Bipass large-area aluminum oxide, titanium dioxide or zirconium dioxide nanotube array film and preparation method thereof

A technology of aluminum oxide and nanotube arrays, applied in the direction of surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve problems such as unstable results, complicated processes, and unsafe operations, and achieve easy control of preparation parameters, The preparation process is simple and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

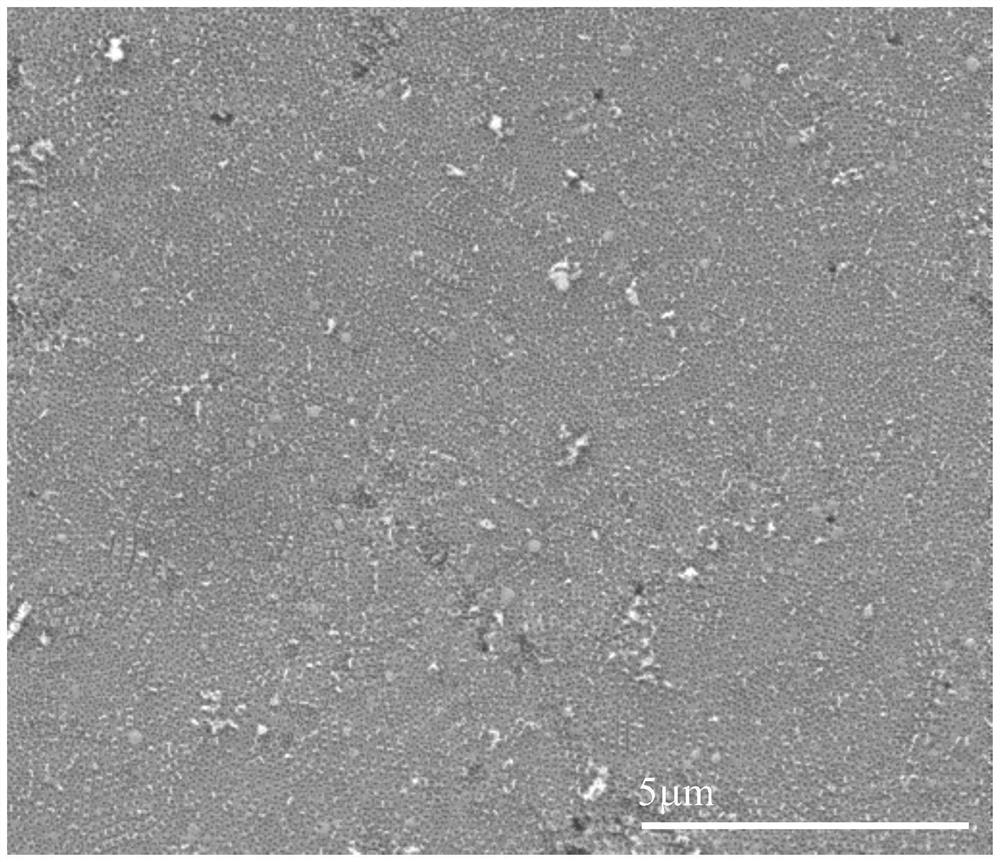

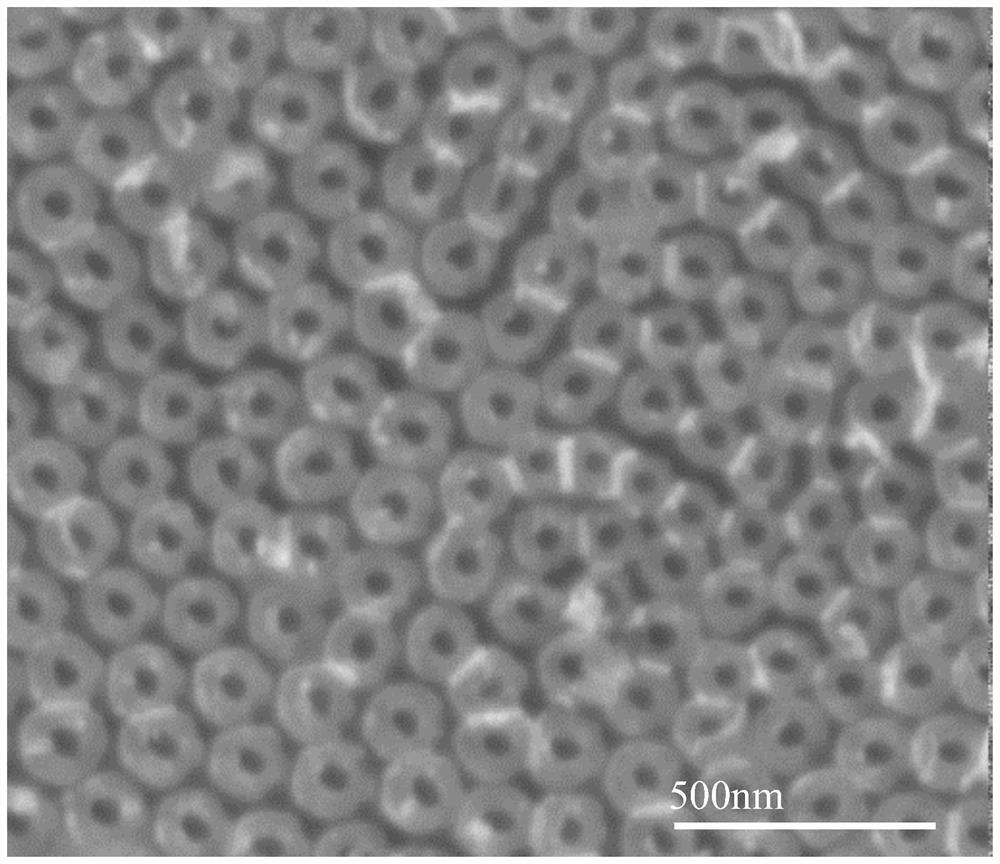

[0028] Double-pass aluminum oxide nanotube array membrane based on oxalic acid small-aperture template

[0029] A square aluminum sheet with a length of 5 cm (purity greater than or equal to 99.9%, and a thickness of 0.2 mm) was removed by conventional mechanical processing to remove the oxide layer on the surface. The electrolyte is prepared from oxalic acid and water, and the content of oxalic acid is 0.3M. Put the processed aluminum sheet into the reaction device, and the diameter of the aluminum sheet exposed to the electrolyte is 4 cm. A refrigerator was used to fix the temperature of the electrolyte at 5° C., and a platinum foil was used as a cathode, and anodized at an anode voltage of 40 V for 2 hours to obtain a nanotube array film with an average pore diameter of 60 nm. Immediately after the reaction, the sample was taken out from the electrolyte and washed with deionized water, then put into a methanol solution of liquid bromine, the volume ratio of liquid bromine ...

