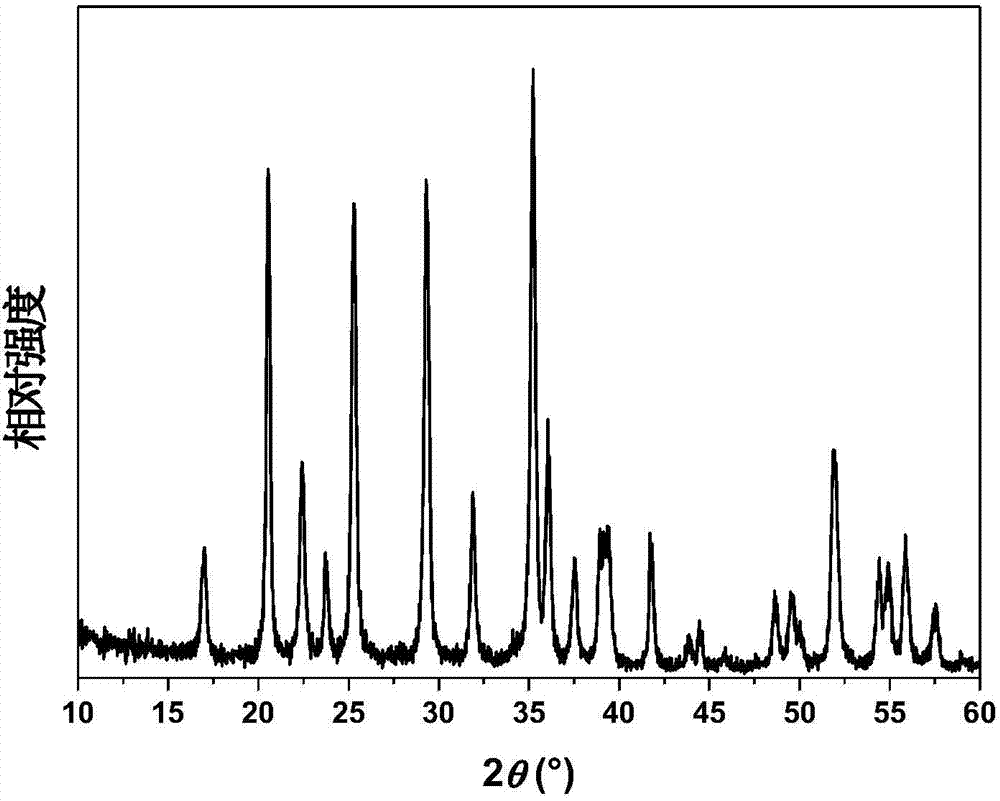

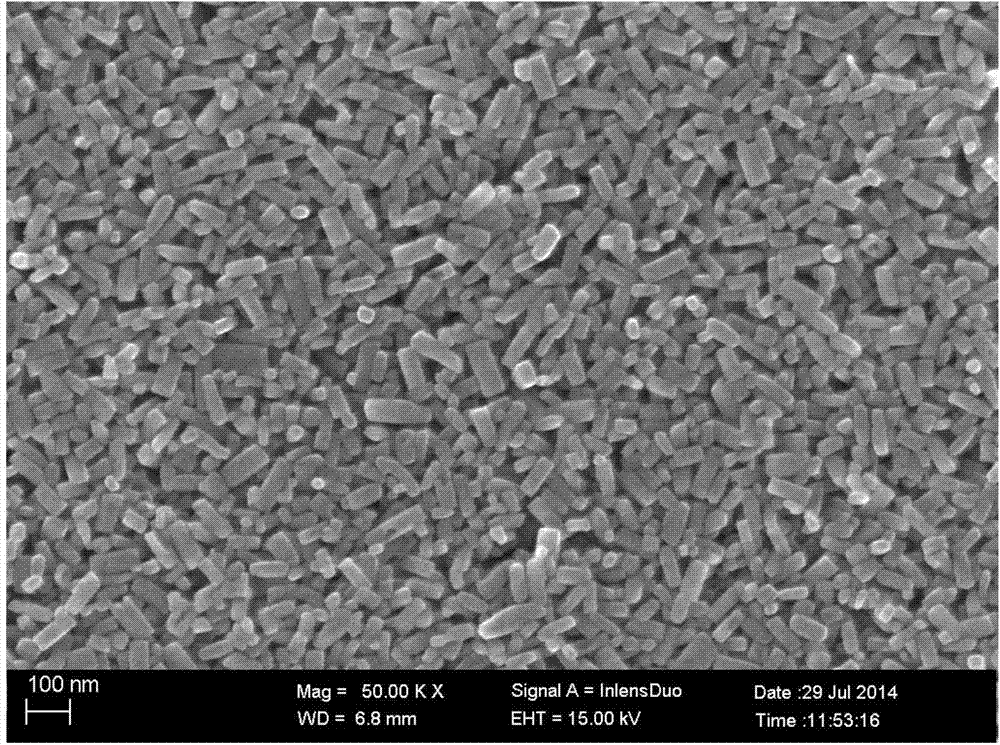

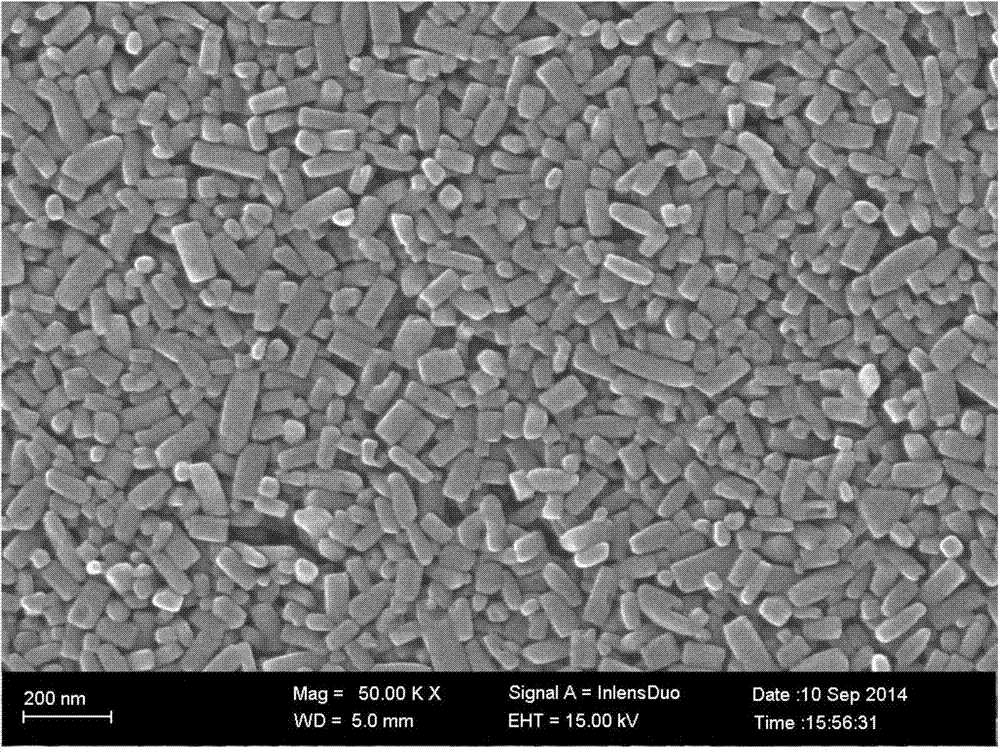

InactiveCN104766972ASimple reaction systemProcess parameters are easyMaterial nanotechnologyCell electrodesSolventSucrose

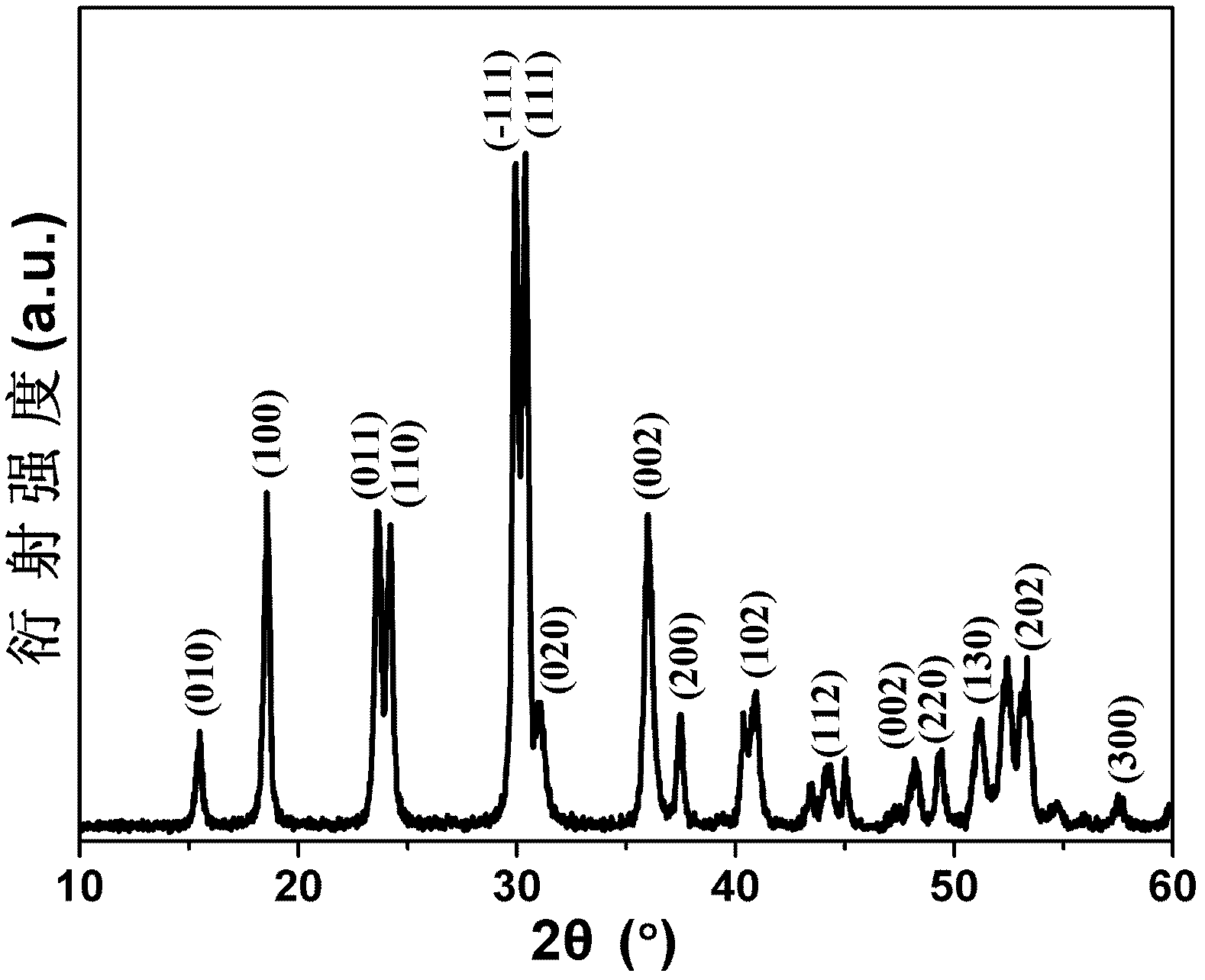

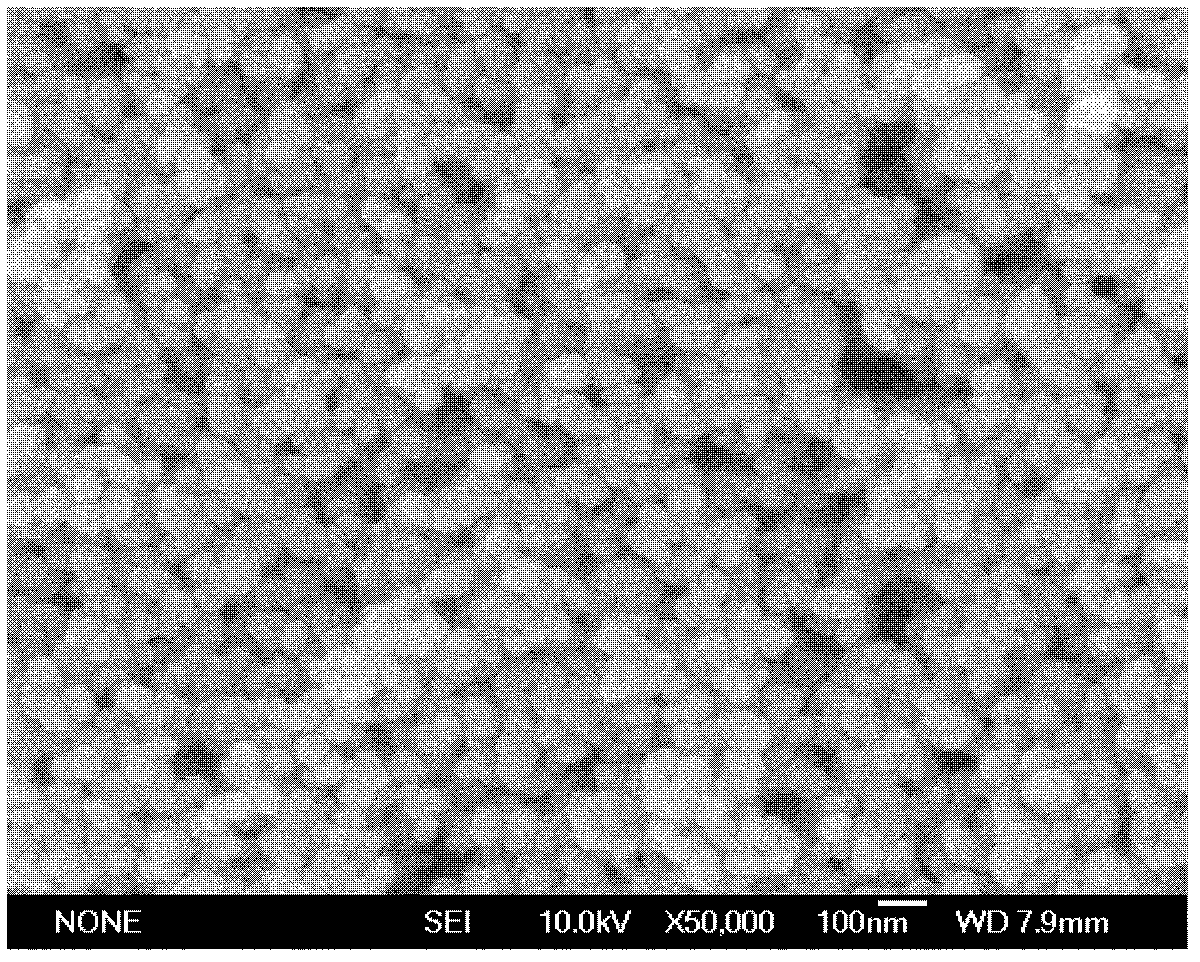

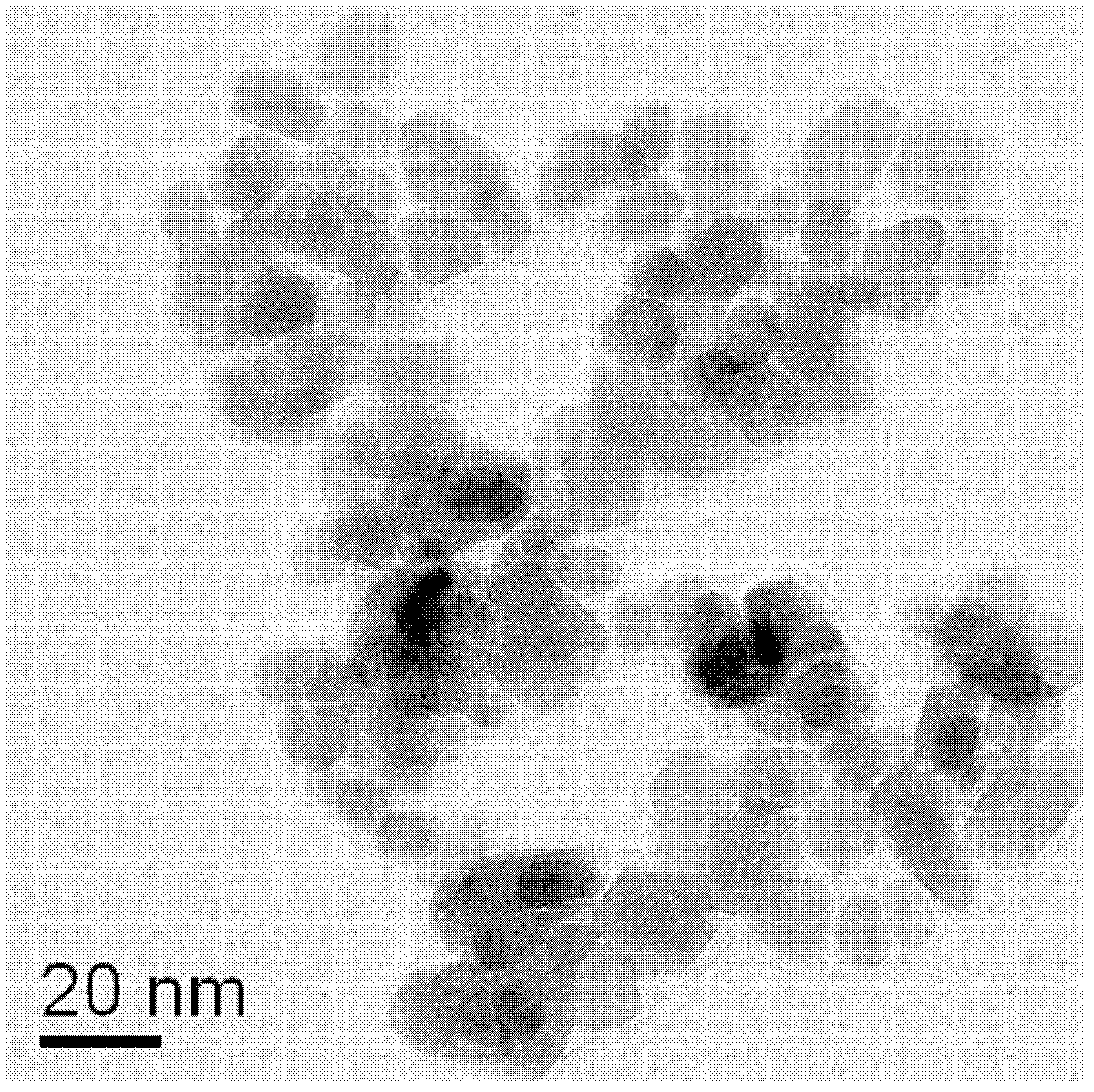

Belonging to the lithium ion battery material technical field in the field of new energy materials, the invention in particular relate to a nanorod-like lithium manganese phosphate anode material and a preparation method thereof. The method includes: taking ethylene glycol and water as the reaction solvent, synthesizing lithium manganese phosphate by a solvothermal technique, and then mixing the lithium manganese phosphate with sucrose to synthesize a carbon-coated lithium manganese phosphate anode material. The method provided by the invention has the characteristics of simple reaction system, easily controllable process parameters, short process, low preparation cost, and easy mass production, and further expands the research work of the lithium manganese phosphate preparation field. The product obtained in the invention has the advantages of high purity, small size, good particle dispersibility, thus being conducive to effective contact of an electrode material and an electrolyte solution, shortening the lithium ion diffusion distance, and improving the rate performance of the lithium ion battery. The lithium manganese phosphate anode material has a low carbon content, and a small amount of carbon coating can improve the material electronic conductivity and also ensures that the lithium ion battery with the product as the anode material can acquire high energy density.

