Preparation method of ultraviolet and visible coexisting electroluminescent device

An electroluminescent device, ultraviolet technology, applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of energy level matching and structural design that increase the difficulty of preparation, affect the luminous efficiency of the device, and increase the difficulty of device preparation, etc., to achieve convenient batch production Simple production, high repeatability, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

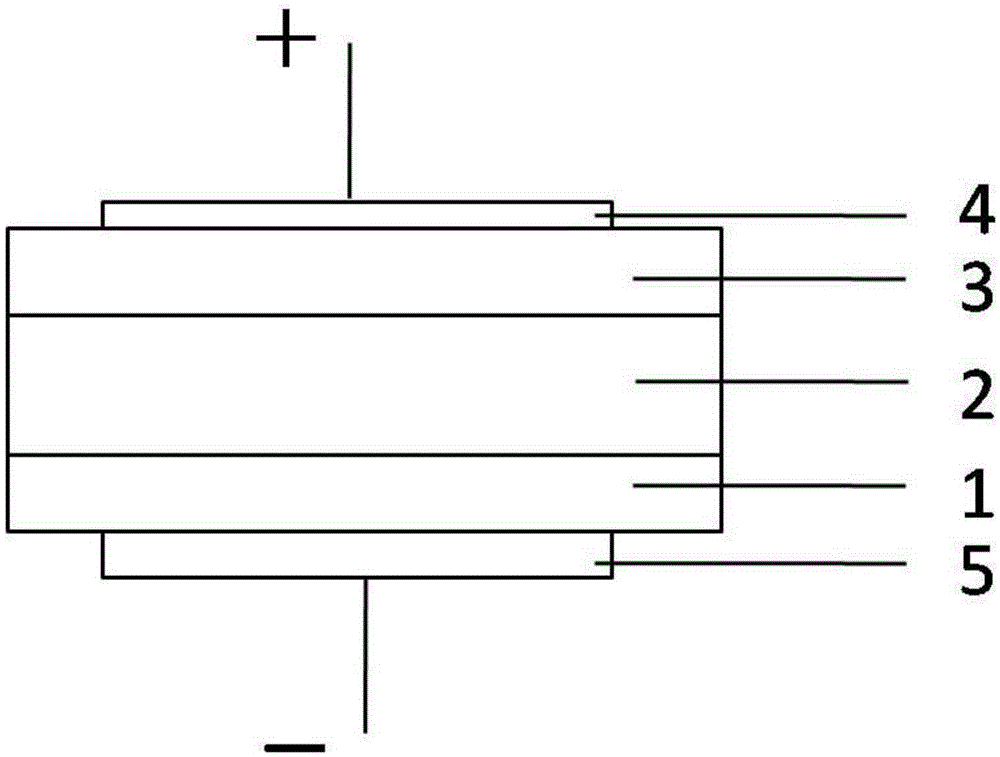

[0019] The invention provides a method for preparing the above-mentioned electroluminescent device, comprising:

[0020] (1) The CdZnO thin film is deposited on the substrate by sputtering, wherein the target used for depositing the CdZnO thin film is a CdZnO ceramic target, and the Cd doping amount in the CdZnO ceramic target is 60% by molar content, and the substrate heating temperature is 400 ~500°C, the sputtering power is 120W, the sputtering time is 1 hour, and the air pressure is 4Pa. Then put the film into a tube furnace under the protection of an inert atmosphere for heat treatment, the heat treatment temperature is 600-800°C, and the heat treatment time is 10-60 minutes;

[0021] (2) The MgO film is prepared on the CdZnO film by the sol-gel method, and then the film is subjected to heat treatment, the heat treatment temperature is 300-400° C., and the heat treatment time is 1-2 hours. ;

[0022] (3) A translucent Au electrode is deposited on the MgO film by sputter...

Embodiment 1

[0025] 1) Clean N-type , with a resistivity of 0.005 ohm cm and a size of 15×15mm 2 , a silicon wafer with a thickness of 675 microns;

[0026] 2) Deposit CdZnO film on Si substrate by radio frequency sputtering, substrate temperature is 400°C; sputtering power is 120W, Ar, O 2 The flow rate is 30:15, the air pressure is 4Pa, the sputtering is for 1 hour, and the thickness is about 400nm. After deposition in N 2 Heat treatment at 600°C for 1 hour in a tube furnace under atmosphere;

[0027] 3) Spin-coat a layer of MgO film on the CdZnO film, dry at 100°C for 10 minutes, and heat-treat at 300°C for 2 hours in air;

