Novel method for quickly preparing high-performance Mg2Si0.3Sn0.7-based thermoelectric material

A thermoelectric material and high-performance technology, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of precise control of the composition that cannot be obtained by the melting method, many times of reaction, and long reaction time. Achieve the effect of extremely short preparation time, uniform distribution of ingredients and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A rapid preparation of high-performance Mg 2 Si 0.3 sn 0.7 A new method based on thermoelectric materials, which includes the following steps:

[0029] 1) Using Mg powder, Si powder, Sn powder and Sb powder as raw materials, according to Mg 2(1+0.08) (Si 0.3 sn 0.7 ) 0.98 Sb 0.02 (The 8% excess of Mg is to compensate for the volatilization loss of Mg). The stoichiometric ratio of the ingredients, the total weight is 5.5g, and the raw material powders are mixed evenly by hand in a mortar to obtain a uniformly mixed powder. The body is pressed into a cylindrical block with a diameter of 12.7mm on a tablet press (5MPa for 5min, then 8MPa for 10min);

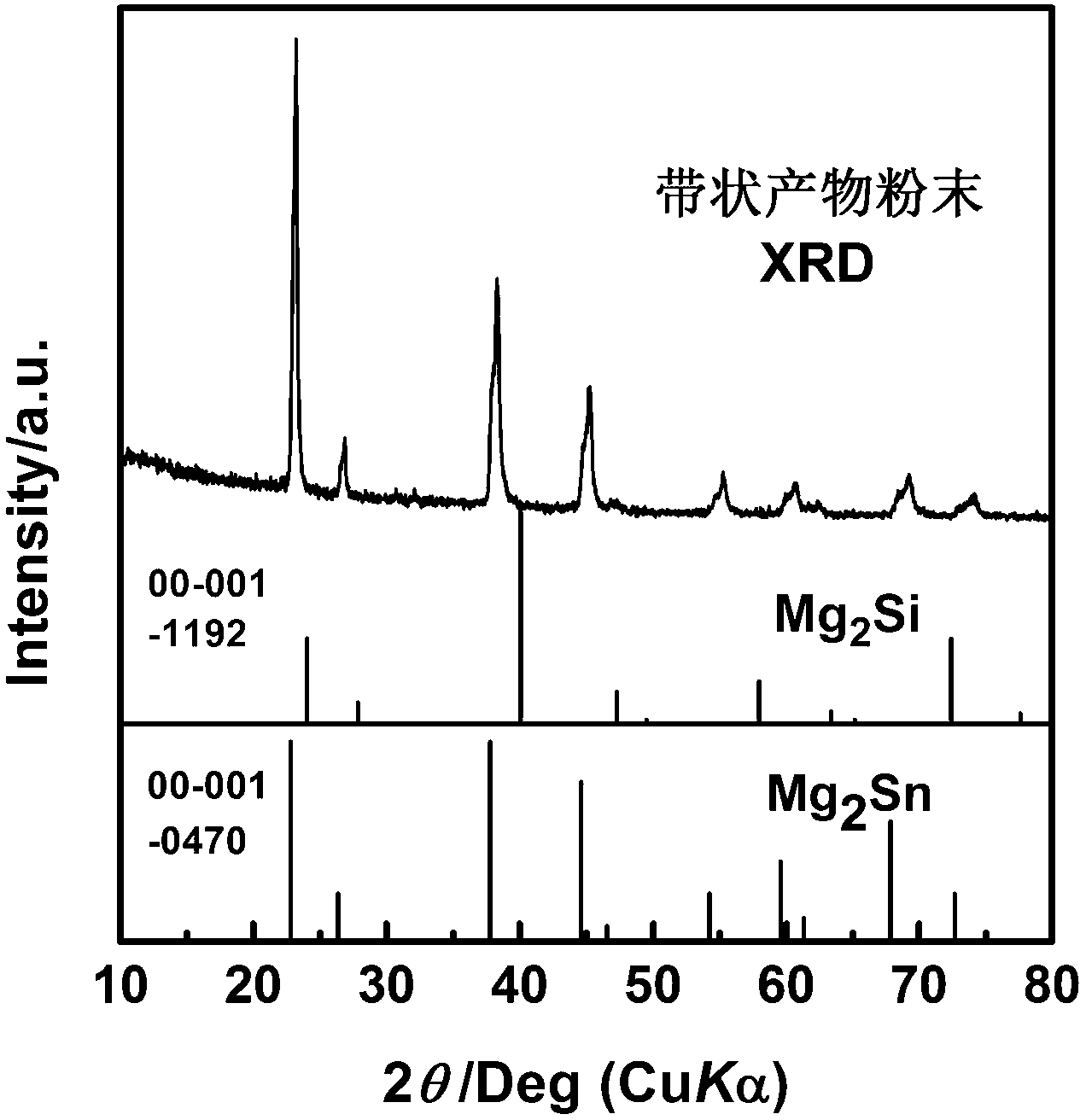

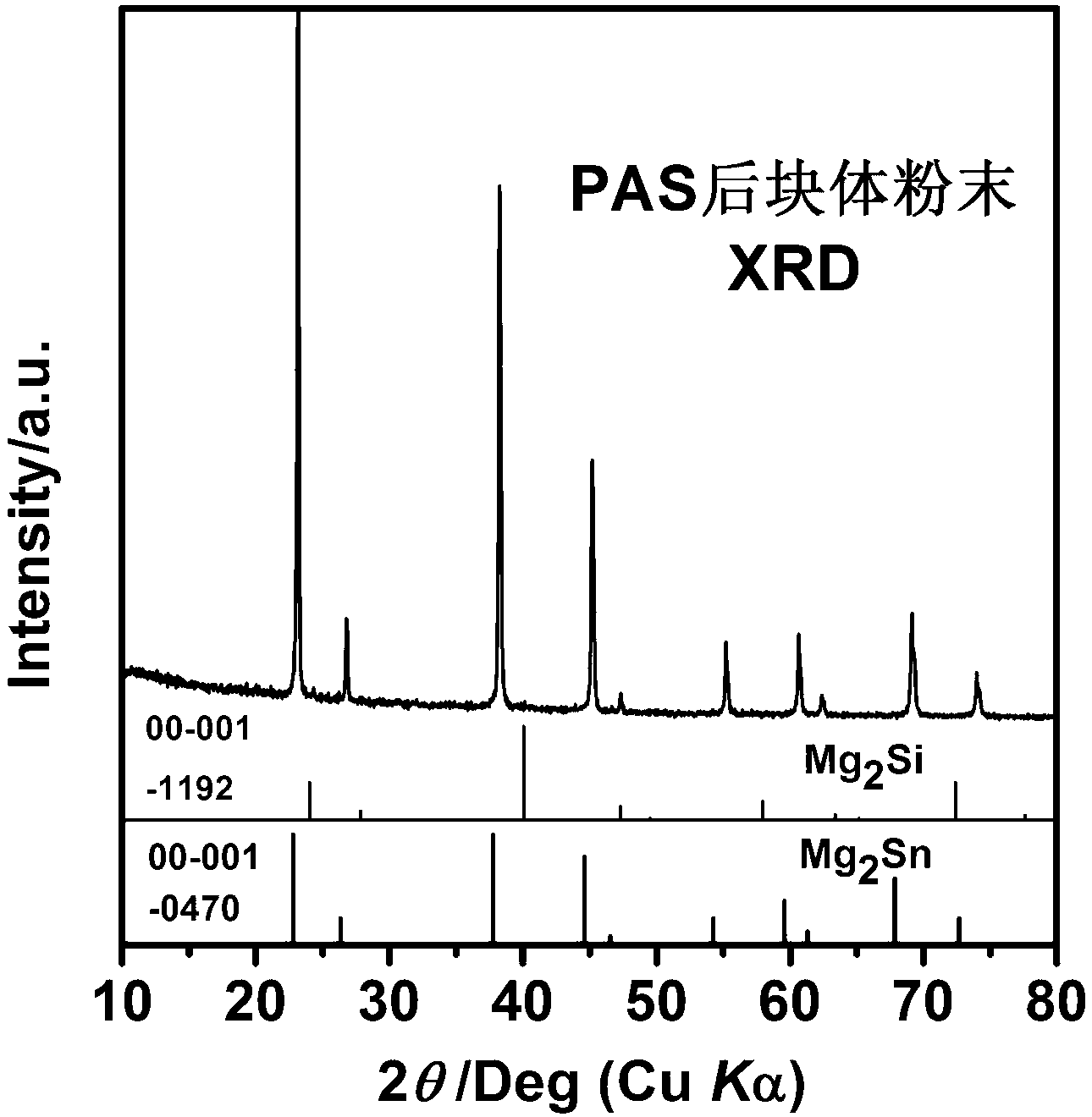

[0030] 2) Put the above-mentioned cylindrical block in a graphite crucible, and then put it in a melt spinning quenching device for melt spinning. The cavity is an argon atmosphere, and the relative pressure is -0.05MPa. When performing melt spinning , the induction voltage is 150V, the rotational speed of the copper ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com