Owner:TSINGHUA UNIV

Bacillus subtilis fermenting method with high rate of maturing gemma

ActiveCN102168055AEasy to get ingredientsLow priceBacteriaMicroorganism based processesLiquid productMicrobiology

The invention discloses a bacillus subtilis fermenting method with a high rate of maturing gemma and belongs to the field of microorganism fermentation engineering. In the method, the target products are produced by activation of bacillus subtilis and two-step fermenting culture. The method comprises the following steps of: inoculating the activated bacillus subtilis first, performing fermentation culture for 8 to 14 hours under the conditions that: the culture temperature is between 35 and 38 DEG C, the cylinder pressure is between 0.02 to 0.06 Mpa, the ventilation rate is 1:0.5-1:1 and the stirring revolution is between 150 and 200 rpm to obtain seed bacterial solution, and inoculating the seed bacterial solution and culturing for 20 to 36 hours to obtain bacillus subtilis liquid products with a high rate of maturing gemma. In the method, the components of the culture medium can be easily obtained and have low price, process parameters are simple, the fermentation period is short, the obtained bacillus subtilis is high in number of living bacteria as well as rate of maturing gemma, the rate of maturing gemma reaches more than 3.0*10<9>CFU / ml, and the number of maturing gemma and the quality of the products are obviously improved.

Owner:大连吉翔农业科技有限公司

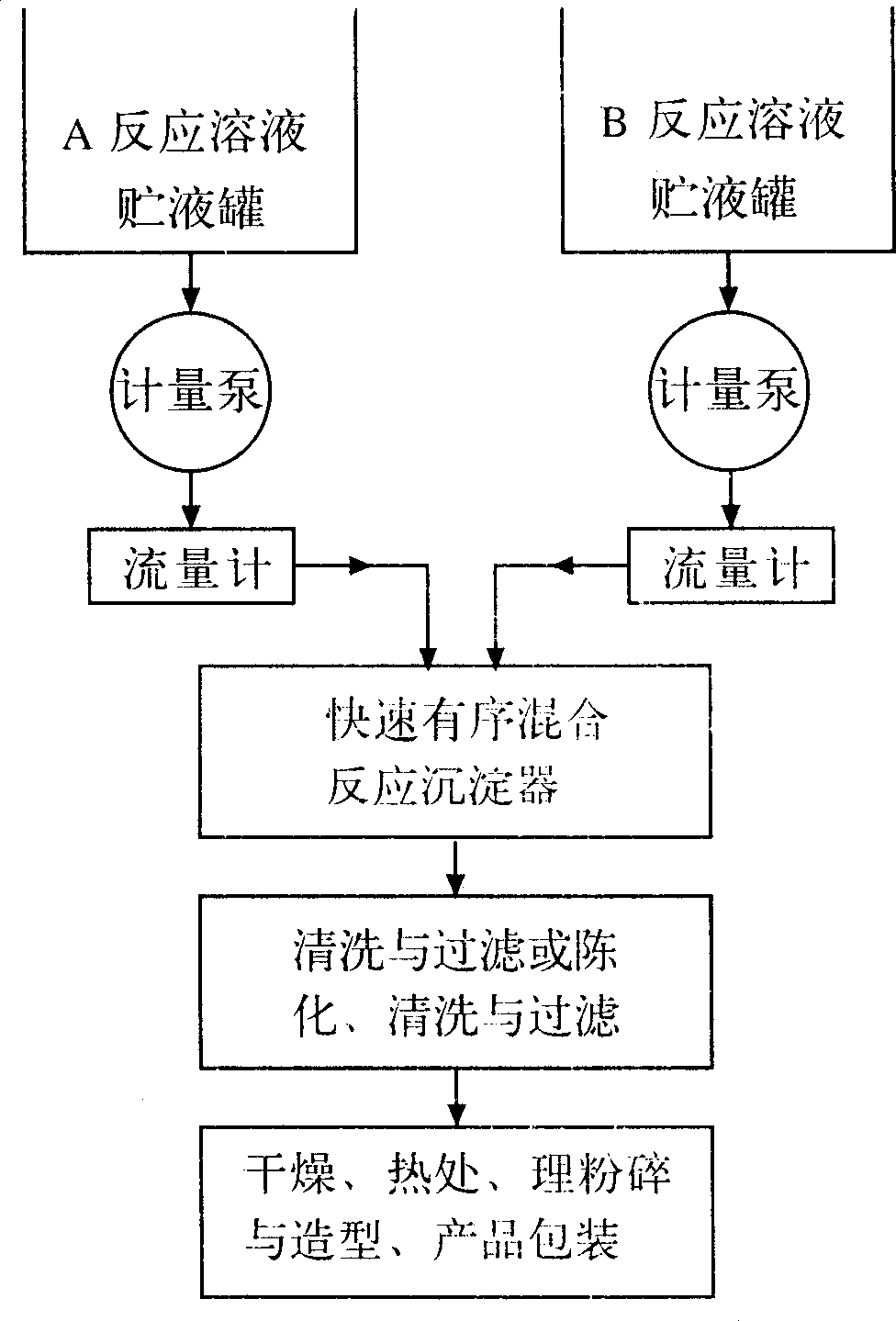

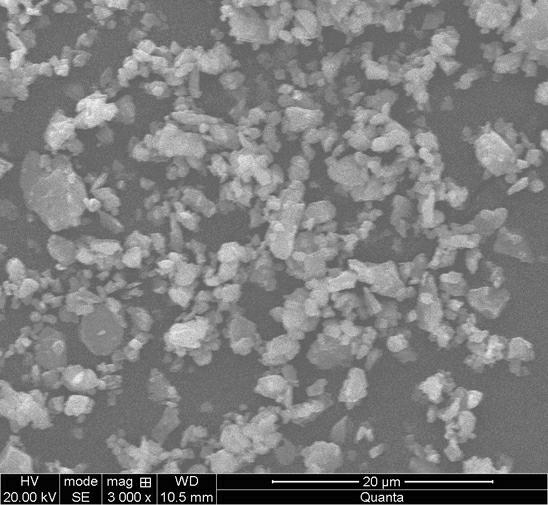

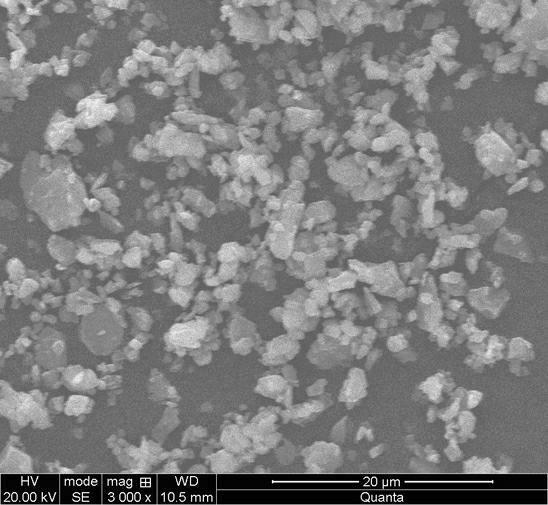

Liquid phase nano powder body and preparation method of nano particle agglutinative structure material

InactiveCN1400044ASmall particle sizeSmall and uniform particle sizeCalcium/strontium/barium carbonatesMaterial nanotechnologySlurryChalcoides

The present invention discloses a nano powder body and nano particle aggregative structure material preparation method. Said method can regulate and control grain size of nano particle, can make saidmaterial possess uniform grain size, good dispersion property and high yield. Its equipment is simple, and consumption is less. Said method mainly includes the following steps: continuously feeding reactant solution into quickly-mixing reaction precipitation equipment, and continuously discharging the precipitate-contained slurry material from said equipment, then making the slurry material undergo the processes of cleaning, filtering or ageing, cleaning and filtering, drying, heat treatment, pulverizing and packaging. Said method can be used for producing various nano powder body and nano particle aggregative structure materials.

Owner:UNIV OF SCI & TECH LIAONING

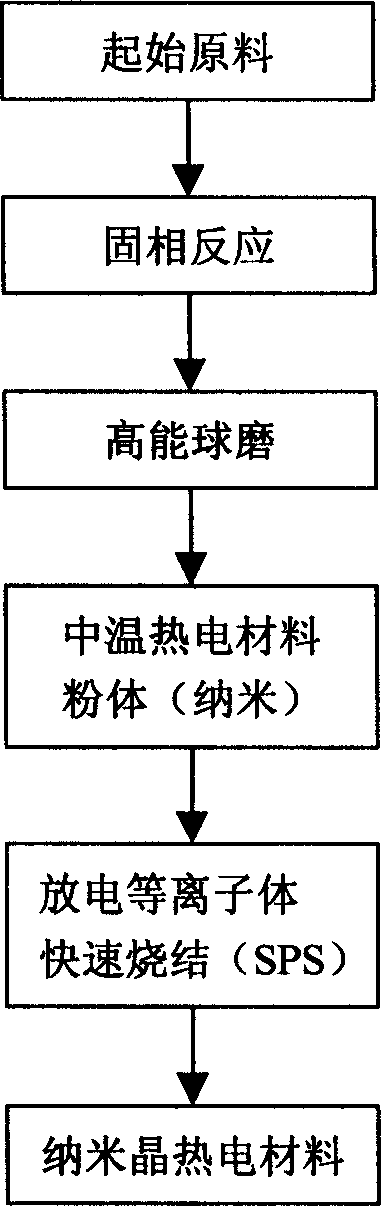

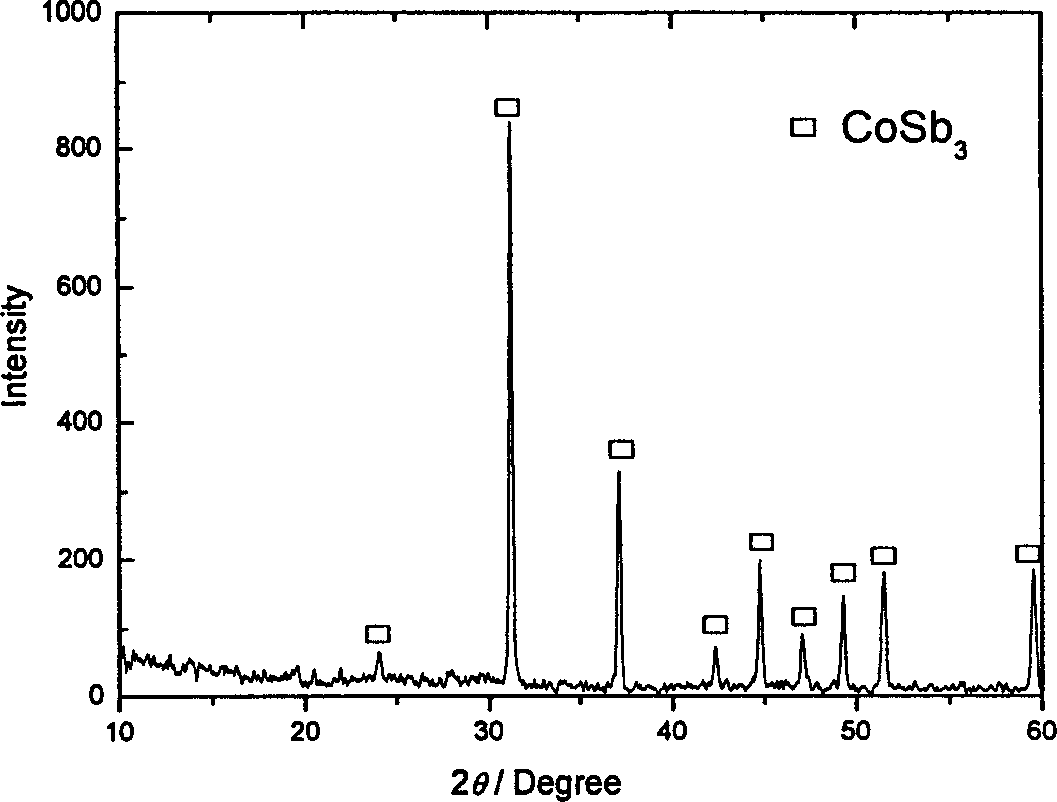

Preparation method for nano skutterudite compound pyro electric material

InactiveCN1594623ASimple preparation processProcess parameters are easyCrystalliteSolid state reaction method

The invention relates to nanometer skutterudite compound thermoelectric material preparation method, i.e. combining high-energy ball milling method with discharging plasma sintering for preparing nanometer skutterudite compound thermoelectric material. Cobalt powder and antimony powder available in the market are used as material, and skutterudite compound CoSb#-[3] is manufactured by solid phase reaction method, then high-energy ball wet milling is adopted, controlling material ball ratio, ball diameter grading, ball mill rotate speed and time, obtaining average grain diameter 50nm powder thermoelectric material, at last nano powder obtained is poured into mould, which is placed in discharging plasma sintering apparatus, obtaining mean crystalline grain size 100nm, high compactness degree,high performance CoSb#-[3] nanocrystalline thermoelectric material. The inventive method adopts nano powder as sintering material, and the discharge plasm sintering temperature is low, which is energy-saving and time-saving, being suitable for industrialized production.

