A preparation of high-brightness and stable organic-inorganic hybrid perovskite ch 3 no 3 pbbr 3 quantum dot approach

A quantum dot, high brightness technology, applied in the field of quantum dots, to achieve the effects of easy control of preparation parameters, simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

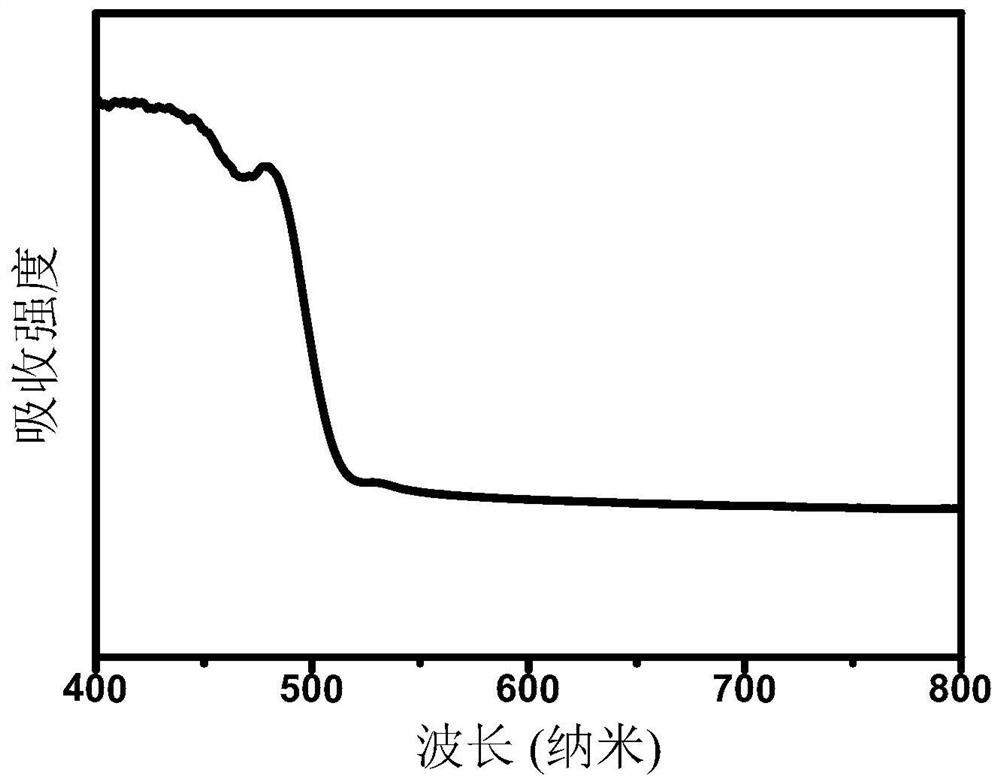

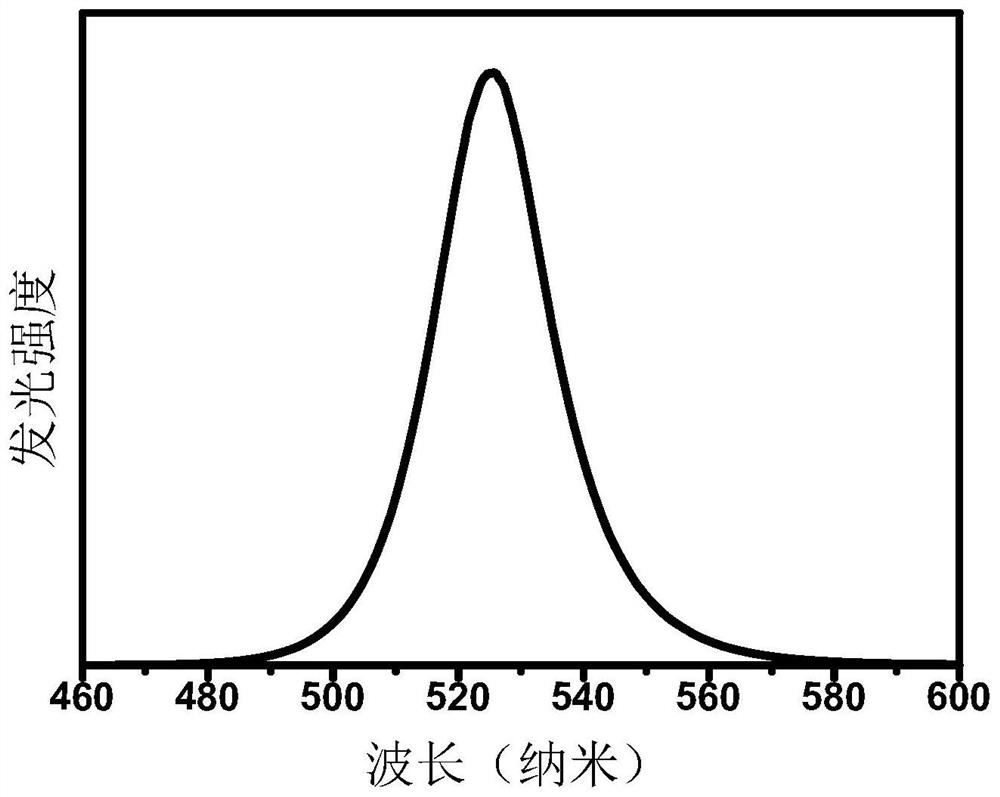

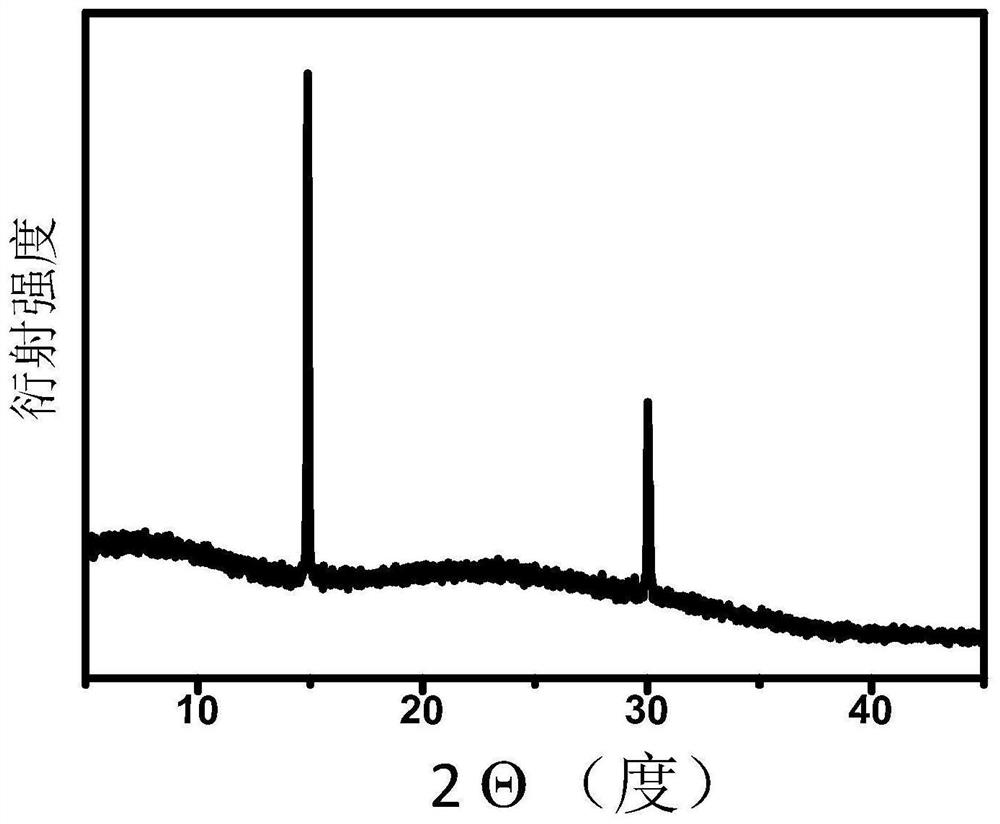

[0023] Under the protection of nitrogen, add 0.0517g (0.16mmol) lead thiocyanate, 0.0538g (0.48mmol) methyl ammonium bromide and 4mL N,N-dimethylformamide into a 20mL glass bottle, and continuously stir for 5- 10min. After filtration, the filtrate was taken as the precursor solution for later use. Take 1mL of precursor solution, add 20μL oleylamine and 0.5mL oleic acid, stir evenly, quickly inject into 10mL 60℃ toluene, and stir for 10min. Centrifuge at 8000rpm for 10-15min, take the supernatant to obtain CH 3 NH 3 PbBr 3 quantum dots. Figure 1-4 respectively for the prepared CH 3 NH 3 PbBr 3 UV-Vis absorption spectrum, fluorescence spectrum, X-ray diffraction spectrum and Fourier transform infrared absorption spectrum of quantum dots. It can be seen from the figure that the