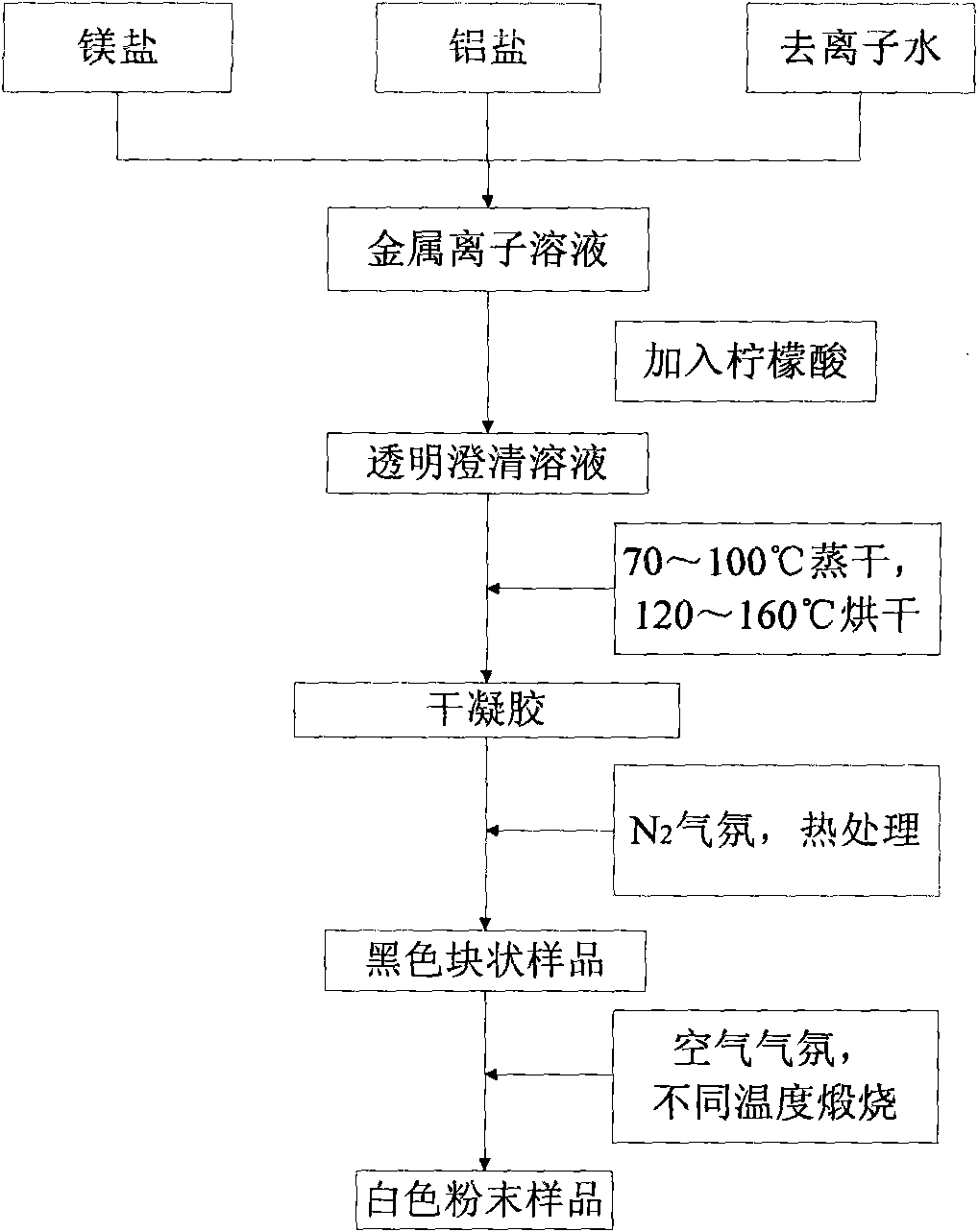

Nano mesoporous magnesium aluminate material and preparation method thereof

A kind of mesoporous magnesium aluminate and nanotechnology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of easy melting and condensation of solid propellants, incomplete combustion, performance loss, etc., to achieve easy control of preparation parameters, improve performance, The effect of high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