Owner:WUHAN UNIV OF TECH

SnO2/TiO2 composite nanofiber photocatalyst and preparation method thereof

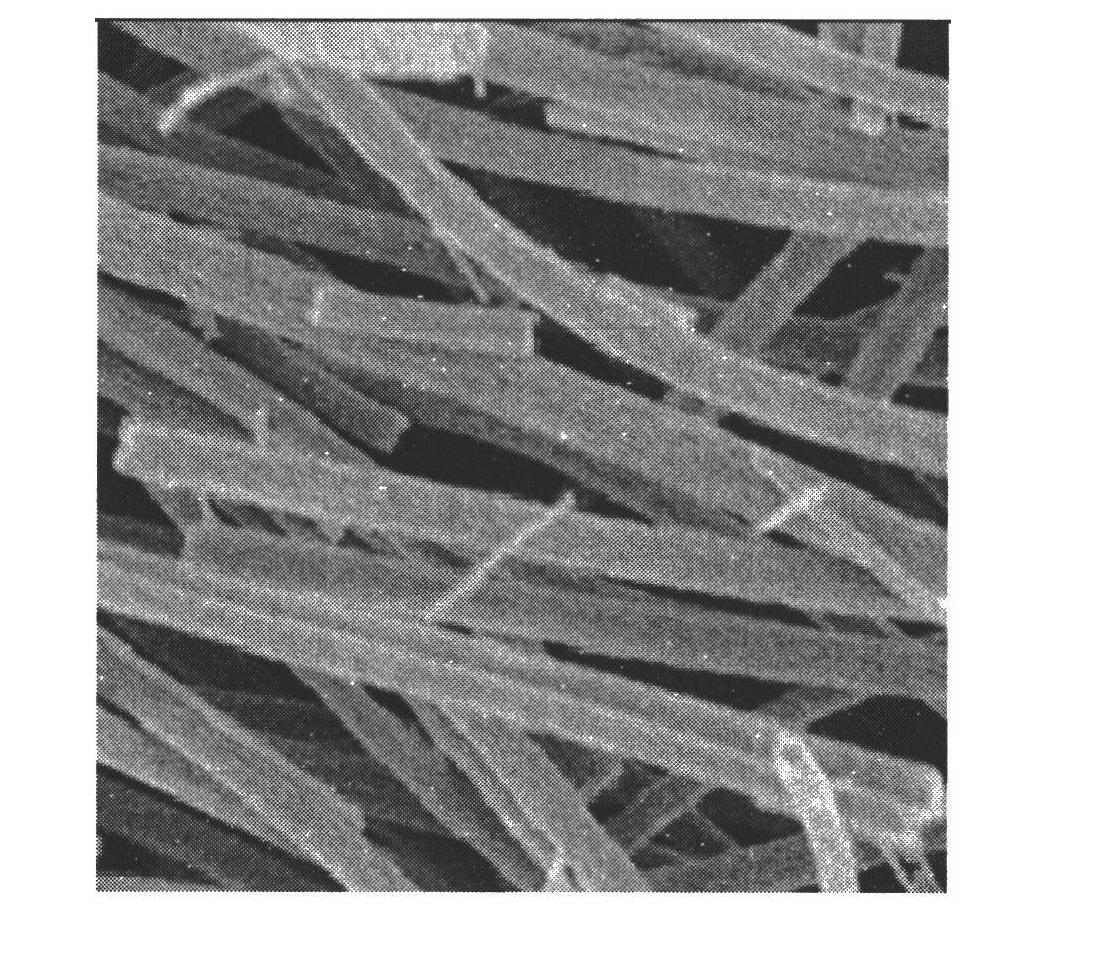

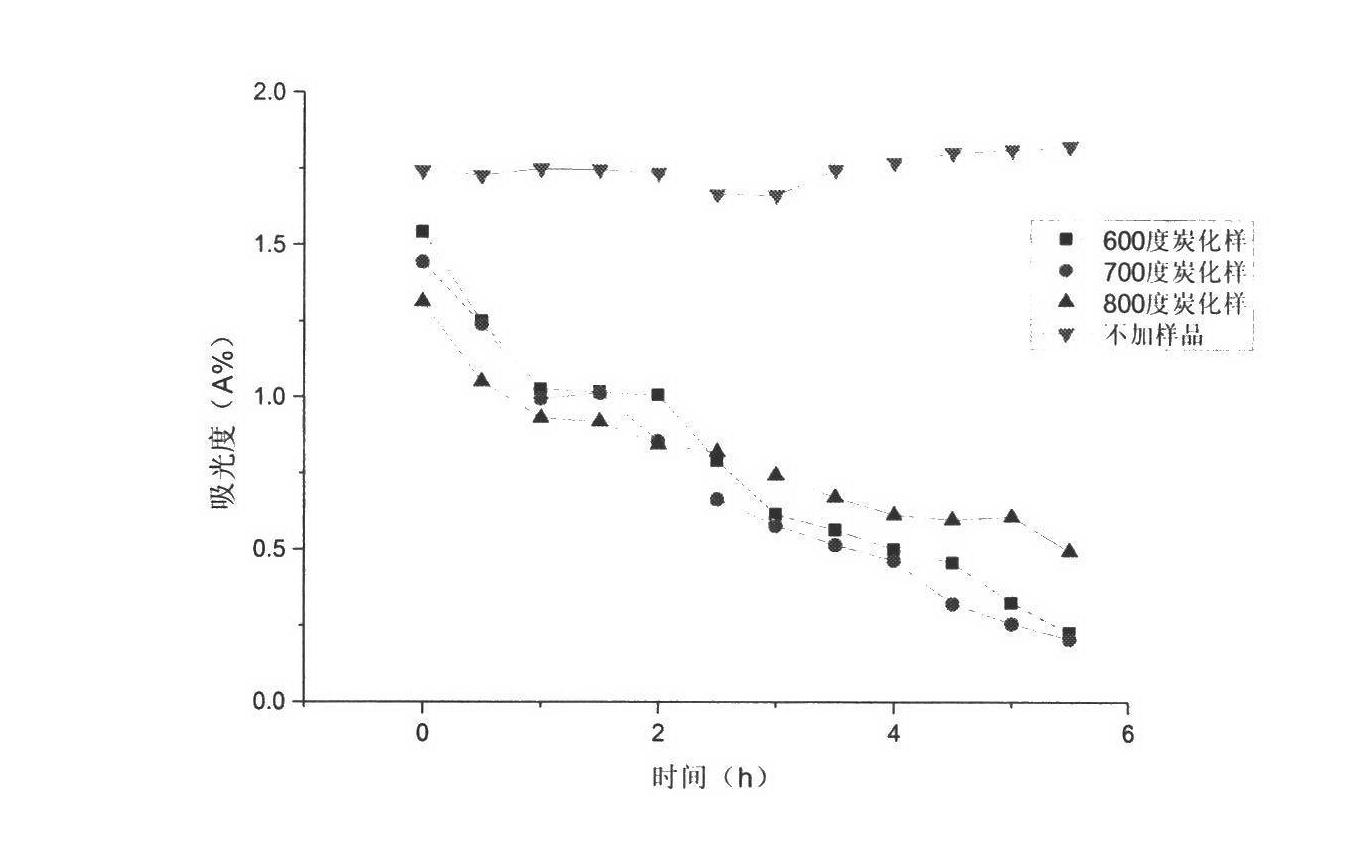

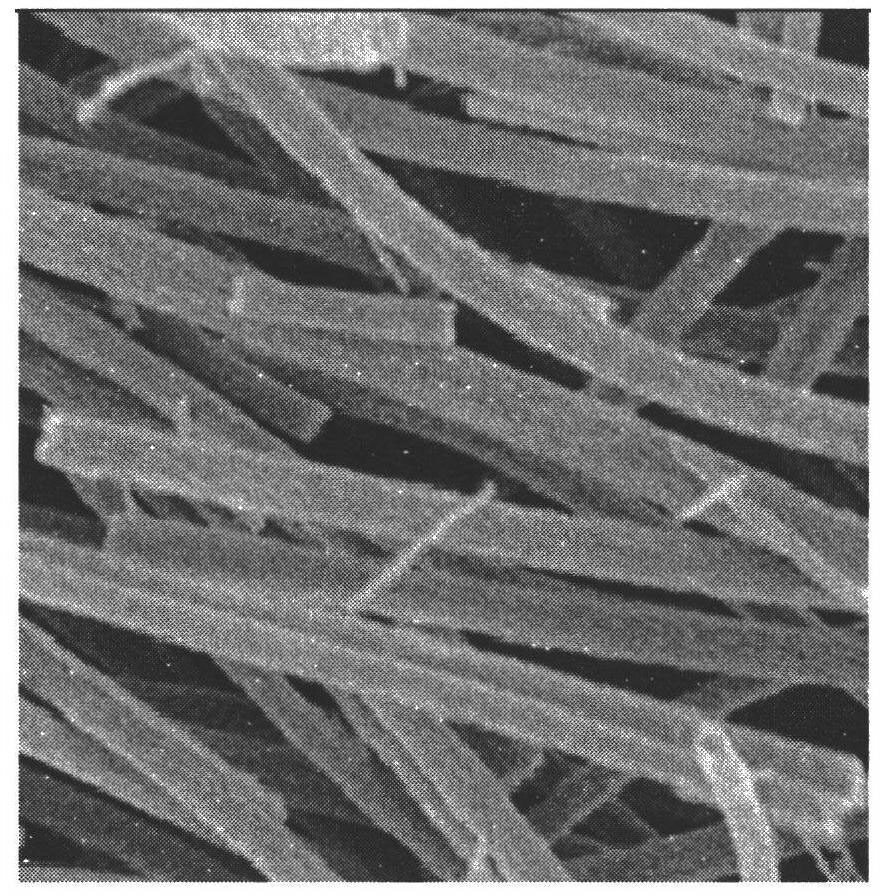

InactiveCN102489289ASimple preparation processProcess parameters are easyMetal/metal-oxides/metal-hydroxide catalystsElectron holeFiber

The invention relates to a SnO2 / TiO2 composite nanofiber photocatalyst and a preparation method thereof, and belongs to the technical fields of macromolecular materials and photocatalysis. SnO2 / TiO2 composite nanofibers prepared by the method are used as a photocatalytic material, the problem of low separation efficiency of a titanium dioxide photon-generated carrier is solved, and the stability of a photo-generated electron-hole pair is increased, so that the photocatalytic activity of titanium dioxide is improved. According to the method, the composite nanofibers are obtained by directly using an electrostatic spinning technology and through calcination in air, and a sol-gel technology with multiple influencing factors is not introduced. The process of preparing the composite nanofibers is optimized, and the adjustment of process parameters is simplified. The material prepared by the method is used as the photocatalytic material, the photocatalytic activity of the material is far higher than that of pure titanium dioxide, and the requirement and development direction of a new-generation titanium dioxide photocatalytic material are met.

Owner:JIANGNAN UNIV

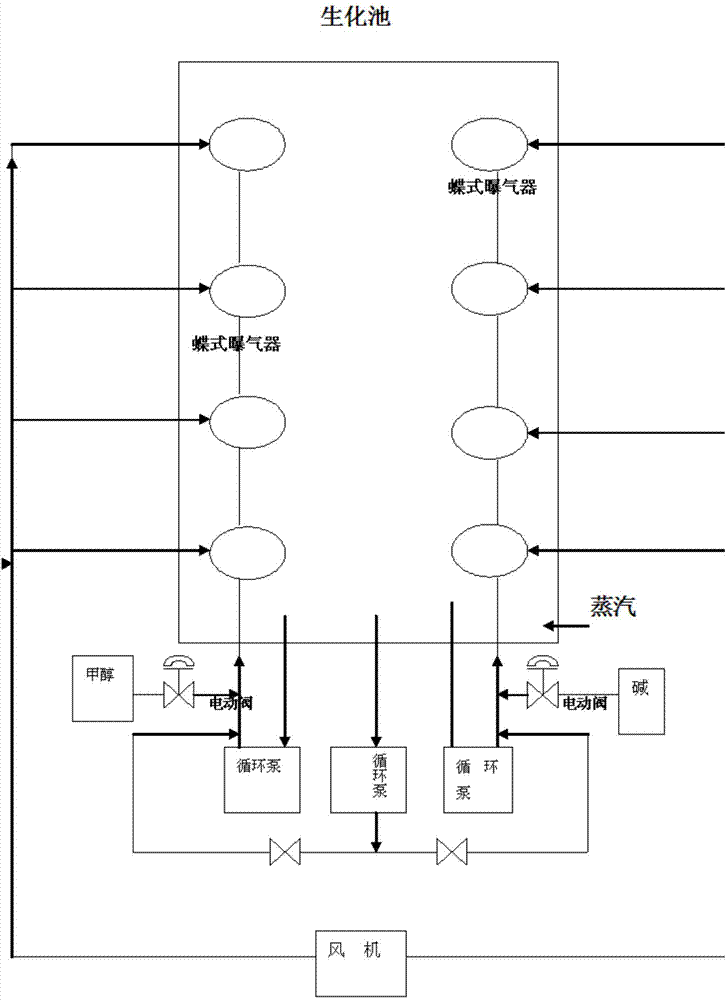

New technology for treating coking wastewater and wastewater from coal chemical industry

ActiveCN103288298AProcess parameters are easyAdjust process parametersMultistage water/sewage treatmentWater/sewage treatment by degassingChemistryCoal chemical industry

Owner:TIANJIN REDSUN WATER IND

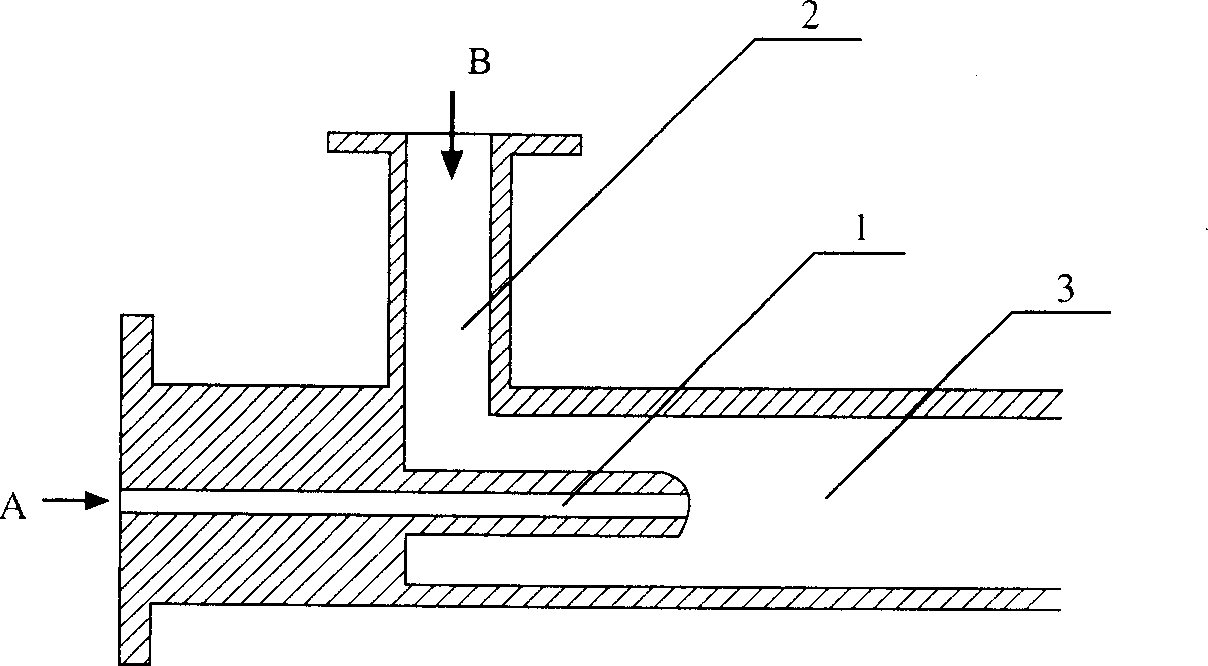

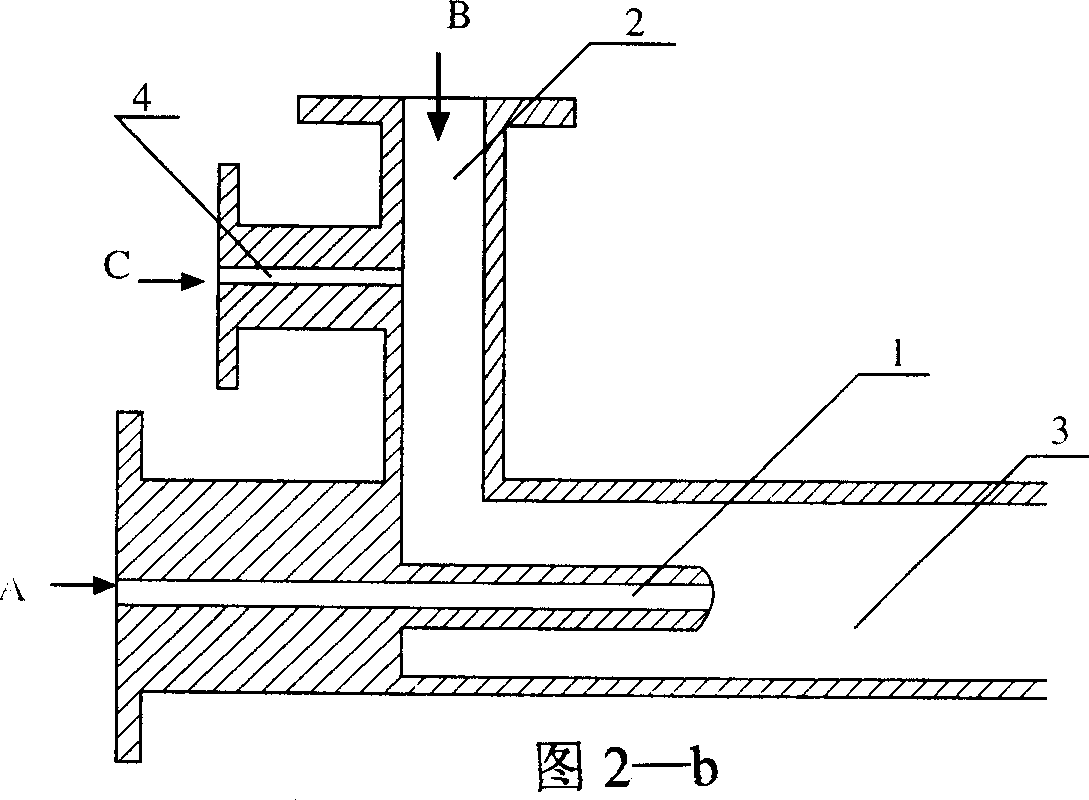

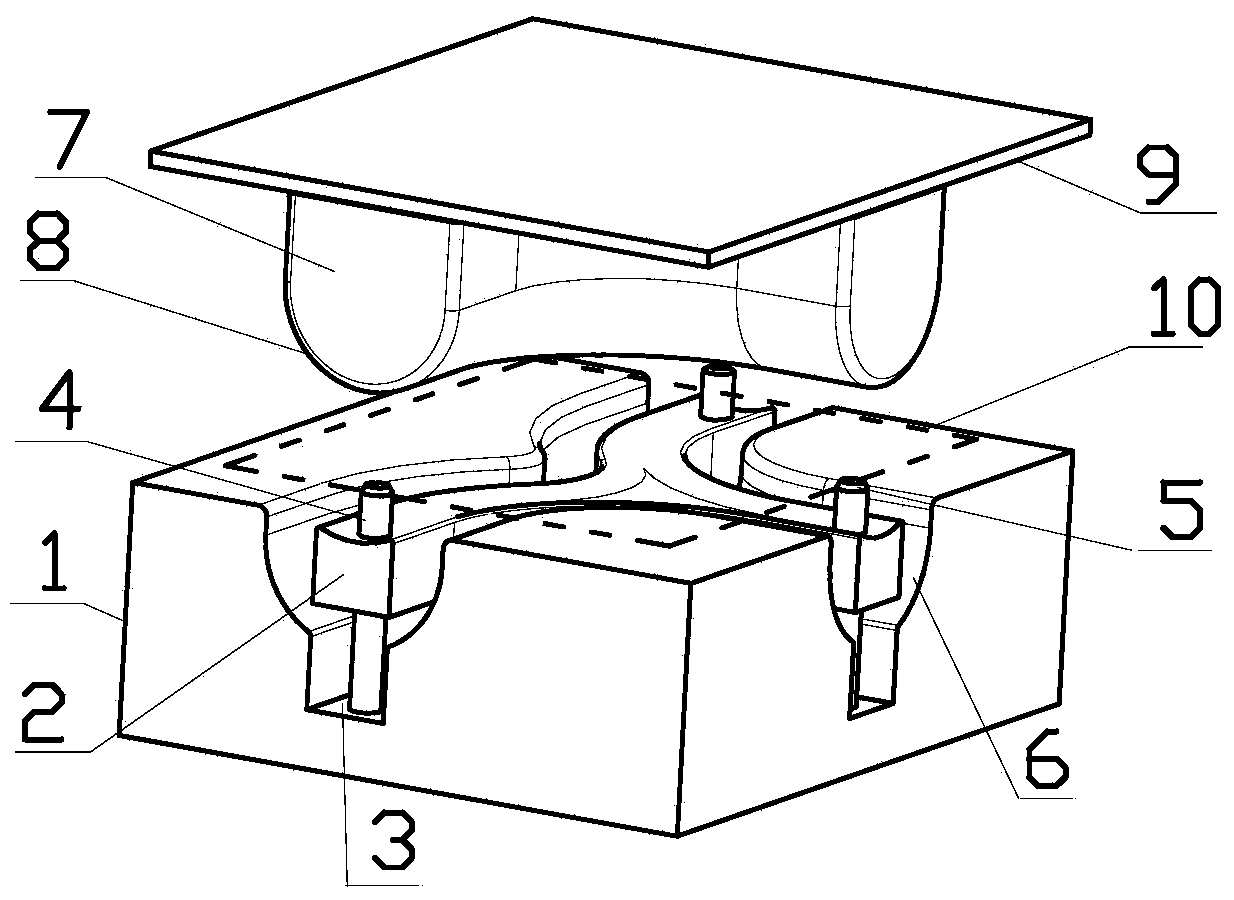

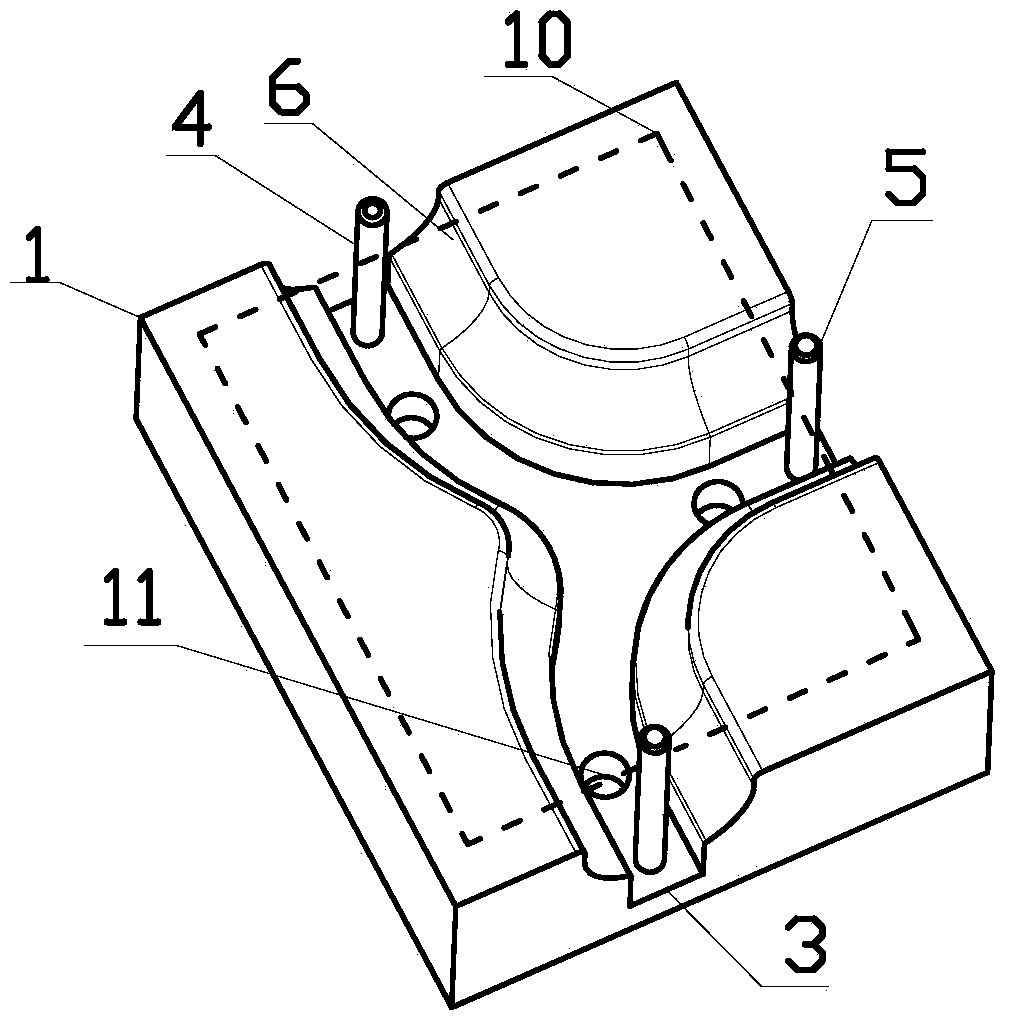

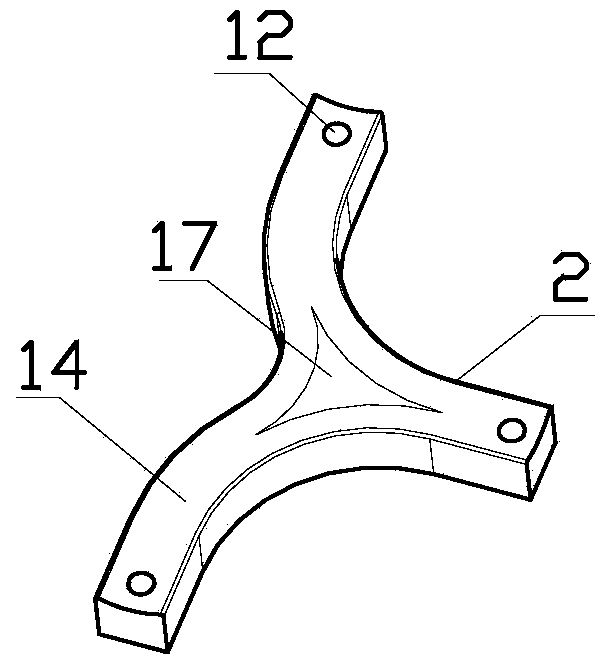

Forming method of tee joint half-tube part and compound punching die

The invention provides a punching forming method of a tee joint half-tube part and a die. The punching die comprises a lower die body, an upper die body and a pressing block, wherein the lower die body is provided with a concave face, a receding groove, a guide column and an ejection rod through hole, the pressing block corresponds to the receding groove in shape, the pressing block is provided with a first guide hole corresponding to the guide column, the upper die body is provided with a convex face corresponding to the concave face, the convex face is provided with a second guide hole corresponding to the guide column, an unfolded rough material is arranged between the convex face of the upper die body and the upper surface of the pressing block, and the part is formed after the upper die body and the pressing block press the rough material and die closing is carried out.