Embodiment 2

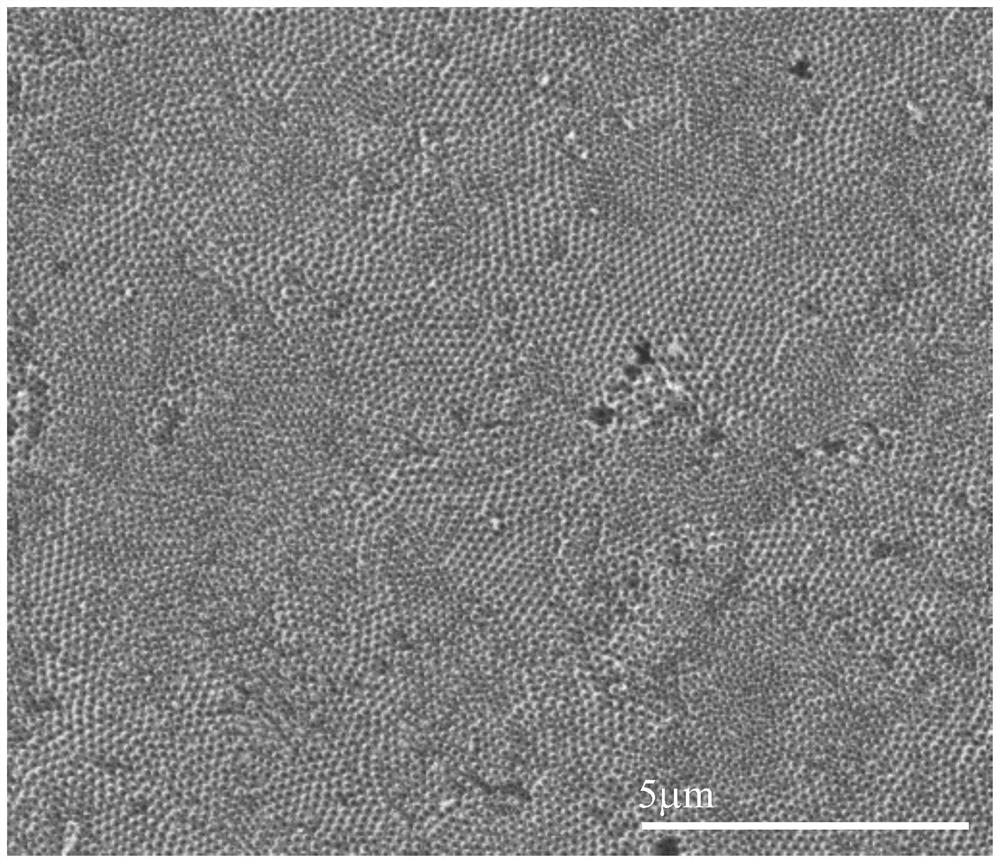

[0031] Based on NH 4 F-Ethylene Glycol Small Pore Template Double Pass Titanium Dioxide Nanotube Array Membrane

[0032] A circular titanium sheet with a diameter of 2 cm (purity greater than or equal to 99.9%, and a thickness of 0.2 mm) was removed by conventional mechanical processing to remove the oxide layer on the surface. The electrolyte consists of NH 4 F, prepared from ethylene glycol, NH 4 The content of F is 0.5 wt.%. Put the processed titanium sheet into the reaction device, and the diameter of the titanium sheet exposed to the electrolyte is 1 cm. A refrigerator was used to fix the temperature of the electrolyte at 5° C., and a graphite electrode was used as a cathode for anodic oxidation at an anode voltage of 60 V for 12 hours to obtain a nanotube array film with an average pore diameter of 80 nm. Immediately after the reaction, the sample was taken out from the electrolyte and washed with deionized water, then put into a methanol solution of liquid bromine, ...

Embodiment 3

[0034] Based on NH 4 F-Glycerol-Glycerol Small Pore Template Double Pass Zirconia Nanotube Array Membrane

[0035] A square zirconium sheet with a length of 4 cm (purity greater than or equal to 99.9%, and a thickness of 0.3 mm) is removed by conventional mechanical processing to remove the oxide layer on the surface. The electrolyte consists of NH 4 F. Glycerin and glycerol are formulated, glycerin and glycerol are mixed at a ratio of 1:1, NH 4 The content of F is 1 wt.%. Put the processed zirconium sheet into the reaction device, and the diameter of the titanium sheet exposed to the electrolyte is 3 cm. At room temperature, using a graphite electrode as a cathode, anodized at an anode voltage of 50V for 3 hours to obtain a nanotube array film with an average pore size of 100 nm. Immediately after the reaction, the sample was taken out from the electrolyte and washed with deionized water, then put into a methanol solution of liquid bromine, the volume ratio of liquid brom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com