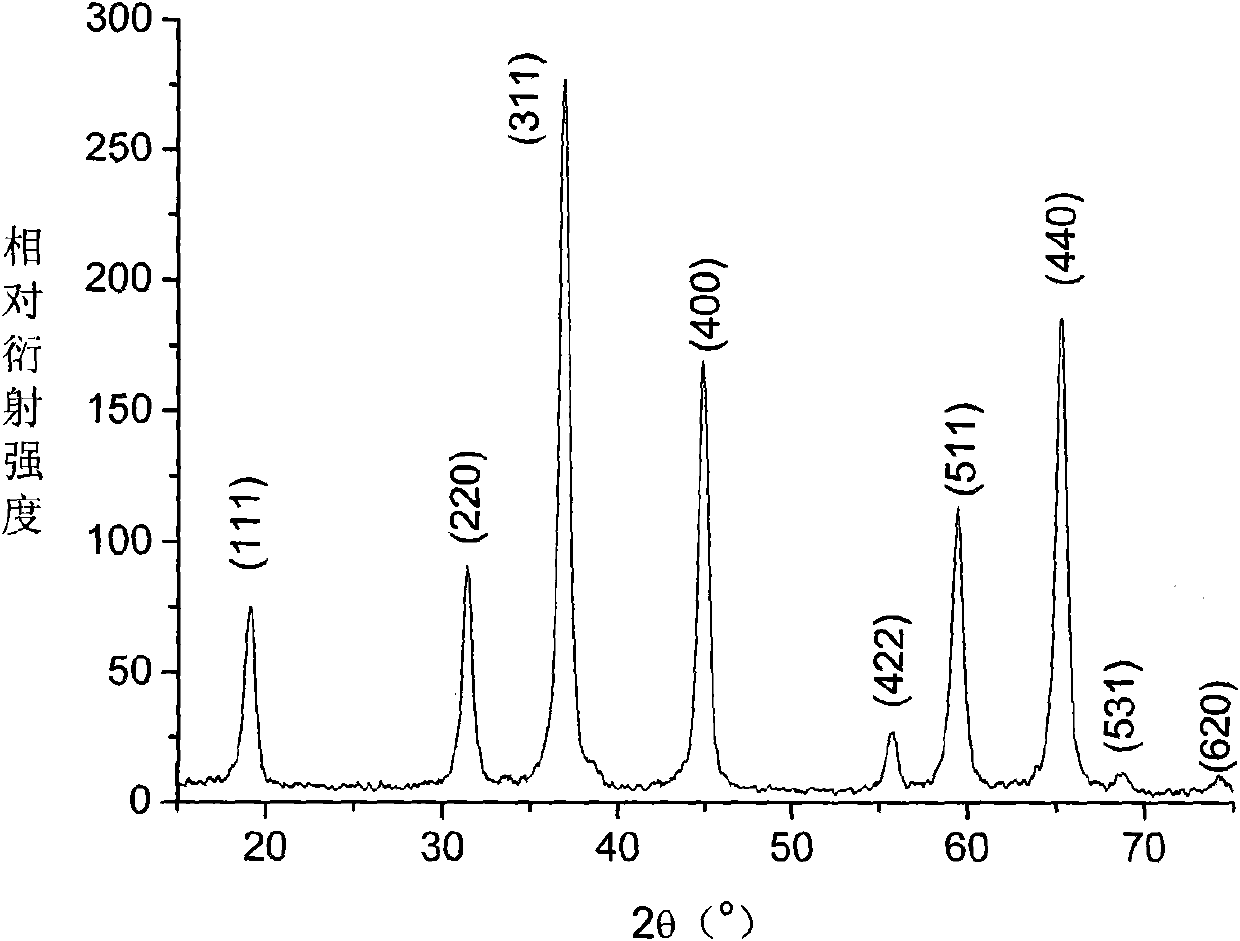

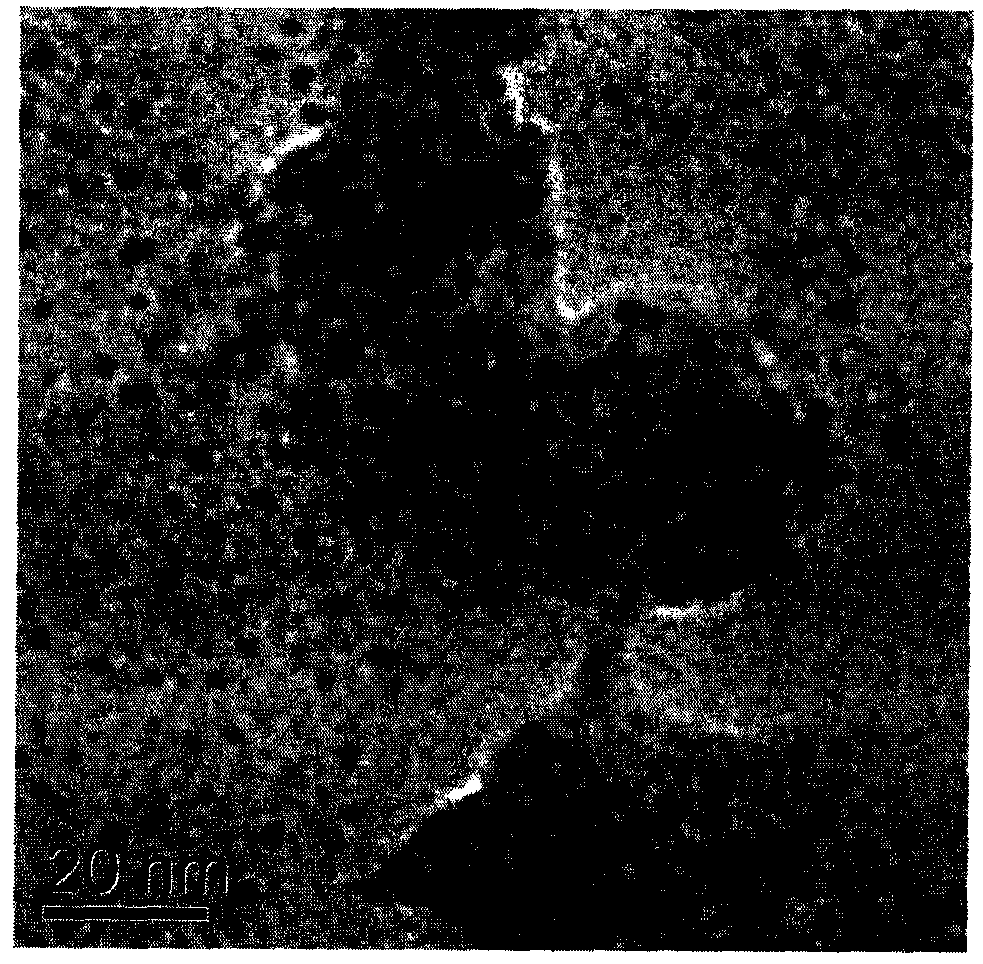

[0031] According to the stoichiometric ratio of the molar ratio of magnesium and aluminum ions being 1:2, weigh magnesium nitrate and aluminum nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, and add citric acid after forming a clear solution to make citric acid and The molar ratio of metal ions is 1.5:1. Use ammonia water to adjust the pH value of the solution to 5, and then heat and evaporate at 70°C to remove water to form a yellow viscous gel. After the water in the gel is evaporated to dryness, move it to a constant temperature oven Heated at 120°C for 6 hours to obtain a fluffy yellow xerogel; grind the xerogel in a mortar, put it in a tube furnace, and set it under N 2 In the atmosphere, calcining at 700° C. for 3 hours to obtain black powder; calcining the obtained black powder in air atmosphere at 700° C. for 2 hours to obtain white nanometer mesoporous magnesium aluminate powder. Its X-ray diffraction analysis (XRD) pattern is as f...

Embodiment 2

[0033] According to the stoichiometric ratio of the molar ratio of magnesium and aluminum ions being 1:2, weigh magnesium nitrate and aluminum nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, and add citric acid after forming a clear solution to make citric acid and The molar ratio of metal ions is 2:1, the pH value of the solution is adjusted to 2 with ammonia water, and then heated and evaporated at 80°C to remove water to form a yellow viscous gel. After