Vacuum degree monitoring method and device in high-voltage vacuum circuit breaker

A vacuum circuit breaker and monitoring device technology, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve problems such as poor applicability, high cost, and threats to circuit breaker insulation, and achieve fast response and simple structure , the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

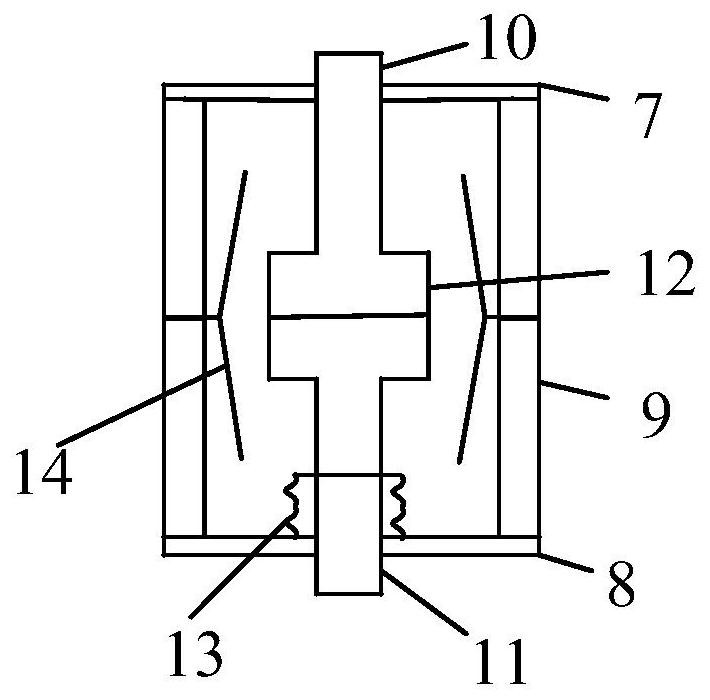

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

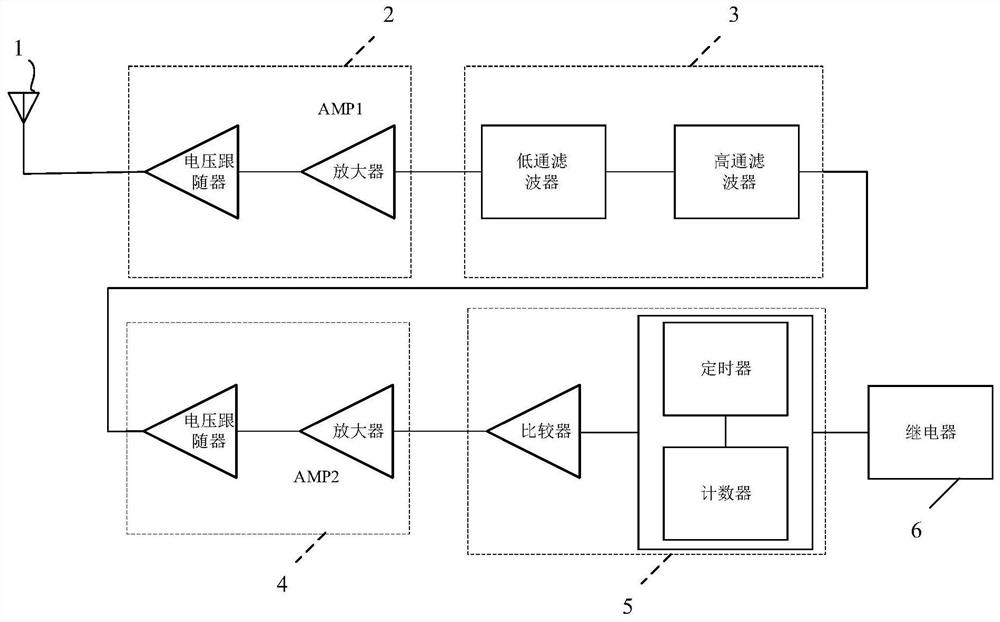

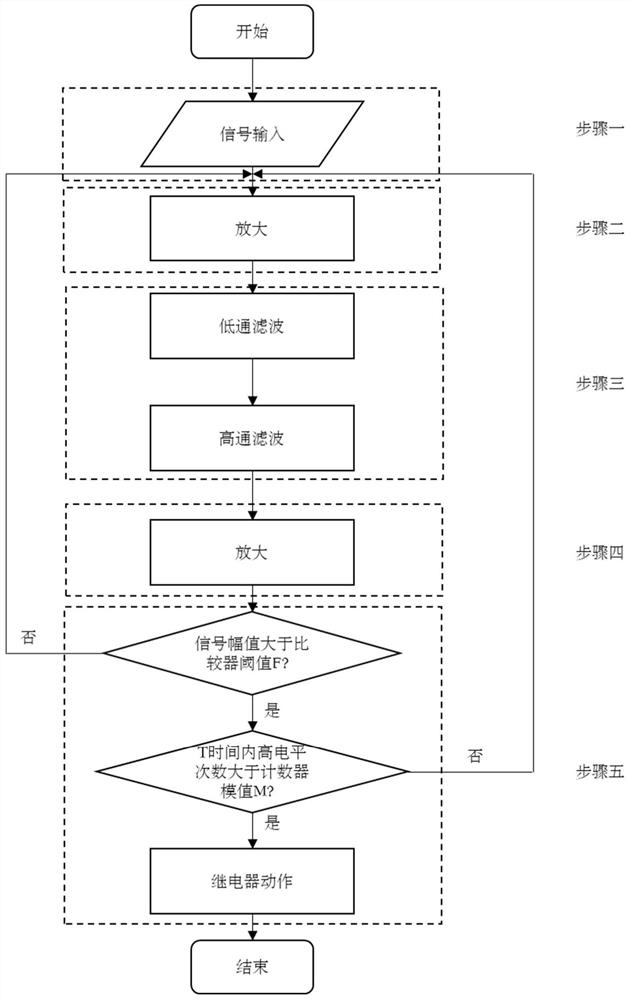

[0033] A method for monitoring vacuum degree in a high-voltage vacuum circuit breaker, comprising the following steps:

[0034] Step 1), obtaining the electromagnetic wave signal of the high-voltage vacuum circuit breaker to be monitored and converting it into an electrical signal;

[0035] Step 2), sequentially performing amplification processing, band-pass filtering processing and re-amplification processing on the converted electrical signal;

[0036] Step 3), comparing the re-amplified electrical signal with the set threshold of the comparator, when the electrical signal whose amplitude is greater than the set threshold of the comparator within the set time reaches the set counter modulus, it is judged to be monitored The vacuum degree of the high-voltage vacuum circuit breaker drops, triggering the action of the relay.

[0037] The threshold value set by the compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com