Complete residual compressive stress straightening device and technology for crankshaft

A residual compressive stress and straightening device technology, applied in the field of crankshaft straightening devices, can solve problems such as fracture, reduced fatigue strength of the crankshaft, inability to perform thermal straightening, etc., and achieve the effects of simple process parameters, reliable quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

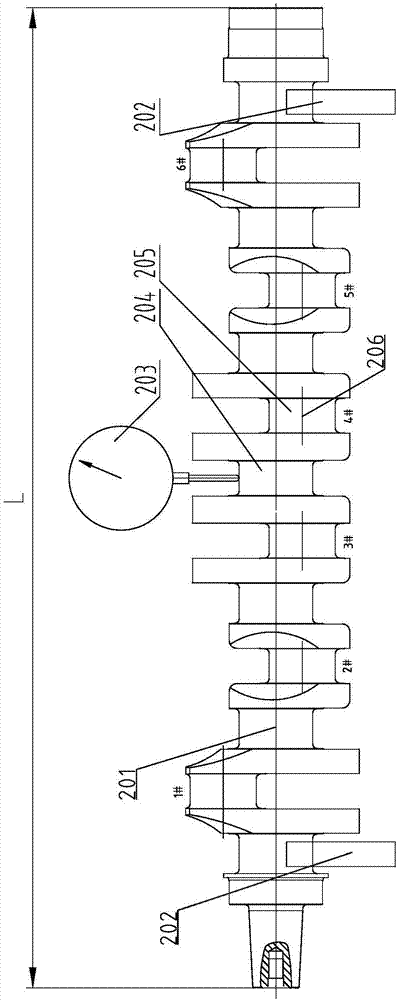

[0068] Example 1: The nitriding crankshaft of a large marine engine is made of QT800-3 nodular cast iron. After fine grinding and nitriding, the bending tolerance of the finished product is 0.15mm, the position b to be straightened is 855mm, and the total length of the crankshaft is 1966mm. as follows:

[0069]

[0070] Then the rolling straightening force required by the crankshaft is 56600N.

example 2

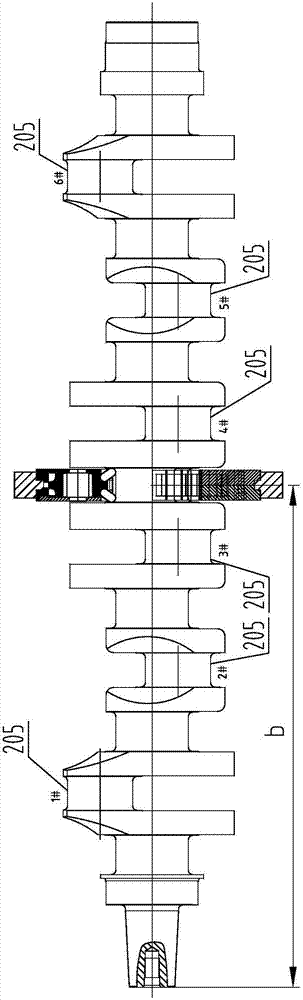

[0071] Example 2: For a quenched steel shaft, the material is 48MnV. After quenching and fine grinding, the bending deviation of the finished product is 0.05mm. The position b to be straightened is 355mm, and the total length is 857mm. The calculation is as follows:

[0072]

[0073] Then the rolling straightening force required by the crankshaft is 21996N.

[0074] According to the experiment, the number of rolling and straightening circles of the crankshaft is set to 1-10 circles, and the straightening speed of the crankshaft is set to 30±10r / min, which can meet the final straightening accuracy requirements. The direct speed is set at 30r / min, which can not only realize high-efficiency production, but also ensure the quality of spindle calibration.

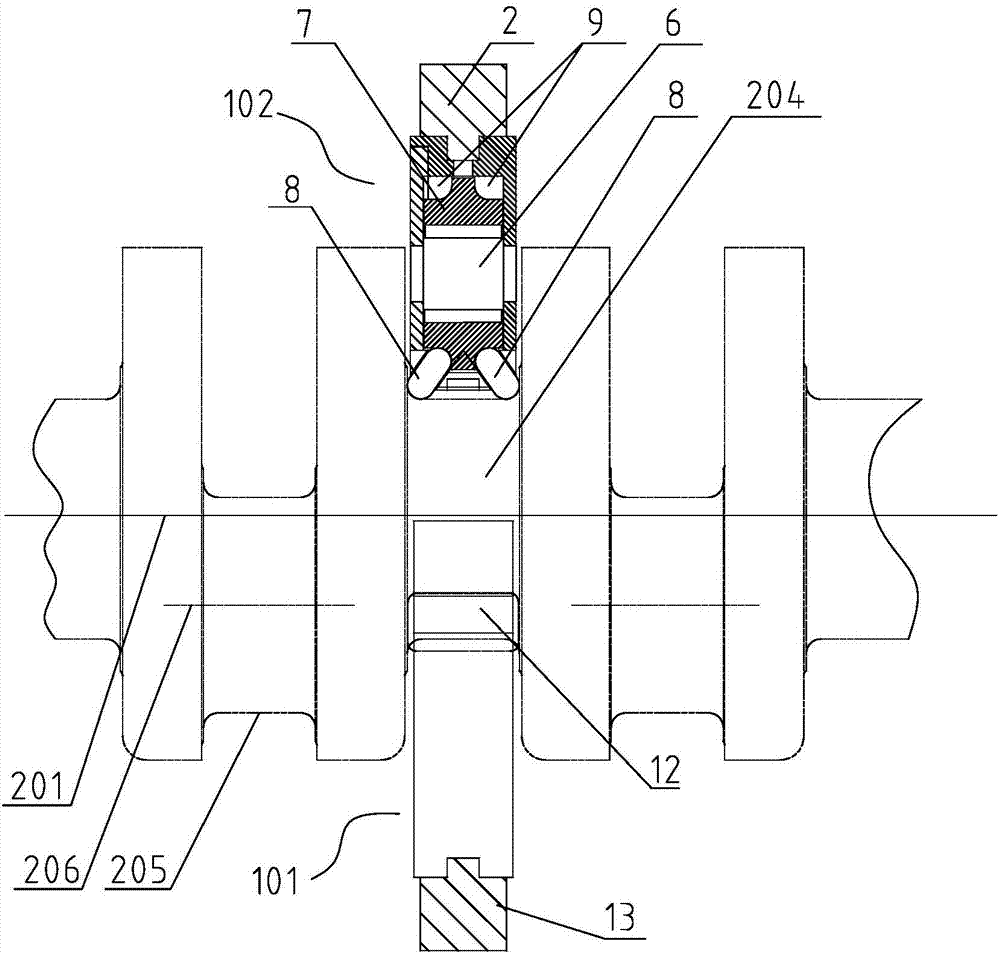

[0075] According to the above parameters, place the upper rolling part and the lower supporting rolling part in the crankshaft full residual compressive stress straightening device at the position to be corrected, set the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com