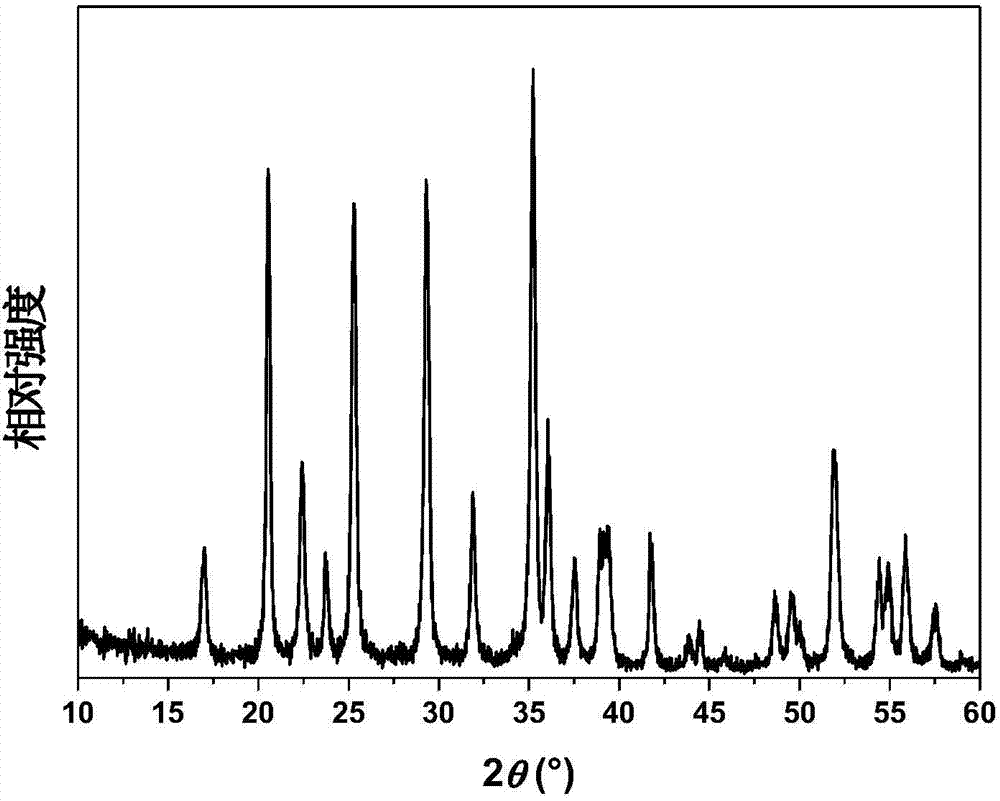

Nanorod-like lithium manganese phosphate anode material and preparation method thereof

A lithium manganese phosphate, cathode material technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as unsatisfactory electrochemical performance, difficulty in providing energy density, complex reaction system, etc. Contact, easy to scale production, the effect of simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

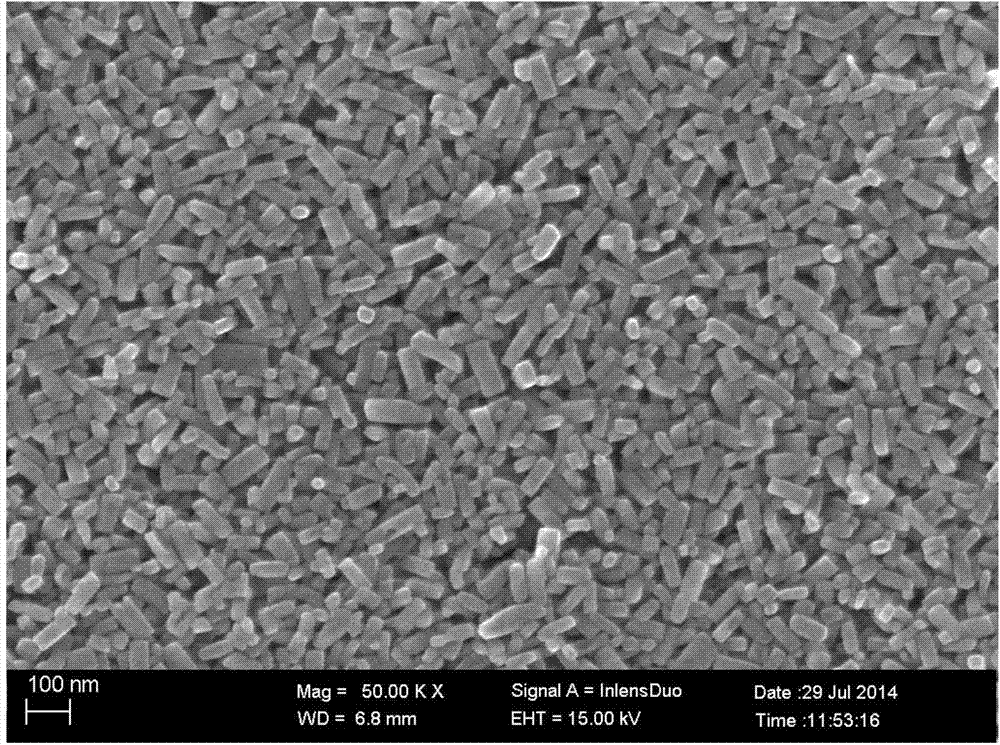

Embodiment 1

[0031] (1) take by weighing 10mmol phosphoric acid and 10mmol monohydrate manganese sulfate, both are dissolved in 5mL water, add 25mL ethylene glycol solution and fully stir, obtain the mixed solution of phosphoric acid and monohydrate manganese sulfate, wherein the volume of water and ethylene glycol The ratio is 1:5, and the concentrations of phosphoric acid and manganese sulfate monohydrate are both 0.33mol / L;

