Silicon with three-dimensional hollow structure and method for preparing same

A three-dimensional hollow and hollow technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of unreported preparation methods, and achieve the effects of easy control of preparation parameters, good crystallization, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

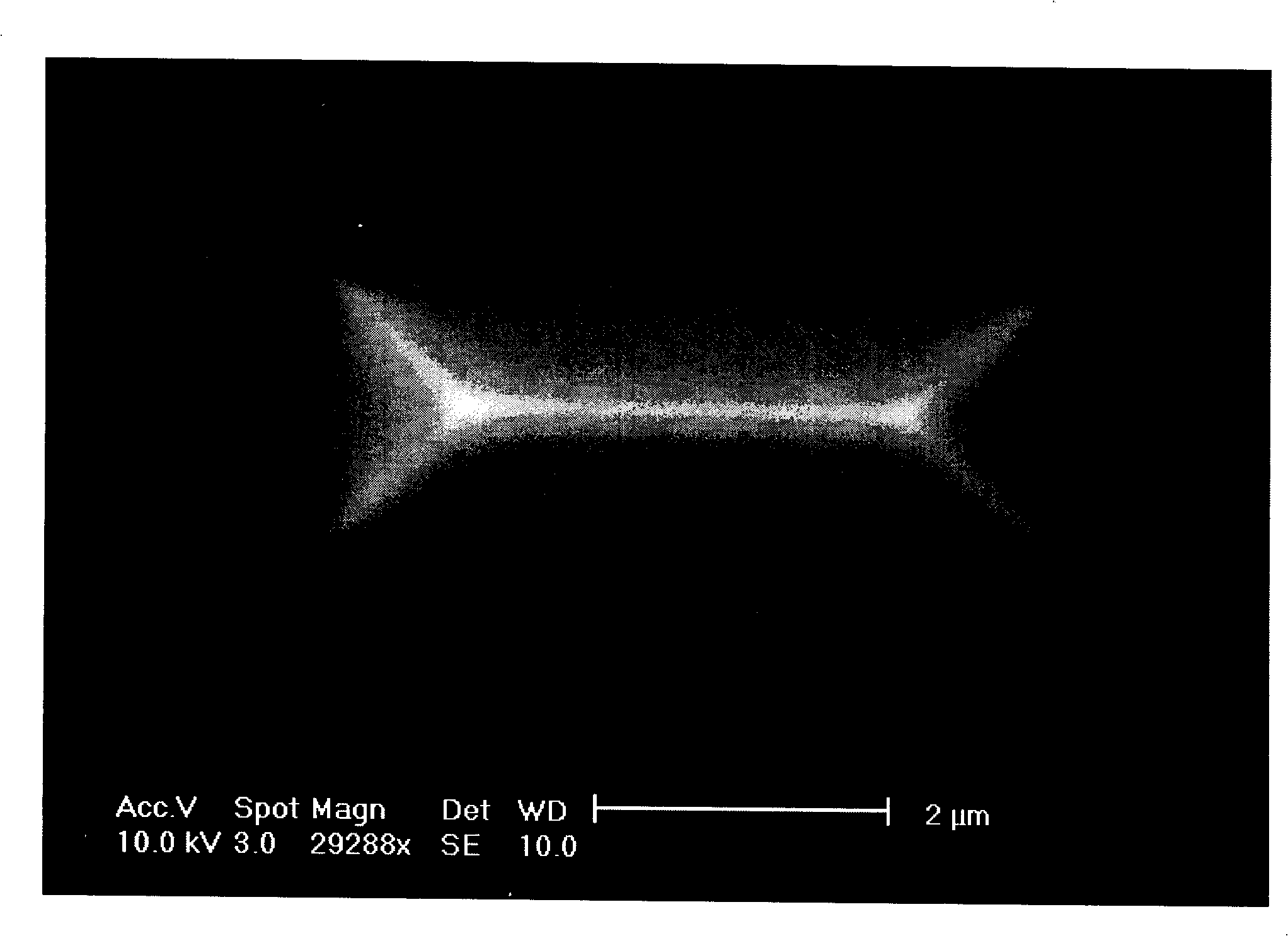

[0030] In this embodiment, the reaction raw materials used are 10mm×10mm silicon wafer (001 plane) and chemically pure metal zinc powder.

[0031] Firstly, the silicon wafer is cleaned by Pilar method to remove the oxide layer on the surface and impurities adsorbed on the surface. The size of the silicon wafer is generally cut into 10mm×10mm.

[0032] First put 3-4 pieces of silicon wafers face up, arrange them in sequence, place them in the quartz boat, and cover the silicon wafers with a layer of metal zinc powder, each with a mass of 0.2-0.3g. The quartz boat is placed in the center of the tube-type heating furnace. In addition, the quartz boat that is also equipped with 3-4 pieces of silicon wafers but not covered with zinc powder is placed in the lower tuyere 15cm away from the center of the tube-type heating up furnace.

