New technology for treating coking wastewater and wastewater from coal chemical industry

A technology for coal chemical wastewater and coking wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, degassed water/sewage treatment, etc., to achieve adjustment of process parameters, good denitrification and removal of nitrate nitrogen, and convenient process parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

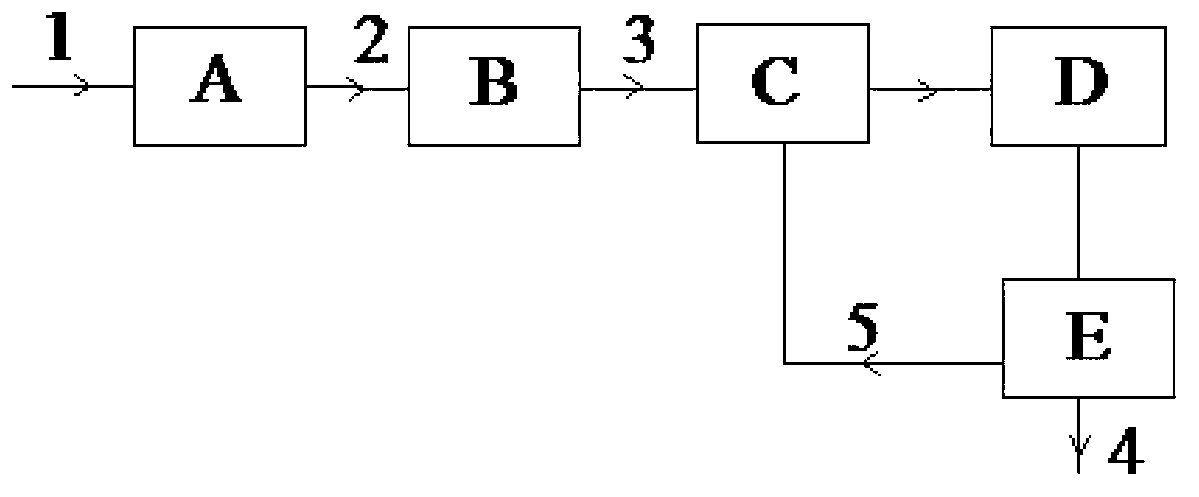

[0039] Using the combined process provided by the present invention to control the influent COD and NH 3 -The actual coking wastewater with N of 3000mg / L and 180mg / L respectively is treated in a small-scale experiment. The experimental water flow rate is 150mL / h. It is pretreated first to remove oil and suspended solids in the water. After pretreatment The coking wastewater 1 enters the resin adsorption tank A. The resin adsorption tank A uses a glass resin adsorption column with a diameter of 15mm, and 8% NaOH solution is desorbed. The COD of the resin adsorption water 2 after the resin adsorption is reduced from 3000mg / L to 750mg / L, the pH of the water 2 absorbed by the resin is 10.6. The resin adsorption effluent 2 removes NH3-N through the air stripping tower B, and the NH3-N of the air stripping tower effluent 3 is reduced from 180mg / L to 40mg / L. The effective volume of anoxic and secondary aerobic bioreactors is 4500mL, and the total residence time is 30h. The hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com