Monocrystalline silicon solar cell and production method thereof

A technology for solar cells and manufacturing methods, applied in the field of solar cells, capable of solving problems such as N-type silicon layer damage and affecting the photoelectric conversion efficiency of P-type monocrystalline silicon solar cells, so as to reduce defect states, improve photoelectric conversion efficiency, and reduce leakage The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

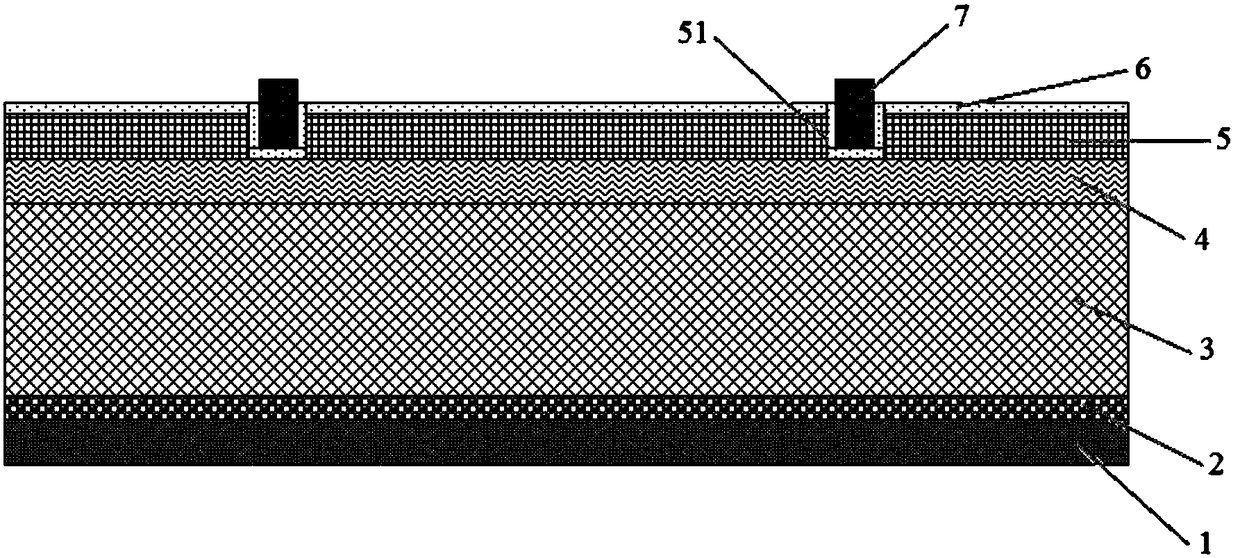

[0020] A method for manufacturing a monocrystalline silicon solar cell, comprising the following steps: (1) forming a textured layer on the upper surface of a P-type monocrystalline silicon wafer; (2) forming a N layer on the upper surface of the P-type monocrystalline silicon wafer. (3) deposit a silicon nitride passivation layer on the N-type silicon layer, and etch the silicon nitride passivation layer to form an opening in the area where the upper electrode is to be formed to expose The N-type silicon layer; (4) Spin-coat a solution containing acetoalkoxy aluminum diisopropoxide on the upper surface of the P-type single crystal silicon wafer, and perform annealing treatment to passivate the silicon nitride (5) sequentially spin-coat the solution containing tungsten sulfide two-dimensional nanomaterial and the solution containing tungsten sulfide on the lower surface of the P-type single crystal silicon wafer A solution of titanium two-dimensional nanomaterials, and anneali...

Embodiment 2

[0024]A method for manufacturing a monocrystalline silicon solar cell, comprising the following steps: (1) forming a textured layer on the upper surface of a P-type monocrystalline silicon wafer; (2) forming a N layer on the upper surface of the P-type monocrystalline silicon wafer. (3) deposit a silicon nitride passivation layer on the N-type silicon layer, and etch the silicon nitride passivation layer to form an opening in the area where the upper electrode is to be formed to expose The N-type silicon layer; (4) Spin-coat a solution containing acetoalkoxy aluminum diisopropoxide on the upper surface of the P-type single crystal silicon wafer, and perform annealing treatment to passivate the silicon nitride (5) sequentially spin-coat the solution containing tungsten sulfide two-dimensional nanomaterial and the solution containing tungsten sulfide on the lower surface of the P-type single crystal silicon wafer A solution of titanium two-dimensional nanomaterials, and annealin...

Embodiment 3

[0028] A method for manufacturing a monocrystalline silicon solar cell, comprising the following steps: (1) forming a textured layer on the upper surface of a P-type monocrystalline silicon wafer; (2) forming a N layer on the upper surface of the P-type monocrystalline silicon wafer. (3) deposit a silicon nitride passivation layer on the N-type silicon layer, and etch the silicon nitride passivation layer to form an opening in the area where the upper electrode is to be formed to expose The N-type silicon layer; (4) Spin-coat a solution containing acetoalkoxy aluminum diisopropoxide on the upper surface of the P-type single crystal silicon wafer, and perform annealing treatment to passivate the silicon nitride (5) sequentially spin-coat the solution containing tungsten sulfide two-dimensional nanomaterial and the solution containing tungsten sulfide on the lower surface of the P-type single crystal silicon wafer A solution of titanium two-dimensional nanomaterials, and anneali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com