[0033] After the sample is loaded into the tube-type heating furnace and sealed completely, the mechanical pump is turned on to pump air, so that the ...

Embodiment 2

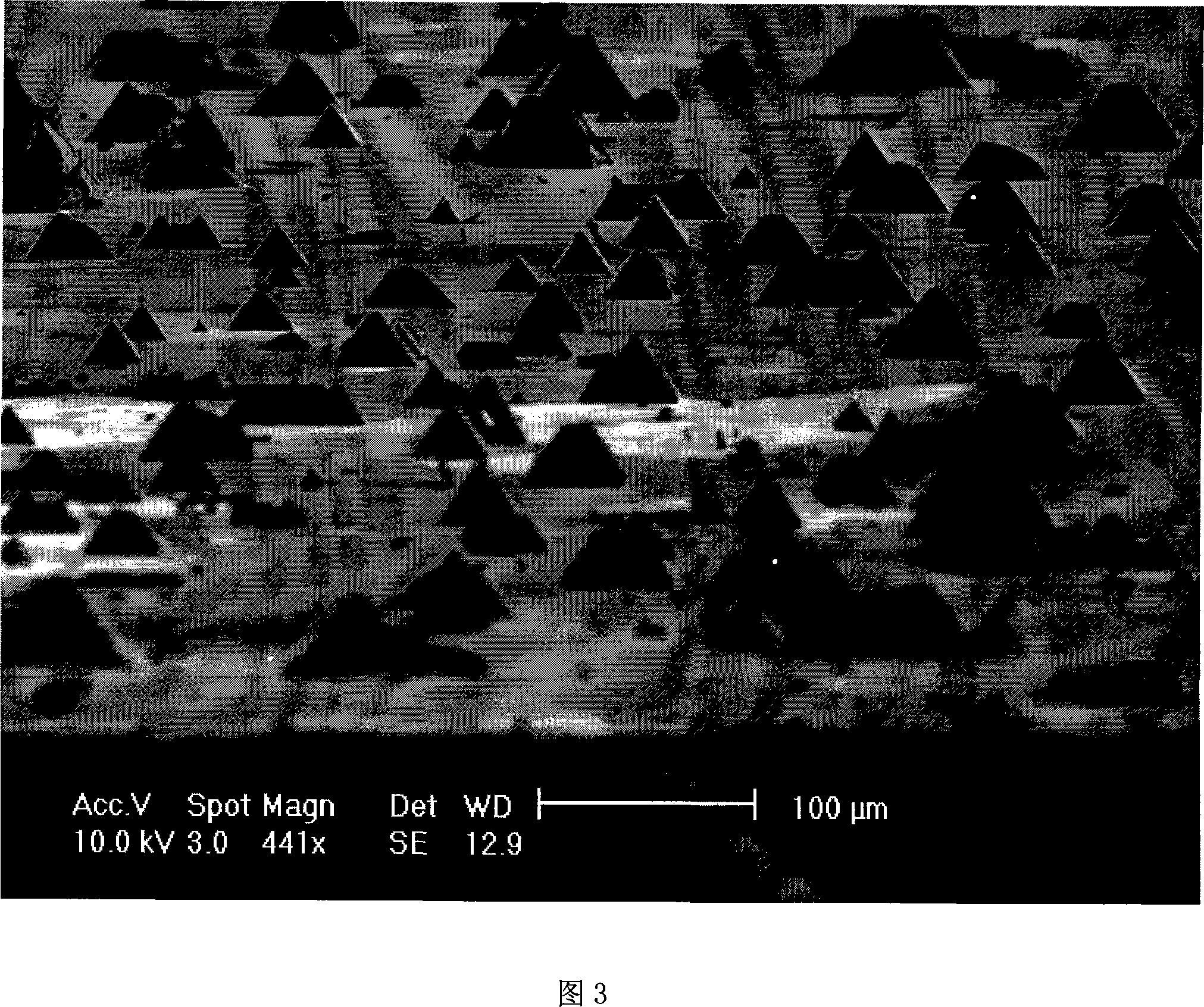

[0038] In this embodiment, the highest temperature is set above 1300°C, and other conditions are the same as in Embodiment 1. The pyramid or roof structure obtained on the silicon chip is not complete, and many gaps appear, such as Figure 4 , as shown in 5.

Embodiment 3

[0040] In this embodiment, the silicon wafer is not covered or thermally evaporated and deposited with zinc powder, and other conditions are the same as in Embodiment 1, only the silicon wafer is heated, and finally no three-dimensional structure of silicon can be obtained.

[0041] It can be seen from the above three examples that the silicon with a three-dimensional hollow structure is obtained by reacting the metal zinc powder and the silicon sheet at high temperature. Other parameters, such as maximum temperature, pressure and holding time, and whether oxygen is introduced or not will also affect the growth of the three-dimensional structure of silicon. Wherein, those skilled in the art can understand that the amount of zinc powder used, the size of the silicon wafer, and the ventilation rate of oxygen are determined according to the heating equipment, and are not limited to the scope given by the embodiments of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com