Sorting method for chips with inappropriate yield to technological level

A classification method and chip technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as misjudgment, little effect, low yield rate, etc., and achieve the effect of improving efficiency and avoiding waste of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

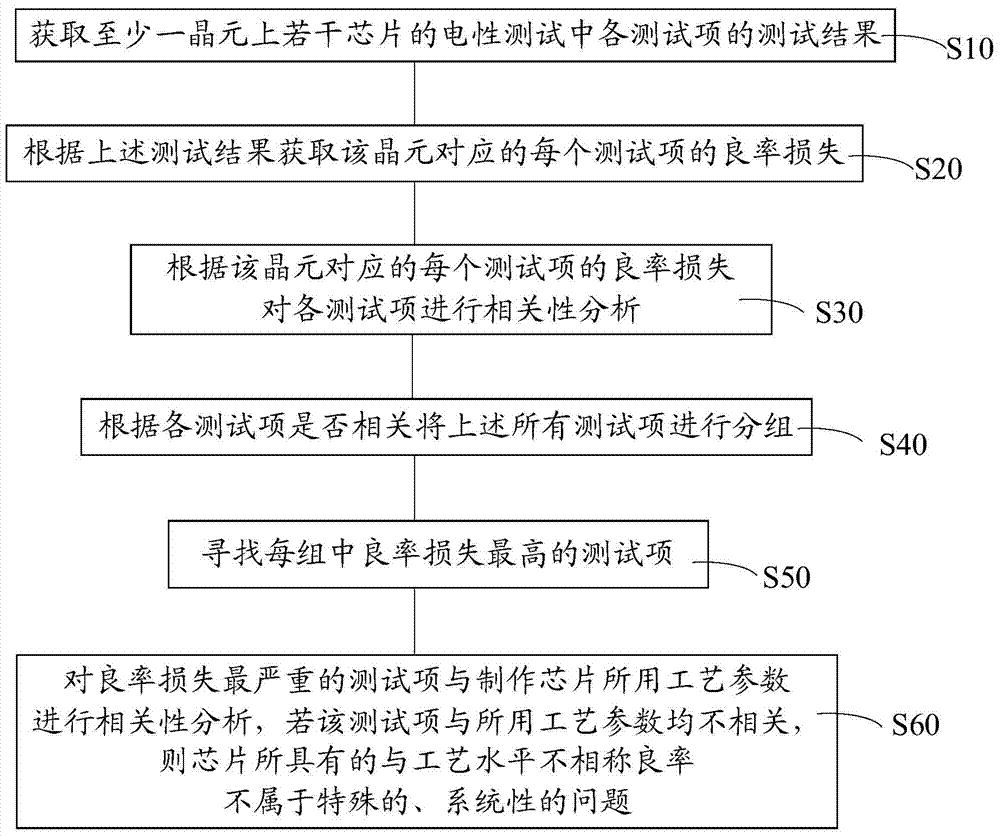

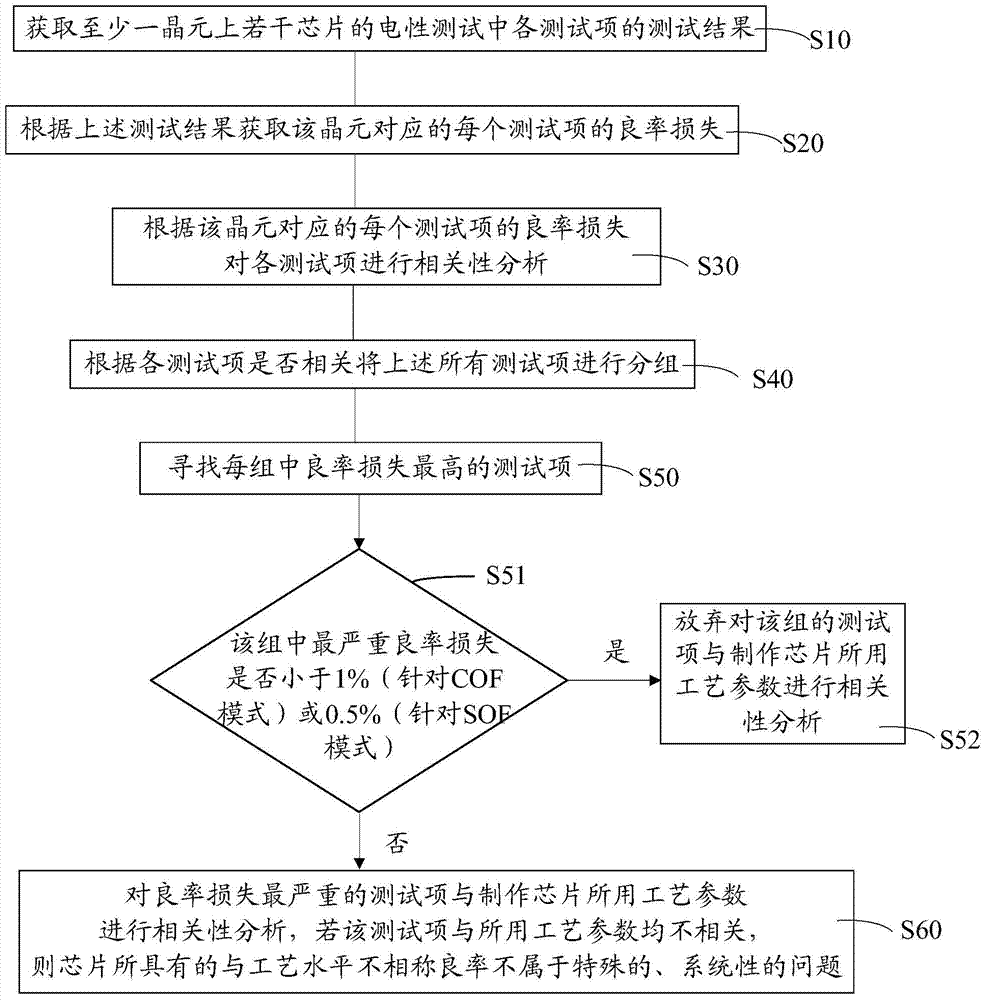

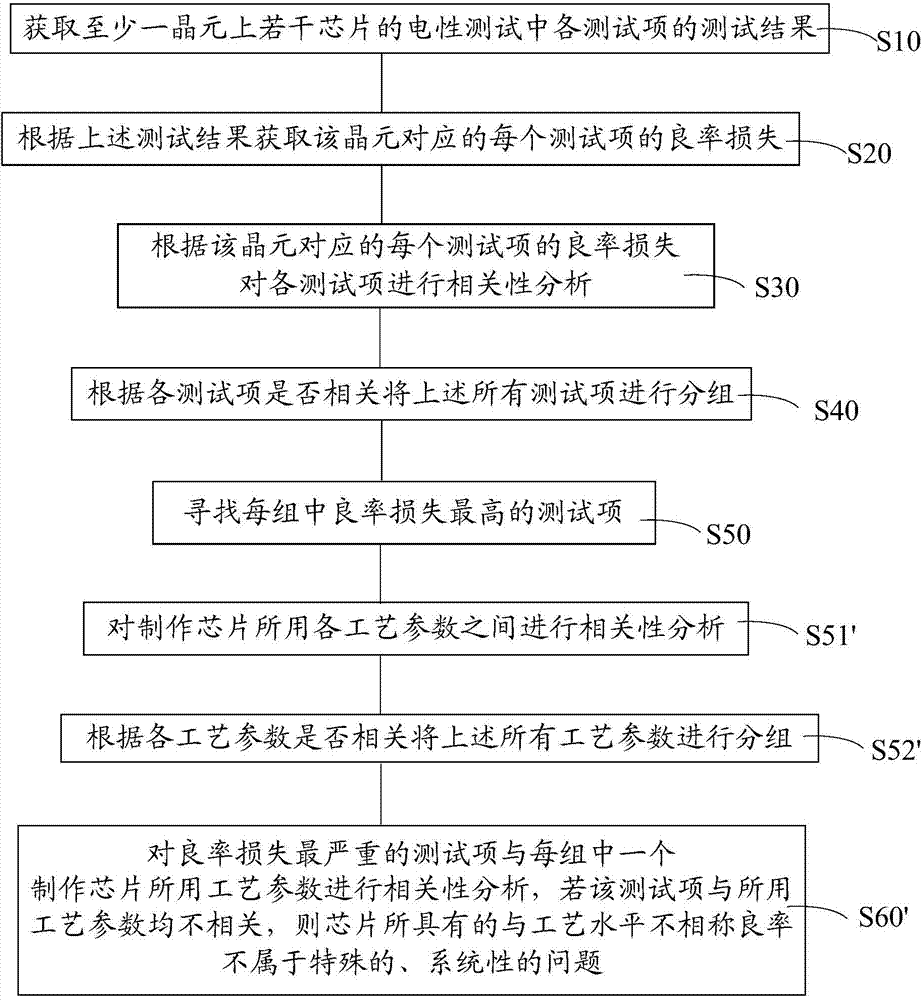

[0039] As mentioned in the background technology, in the prior art, when classifying chips with a yield rate that is not commensurate with the technological level, misjudgment is likely to occur, and the yield rate is too low due to, for example, defects in the product itself, insufficient design, etc. Classified as a special and systematic problem, this will cause the manufacturer to spend a lot of manpower and material resources to improve the yield of the product with little effect. In view of the above problems, the present invention proposes based on the individualized product itself, and according to the test results of each test item in the chip electrical test, a correlation analysis is carried out between the test item and the process parameters used for making the chip. If it is not relevant, it is judged that the low yield rate of the chip is not a special and systematic problem; in addition, in order to avoid the large amount of calculation in the correlation analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com