Owner:XI'AN AIRCRAFT INTERNATIONAL

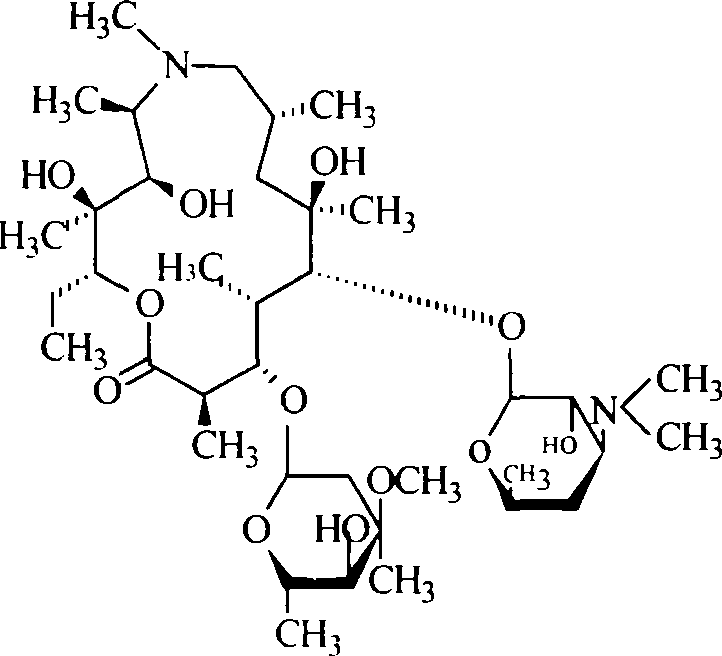

Slow released dry azithromycin suspension and its prepn

InactiveCN1887272ASlow release rateImprove complianceAntibacterial agentsPowder deliveryMicrosphereAcrylic polymer

The present invention provides one kind of slow released dry azithromycin suspension and its preparation process. The medicine of the present invention has slow released azithromycin microsphere prepared through spray drying process, and capsule wall material for coating azithromycin medicine made of viscous medicinal polymer material or insoluble medicine polymer material, such as acrylic polymer, gelatin, Arabic gum, carboxymethyl cellulose salt, etc. and preferably of acrylic polymer. The slow released dry azithromycin suspension has improved administration compliance and convenience, and high bioavailability.

Owner:漆新国 +2

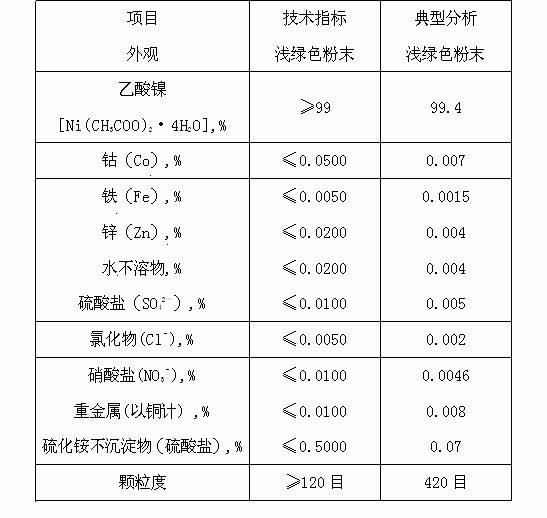

Production process of coarse particle nickel acetate

InactiveCN102020550ASimple production processProcess parameters are easyCarboxylic acid salt preparationCarboxylic compound separation/purificationChemistryMother liquor

The invention discloses a production process of superfine powdered nickel acetate, which comprises the following steps: synthesis: reacting glacial acetic acid and basic nickel carbonate under the condition of stirring according to the molar ratio, adding the glacial acetic acid and the basic nickel carbonate in batches, and continuously reacting until all substances are fully reacted, wherein the adopted industrial firstclass glacial acetic acid has the content of over 99.5%, the adopted basic nickel carbonate has the Ni content of 19+ / -1%, and the molar ratio of the basic nickel carbonate to the glacial acetic acid is 1:1.1-1.5; dehydration: performing solid-liquid separation on the well synthesized nickel acetate, and recycling the mother liquor; and drying to obtain the superfine powdered nickel acetate. The invention has simple production processes, easily controlled process parameters, small environment pollution, high production efficiency, high one-time recovery, no special requirements for production equipment, low labor intensity and less process consumption; and compared with the existing nickel acetate powder in the market, the obtained product has obviously improved quality, stability, reliability and good process repeatability which is proved by large-scale industrialized production.

Owner:江西核工业兴中科技有限公司

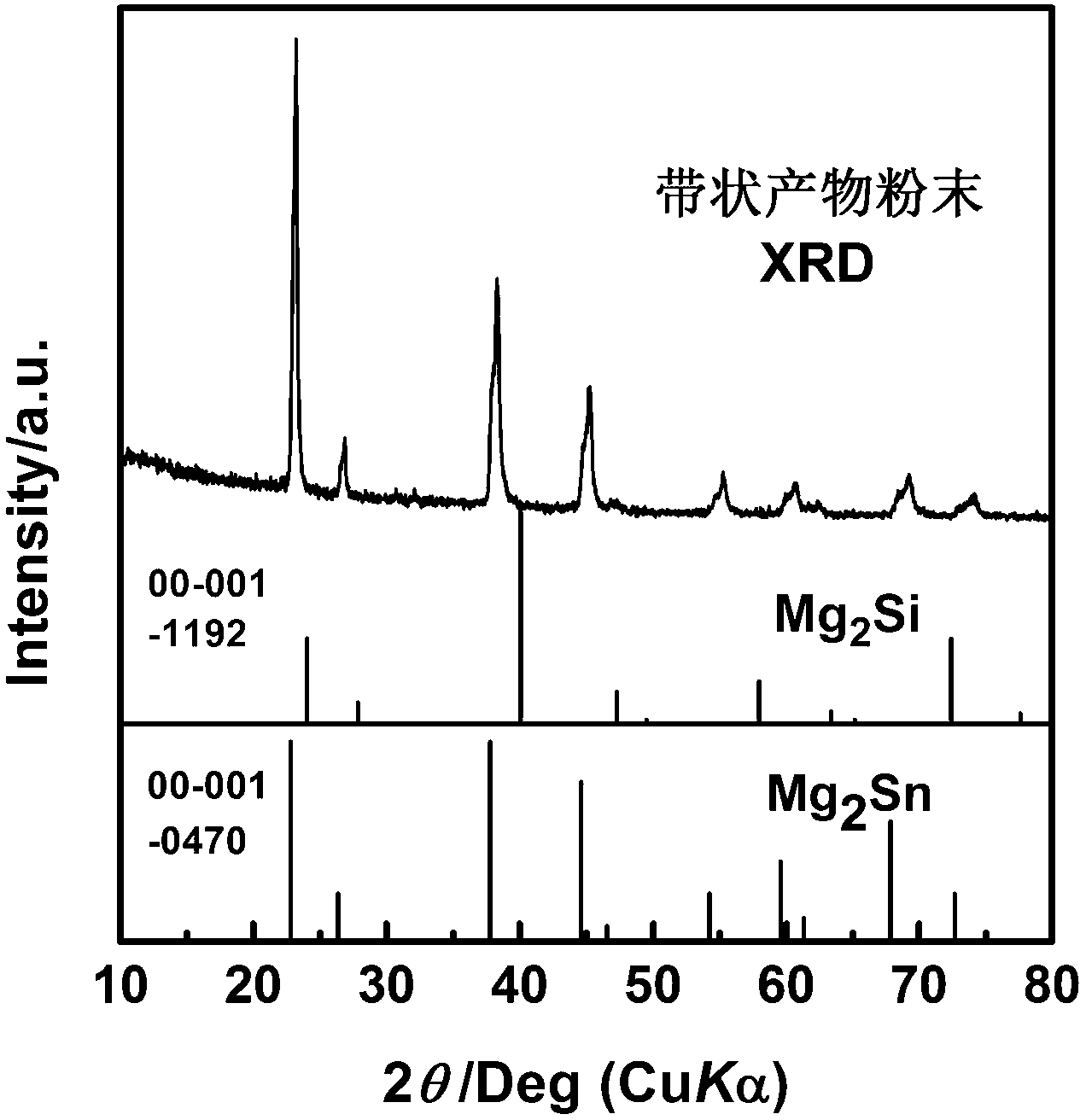

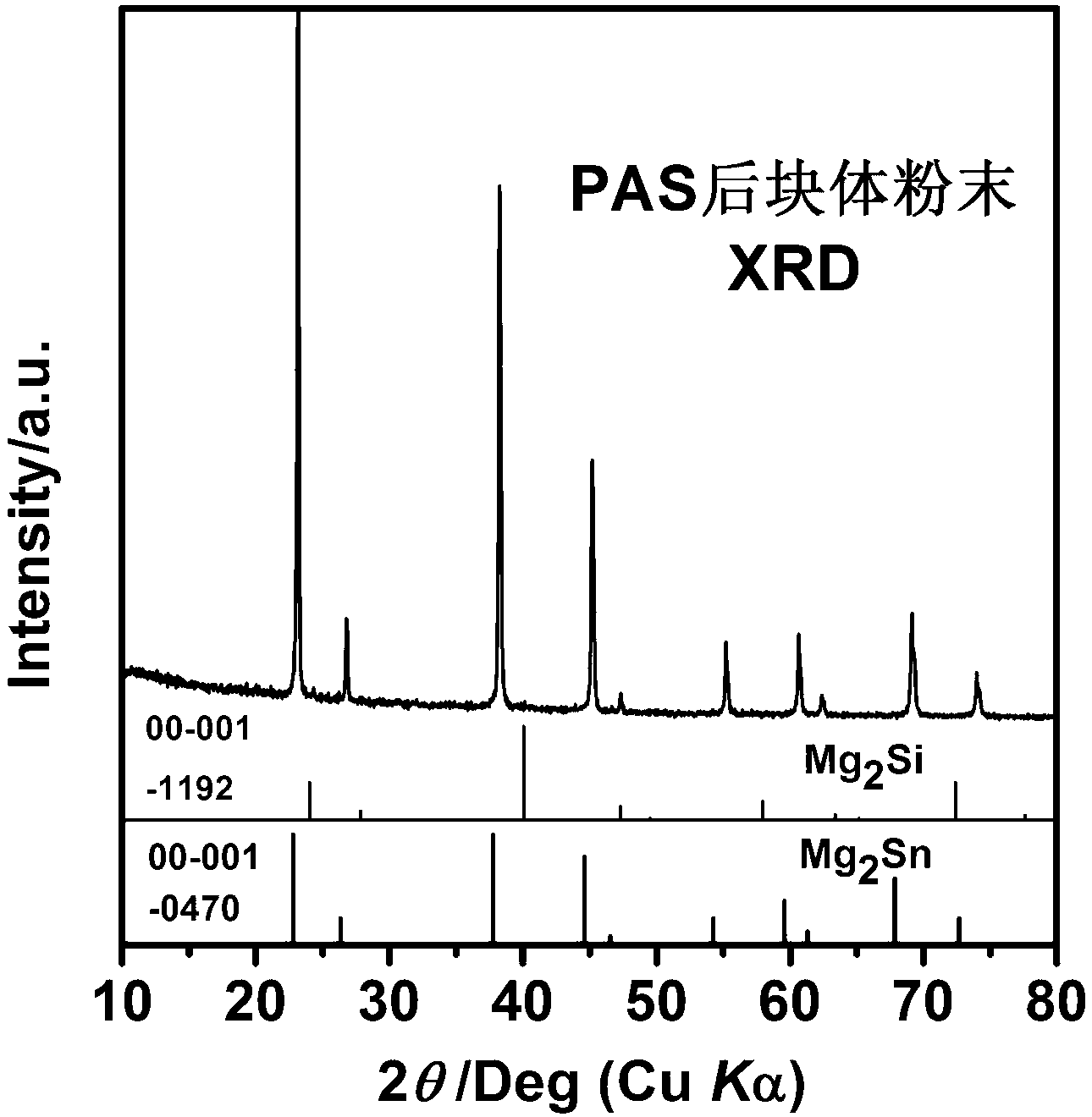

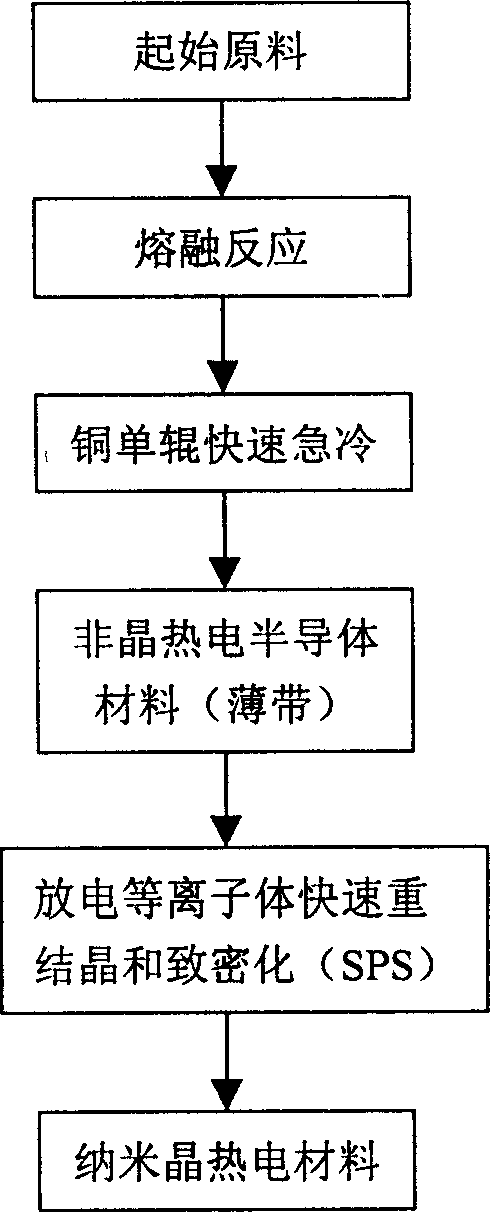

Novel method for quickly preparing high-performance Mg2Si0.3Sn0.7-based thermoelectric material

ActiveCN103320636ASimple preparation processShort reaction timeThermoelectric device manufacture/treatmentThermoelectric device junction materialsPhysicsPlasma activation

The invention relates to a novel method for quickly preparing a high-performance Mg2Si0.3Sn0.7-based thermoelectric material, which comprises the following steps of: 1) weighing according to the stoichiometric ratio of each atom in a thermoelectric material Mg2(1+0.08)(Si0.3Sn0.7)(1-y)Sby (0<=y<=0.025), uniformly mixing the raw material powder in a mortar, and pressing the uniformly mixed powder into a block; 2) putting the obtained block into a graphite crucible, and performing fusion spin-throwing in melt spin-throwing quenching equipment to obtain a Mg2(Si0.3Sn0.7)(1-y)Sby strip product; and 3) grinding the Mg2(Si0.3Sn0.7)(1-y)Sby strip product into powder, and performing discharge plasma activation sintering to obtain the high-performance Mg2Si0.3Sn0.7-based thermoelectric material. The method provided by the invention has the characteristics of energy saving, short preparation time, simple technological parameters and the like; and the thermoelectric merit figure ZT of the obtained block can reach 1.3.

Owner:WUHAN UNIV OF TECH

Purification process of desulfurization gypsum and gypsum raw materials purified through process

InactiveCN102616825ASimple processProcess parameters are easyCalcium/strontium/barium sulfatesGranularityImpurity

The invention discloses a purification process of desulfurization gypsum and gypsum raw materials purified through the process, which solve the problems that the existing purification process of desulfurization gypsum has large energy consumption and complex process, and the purified product has low purity. The purification process of the desulfurization gypsum comprises the following steps of material extracting, grinding and screening, primary ball-milling, scouring, flotation, clarification, and secondary ball-milling; and integrates physics, chemistry, mineral separation, powder preparation and other processing technologies into a whole. The product prepared by the process has high quality, and has the whiteness reaching to 93-95 percent. The purification process of the desulfurization gypsum and the gypsum raw materials purified through the process have the advantages that the process is simple, the practicability is strong, the energy consumption is low, the impurities extracted from the gypsum are fewer, and the granularity of the product is more uniform.

Owner:HENAN UNIV OF URBAN CONSTR

Method for culturing bacillus subtilis through high-density fermentation

InactiveCN103992977AThe process parameters are simpleShort fermentation cycleBacteriaMicroorganism based processesBacilliCulture mediums

The invention discloses a method for culturing bacillus subtilis through high-density fermentation, belonging to the field of microbial fermentation engineering. The method is used for increasing the thalli yield and spore rate of the bacillus subtilis. The method comprises the steps of activating the bacillus subtilis and performing two-step fermentation culture to produce a target product. The method has the advantages that the components of a culture medium are readily available and cheap, the process parameters are simple, the fermentation period is short, the cell biomass of the obtained bacillus subtilis can reach over 9*10<9>cfu / ml, and the spore rate is over 90%. The quality and stability of the product are significantly improved.