prepared CH 3 NH 3 PbBr 3 The luminescence peak of the quantum dot is located at 525 nanometers, has a cubic crystal structure, an average particle diameter of 5.25 nanometers, and a fluorescen...

Embodiment 2

[0025] Under nitrogen protection, add 0.0587g (0.16mmol) lead bromide, 0.0179g (0.16mmol) methyl ammonium bromide and 4mL N,N-dimethylformamide into a 20mL glass bottle, and stir continuously for 5-10min . After filtration, the filtrate was taken as solution A for later use.

[0026] Under nitrogen protection, add 0.0517g (0.16mmol) lead thiocyanate, 0.0538g (0.48mmol) methyl ammonium bromide and 4mL N,N-dimethylformamide into a 20mL glass bottle, and continuously stir for 5- 10min. After filtration, the filtrate was taken as solution B for later use.

[0027] Take 0.4mL of solution A and 0.6mL of solution B, add 20μL of oleylamine and 0.5mL of oleic acid, stir evenly, quickly inject into 10mL of 60°C toluene, and stir for 10min. Centrifuge at 8000rpm, take the supernatant, ie CH 3 NH 3 PbBr 3 Quantum dot solution. Figure 5 For CH prepared in Example 2 3 NH 3 PbBr 3 Transmission electron micrograph of quantum dots. Figure 6 For CH prepared in Example 2 3 NH 3 Pb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com