Noble metal directional loaded titanium dioxide photocatalyst and preparation method thereof

A technology of titanium dioxide and photocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the practical application that restricts the performance of photocatalyst, and the high recombination rate of photogenerated carriers , narrow spectral response range, etc., to achieve the effects of easy control of preparation parameters, improved photon quantum efficiency, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of titania carrier material

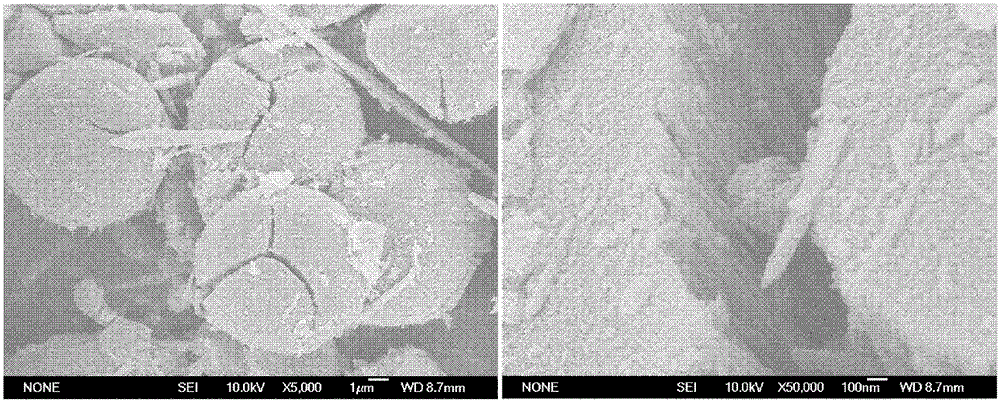

[0031] keep the temperature at 0 o Under the condition of C, 9.5mL of titanium tetrachloride was added dropwise to 30.5mL of deionized water under magnetic stirring to form a solution with a titanium ion concentration of 2.1M, and the resulting solution was stirred for 8 hours, and then Slowly warm up to 25 o C and insulated and stirred for 8 hours to obtain a colloidal solution, the obtained colloidal solution was packed into a polytetrafluoroethylene liner with a filling degree of 40%, the liner was put into a stainless steel hydrothermal kettle, and placed in a program-controlled oven at 120°C After heat treatment for 10 hours, a white precipitate was obtained, which was washed several times with deionized water, dried in an oven at 40°C for 20 hours, and finally titanium dioxide microspheres were obtained. Analysis by X-ray diffraction pattern shows that its phase is titanium dioxide of rutile phase. Observi...

Embodiment 2

[0032] Example 2: Preparation of noble metal oriented loaded titanium dioxide photocatalyst

