A high-performance graphene-supported mesoporous nickel-iron alloy electrocatalyst and its preparation method

A nickel-iron alloy, electrocatalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., to achieve good repeatability, inhibition of particle agglomeration, and easy control of preparation parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

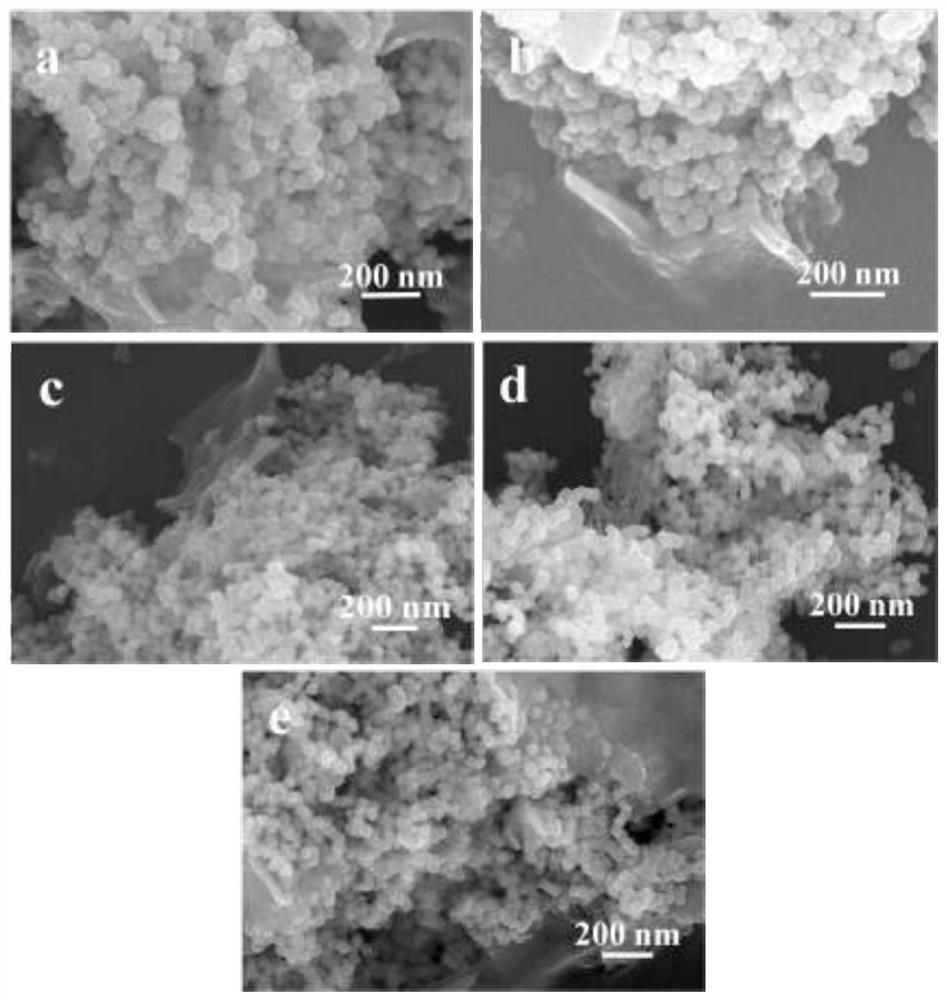

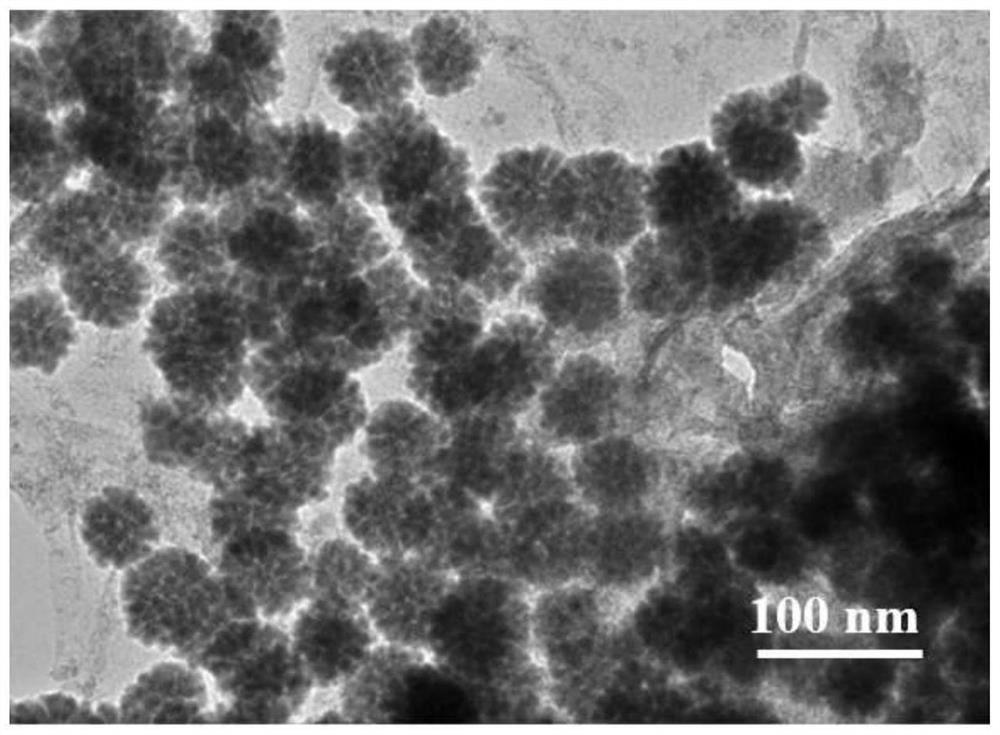

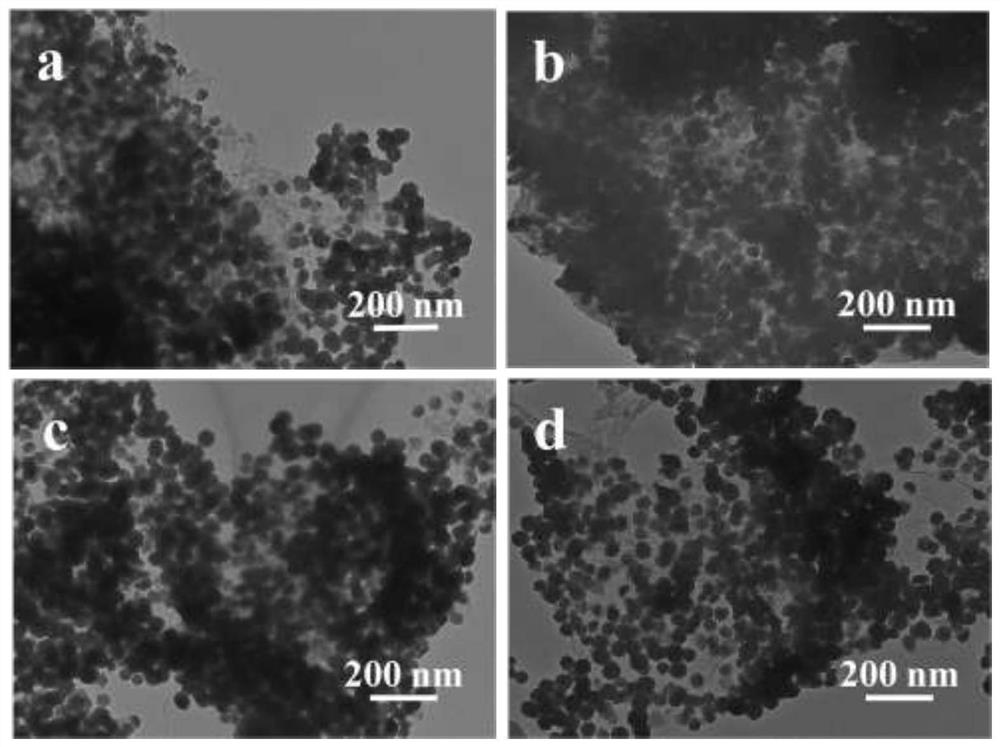

[0022] The preparation method of graphene supported mesoporous nickel-iron alloy, the steps are as follows:

[0023] (1) Using the modified Hummers method, graphene oxide (GO) was synthesized by exfoliating oxidized natural graphite powder. The obtained graphene oxide was repeatedly centrifuged and washed with 5% dilute hydrochloric acid and deionized water until the supernatant was neutral. Graphene oxide was collected by high-speed centrifugation and freeze-dried.

[0024] (2) disperse the graphene oxide obtained in step (1) in tin protochloride (SnCl 2 ) of hydrochloric acid solution (PH ≈ 3.0), mixed and stirred for 10 minutes. After several washes with deionized water, the graphene and SnCl 2 Palladium chloride (PdCl 2 ) hydrochloric acid solution (PH ≈ 3.0), mixed and stirred for 5 minutes. After being washed several times with deionized water, they were collected by centrifugation to obtain graphene oxide-supported mesoporous Pd nanoparticles (Pd / GO). Among them, ...

Embodiment 2

[0031] The preparation method of graphene-supported mesoporous nickel-iron alloy has the same steps as in Example 1, except that the reduction reaction temperature in step (4) is 20° C., and the obtained results are basically the same as in Example 1.

Embodiment 3

[0033] The preparation method of graphene-loaded mesoporous nickel-iron alloy, the steps are the same as in Example 1, the difference is that step (4) NiCl 2 The mass ratio to the reducing agent dimethylamine borane (DMAB) is 1:1, and the obtained results are basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com