Palladium oxide supported zinc-based catalyst and preparation method and application thereof

A palladium oxide and catalyst technology, which is applied in the field of catalytic combustion of organic gas pollutants, can solve problems such as poor stability, high catalyst cost, and low palladium loading, and achieve the effects of low loading, good dispersion, and high solution cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

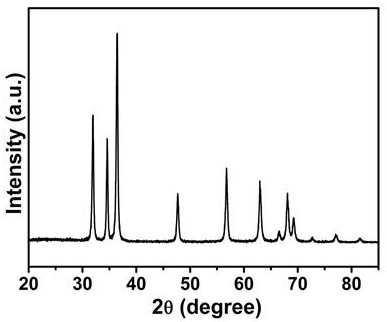

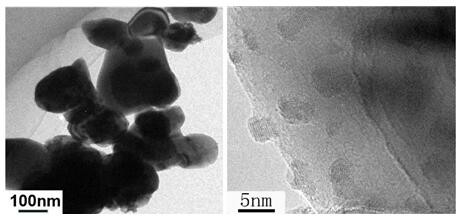

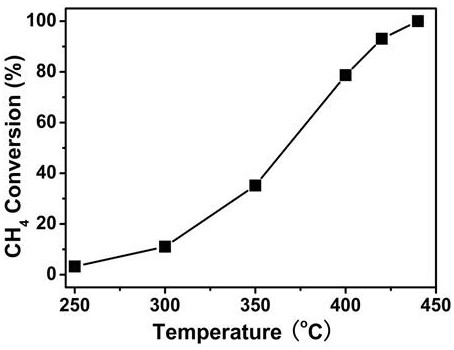

[0035] At room temperature, 50 mmol of zinc acetate and 5 mmol of zinc nitrate were completely dissolved in 80 mL of absolute ethanol by stirring to obtain a clear and transparent solution, which was then transferred to a polytetrafluoroethylene reactor, sealed with a stainless steel outer lining, and placed in an oven for 150 o C was reacted for 5 h, and after naturally cooling to room temperature, the resulting product was filtered, washed, and dried to obtain the zinc oxide carrier. The prepared zinc oxide sample of 1g was added into 100ml deionized water under stirring, and then dripped with a concentration of 0.005g / ml palladium nitrate solution (the weight percentage of palladium oxide was 0.4%), at 40 o C ultrasonication for 1 hour, the ultrasonic frequency is 20kHz, and the ultrasonic power is 150W, the resulting product is filtered, washed, and placed in an oven at 80 o C drying treatment for 5 hours, placed in a muffle furnace at 500 o C is calcined for 2 hours to o...

Embodiment 2

[0038] At room temperature, 50 mmol of zinc acetate and 5 mmol of zinc nitrate were completely dissolved in 80 mL of absolute ethanol by stirring to obtain a clear and transparent solution, which was transferred to a polytetrafluoroethylene reactor, sealed with a stainless steel outer lining, and placed in an oven for 150 o C was reacted for 5 h, and after naturally cooling to room temperature, the resulting product was filtered, washed, and dried to obtain the zinc oxide carrier. The prepared zinc oxide sample of 1g was added into 100ml deionized water under stirring, and then dripped with a concentration of 0.005g / ml palladium nitrate solution (the weight percentage of palladium oxide was 0.2%), at 40 o C ultrasonic 2 hours, ultrasonic frequency is 20kHz, ultrasonic power is 150W, gained product is filtered, washed, in oven 80 o C drying treatment for 5 hours, placed in a muffle furnace at 500 o C is calcined for 2 hours to obtain palladium oxide supported zinc-based cataly...

Embodiment 3

[0040]At room temperature, 50 mmol of zinc acetate and 5 mmol of zinc nitrate were completely dissolved in 80 mL of absolute ethanol by stirring to obtain a clear and transparent solution, which was then transferred to a polytetrafluoroethylene reactor, sealed with a stainless steel outer lining, and placed in an oven for 150 o C was reacted for 5 h, and after naturally cooling to room temperature, the resulting product was filtered, washed, and dried to obtain the zinc oxide carrier. The prepared zinc oxide sample of 1g was added into 100ml deionized water under stirring, and then dripped with a concentration of 0.005g / ml palladium chloride solution (the weight percentage of palladium oxide was 0.6%), at 40 o C ultrasonication for 1 hour, the ultrasonic frequency is 20kHz, and the ultrasonic power is 150W, the resulting product is filtered, washed, and placed in an oven at 80 o C drying treatment for 5 hours, placed in a muffle furnace at 500 o C is calcined for 2 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com