Method for preparing perovskite quantum dot-polymer porous composite material

A porous composite material and composite material technology are applied in the field of preparing high-brightness and high-stability perovskite quantum dot-polymer porous composite materials, which can solve the problem of large specific surface area, high surface energy and low stability of perovskite quantum dots. and other problems, to achieve the effects of easy control of preparation parameters, simple process and high luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

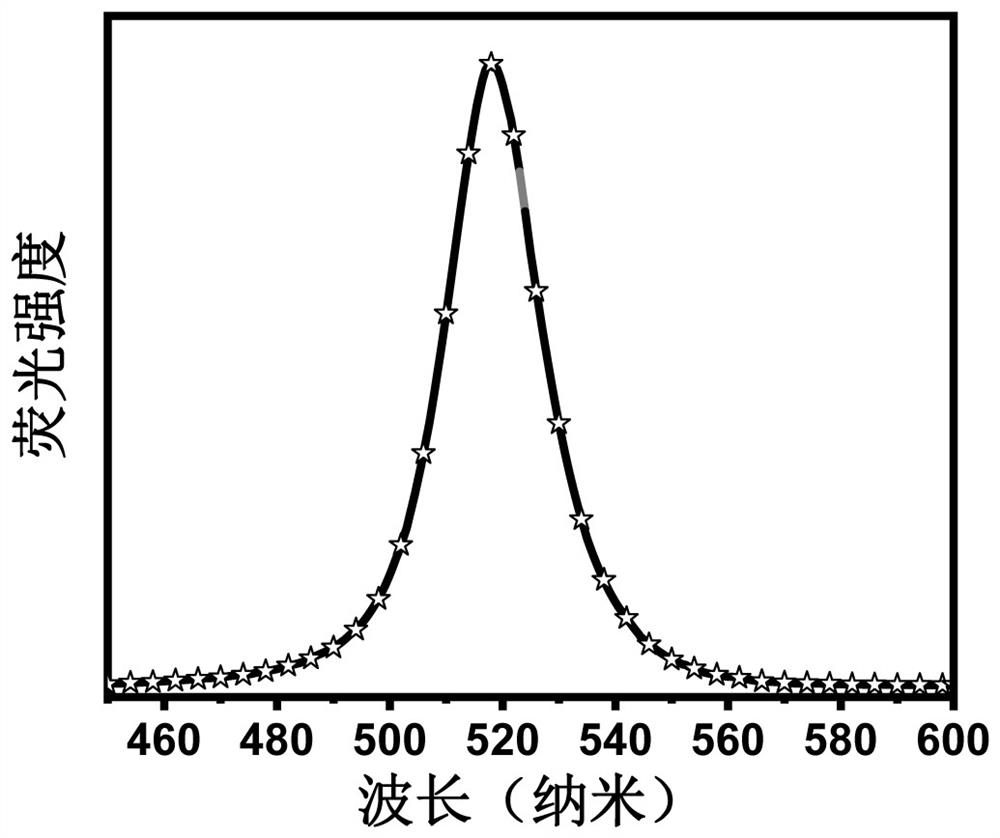

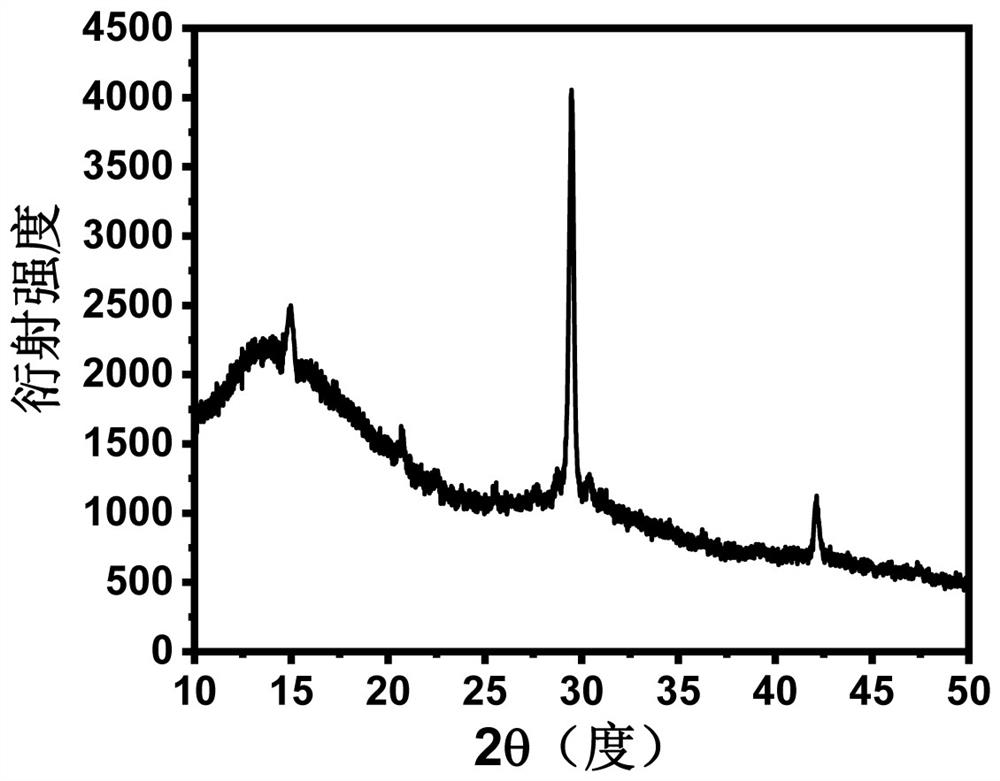

Embodiment 1

[0028] Dissolve lead methacrylate in methyl methacrylate (MMA) at a concentration of 6×10 -5 mol / mL solution 1mL, add 0.03 g of 2-2 azobisisobutyronitrile (AIBN) at the same time, mix well and filter out large particles with a filter head, add the solution dropwise to cube sugar and vacuum process to make the cube The air in the sugar is discharged, and the air in the sugar cube is exhausted by repeating it several times, and the solution fills the gaps in the sugar cube. Wrap the solution-filled sugar cubes with aluminum foil to avoid loss due to volatilization of the solution. Placed in an oven at 65°C for 12 h. Immerse the cross-linked sugar cube in a large amount of distilled water to dissolve the sugar in it to obtain a polymer, and then dry the polymer after the sugar cube is dissolved to obtain thermally cross-linked polymethyl methacrylate copolymer lead methacrylate porous composites. Afterwards, cesium bromide was dissolved in dimethyl sulfoxide solvent, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com