Owner:WEIHAI GOLD FEED

Amorphous crystallization preparation method for nano crystal thermoelectric semiconductor material

A nanocrystalline thermoelectric semiconductor material amorphous crystallization production method is provided, compriseing the stepss of: first adopting high-frequency heating and obtaining uniform alloy melt at 1100 DEG C, then cooling smelt to get thin strip or filament shaped amorphous sample using liquid phase quenching method, cooling speed being 10<5>-10<6> DEG C / sec, grinding amorphous sample and place in mould, placing mould in discharge plasm fast recrystallization and densification sintering apparatus, recrystallization and densification temperature being 600 DEG C, pressure 30Mpa,time 7-8min, obtaining high purity, average mean crystal grain size 70-80nm,uniform crystalline grain, high performance block nanocrystalline thermoelectric semiconductor material. The invention provides a technology for scale preparation of block nanocrystalline thermoelectric semiconductor material.

Owner:WUHAN UNIV OF TECH

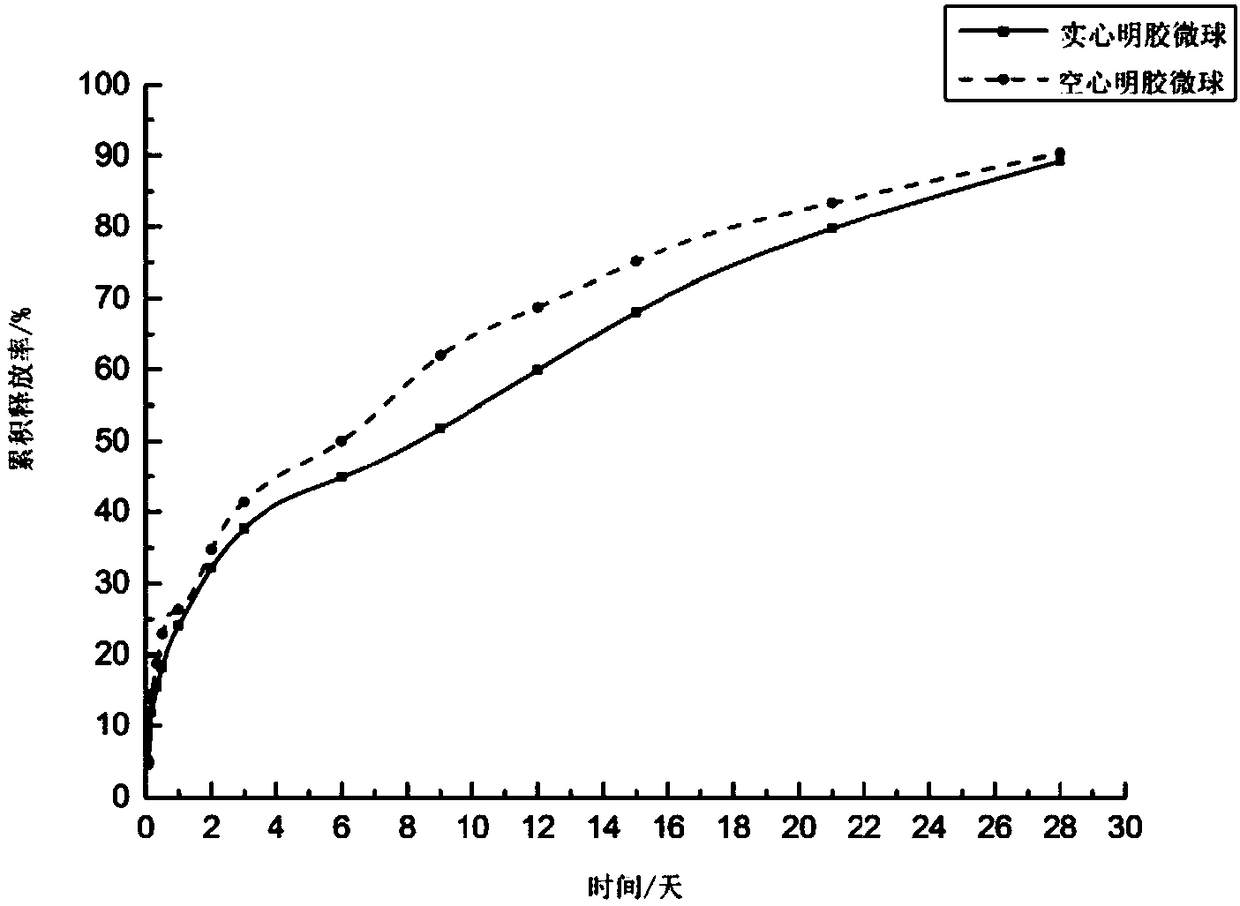

Hollow slow-release microsphere used for loading medicine and preparation method thereof

ActiveCN108451925AGood biocompatibility and degradabilityLow pricePeptide/protein ingredientsMacromolecular non-active ingredientsDrugPolystyrene microsphere

The invention discloses a hollow slow-release microsphere used for loading medicine and a preparation method thereof, and belongs to the technical field of medical slow-release microspheres. The method comprises the steps that an emulsification-crosslinking method is adopted to coat a shell-layer polymer material on the surface of a polystyrene microsphere to obtain the core-shell structure microsphere with the polystyrene microsphere as the core and with gelatin, sodium alginate tech grade, chitosan and polylactic acid as the shell, then the core polystyrene microsphere is immersed, dissolvedand removed through tetrahydrofuran, crosslinking and solidification are carried out on the microsphere to obtain the hollow slow-release microsphere, then the medicine is loaded on the hollow-structure microsphere, and the drug loading capacity of the medicine is greatly increased.

Owner:CENT SOUTH UNIV

Manganese tungstate electrode material and preparation method thereof

InactiveCN102664105AParticle size controllableUniform particle distributionElectrolytic capacitorsCapacitanceNanoparticle

The invention relates to a manganese tungstate electrode material and a preparation method thereof. A primary particle of the electrode material has a nanometer particle structure and a controllable particle size of 5 to 500 nm. A manganese tungstate super-capacitor electrode material which is prepared by the method has specific capacitance of more than 153 F.g<-1>. Compared with the conventional preparation method, the preparation method has the advantages of operability, practical process, high reproducibility, low cost, high material purity, high electrochemical performance and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

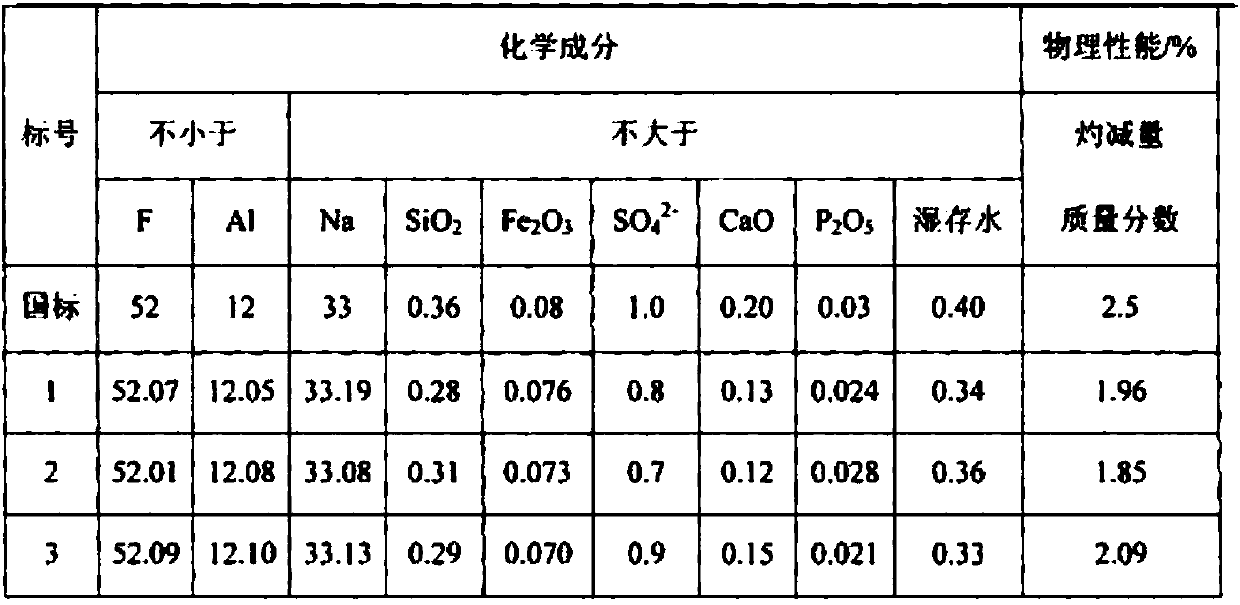

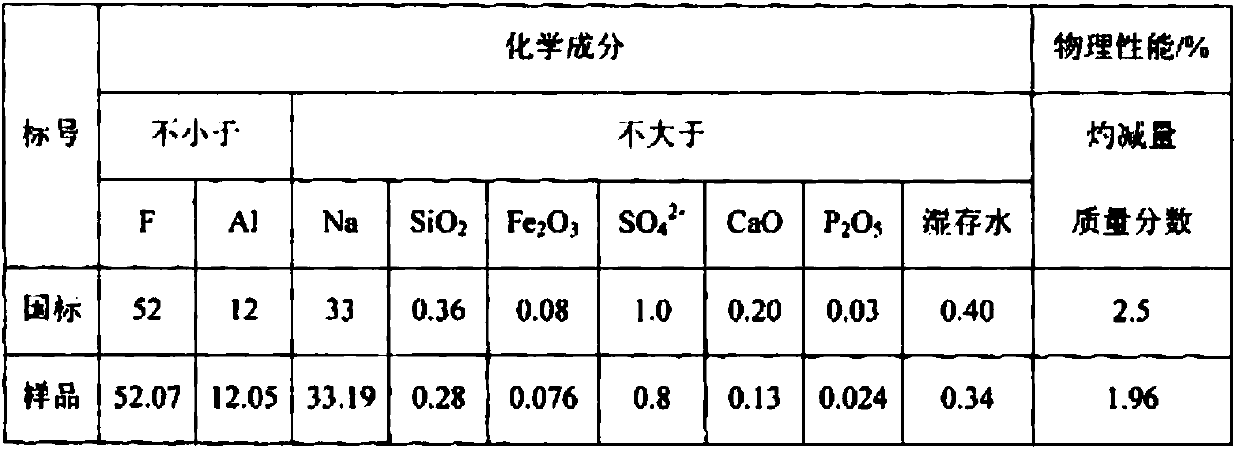

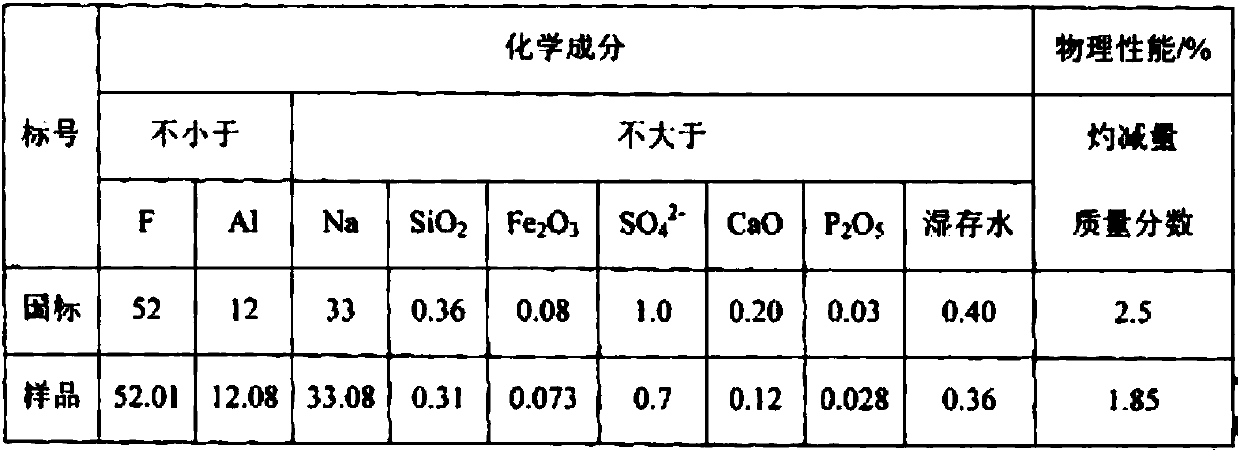

Process for preparing cryolite by using HF (hydrogen fluoride) waste liquid and cryolite prepared through process

InactiveCN107720795ASimple processProcess parameters are easyAluminium fluoridesSocial benefitsChemical treatment

The invention discloses a process for preparing cryolite by using HF (hydrogen fluoride) waste liquid and cryolite prepared through the process. By the process, the cryolite is prepared by a series ofprocedures including liquid selection, adjustment of acidity and alkalinity, preliminary stirring, preliminary filtering, material adding, secondary stirring, secondary filtering, washing, and drying. The process is simple and convenient to operate and realize; furthermore, process parameters of each step are simple; by integration of physical and chemical treatment processes, the process is highin operability; the whole process is higher in operability, higher in safety coefficient and lower in energy consumption; the prepared cryolite can meet the quality standard; furthermore, a feasiblemeasure is provided for treatment of HF waste liquid, so that aims of treating wastes by wastes and turning wastes into treasures are fulfilled; the waste HF does not generate waste CaF2 anymore, andthe aims of industrial discharge reduction, resource recycling, green technology and reclamation of the wastes are completely fulfilled; the process has very important economical and social benefits.

Owner:达州励志环保科技有限公司

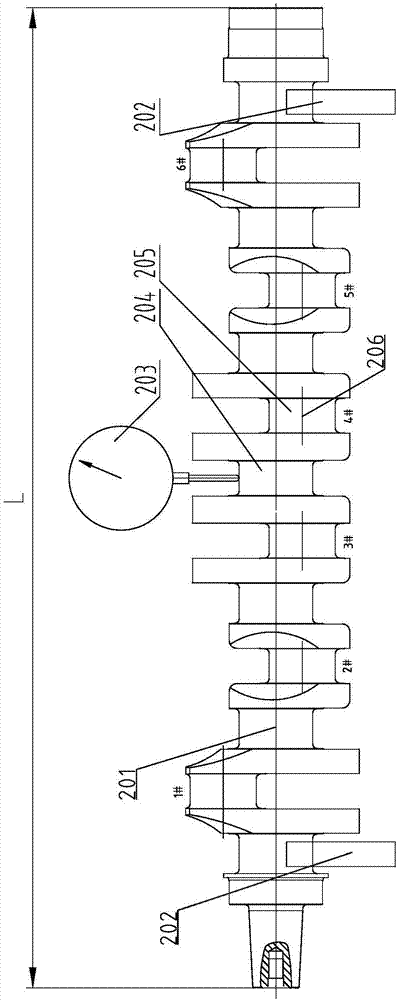

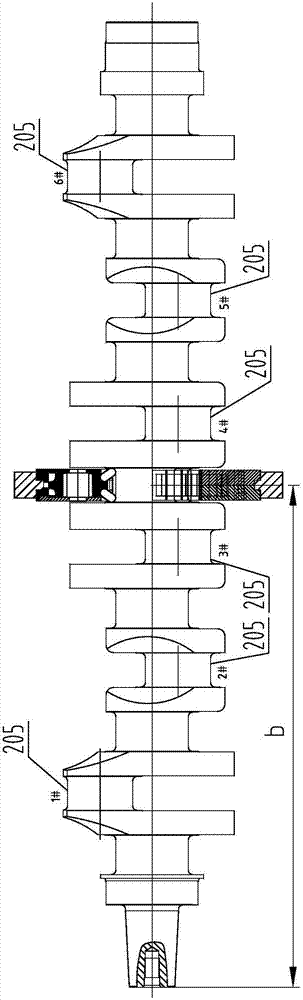

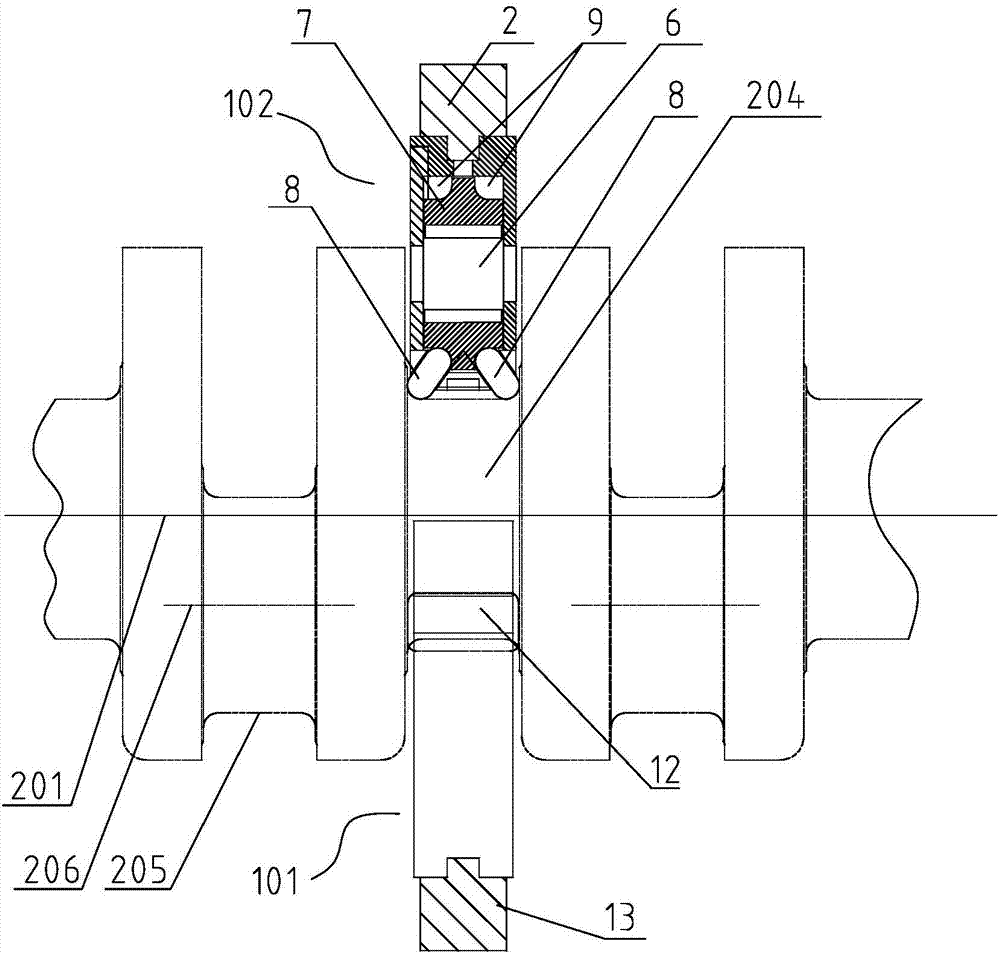

Complete residual compressive stress straightening device and technology for crankshaft

The invention provides a complete residual compressive stress straightening device and technology for a crankshaft. The device and technology solve the technical problems that after an existing crankshaft finished product is accurately ground, a straightening technology is required, cold straightening is not allowed, press rectification cannot be conducted on a press machine, either, and therefore tensile stresses can be formed on the surfaces, opposite to loading force, of the circular bead positions at the two ends easily, the original fatigue strength of the crankshaft is lowered, and cracking can happen easily in the work running process of an engine. The complete residual compressive stress straightening device is provided with an upper rolling swing arm and a lower rolling swing arm. One end of the upper rolling swing arm and one end of the lower rolling swing arm are hinged together through an open pressurization device, and the other end of the upper rolling swing arm is provided with an upper rolling part. The upper rolling part comprises an upper rolling wheel, and the upper rolling wheel is connected with the upper rolling part in a rotating mode. The other end of the lower rolling swing arm is provided with a lower support rolling part. The lower support rolling part comprises lower support roller wheels, and the lower support roller wheels are connected with the lower support rolling part in a rotating mode. The complete residual compressive stress straightening device and technology can be widely applied to correction happening when radial run-out of the crankshaft is out of tolerance.