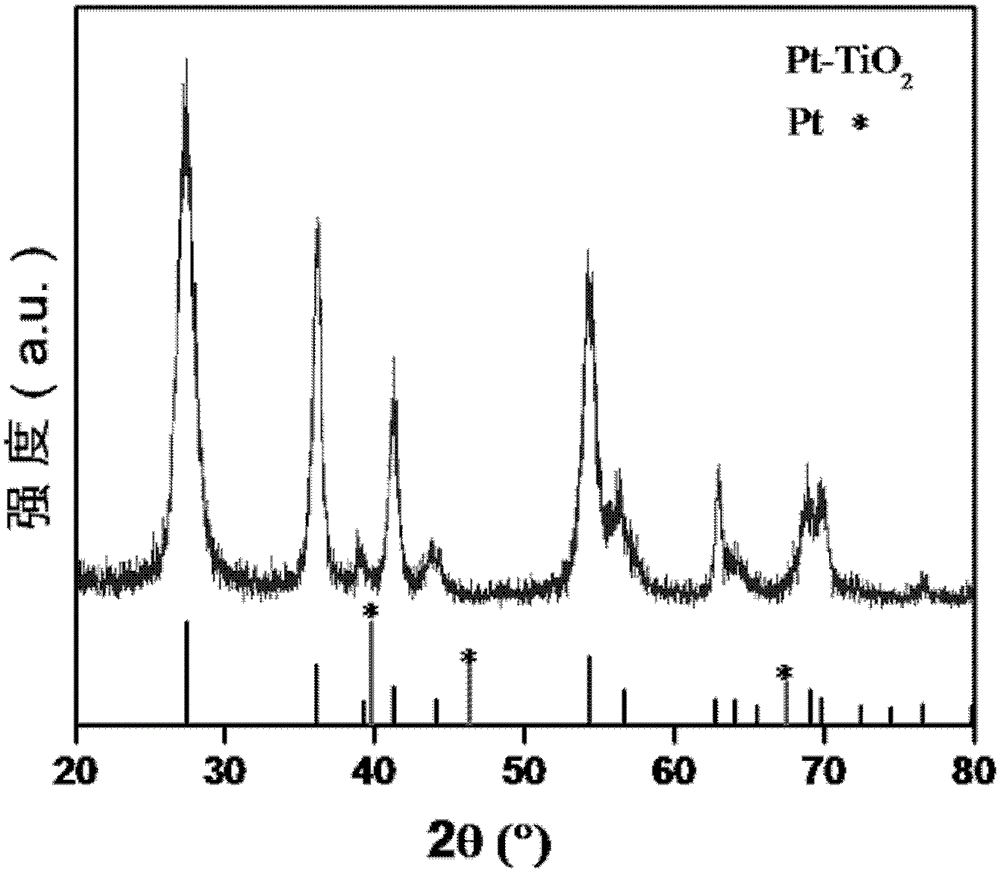

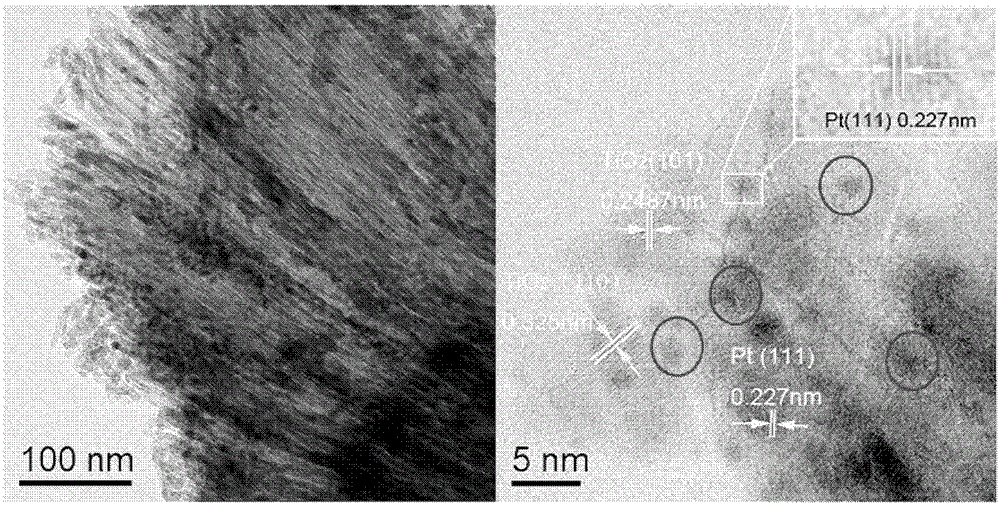

[0033] Take 0.025mmol of chloroplatinic acid to make 60mL of aqueous solution, after fully stirring, add 0.5g of the titanium dioxide support material prepared in Example 1, and then vigorously stir for 2 hours. Keep the stirring speed constant, place the obtained suspension under a xenon lamp, and turn on the xenon lamp to illuminate for 6 hours. After the light is finished, let the suspension stand still, discard the supernatant, collect the precipitate, wash and centrifuge several times with deionized water to obtain the final product, put the product in an oven, and dry it at 80°C for 5 hours to obtain the noble metal platinum-modified titanium dioxide powder. figure 1 The X-ray diffraction spectrum of the self-assembled titanium dioxide microsphere powder modified by metal platinum modified in this embodiment, as can be seen from the spectrum, its phase is titanium dioxide of th...

Embodiment 3

[0034] Embodiment 3: the preparation of titania carrier

[0035] at a temperature of 20 o Under the condition of C, 36.2mL of titanium tetrachloride was added dropwise to 53.8mL of deionized water under the action of a magnetic stirrer to form a solution with a titanium ion concentration of 3.6M, and the resulting solution was stirred for 0.5 hours. Then slowly increase the temperature to 50 o C and insulated and stirred for 8 hours to obtain a colloidal solution, and the obtained colloidal solution was packed into a polytetrafluoroethylene lining with a filling degree of 90%, and the lining was put into a stainless steel hydrothermal kettle and placed in a program-controlled oven at 200°C After heat treatment for 2 hours, a white precipitate was obtained, which was washed several times with deionized water, dried in an oven at 80°C for 5 hours, and finally titanium dioxide microspheres were obtained. Analysis by X-ray diffraction pattern shows that its phase is titanium dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com