Preparation method for vanadium dioxide nano-particle film

A vanadium dioxide nano-particle film technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the uneven grain size inside the film, weaken the phase transition performance of the film, and lose the functional characteristics of the film and other problems, to achieve the effect of short heat treatment time, high crystallinity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Using a metal vanadium target as a sputtering source, a 500nm thick metal vanadium film was sputtered on a clean substrate under argon gas, and the substrate temperature was kept at 200°C;

[0023] 2) Raise the temperature of the tube annealing furnace with one end open, keep it warm when it reaches 500°C, feed nitrogen gas from the non-open end of the furnace tube, and keep the nitrogen flow rate at 2L / min;

[0024] 3) Put the prepared metal vanadium film into a quartz crucible, and then push the crucible into the above-mentioned tubular annealing furnace for annealing. The annealing time is 10 minutes, and then pull out the crucible for rapid air cooling.

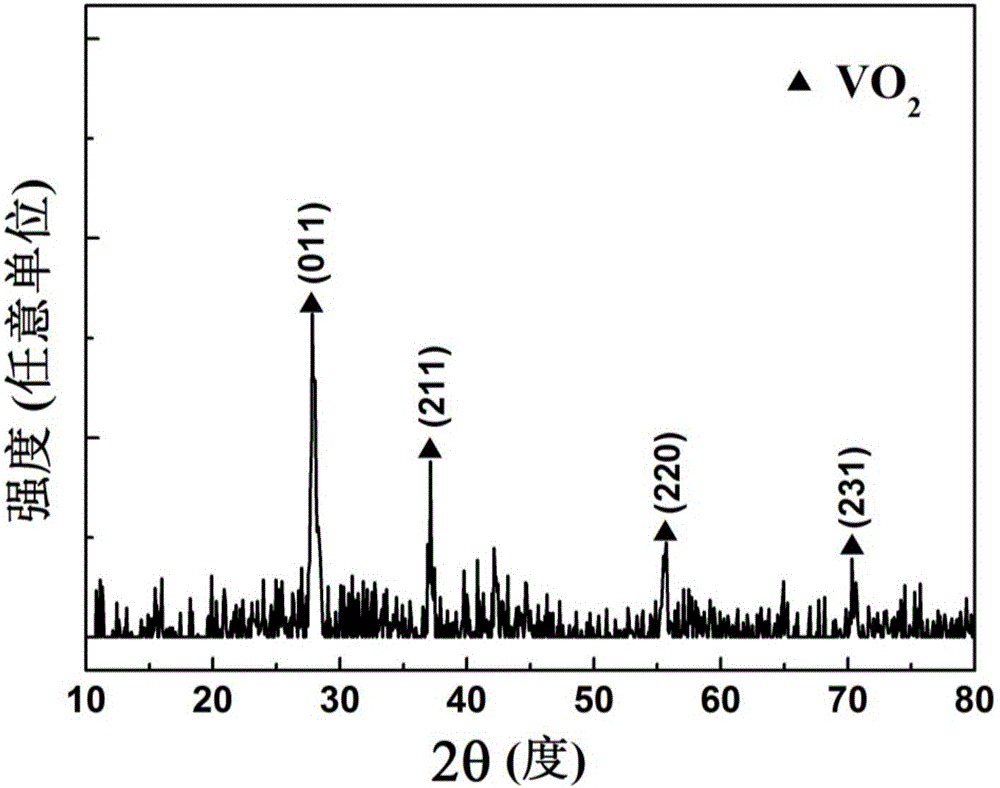

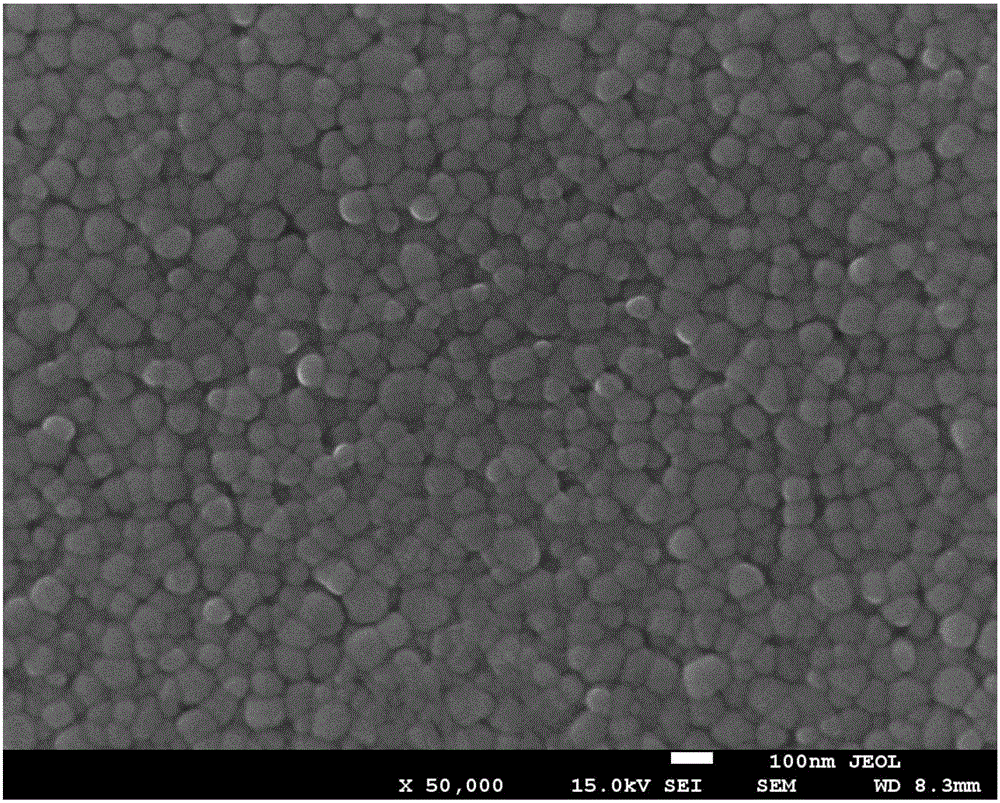

