Oriented electrical steel sheet and manufacturing method thereof

A technology of oriented electrical steel sheets and steel sheets, which is applied to circuits, electrical components, manufacturing tools, etc., can solve the problems of low-efficiency preparation methods, rising energy costs, and falling yields, and achieve excellent magnetic properties, high magnetic flux density, Excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

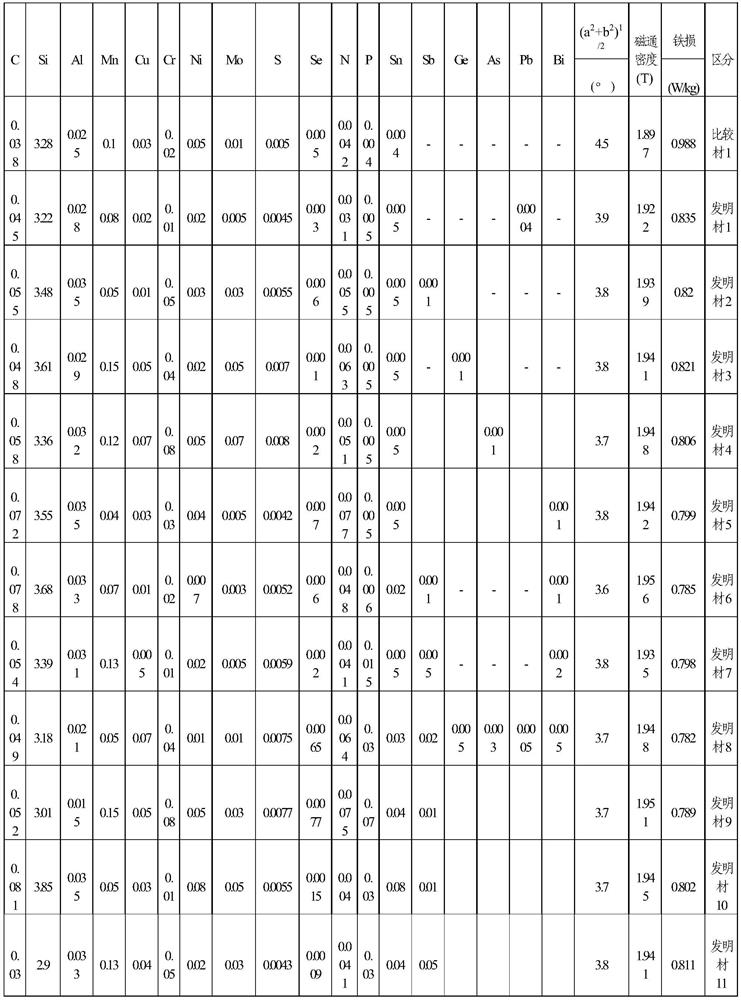

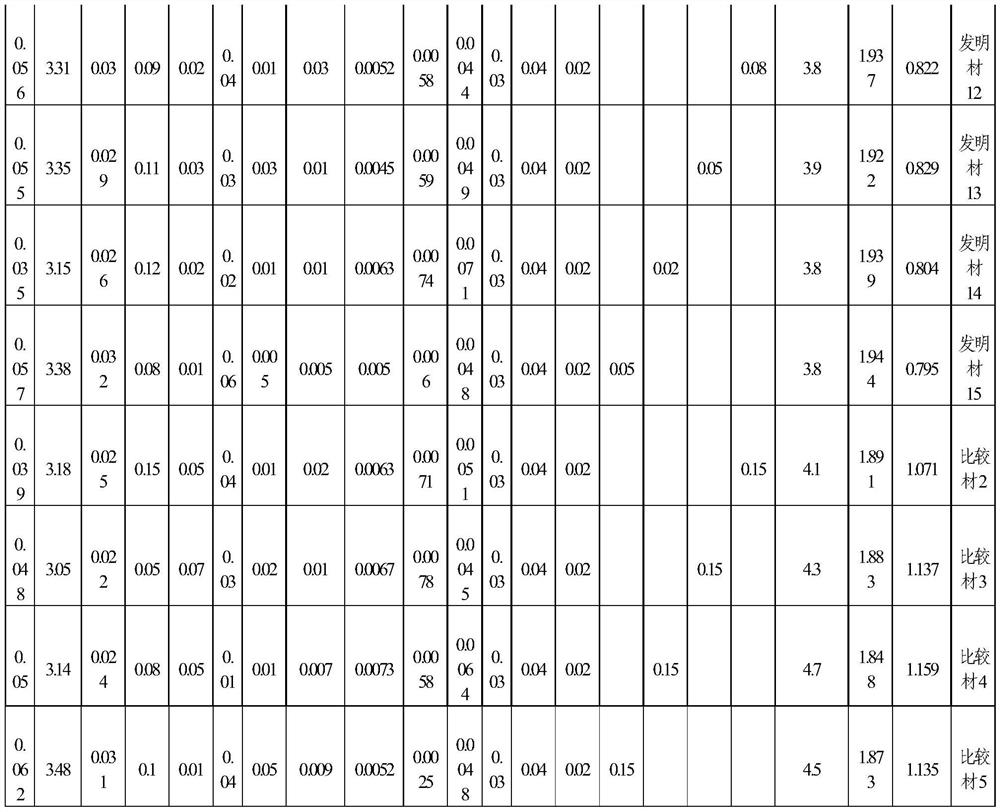

[0107] As shown in Table 1 below, C, Si, Mn, acid-soluble Al, N, S, Se, Cu, Ni, Cr and Mo are used as the basic composition, and the contents of P, Sn, Sb, Ge, As, Pb and Bi are changed to To prepare steel, the steel of this composition system is vacuum-dissolved to prepare cast slabs.