Owner:TIANRUN IND TECH CO LTD

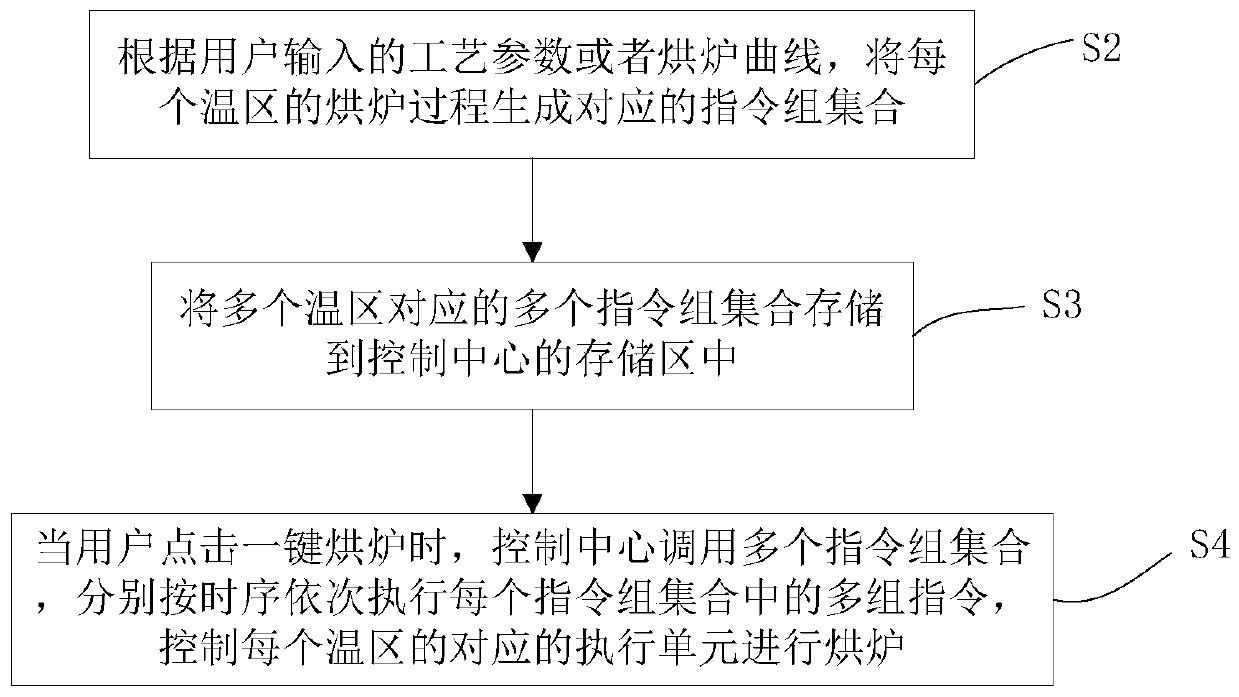

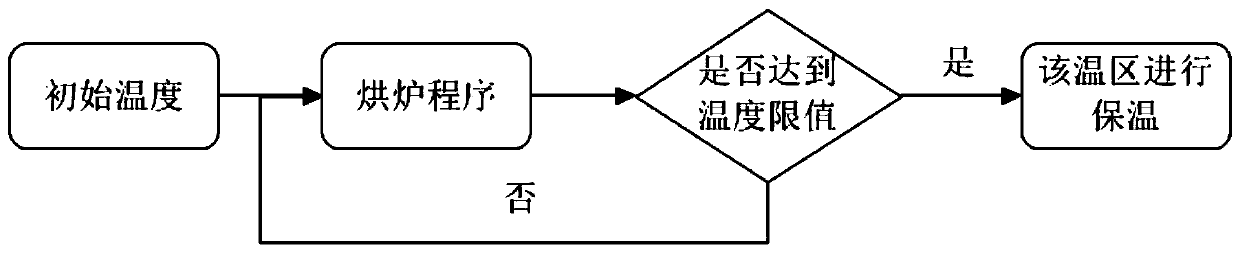

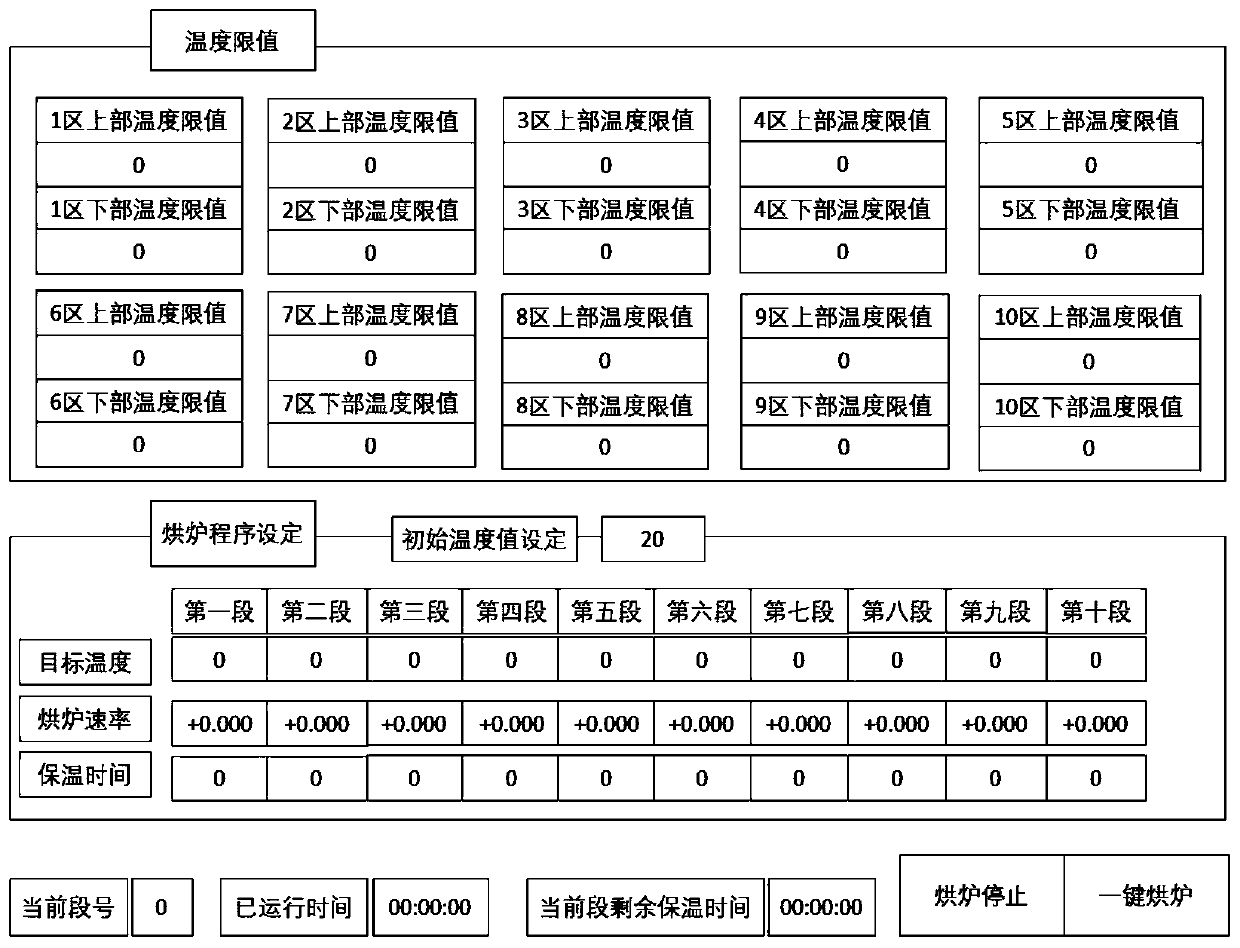

One-key kiln baking method and system used for continuous type kiln

InactiveCN109813115AReduce dependenceGood oven effectLinings repairControl devices for furnacesParallel computingExecution unit

The invention discloses a one-key kiln baking method and system used for a continuous type kiln. The method comprises the steps that the continuous type kiln is divided into multiple temperature areas, according to process parameters or a kiln baking curve input by a user, the kiln baking process of each temperature area generates a corresponding instruction group set, each instruction group set comprises multiple groups of instructions arranged according to the timing sequence, each group of instructions comprises the operation that the temperature area is subjected to temperature rise to thepreset target temperature according to the preset kiln baking rate and the temperature continues the preset heat preservation time; the instruction group sets corresponding to the temperature areas are stored in a storage area of a control center; when a user clicks one-key kiln baking, the control center calls multiple instruction group sets, multiple groups of instructions in each instruction group set are sequentially executed according to the timing sequence, and a corresponding execution unit of each temperature area is controlled to carry out kiln baking. The kiln baking effect is better, the automation degree is higher, and reliability is higher.

Owner:HUNAN JINLU TECH CO LTD

Coarse particle nickel acetate and preparation method thereof

ActiveCN104860811ASimple production processProcess parameters are easyOrganic compound preparationCarboxylic acid salt preparationIron contentCoarse particle

The present invention discloses coarse particle nickel acetate. The nickel acetate is characterized in that is pale green crystals, has nickel acetate content of greater than 99.0%, an average particle size of not less than 3mm, cobalt content of no more than 0.005%, iron content of no greater than 0.0005%, zinc content of no more than 0.0005%, insoluble content of no more than 0.002%, sulfate content of no more than 0.001%, chloride content of no more than 0.002% and the nitrate content of no more than 0. 002%. The invention also discloses a preparation method of the coarse particle nickel acetate. The present invention provides a process route for producing coarse nickel acetate; compared with the traditional process, the process route has the advanategs of simple production process, easily control of the process parameters, little environmental pollution, high production efficiency, high one-time recovery rate, no special production equipment requirements, low labor intensity and low process consumption; and compared with the conventional nickel acetate, the coarse particle nickel acetate has stable and reliable quality. Therefore, the process with good repeatability is applicable to large-scale production in plants.

Owner:JIANGXI NUCLEAR IND XINGZHONG NEW MATERIALS

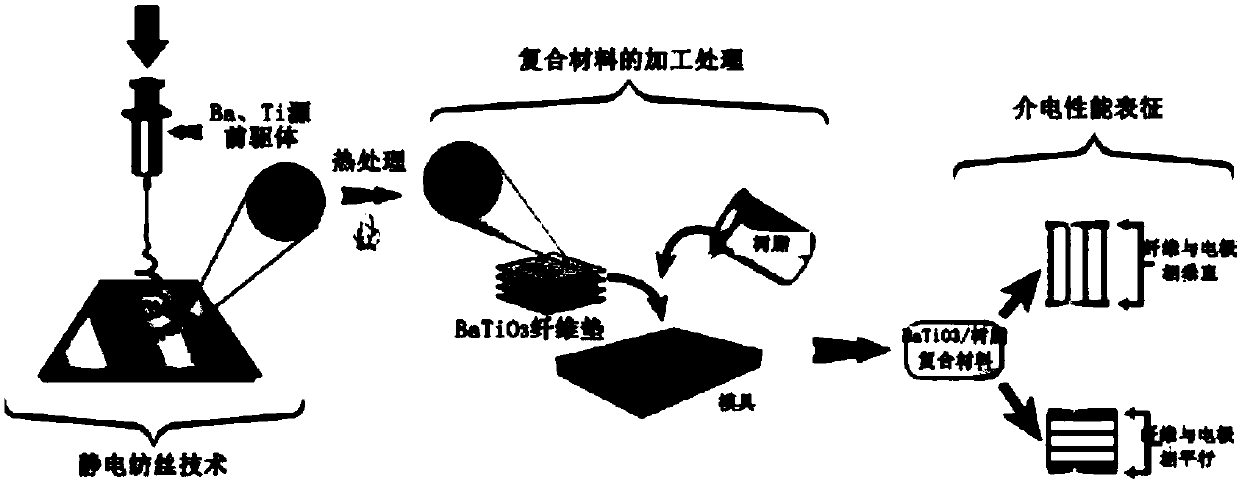

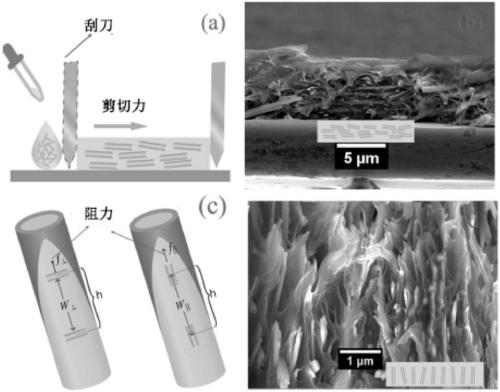

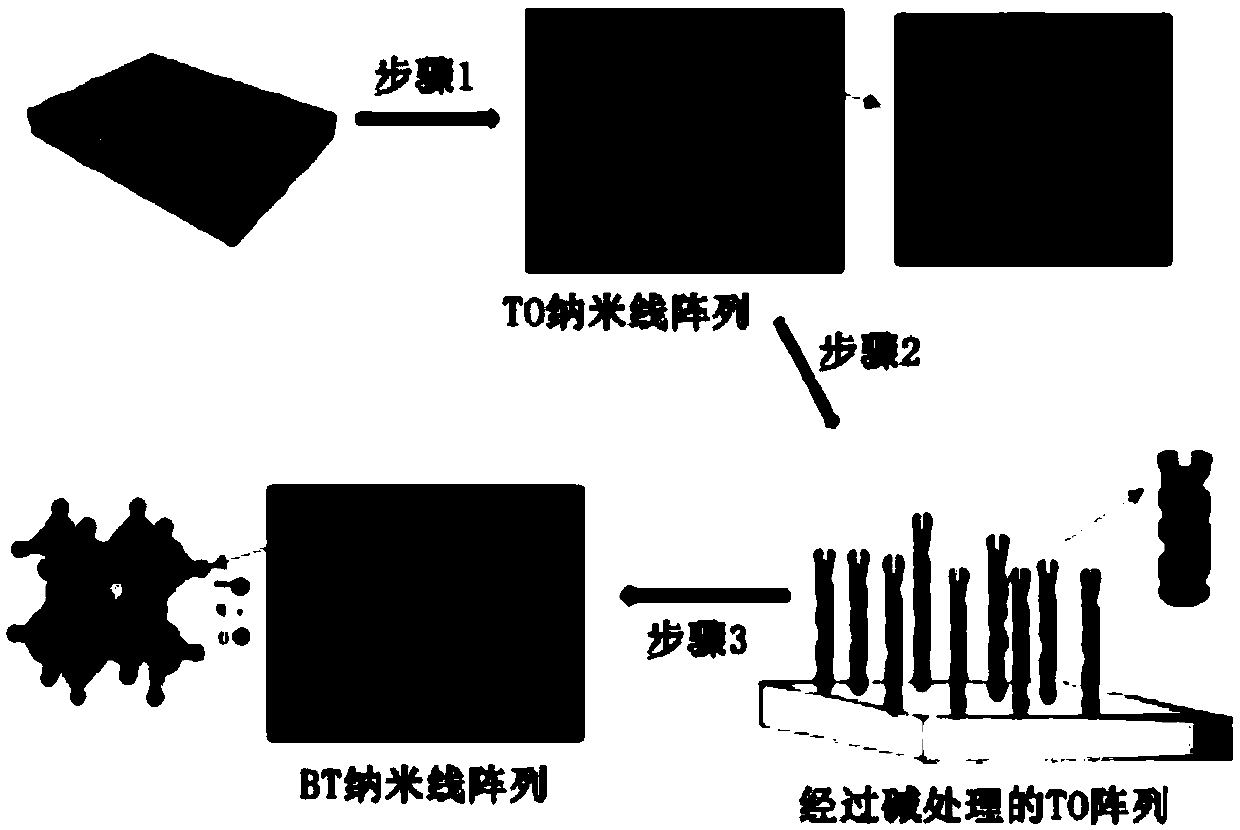

Method for preparing brand-new dielectric composite material

The invention belongs to the field of dielectric composite materials, and particularly relates to a method for preparing a brand-new dielectric composite material. The method specifically comprises the steps of constructing a layered porous ceramic structure which is directionally arranged by means of a freezing casting method, and filling the layered porous ceramic structure with a polymer to obtain the required dielectric composite material. According to the method, the freezing casting method and the preparation of the dielectric composite material are innovatively combined, and the directional, layered and porous material is simply and effectively obtained. Since solvents for preparing slurry are diversified, the method is suitable for ceramic, metal and other material systems; meanwhile, the technology parameters are simple, regulation is convenient, and the porous layered structure with high directionality can be achieved.

Owner:CENT SOUTH UNIV

Spicy beef jerky and preparation method thereof

InactiveCN107183545ADelicious and uniqueTaste and flavor are mellow and deliciousFood ingredient as taste affecting agentLipidic food ingredientsFlavorChemistry

The invention provides a spicy beef jerky and a preparation method thereof. The beef jerky is prepared through 1kg of fresh beef, 100-200g of vegetable oil, 50-90g of chilli, 40-80g of cedrela sinensis, 2-10g of mentha haplocalyx, 1-3g of star aniseed powder, 2-10g of green prickleyash, 5-15g of garlic, 1-6g of cinnamon, 1-6g of lemon juice, 3-8g of edible salt, and 400-800ml of water. According the spicy beef jerky, cedrela sinensis and mentha haplocalyx are ingeniously mixed to prepare the beef jerky, and the prepared beef jerky is delicious and unique in taste; chilli, star aniseed powder, green prickleyash, garlic, cinnamon and lemon juice are added to enable mellow and tasty flavor and mouthfeel of the beef jerky; the beef jerky is proper in spice and is welcomed by customers; the spicy beef jerky is a novel flavored jerky product having the advantages of being green, complete in nutrition, leisure and convenient; in addition, the preparation process is simple; the process parameters are easily controlled; the production cost is low; and the preparation method is very suitable for the beef deep processing and mass production.