[0032] (2) take by weighing 30mmol monohydrate lithium hydroxide, be dissolved in 30mL ethylene glycol to obtain lithium hydroxide solution, wherein the concentration of lithium hydroxide is 1mol / L;

[0033] (3) adding the lithium hydroxide solution prepared in step (2) to the mixed solution of phosphoric acid prepared in step (1) and manganese sulfate monohydrate at a rate of 2 mL / min, and fully stirring to obtain a uniform suspension;

[0034] (4) Transfer the suspension in step (3) to a high-pressure reaction kettle for solvothermal reaction, the reaction temper...

Embodiment 2

[0040] (1) take by weighing 20mmol phosphoric acid and 20mmol monohydrate manganese sulfate, both are dissolved in 10mL water, add 20mL ethylene glycol solution and fully stir, obtain the mixed solution of phosphoric acid and monohydrate manganese sulfate, wherein the volume of water and ethylene glycol The ratio is 1:2, and the concentrations of phosphoric acid and manganese sulfate monohydrate are both 0.66mol / L;

[0041] (2) take by weighing 60mmol monohydrate lithium hydroxide, be dissolved in 30mL ethylene glycol to obtain lithium hydroxide solution, wherein the concentration of lithium hydroxide is 2mol / L;

[0042] (3) adding the lithium hydroxide solution prepared in step (2) into the mixed solution of phosphoric acid prepared in step (1) and manganese sulfate monohydrate at a rate of 5mL / min, and fully stirring to obtain a uniform suspension;

[0043] (4) Transfer the suspension in step (3) to a high-pressure reaction kettle for solvothermal reaction, the reaction temp...

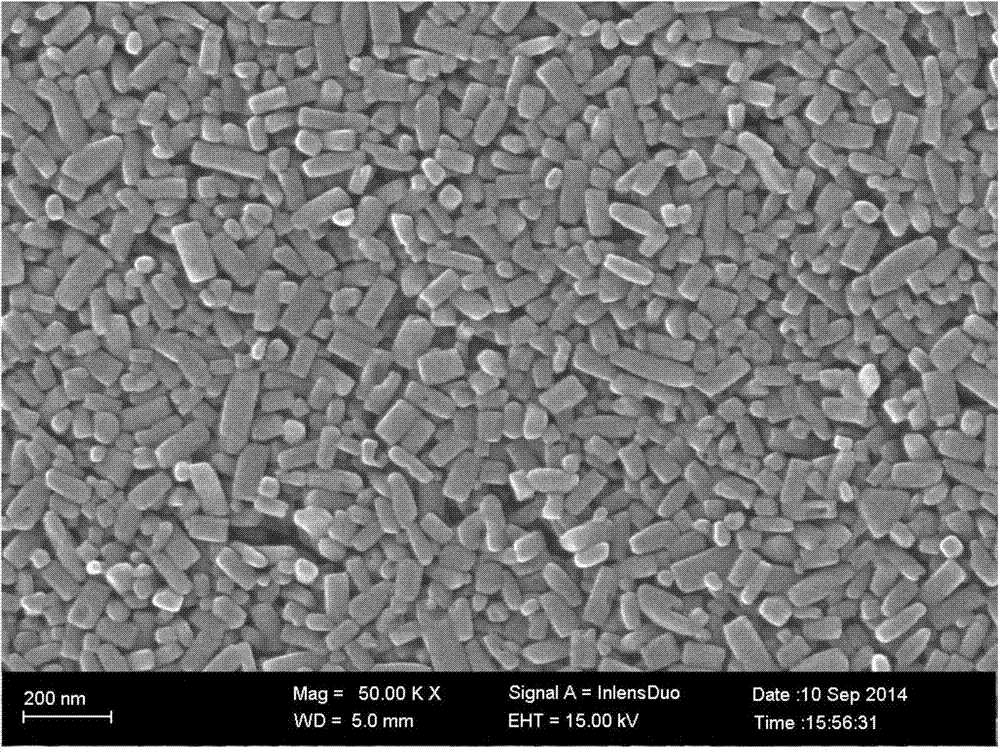

Embodiment 3

[0049] (1) take by weighing 10mmol phosphoric acid and 10mmol monohydrate manganese sulfate, both are dissolved in 10mL water, add 20mL ethylene glycol solution and fully stir, obtain the mixed solution of phosphoric acid and monohydrate manganese sulfate, wherein the volume of water and ethylene glycol The ratio is 1:2, and the concentrations of phosphoric acid and manganese sulfate monohydrate are both 0.33mol / L;

[0050] (2) take by weighing 30mmol monohydrate lithium hydroxide, be dissolved in 30mL ethylene glycol to obtain lithium hydroxide solution, wherein the concentration of lithium hydroxide is 1mol / L;

[0051] (3) adding the lithium hydroxide solution prepared in step (2) to the mixed solution of phosphoric acid prepared in step (1) and manganese sulfate monohydrate at a rate of 10 mL / min, fully stirring to obtain a uniform suspension;

[0052] (4) The suspension in step (3) was transferred to a high-pressure reaction kettle for solvothermal reaction, the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com