Cracked lujun glaze

A Lujun glaze and chipping technology, applied in the field of chipping furnace Jun glaze, can solve the problem of easy loss of glaze, only one large blank or 2-3 small blanks can be fired, and the success rate Low-level problems, to achieve the effect of increasing opacity, high yield, and natural hair color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

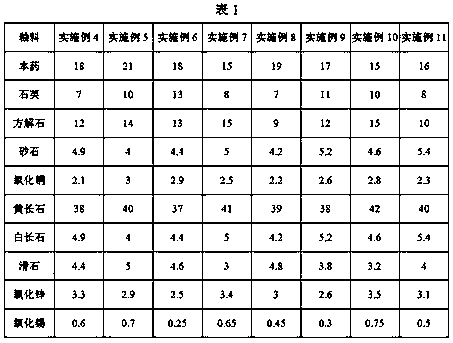

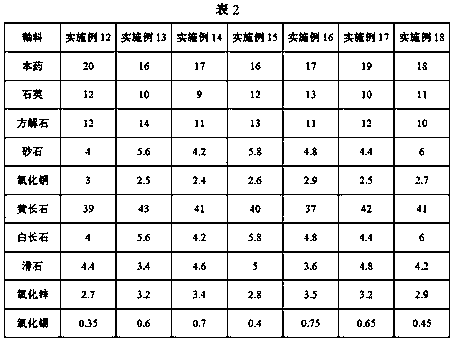

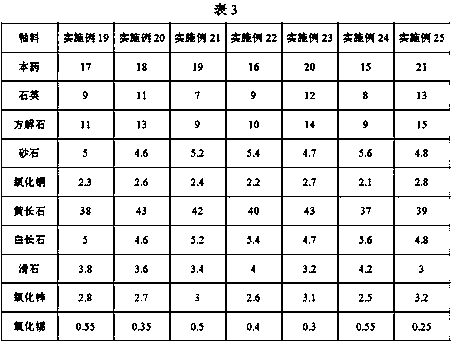

[0018] A split Lujun glaze, prepared from the following raw materials in parts by weight: 15-21 parts of this medicine, 7-13 parts of quartz, 9-15 parts of calcite, 4-6 parts of sandstone, and 2-3 parts of copper oxide , 37-43 parts of yellow feldspar, 4-6 parts of white feldspar, 3-5 parts of talc, 2.5-3.5 parts of zinc oxide, and 0.25-0.75 parts of tin oxide.

[0019] The preparation method of the above-mentioned split Lujun glaze comprises the following steps:

[0020] (1) Preparation of glaze slurry: Add appropriate amount of water to mix the above raw materials, and ball mill to obtain glaze slurry with a mass concentration of 55-57%;

[0021] (2) Glazing: immerse the green body in the glaze slurry prepared in step (1) for a while, then immerse it again for a while, take it out, and use the water absorption of the green body to make the glaze slurry evenly adhere to the surface of the green body;

[0022] (3) Firing, the firing temperature is 1270-1290°C.

[0023] The f...

Embodiment 2

[0029] A piece of Lujun glaze prepared from the following raw materials in parts by weight: 18 parts of this medicine, 10 parts of quartz, 12 parts of calcite, 5 parts of sandstone, 2.5 parts of copper oxide, 40 parts of feldspar, and 5 parts of white feldspar , 4 parts of talc, 3 parts of zinc oxide, and 0.5 part of tin oxide.

[0030] The preparation method of the above-mentioned split Lujun glaze comprises the following steps:

[0031] (1) Preparation of glaze slurry: Add appropriate amount of water to mix the above raw materials, and ball mill to obtain glaze slurry with a mass concentration of 56%;

[0032] (2) Glazing: immerse the green body in the glaze slurry prepared in step (1) for a while, then immerse it again for a while, take it out, and use the water absorption of the green body to make the glaze slurry evenly adhere to the surface of the green body;

[0033] (3) Firing, the firing temperature is 1280°C;

[0034] The firing process specifically includes the fo...

Embodiment 3

[0040] A piece of Lujun glaze prepared from the following raw materials in parts by weight: 20 parts of this medicine, 8 parts of quartz, 10 parts of calcite, 6 parts of sandstone, 3 parts of copper oxide, 43 parts of yellow feldspar, and 4 parts of white feldspar , 4.5 parts of talc, 2.5 parts of zinc oxide, and 0.4 parts of tin oxide.

[0041] The preparation method of the above-mentioned split Lujun glaze comprises the following steps:

[0042] (1) Preparation of glaze slurry: Add appropriate amount of water to mix the above raw materials, and ball mill to obtain glaze slurry with a mass concentration of 57%;

[0043] (2) Glazing: immerse the green body in the glaze slurry prepared in step (1) for a while, then immerse it again for a while, take it out, and use the water absorption of the green body to make the glaze slurry evenly adhere to the surface of the green body;

[0044] (3) Firing, the firing temperature is 1270°C;

[0045] The firing process specifically includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com