the water in the gel is evaporated to dryness, move it to a constant temperature oven Heated at 150°C for 3 hours to obtain a fluffy yellow xerogel; ground the xerogel in a mortar, put it in a tube furnace, and heated it under N 2 Calcining at 800° C. for 0.5 hour in the atmosphere to obtain black powder; calcining the obtained black powder at 600° C. for 1 hour in air atmosphere to obtain white nanometer mesoporous magnesium aluminate powder. The X-ray diffraction analysis results show t...

Embodiment 3

[0035] According to the stoichiometric ratio of the molar ratio of magnesium and aluminum ions being 1:2, weigh magnesium acetate and aluminum nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, and add citric acid after forming a clear solution to make citric acid and The molar ratio of metal ions is 2.5:1. Use ammonia water to adjust the pH value of the solution to 3, and then heat and evaporate at 100°C to remove water to form a yellow viscous gel. After the water in the gel is evaporated to dryness, move it to a constant temperature oven Heated at 160°C for 2 hours to obtain a fluffy yellow xerogel; grind the xerogel in a mortar, put it in a tube furnace, and set it under N 2 In the atmosphere, calcining at 900° C. for 0.5 hours to obtain black powder; calcining the obtained black powder in air atmosphere at 500° C. for 2 hours to obtain white nanometer mesoporous magnesium aluminate powder. The X-ray diffraction analysis results show that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com