A kind of positive electrode composite material of lithium ion battery and preparation method thereof

A lithium-ion battery and composite material technology, applied in the field of lithium-ion batteries, can solve the problems of large product particle size, poor electrochemical performance, and high production cost, and achieve the effects of uniform particle distribution, low formation temperature, and increased transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: LiMnPO 4 Preparation of carbon composite cathode materials

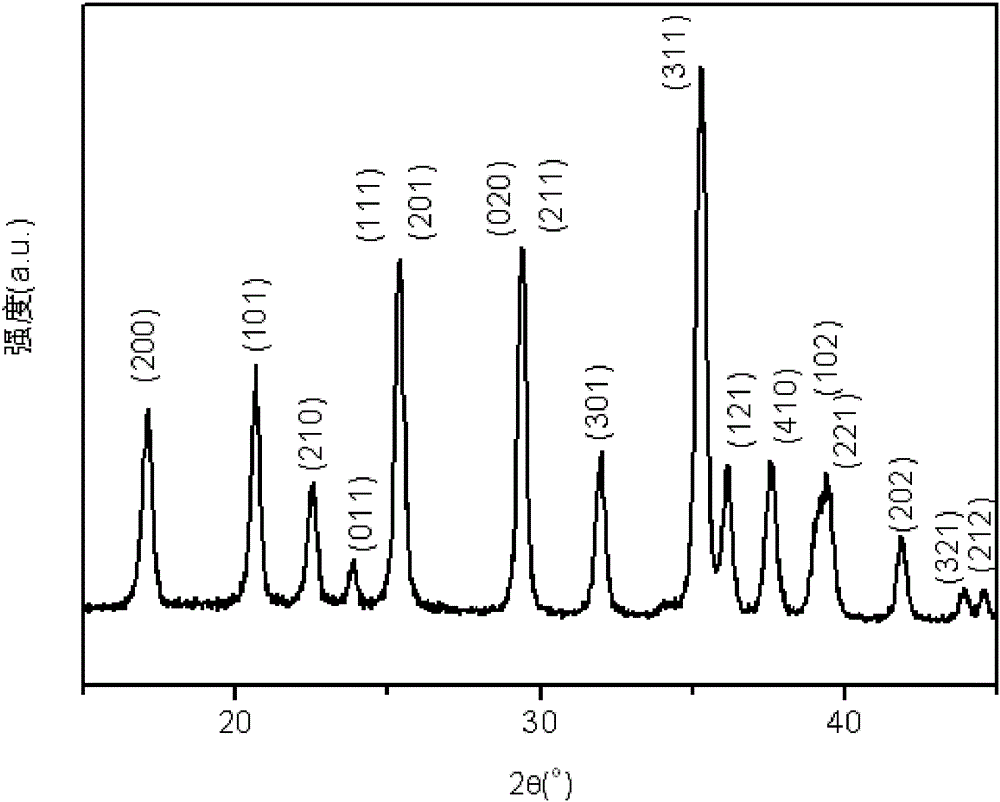

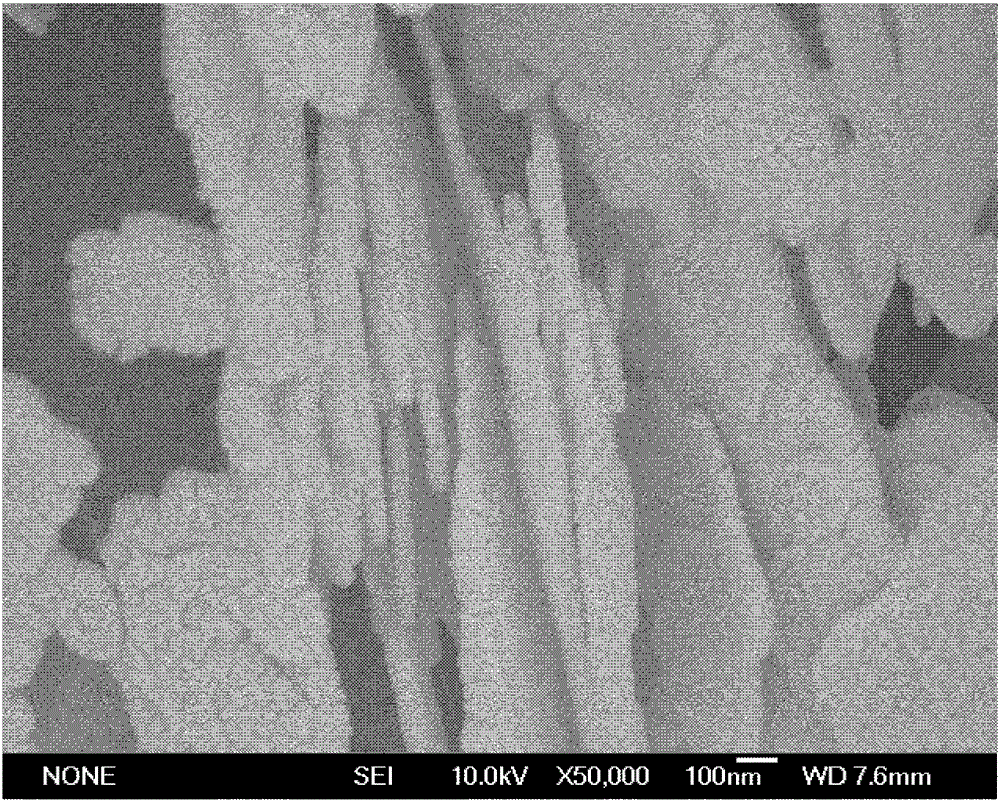

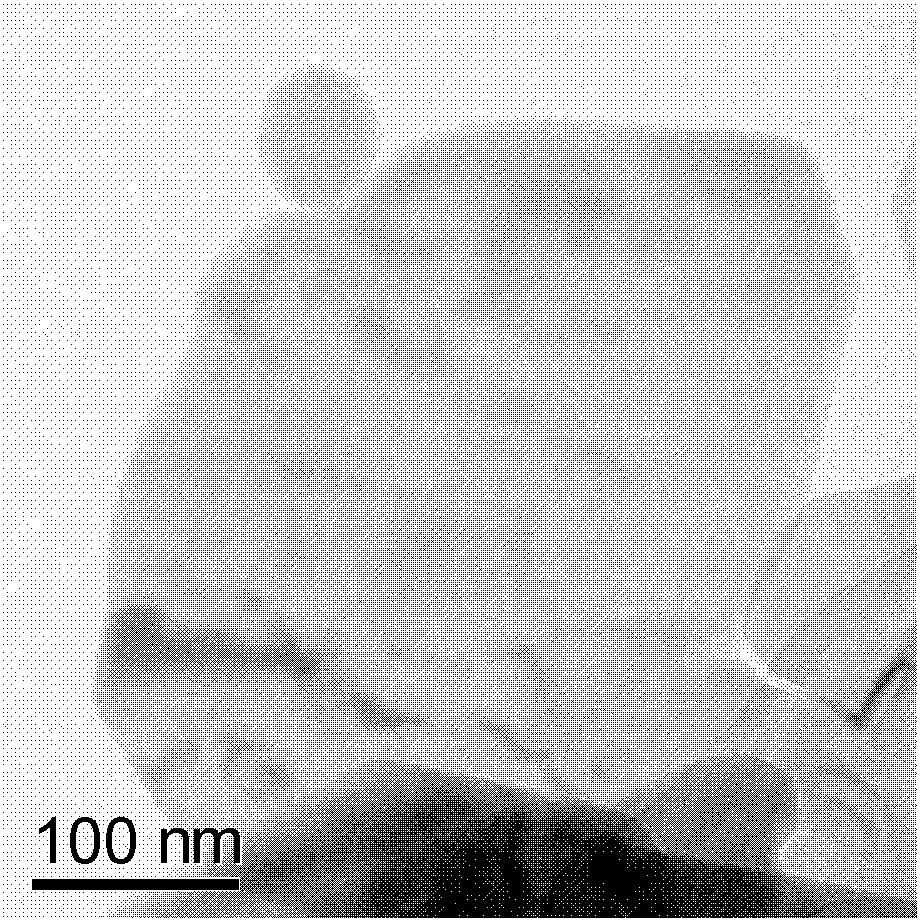

[0025] Dissolve manganese acetate in 30ml of diethylene glycol to prepare a solution with a manganese ion concentration of 0.02M, then dissolve lithium dihydrogen phosphate in 30ml of diethylene glycol to prepare a solution with a phosphate concentration of 0.02M, and then Slowly added dropwise to the diethylene glycol solution of manganese acetate prepared, stirred for 3 hours to obtain a pink suspension; the obtained suspension was put into a 100ml hydrothermal kettle, and heat-treated at a temperature of 180°C for 10 hours to obtain Pink precipitate; the precipitate was washed with deionized water and absolute ethanol respectively, and then dried at 60°C for 24 hours to obtain a final tap density of 1.2g / cm 3 LiMnPO 4 Nano powder. Its X-ray diffraction analysis (XRD) results show that its crystal phase is an olivine structure, such as figure 1 shown. Scanning electron microscope (SEM) photos...

Embodiment 2

[0028] Example 2: LiMn 0.98 Mg 0.02 PO 4 Preparation of carbon composite cathode materials