[0025] figure 1 It is the XRD pattern of the vanadium dioxide nanoparticle film prepared in Example 1, it can be seen that the film only contains a single vanadium dioxide phase, and no other impurity phases are formed. figure 2 It is the SEM image of the vanadium dioxide nanoparticle film prepared in Example ...

Embodiment 2

[0027] 1) Using a metal vanadium target as a sputtering source, a 200nm thick metal vanadium film was sputtered on a clean substrate under argon gas, and the substrate temperature was kept at 200°C;

[0028] 2) Raise the temperature of the tube annealing furnace with one end open, keep it warm at 570°C, and feed nitrogen gas from the non-open end of the furnace tube, and keep the nitrogen flow rate at 2L / min;

[0029] 3) Put the prepared metal vanadium film into a quartz crucible, and then push the crucible into the above-mentioned tubular annealing furnace for annealing. The annealing time is 5 minutes, and then pull out the crucible for rapid air cooling.

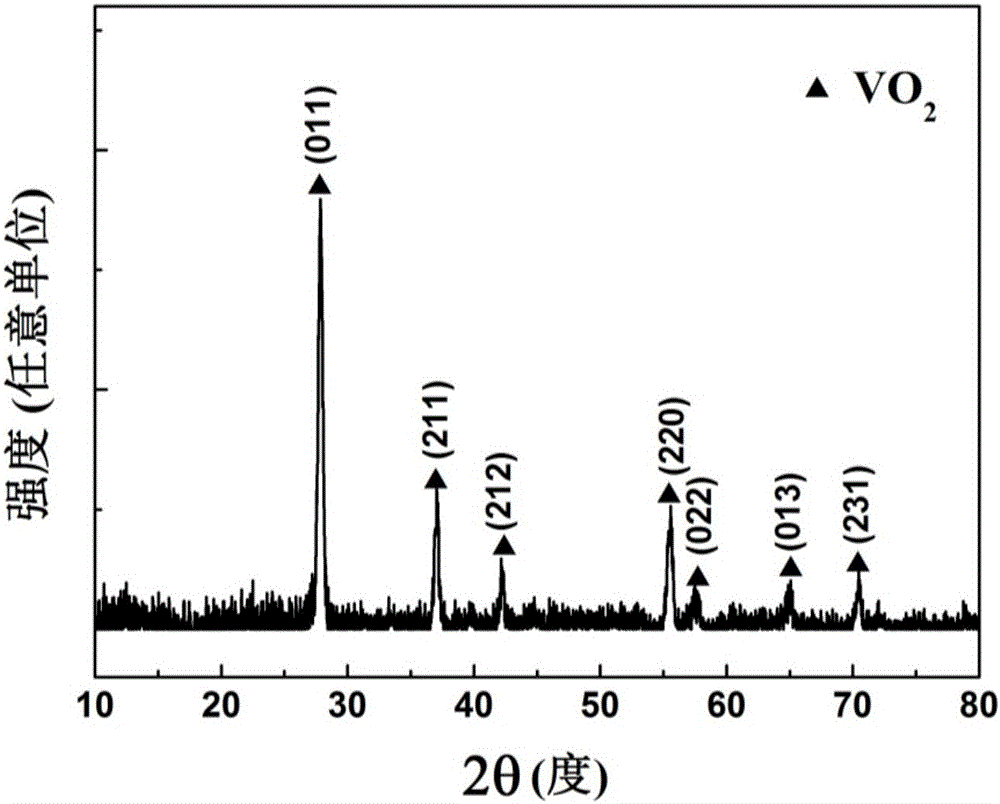

[0030] image 3 It is the XRD pattern of the vanadium dioxide nanoparticle film prepared in Example 2, it can be seen that the film only contains a single vanadium dioxide phase, and no other impurity phases are formed. Figure 4 It is the SEM image of the vanadium dioxide nanoparticle film prepared in Example 2. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com