Method for preparing high-stability perovskite quantum dot film by in-situ crosslinking method

An in-situ cross-linking, perovskite technology, applied in the field of quantum dots, can solve the problems of unfavorable perovskite quantum dots, large specific surface area, low formation energy, etc., and achieve easy control of preparation parameters, good repeatability, and efficient fluorescence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Lead methacrylate (Pb(MMA) 2 ) was dissolved in methyl methacrylate (MMA) at a concentration of 9×10 - 5 Add 1 mL of mol / mL lead methacrylate in methyl methacrylate solution, then add 0.028 g of azoisobutyronitrile, sonicate the prepared solution for 2-3 minutes, and then filter. Heat the filtered solution on a hot stage, the heating temperature is 100 °C, and the heating time is 10~15min. The heated solution was spin-coated to form a film at a speed of 3500 r / min for 30 s and a drop volume of 60 μL. Then in the state of spin coating (3500 r / min, time 30 s), 10×10 -5 A mol / mL solution of methylamine bromide in isopropanol was dropped onto the film. Place the prepared film on a hot stage and heat it at 100 °C for 30 min to prepare MAPbBr 3 / PMMA hybrid film. Figure 1-3 The prepared MAPbBr 3 Photographs, fluorescence spectra and thermal stability of PMMA / PMMA hybrid films under UV light. It can be seen from the figure that the prepared MAPbBr 3 MAPbBr in / PMMA h...

Embodiment 2

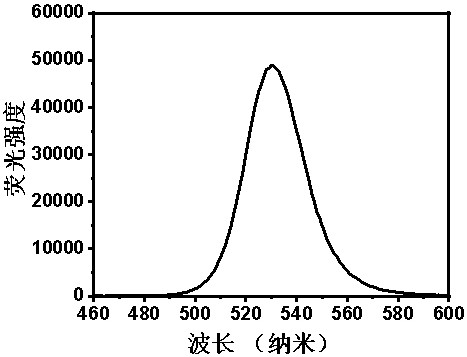

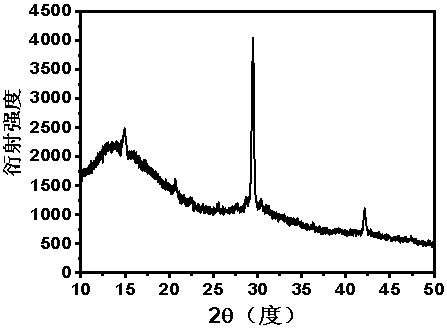

[0034] Lead methacrylate (Pb(MMA) 2 ) was dissolved in methyl methacrylate (MMA) at a concentration of 4.5×10 - 5 Add 1 mL of mol / mL lead methacrylate in methyl methacrylate solution, then add 0.028 g of azoisobutyronitrile, sonicate the prepared solution for 2-3 minutes, and then filter. Heat the filtered solution on a hot stage, the heating temperature is 100 °C, and the heating time is 10~15min. The heated solution was spin-coated to form a film at a speed of 3500 r / min for 30 s and a drop volume of 60 μL. Then in the state of spin coating (3500 r / min, time 30 s), 10×10 -5 A mol / mL solution of formamidine bromide in isopropanol was dropped onto the film. Place the prepared film on a hot stage and heat it at 100 °C for 30 min to prepare FAPbBr 3 / PMMA hybrid film. Figure 4-6 Respectively for the prepared FAPbBr 3 Photo, fluorescence spectrum, and X-ray diffraction pattern of the / PMMA hybrid film under ultraviolet light. As can be seen from the figure, the prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com