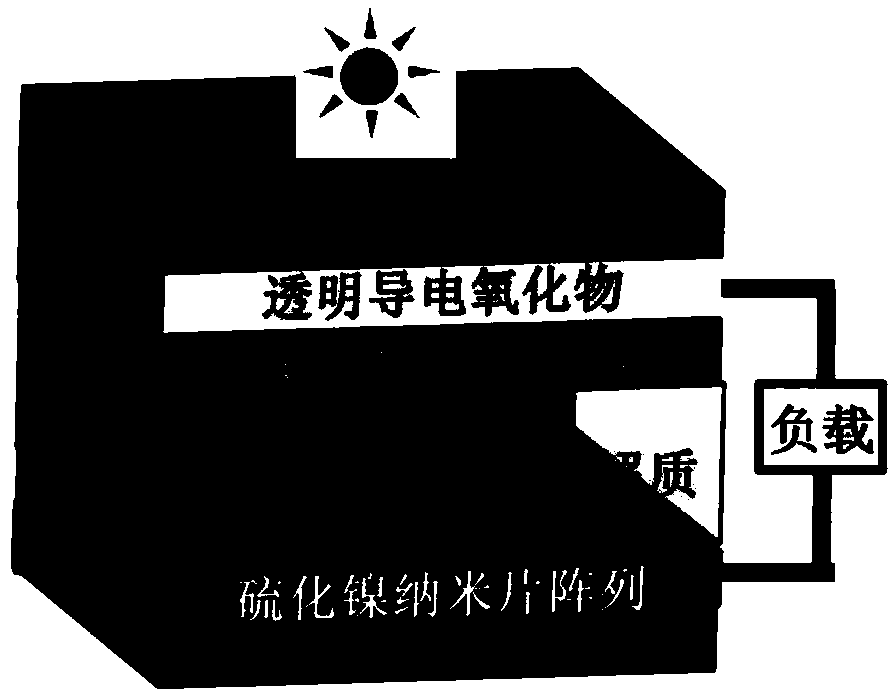

Preparation method for dye-sensitized solar cell counter electrode based on nickel sulfide nanosheets

A technology of solar cells and dye sensitization, which is applied in the field of preparation of counter electrodes of dye-sensitized solar cells based on nickel sulfide nanosheets, can solve the problems of complex process steps and difficulty in large-scale production, and achieve easy control and repeatability of preparation parameters. Good performance and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.35g of nickel ethylxanthate powder and put it in a vacuum drying oven, place the glass sheet near the nickel ethylxanthate powder, heat to 200°C, keep it warm for 30 minutes, cool to room temperature and take out the glass sheet to obtain vulcanization Nickel nanosheet array counter electrode.

[0028] Preparation of solar cell: Assemble the dye-sensitized titanium dioxide nanocrystalline photoanode and the prepared counter electrode, and inject electrolyte solution to make a dye-sensitized solar cell (for specific preparation methods, please refer to the literature Nature, 1991, 353-737).

[0029] figure 2 is a scanning electron micrograph of nickel sulfide nanosheets.