Owner:NANNING UNIV

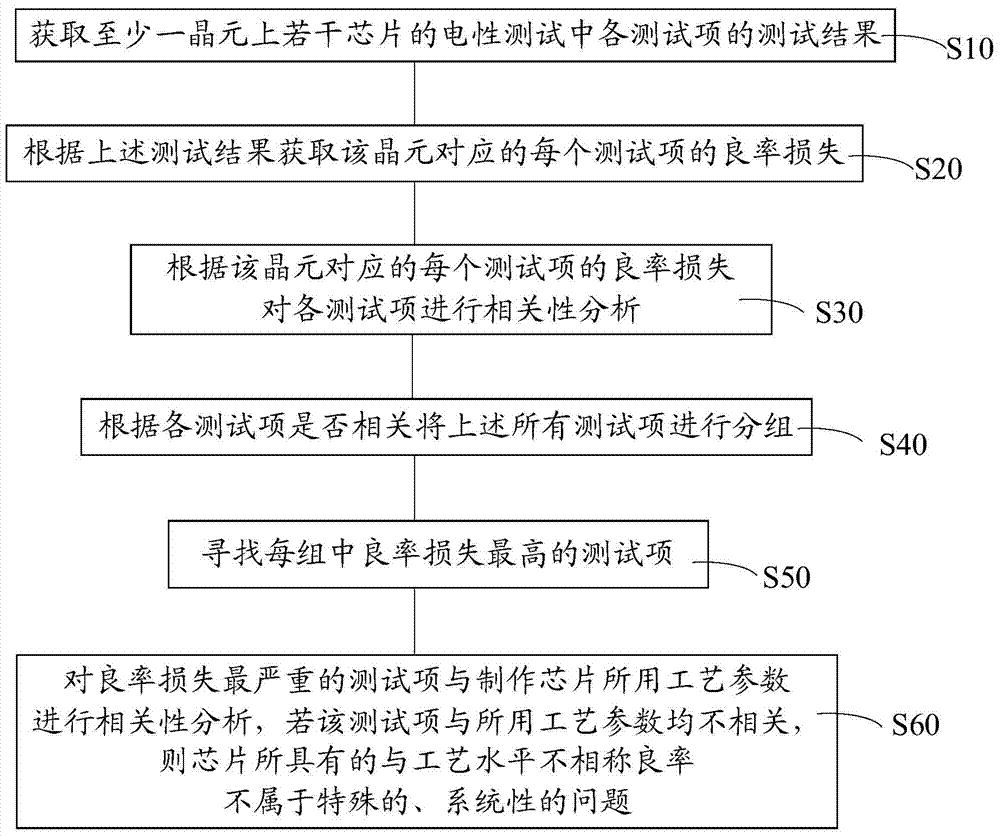

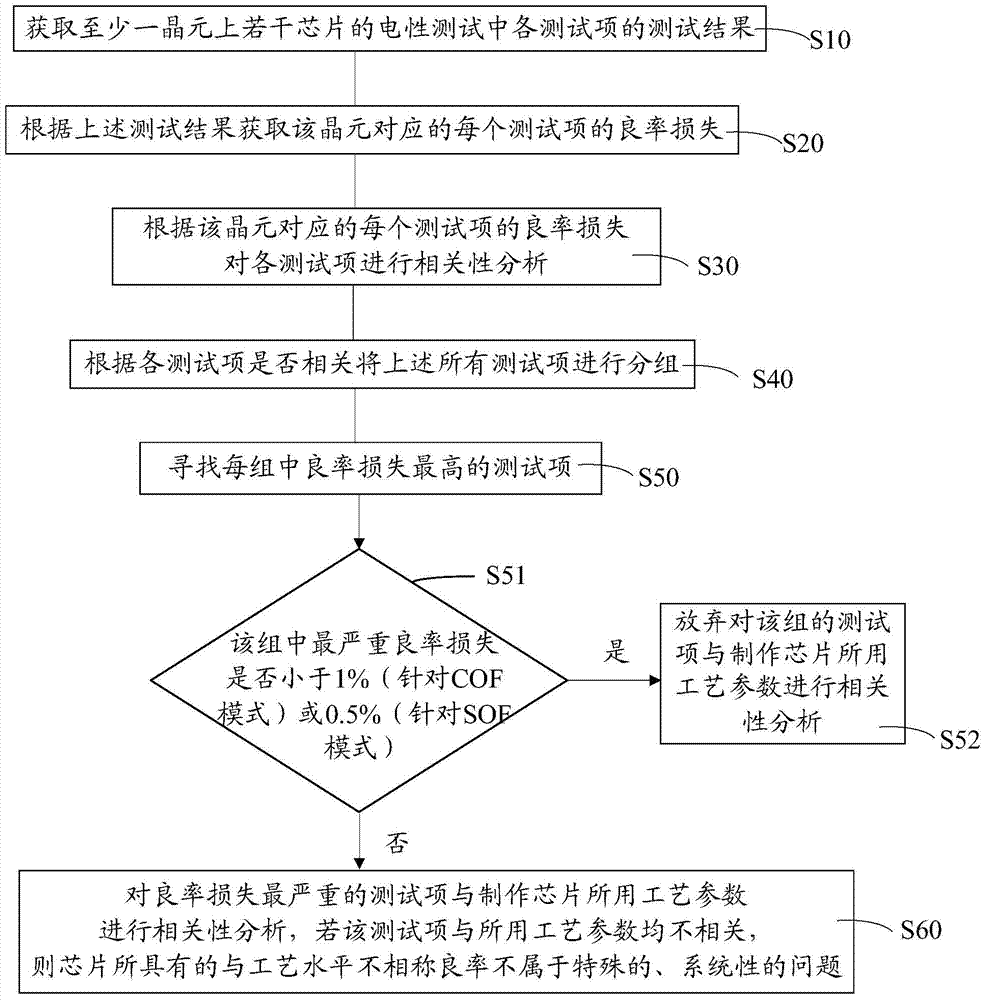

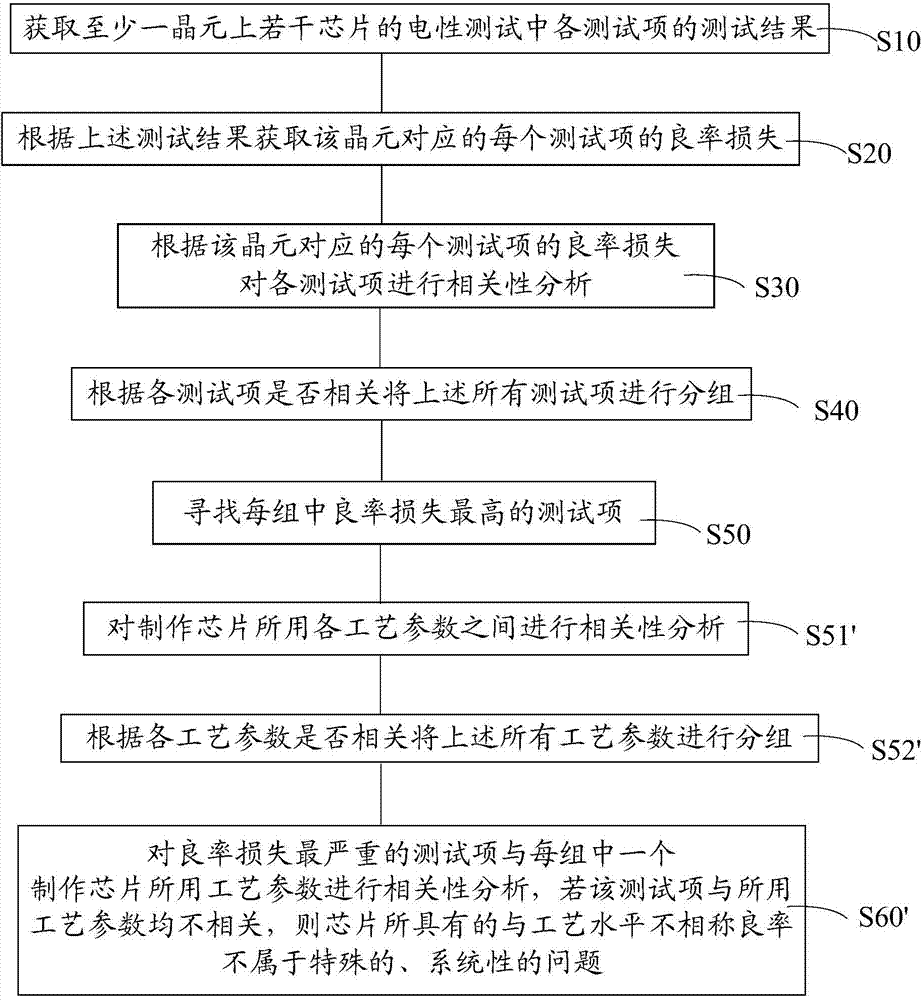

Sorting method for chips with inappropriate yield to technological level

ActiveCN104752259AAvoid wasting manpower and material resourcesImprove efficiencySemiconductor/solid-state device manufacturingLower yieldPersonalization

The invention discloses a sorting method for chips with inappropriate yield to technological level. The method analyzes correlation to the test item and technology parameter for manufacturing chips based on personalized product according to the test result of each test item in the chip electrical performance test, if the test item is uncorrelated to the technology parameter, judging that the yield which is inappropriate to the technological level of the chip does not belong to the specific and specific problem; in addition, in order to avoid large amounts of computation and improve the efficiency, only analyzing the correlation for the test item with lowest yield in the related group and technology parameter rather than analyzing the correlation for each test item; the sorting method can accurately judge that the cause reason for the inappropriate chip yield to the technological level is the specific and specific problem and the waste of manpower and material resources can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

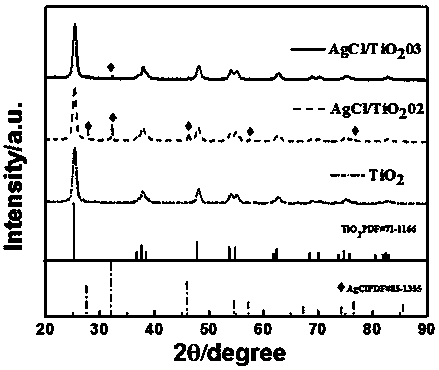

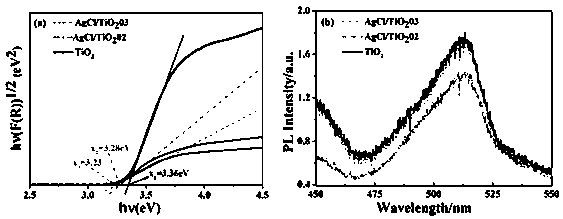

Preparation method of visible light photo-catalyst

ActiveCN108097276AIncrease roughnessPromote generationCatalyst activation/preparationPhoto catalyticCentrifugation

The invention relates to a preparation method of a visible light photo-catalyst and belongs to the technical field of photo-catalytic composite materials. The method includes steps of: a) with tetrabutyl titanate as a titanium source, performing sol-gel process and hydrothermal treatment to prepare a white solid, grinding the white solid into a powder, and sintering the powder in a muffle furnaceto prepare TiO2 powder; b) adding the TiO2 powder to an ionic exchange liquid and adding a less amount of an inhibitor to inhibit hydrolysis of the ionic exchange liquid, performing magnetic stirring,centrifugation and drying to obtain TiO2 powder of which the surface is supported with Cl<-> and Sn<2+> ions; c) adding the powder to an AgNO3 solution, and in a dark environment, fully stirring thesolution to obtain the nano AgCl / TiO2 which is uniformly dispersed and has very high photo-catalytic activity. In the AgCl / TiO2 visible light photo-catalyst, the nano AgCl is well-distributed on surface of the TiO2. Due to surface roughness of the TiO2 powder, agglomeration of nano-particles is effectively inhibited, so that the visible light photo-catalytic efficiency of the AgCl / TiO2 is significantly improved.

Owner:陕西天璇涂层科技有限公司

Reduced glutathione for injection and pre-freezing method thereof

InactiveCN105434368AGood resolubilityEliminate Product Safety RisksPowder deliveryDigestive systemGlutathione-SHFreeze dry

The invention relates to a reduced glutathione for injection and a pre-freezing method thereof. The pre-freezing method includes the following steps that S1, a glutathione solution is prepared and filled; S2, the partition plate temperature of a freeze-drying machine is reduced to be -25 to -35 DEG C; S3, the filled glutathione solution in the step S1 is put on a partition plate of the freeze-drying machine after the step S2 is completed, constant temperature is kept for 2 to 6 hours after the temperature of a product is reduced to be -25 to -35 DEG C, and a reduced glutathione frozen body is obtained, wherein a vacuum pump is started within 0.5 to 1 hour before constant temperature completion in the step S3 to enable the vacuum degree to be smaller than 10 Pa. The reduced glutathione used for injection and prepared by means of the pre-freezing method has the advantages of being high in safety, simple in freeze-drying operation, good in resolubility and stable and reliable in product quality.

