Preparation method of visible light photo-catalyst

A photocatalyst and visible light technology, which is applied in the field of visible light photocatalyst preparation, can solve the problems of low utilization rate of visible light and low photon quantum efficiency, and achieve the effects of easy control of doping amount, simple process parameters and polymerization inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

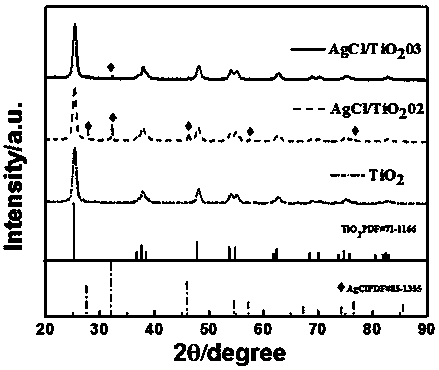

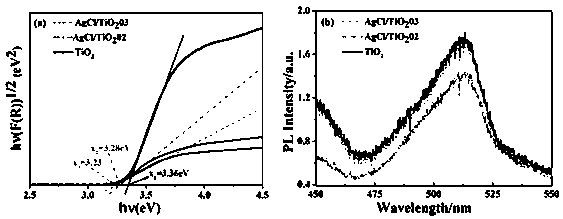

[0027] Efficient preparation of nano AgCl / TiO by ion exchange method 2 The visible light photocatalyst, its specific steps are as follows:

[0028] (1) Take 10mL of tetrabutyl titanate and add it to 20mL of ethanol, and mix thoroughly to obtain ethanol solution A of tetrabutyl titanate, take 5mL of distilled water and add it to 25mL of ethanol, and mix thoroughly to obtain an ethanol solution mixed with distilled water b.

[0029] (2) Add solution B dropwise to solution A which is constantly stirring according to the volume ratio of 1:1. After adding solution B dropwise, stir the mixed solution under magnetic stirring for 5 minutes to obtain a sol.

[0030] (3) Pour the above sol into a hydrothermal reactor and react under high pressure at 140°C for 24h to obtain TiO 2 wet gel, dry the wet gel in an oven at 80°C for 24 hours to obtain a dry gel.

[0031] (4) Grind the obtained dry gel into a powder and sieve it under a 500-mesh sieve, and then calcinate at 400°C for 6h to o...

Embodiment 2

[0037] Efficient preparation of nano AgCl / TiO by ion exchange method 2 The visible light photocatalyst, its specific steps are as follows:

[0038] (1) Take 10mL of tetrabutyl titanate and add it to 30mL of ethanol, and mix thoroughly to obtain ethanol solution A of tetrabutyl titanate, take 5mL of distilled water and add it to 30mL of ethanol, and mix thoroughly to obtain an ethanol solution mixed with distilled water b.

[0039] (2) Add the solution B dropwise to the continuously stirring solution A according to the volume ratio of 1:1.2. After adding the solution B dropwise, stir the mixed solution under magnetic stirring for 5 minutes to obtain a sol.

[0040] (3) Pour the above sol into a hydrothermal reactor and react under high pressure at 160°C for 18 hours to obtain TiO 2 wet gel, dry the wet gel in an oven at 90°C for 22 hours to obtain a dry gel.

[0041] (4) Grind the obtained dry gel into a powder and sieve it under a 300-mesh sieve, and then calcinate at 500°C...

Embodiment 4

[0056] Efficient preparation of nano AgCl / TiO by ion exchange method 2 The visible light photocatalyst, its specific steps are as follows:

[0057] (1) Take 10mL of tetrabutyl titanate and add it to 50mL of ethanol, and mix thoroughly to obtain ethanol solution A of tetrabutyl titanate, take 5mL of distilled water and add it to 35mL of ethanol, and mix thoroughly to obtain an ethanol solution mixed with distilled water b.

[0058] (2) Add solution B dropwise to the constantly stirring solution A at a volume ratio of 1:1.5. After adding solution B dropwise, stir the mixed solution under magnetic stirring for 5 minutes to obtain a sol.

[0059] (3) Pour the above sol into a hydrothermal reactor and react under high pressure at 180°C for 16 hours to obtain TiO 2 wet gel, dry the wet gel in an oven at 100°C for 20 hours to obtain a dry gel.

[0060] (4) Grind the obtained dry gel into powder and sieve it under a 500-mesh sieve, and then calcinate at 600°C for 3h to obtain TiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com