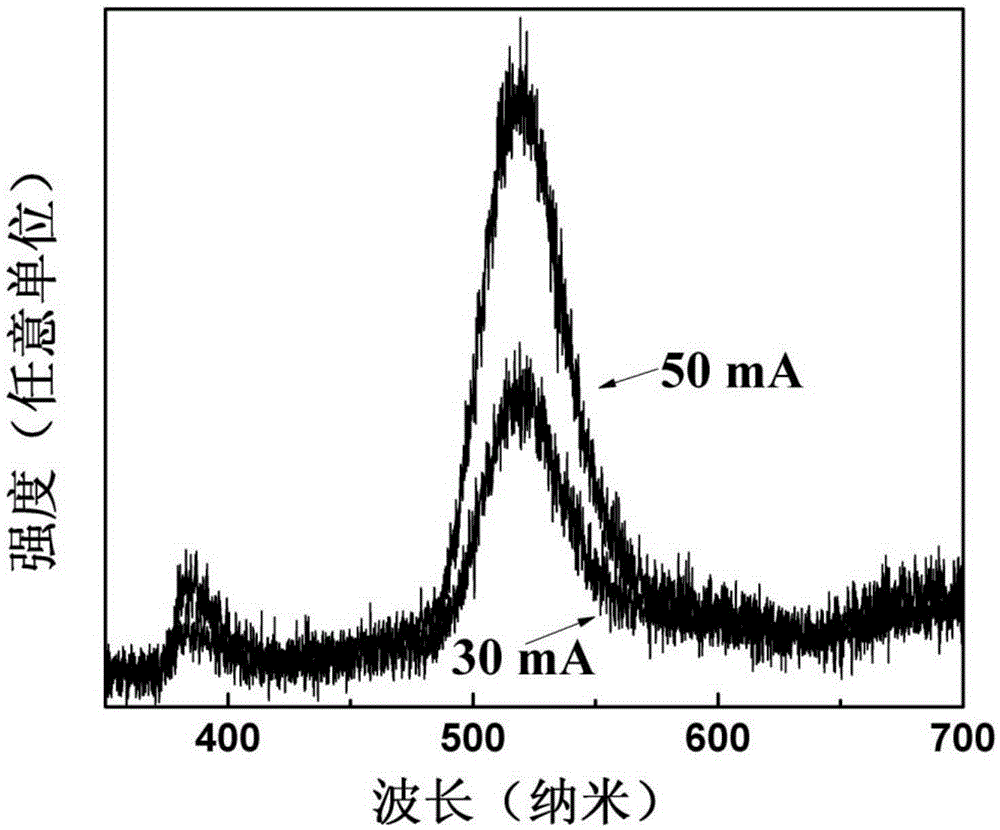

[0028] 4) A translucent Au electrode 4 about 20 nm thick is sputtered on the MgO film, and an Au electrode (ohmic contact electrode 5 ) about 100 nm thick is sputtered on the backside of the silicon substrate. The sputtering power is 45W, the Ar flow rate is 20, the air pressure is 5Pa, and the substrate temperature is 150°C. The front electrode was sputtered f...

Embodiment 2

[0031] 1) Clean N-type , with a resistivity of 50 ohm cm and a size of 15×15mm 2 , a silicon wafer with a thickness of 675 microns;

[0032] 2) Deposit CdZnO film on Si substrate by radio frequency sputtering, substrate temperature is 500°C; sputtering power is 120W, Ar, O 2 The flow rate is 30:15, the air pressure is 4Pa, the sputtering is for 1 hour, and the thickness is about 400nm. After deposition in N 2 Heat treatment at 800°C for 10 minutes in a tube furnace under atmosphere;

[0033] 3) Spin-coat a layer of MgO film on the CdZnO film, dry at 100°C for 10 minutes, and heat-treat at 400°C for 1 hour in air;

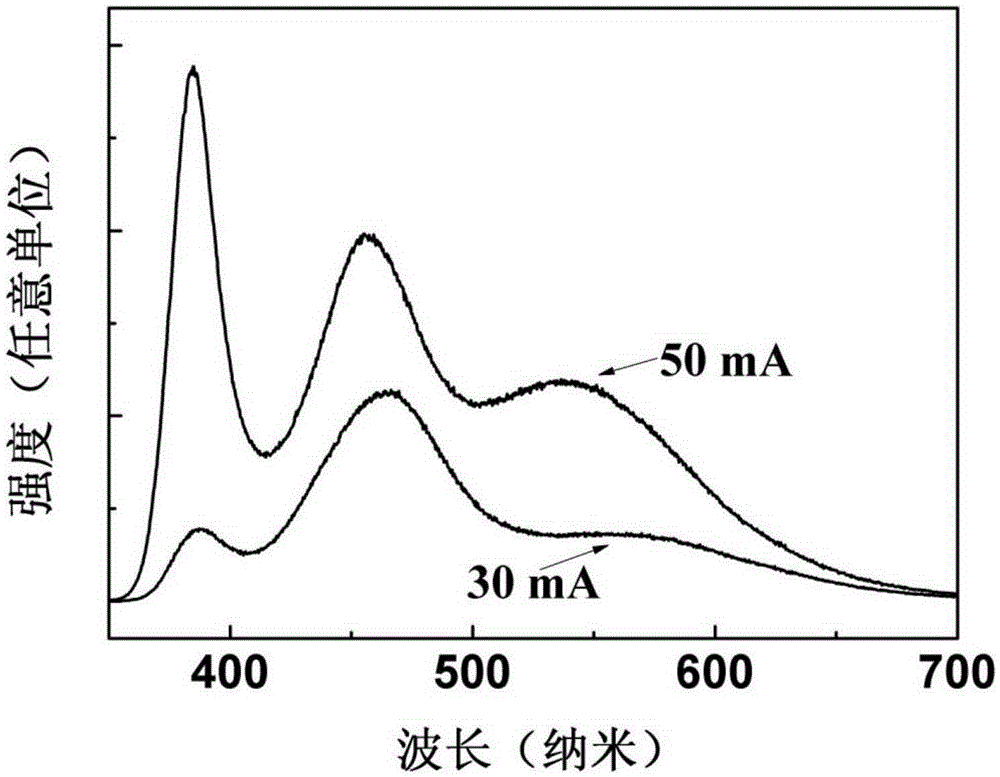

[0034] 4) A translucent Au electrode 4 about 20 nm thick is sputtered on the MgO film, and an Au electrode (ohmic contact electrode 5 ) about 100 nm thick is sputtered on the backside of the silicon substrate. The sputtering power is 45W, the Ar flow rate is 20, the air pressure is 5Pa, and the substrate temperature is 150°C. The front electrode was sputtered f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com