Owner:GUANGZHOU BAIYUNSHAN MINGXING PHARM CO LTD

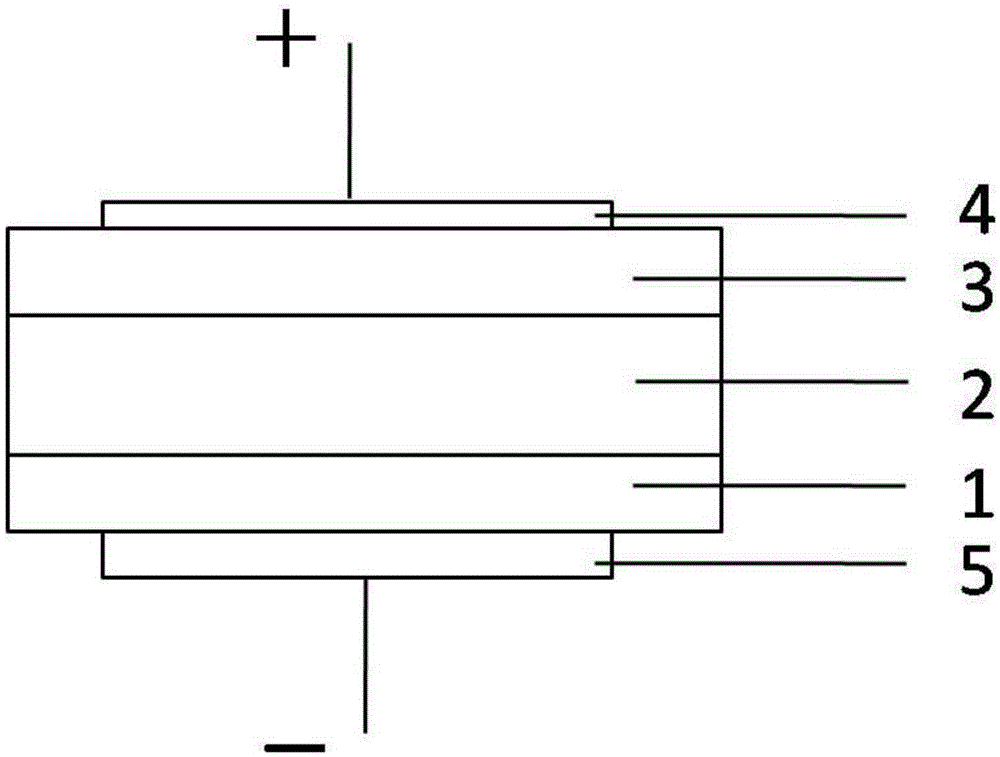

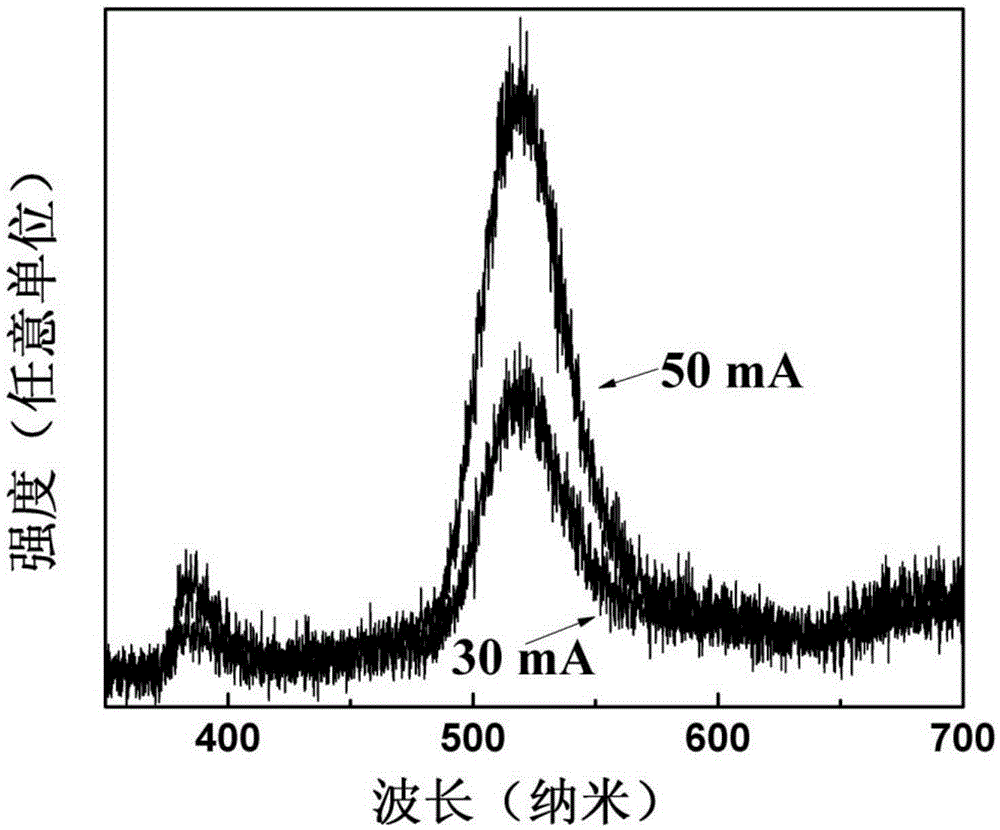

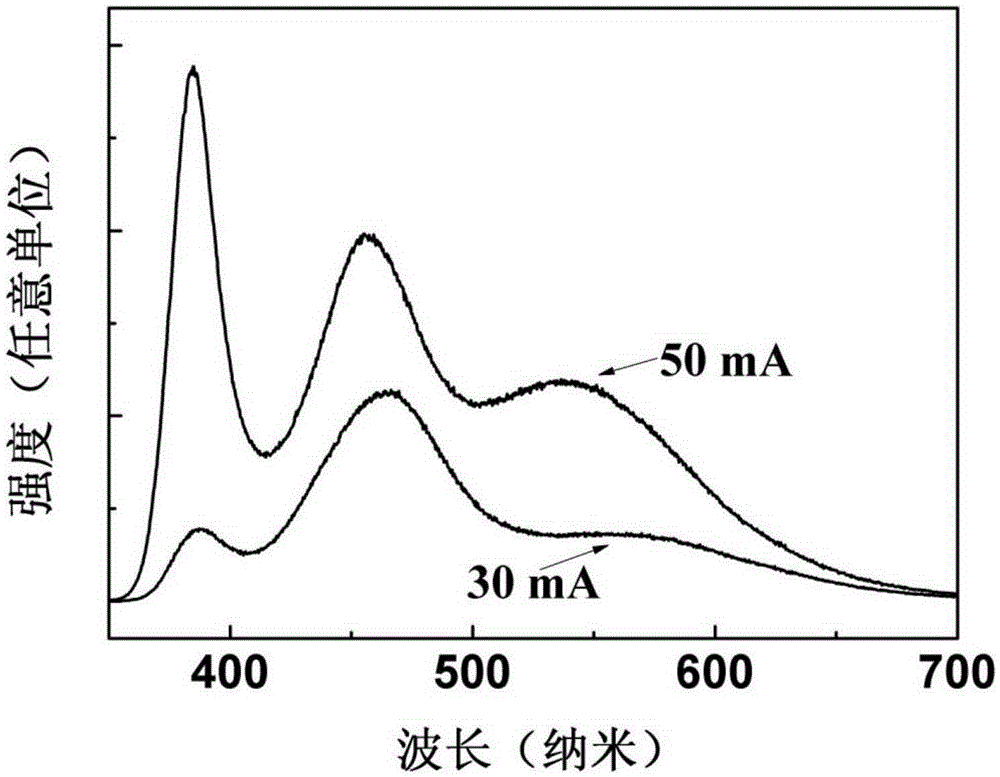

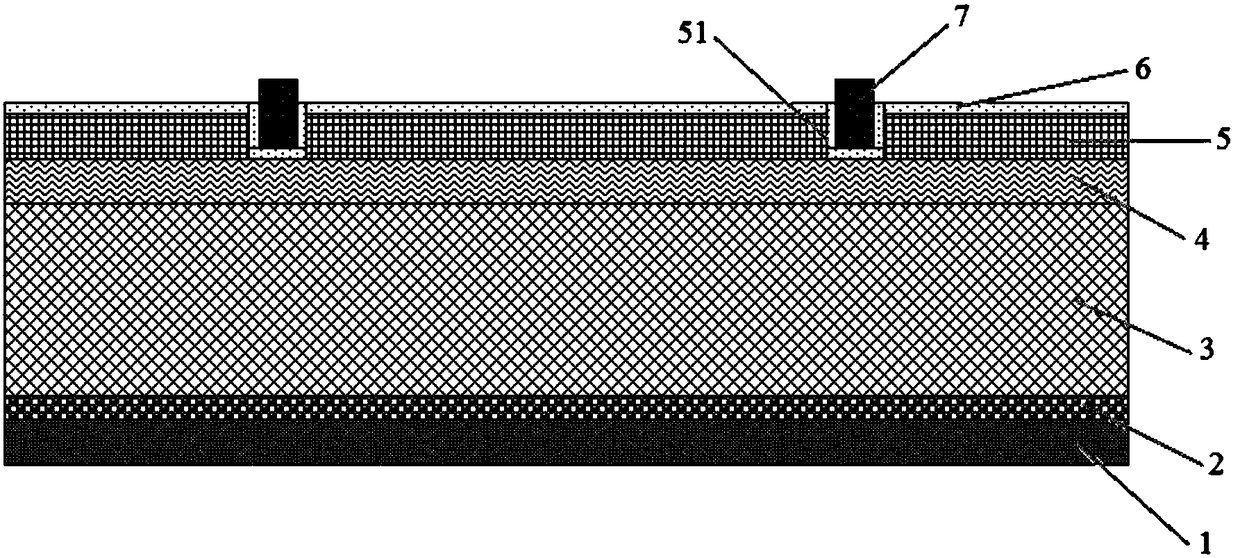

Preparation method of ultraviolet and visible coexisting electroluminescent device

ActiveCN105336820AAchieve UVProcess parameters are easySemiconductor devicesOhmic contactThermal treatment

The invention belongs to the field of photoelectric devices, relates to a preparation method of an ultraviolet and visible coexisting electroluminescent device, and particularly relates to a preparation method of an ultraviolet and visible coexisting electroluminescent device with an Au / MgO / CdZnO / SiMIS structure. The device comprises a substrate. A CdZnO thin film, a MgO thin film and an Au electrode are deposited on the front surface of the substrate from the bottom to the top in turn. An ohmic contact electrode is deposited on the back surface of the substrate. According to the device, a ZnO and CdZnO coexisting thin film luminescent layer is obtained by performing thermal treatment on the sputtering CdZnO thin film, and the thin film is enabled to emit electroluminescence arranged in an ultraviolet and visible region under certain forward bias voltage (the substrate is connected with negative voltage). Besides, the structure and the realization mode of the device are simple, and the preparation technology and the used equipment are compatible with the current mature silicon device technology.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Novel method for culturing and acclimating activated sludge in winter

InactiveCN103755013AShort training timePromote growth and reproductionSustainable biological treatmentBiological water/sewage treatmentActivated sludgeSludge cake

The invention discloses a novel method for culturing and acclimating activated sludge in winter. The method comprises the following steps: injecting industrial water into IMC biochemical pools, wherein the water depth is 70-80% of the pool depth, and the temperature of pool water is increased to 30-35 DEG C by steam; placing municipal sewage dehydrated sludge cake in the IMC biochemical pools, wherein addition for each pool is 50-60 tons; starting circulating pumps of the biochemical pools for mixing, starting the blowers for aeration, adding flour and alkali, ceasing the blowers for a rest; culturing the sludge according to process parameters in an implementation scheme; after successful propagation of the sludge, starting a sludge acclimation stage; forming multiple stages of A / O in the biochemical pools, wherein a single biochemical pool currently comprises 4 A / O stages, or determining the frequency of A / O according to the quality of sewage; stopping the circulating pumps to reach a precipitation state in the biochemical pools; and draining water in the biochemical pools, and discharging according to standards. The method for culturing and acclimating activated sludge has the advantages of short time for culture and acclimation, simple scheme, stable process parameters, easiness for operation, and low cost for acclimation.

Owner:GNSG ANHUI HONG SIFANG

Rust remover suitable for precise steel parts, and rust removal process thereof

InactiveCN107988608AStrong rust removal abilitySuitable for rust removalO-Phosphoric AcidMaterials science

The invention discloses a rust remover suitable for precise steel parts, and a rust removal process thereof, and relates to the field of mechanical technologies. The rust remover is composed of the following raw materials in percentage by mass: 10-20% of chromic anhydride, 0.8-1.5% of sulfuric acid, 13-18% of phosphoric acid and 60.5-76.2% of water. The rust remover disclosed by the invention is prepared through mixing the abovementioned raw materials in mass proportions, and the prepared rust remover is high in rust removal capacity, low in environmental pollution and suitable for rust removal for the precise steel parts; and a preparation method for the rust remover disclosed by the invention is simple in process parameters and high in preparation efficiency.

Owner:永康市狐桃工贸有限公司

Monocrystalline silicon solar cell and production method thereof

ActiveCN108281512AImprove fill factorImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationInterface layerN type silicon

The invention relates to a monocrystalline silicon solar cell and a production method thereof. The production method includes: forming a texturizing layer on the upper surface of a P-type monocrystalline silicon wafer; forming an N-type silicon layer on the upper surface of the P-type monocrystalline silicon wafer; depositing a silicon nitride passivation layer on the N-type silicon layer, and etching the silicon nitride passivation layer to forming an opening in an area for forming an upper electrode so as to expose the N-type silicon layer; coating the upper surface of the P-type monocrystalline silicon wafer with a solution containing acetyl alkoxy aluminum diisopropoxide in a spin manner, and annealing; sequentially coating the lower surface of the P-type monocrystalline silicon waferwith a solution containing a tungsten sulfide two-dimensional nano material and a solution containing a titanium sulfide two-dimensional nano material in a spin manner, and annealing to form a composite interface layer; forming the upper electrode on the upper surface of the P-type monocrystalline silicon wafer, and forming a lower electrode on the lower surface of the P-type monocrystalline silicon wafer. The monocrystalline silicon solar cell produced by the method is excellent in photoelectric conversion efficiency.

Owner:宁波欧达光电有限公司

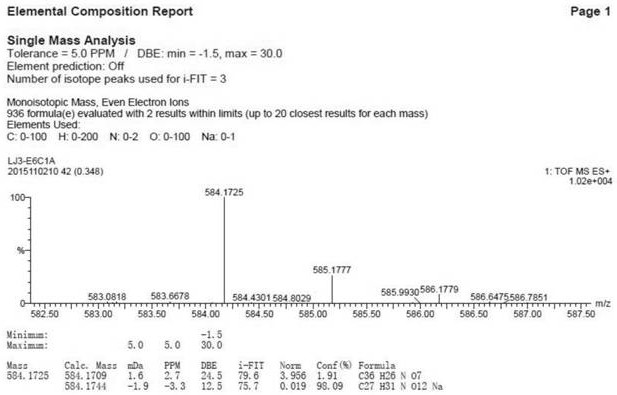

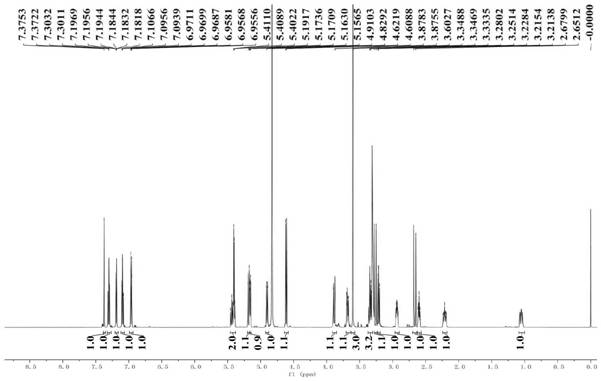

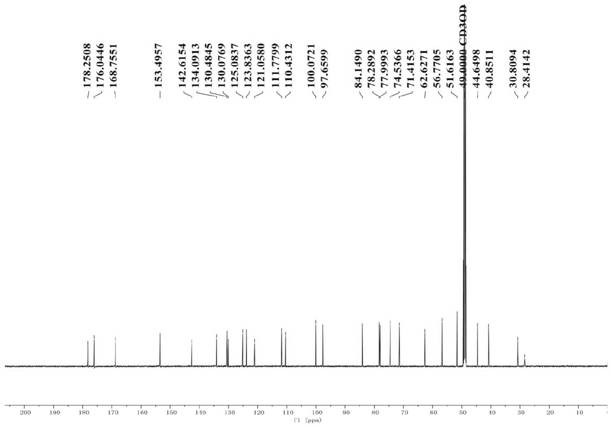

Iridoid glycoside compound and preparation method and application thereof

ActiveCN112300223AEasy to manufactureFast preparationOrganic active ingredientsSugar derivativesMetaboliteChemical compound

The invention provides an iridoid glycoside compound or pharmaceutically acceptable salt, a solvate, tautomer, a stereoisomer, prodrug molecules and a metabolite thereof. A cell experiment verifies that the nitrogen-containing iridoid glycoside compound prepared by the invention shows an excellent anti-inflammatory effect, and can be used as a lead compound for developing novel anti-inflammatory drugs.

Owner:JIANGSU KANION PHARMA CO LTD

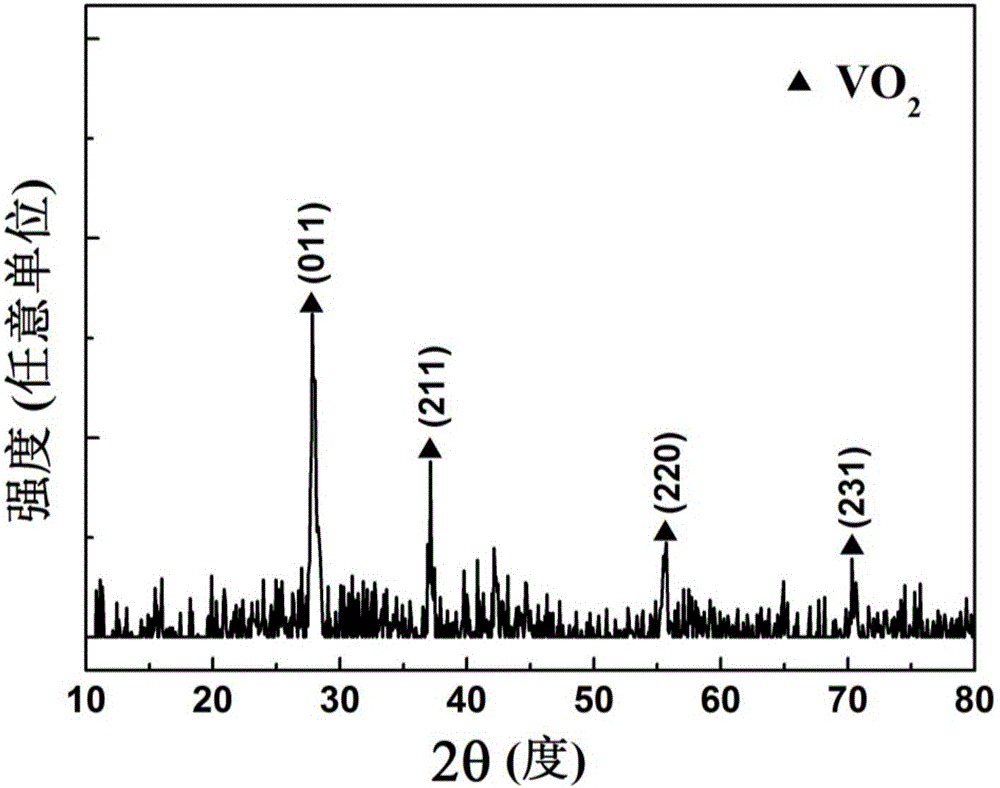

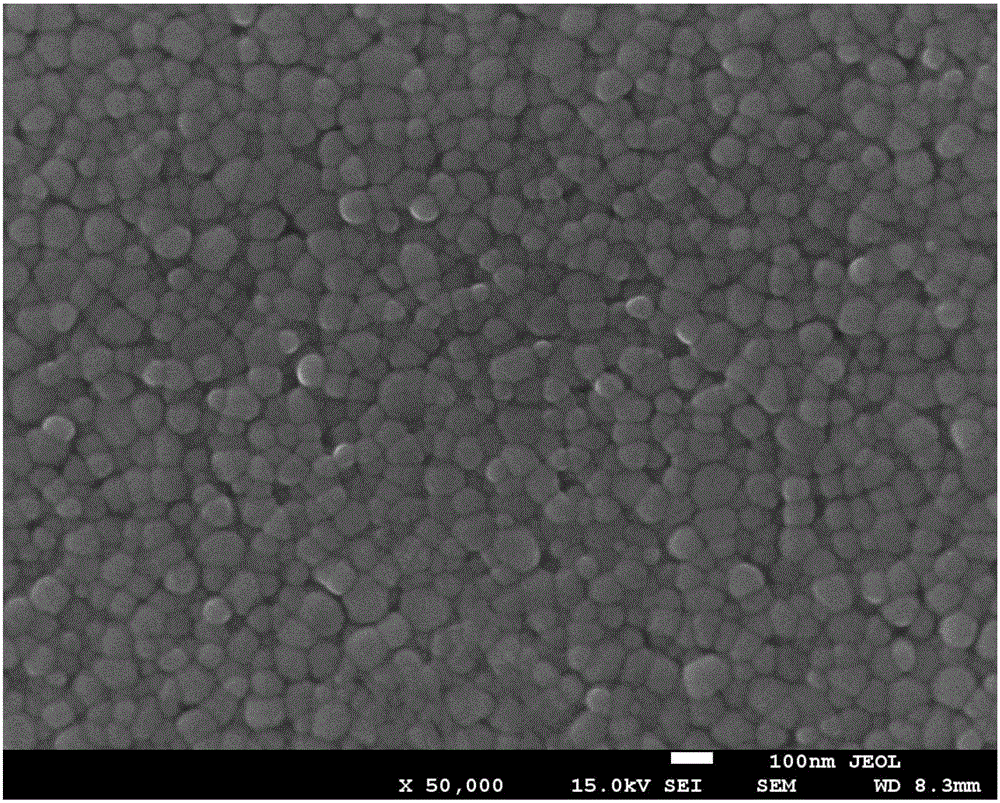

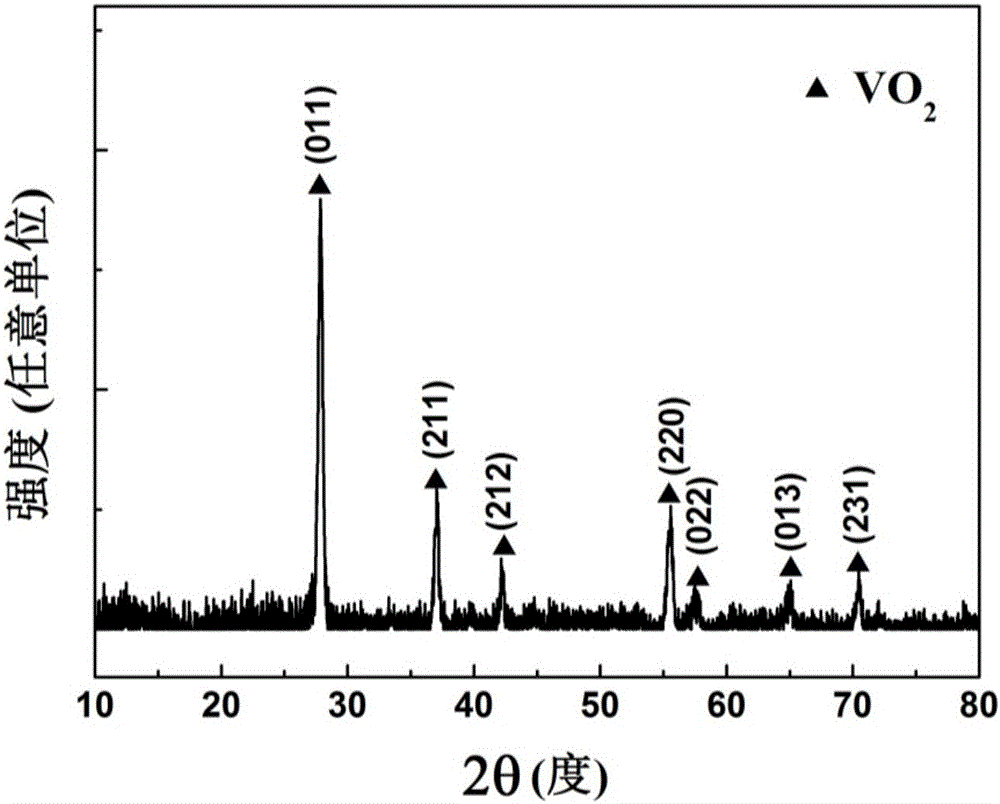

Preparation method for vanadium dioxide nano-particle film

ActiveCN106048532AGet rid of dependenceEasy and quick to makeVacuum evaporation coatingSputtering coatingVanadium dioxideTube furnace

The invention relates to the field of intelligent film material, in particular to a preparation method for a vanadium dioxide nano-particle film. According to the preparation method, a metal vanadium film is prepared through the magnetron sputtering method, then is placed into an open tube furnace with nitrogen gas for undergoing high temperature annealing treatment and is fast taken out and cooled after heat preservation for a certain period of time. According to the preparation method, complex vacuum heat treatment equipment is not needed, and the required vanadium dioxide film can be obtained through the simple oxidation reaction. The process and the technology are simple and controllable, grains of the prepared film are uniform in size and small, and the phase transition property is obvious. A new technology low in cost, short in cycle and capable of being applied industrially is provided for the vanadium dioxide film material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com