Method for preparing brand-new dielectric composite material

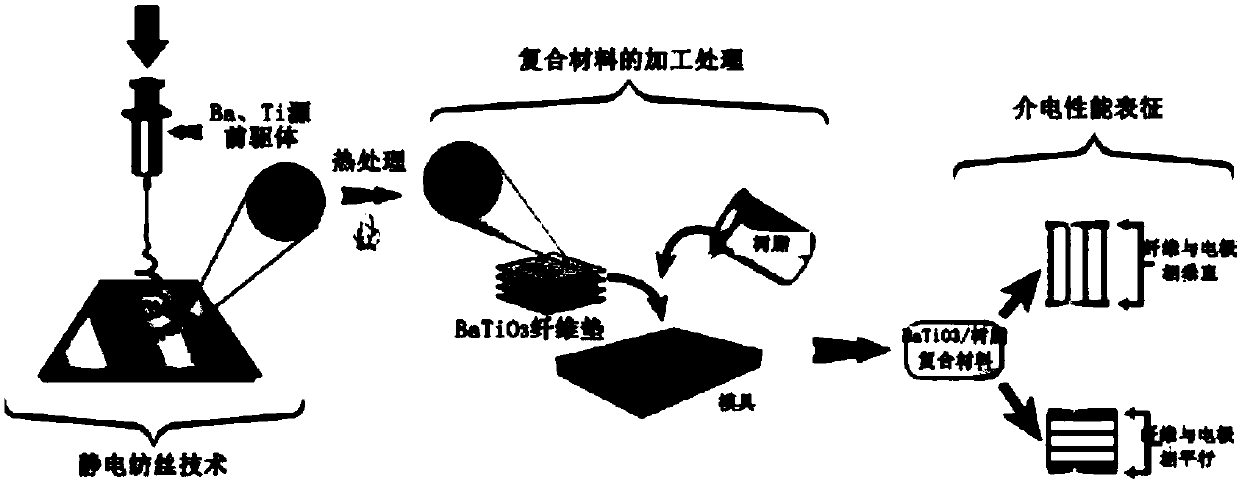

A composite material and dielectric technology, which is applied in the field of preparing a new dielectric composite material, to achieve the effect of high orientation, high porous layered structure, and convenient regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

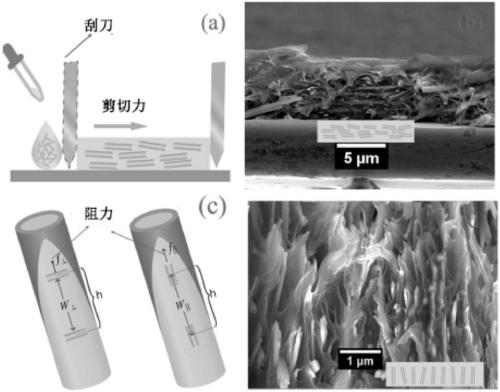

Method used

Image

Examples

Embodiment

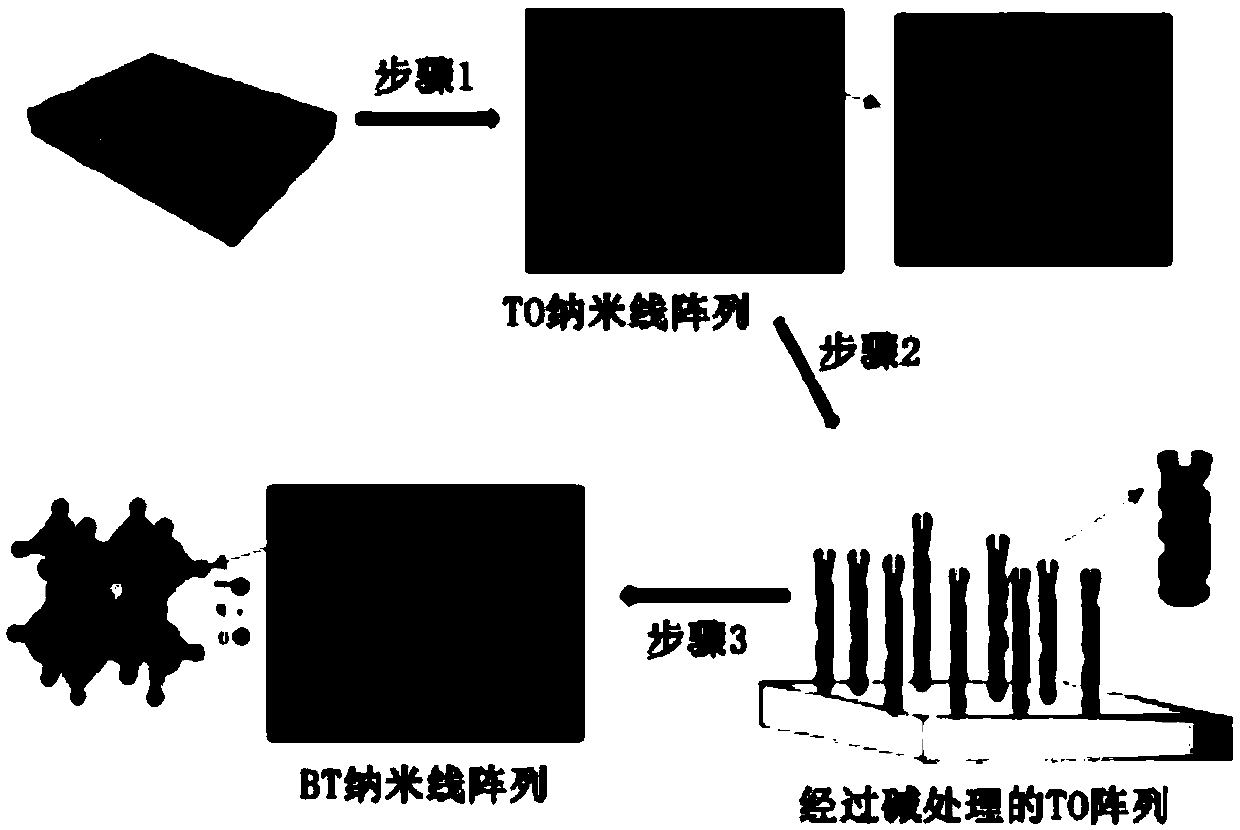

[0040] Such as Figure 5 shown, including the following steps:

[0041] (1) Prepare barium titanate slurry. Weigh a certain amount of deionized water, BaTiO 3 Powder and BaTiO 3 Powder 1wt% dispersant, mix, prepare BaTiO respectively 3 Three groups of slurries with volume ratios of 10vol%, 20vol%, and 30vol%, respectively. After ball milling for 24 hours, add BaTiO to the above slurry 3 Powder 1wt% binder solution, stirred slowly for at least 12 hours. Then carry out defoaming treatment: add a few drops of defoaming agent to the obtained slurry, mix well and put it into a vacuum drying oven to evacuate. The consumption of described defoamer is BaTiO 3 0.1% of powder mass.

[0042] Described defoamer is the defoamer such as alcohols, esters, as methyl alcohol, ethylene glycol, isopropanol, sec-butanol, n-octanol, tributyl phosphate etc., for the convenience of operation, the present embodiment uses is n-butanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com