[0108] After heating this slab to a temperature of 1150° C., rough rolling was performed six times to prepare a 40 mm bar, and after that, it was hot rolled to a thickness of 2.3 mm, cooled rapidly to 600° C., and then coiled.

[0109] At this time, for the first, second, and third rough rolling, rolling is performed at a rolling reduction of 20% or more, so that rough rolling is performed at a total cumulative rolling reduction of 60% or more.

[0110] Such a hot-rolled steel sheet was annealed at 1050° C., pickled, and then subjected to strong cold rolling so that the thickness of the steel sheet became 0.23 mm.

[0111] For the cold-rolled steel sheet, after heating to 850° C. at a heating...

Embodiment 2

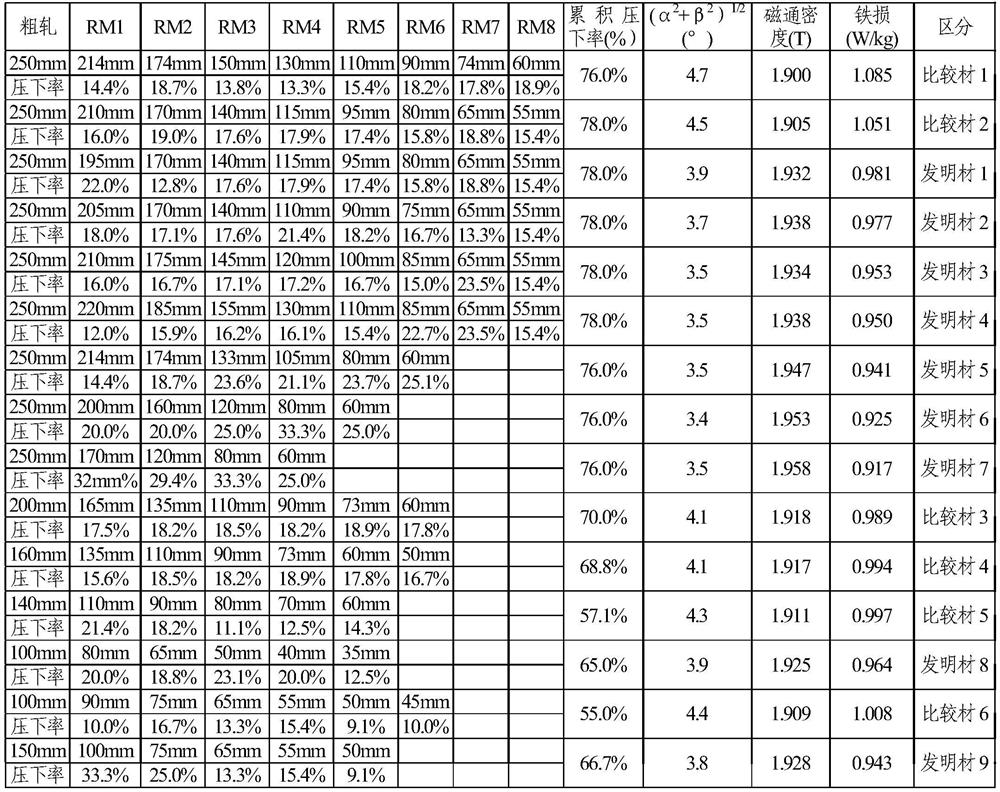

[0121] A steel slab having the composition of Invention Material 12 evaluated in Example 1 and produced by vacuum dissolution was heated at 1200°C.

[0122] After rough rolling was performed by changing the number of times of rough rolling and rolling reduction on the heated billet, a hot rolled sheet having a thickness of 2.6 mm was prepared by hot rolling.

[0123] Such a hot-rolled steel sheet was subjected to hot-rolled sheet annealing at 1080° C., pickling, and then strong cold rolling so that the thickness of the steel sheet became 0.30 mm.

[0124] For the cold-rolled steel plate, after heating to 860°C at a heating rate of 30°C / sec, it is kept in a wet mixed atmosphere of hydrogen, nitrogen, and ammonia for 150 seconds to recrystallize once, and nitriding treatment is carried out at the same time, so that The total nitrogen content of the steel sheet was 180 ppm.

[0125] Next, an annealing separator mainly composed of MgO is coated on the steel sheet, and the final h...

Embodiment 3

[0132] A steel slab having the composition of Invention Material 8 evaluated in Example 1 and produced by vacuum dissolution was heated at 1130°C.

[0133] A total of six times of rough rolling are carried out on the heated billet, among which the reduction ratio of 20% or more is adopted in the third, fourth, fifth and sixth rough rolling, and the rough rolling is carried out with a cumulative reduction ratio of 76.0%. , After preparing a 60mm bar, it was hot-rolled to a thickness of 2.3mm.

[0134] Such a hot-rolled steel sheet was annealed at 1100° C., pickled, and then subjected to strong cold rolling so that the thickness of the steel sheet became 0.23 mm.

[0135] During cold rolling, change the rolling temperature to 50-350°C and perform rolling until the thickness becomes the thickness of the final product, then heat the cold-rolled steel sheet to 855°C at a heating rate of 70°C / sec, , nitrogen, and ammonia in a mixed atmosphere for 180 seconds to cause primary recrys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com