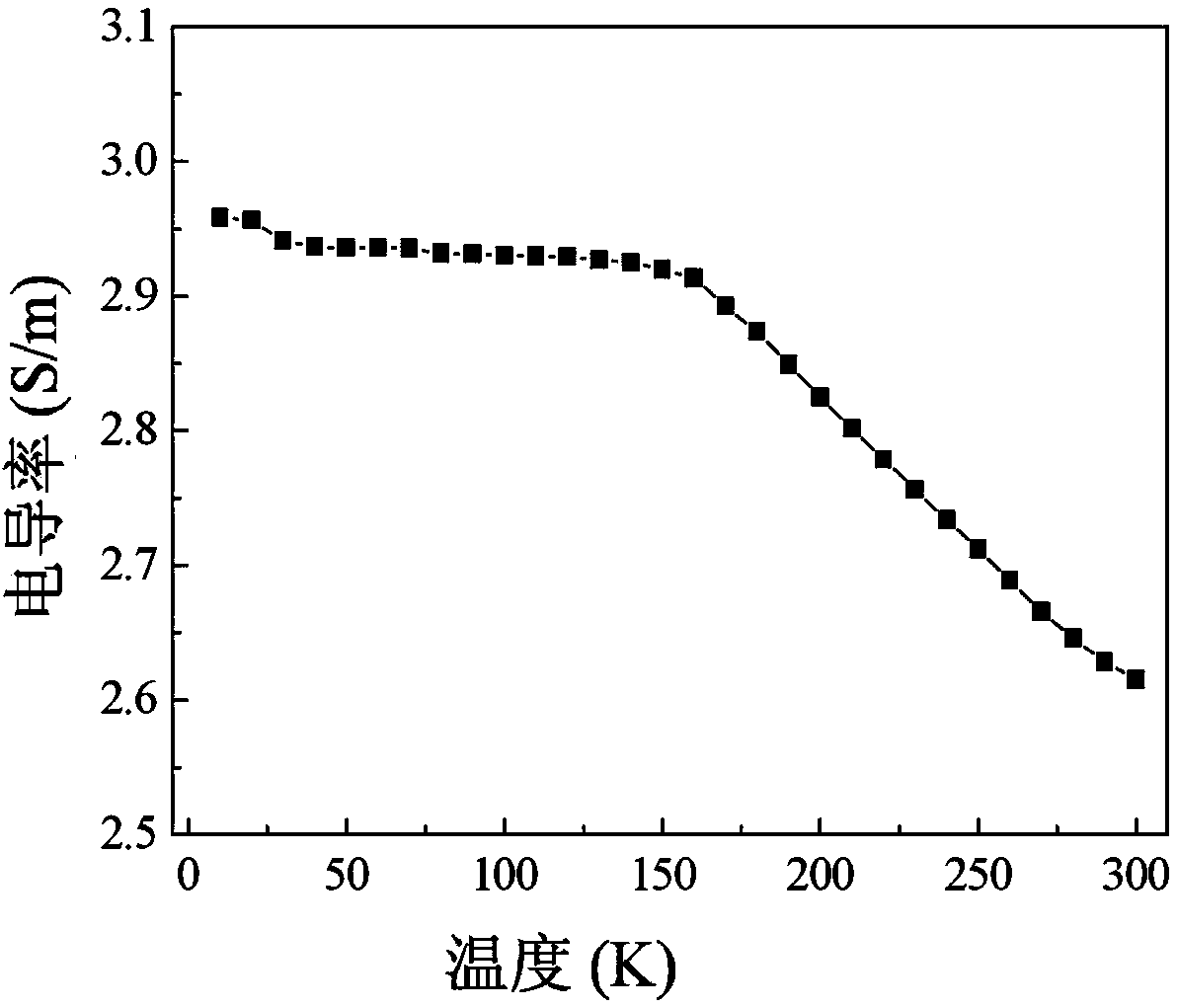

[0030] image 3 is the conductivity curve of the nickel sulfide nanosheet array. It can be seen from the figure that the room temperature conductivity of nickel sulfide nanosheet array is as high as 2.6×10 5 S / m.

[0031] Figure 4is the cyclic-voltammetry curve of the nickel sulfide n...

Embodiment 2

[0034] Weigh 0.5g of nickel isobutyl xanthate powder into a box-type resistance furnace, place a polyimide plastic sheet near the nickel isobutyl xanthate powder, heat to 160°C, keep it warm for 200 minutes, and cool to room temperature Take out the polyimide plastic sheet to obtain the nickel sulfide nanosheet array counter electrode. The solar cell preparation method is the same as that in Example 1.

Embodiment 3

[0036] Weigh 0.2g of nickel propylxanthate powder and put it into a tubular resistance furnace, place the glass sheet near the nickel propylxanthate powder, heat to 360°C, keep it warm for 10 minutes, cool to room temperature and take out the glass sheet to obtain Nickel sulfide nanosheet array counter electrode. The solar cell preparation method is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com