[0029]According to the stoichiometric ratio that the molar ratio of manganese ion and magnesium ion is 98:2, weigh and dissolve manganese sulfate and magnesium sulfate in 30ml polyethylene glycol 300 to prepare a solution with a metal ion concentration of 0.01M, and then add phosphoric acid Lithium dihydrogen was dissolved in 30ml of polyethylene glycol 300 to prepare a solution with a phosphate concentration of 0.01M, and then slowly added dropwise to the prepared polyethylene glycol 300 solution of manganese sulfate and magnesium sulfate, and stirred for 6 hours , to obtain a pink suspension; the obtained suspension was packed into a 100ml hydrothermal kettle, and heat-treated at a temperature of 120°C for 24 hours to obtain a pink precipitate; the precipitate was washed with deionized water and absolute ethanol respectively, Then dry at 80°C for 24 hours, and finally obtain a tap...

Embodiment 3

[0032] Example 3: LiMn 0.96 Mg 0.04 PO 4 Preparation of carbon composite cathode materials

[0033] According to the stoichiometric ratio of the molar ratio of manganese ions and magnesium ions being 96:4, dissolve manganese chloride and magnesium chloride in 30ml polyethylene glycol 400 to prepare a solution with a metal ion concentration of 0.05M, and then add phosphoric acid Lithium dihydrogen was dissolved in 30ml of polyethylene glycol 400 to prepare a solution with a phosphate concentration of 0.05M, and then slowly added dropwise to the prepared polyethylene glycol 400 solution of manganese chloride and magnesium chloride, and stirred for 12 hours , to obtain a pink suspension; put the obtained suspension into a 100ml hydrothermal kettle, and heat-treat it at 140°C for 18 hours to obtain a pink precipitate; wash the precipitate with deionized water and absolute ethanol respectively, Then dry at 100°C for 10 hours, and finally obtain a tap density of 1.3g / cm 3 LiMn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com