Hollow slow-release microsphere used for loading medicine and preparation method thereof

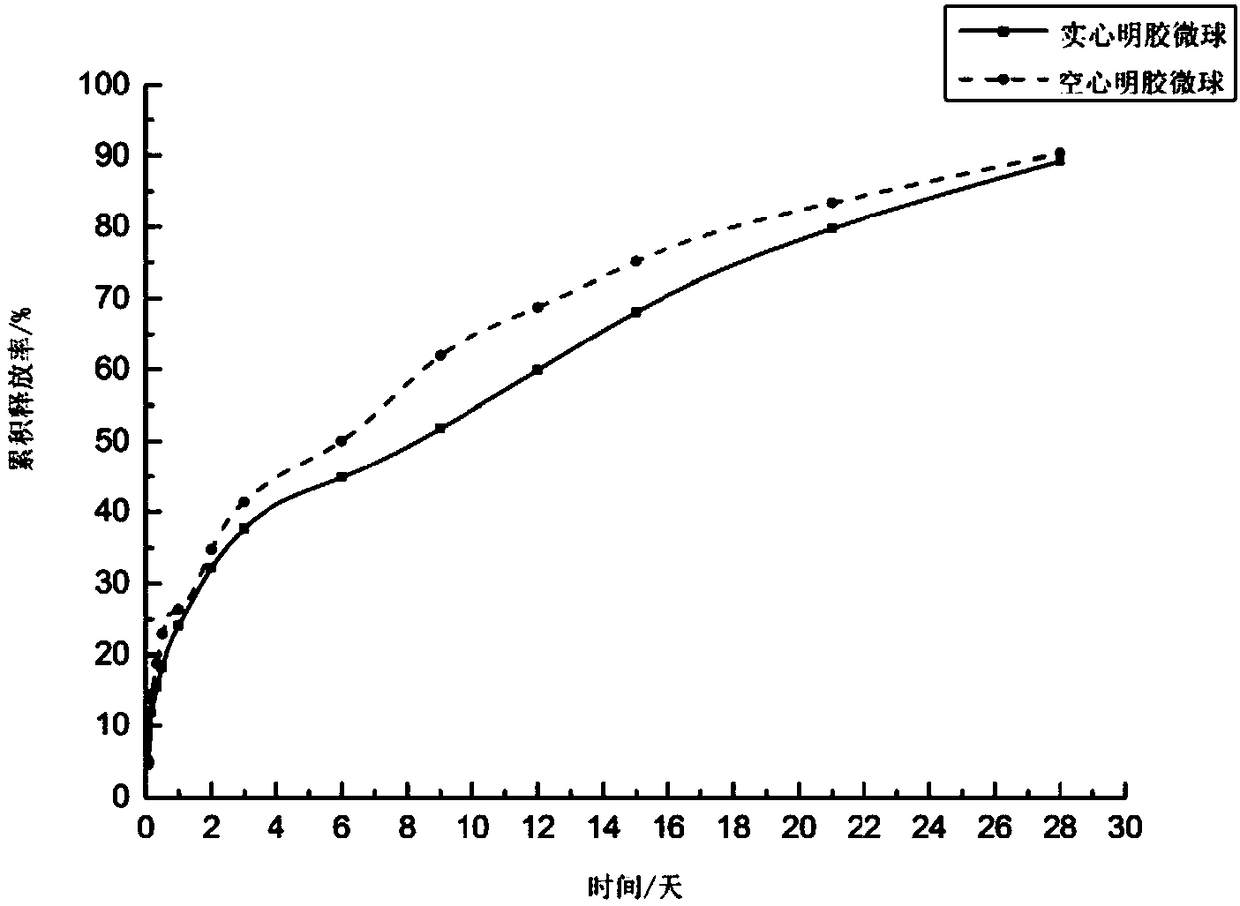

A slow-release microsphere and hollow technology, which is applied to pharmaceutical formulations, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc., can solve the problems of low loading and slow drug loading, and achieve the preparation method It has the effect of low price and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the hollow sustained-release microspheres for drug loading in this embodiment comprises the following steps:

[0032] (1) Polystyrene microspheres are prepared by emulsification cross-linking method, polystyrene microspheres and emulsifier are added to oil phase paraffin, the shell polymer material is dissolved in water and then added dropwise to oil phase paraffin, stirring After emulsification, cool in an ice-water bath to below 5°C, add glutaraldehyde dropwise for cross-linking for 0.5 h, then add acetone, and obtain solid microspheres after layered filtration.

[0033] Wherein, preparing polystyrene microspheres comprises the following steps:

[0034] (11) Mix sodium lauryl sulfate with a concentration of 0.015g / mL and potassium persulfate with a concentration of 0.012g / mL according to the volume ratio of 85:15, fill with inert gas and heat and stir in a water bath at 60°C 20min, the stirring speed is 200rpm; the monomer styrene is dissolv...

Embodiment 2

[0040] The preparation method of the hollow sustained-release microspheres for drug loading in this embodiment comprises the following steps:

[0041] (1) Polystyrene microspheres are prepared by emulsification and cross-linking method, polystyrene microspheres and emulsifier are added to the oil phase paraffin, the shell polymer material is dissolved in water and then added dropwise to the oil phase paraffin, stirring After emulsification, cool in an ice-water bath to below 5°C, add glutaraldehyde dropwise for cross-linking for 2 hours, then add acetone, and obtain solid microspheres after layered filtration.

[0042] Wherein, preparing polystyrene microspheres comprises the following steps:

[0043] (11) Mix sodium lauryl sulfate with a concentration of 0.02g / mL and potassium persulfate with a concentration of 0.018g / mL according to a volume ratio of 95:5, fill with inert gas and heat and stir in a water bath at 90°C 5min, the stirring speed is 1000rpm; the monomer styrene ...

Embodiment 3

[0049] The preparation method of the hollow sustained-release microspheres for drug loading in this embodiment comprises the following steps:

[0050] (1) Polystyrene microspheres are prepared by emulsification and cross-linking method, polystyrene microspheres and emulsifier are added to the oil phase paraffin, the shell polymer material is dissolved in water and then added dropwise to the oil phase paraffin, stirring After emulsification, cool in an ice-water bath to below 5°C, add glutaraldehyde dropwise for cross-linking for 1 hour, then add acetone, and obtain solid microspheres after layered filtration.

[0051] Wherein, preparing polystyrene microspheres comprises the following steps:

[0052] (11) Mix sodium lauryl sulfate with a concentration of 0.018g / mL and potassium persulfate with a concentration of 0.015g / mL at a volume ratio of 90:10, fill with inert gas and heat and stir in a water bath at 80°C 15min, the stirring speed is 500rpm; the monomer styrene is dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com